Cargo box loading and unloading device of logistics unmanned aerial vehicle warehouse and control method

A technology for loading and unloading devices and cargo boxes, which is applied in the direction of equipment for transporting goods, etc., which can solve problems such as inconvenient use, falling, and tilting of cargo boxes, and achieve the effects of avoiding tilting or falling, reducing waste, and accurate loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

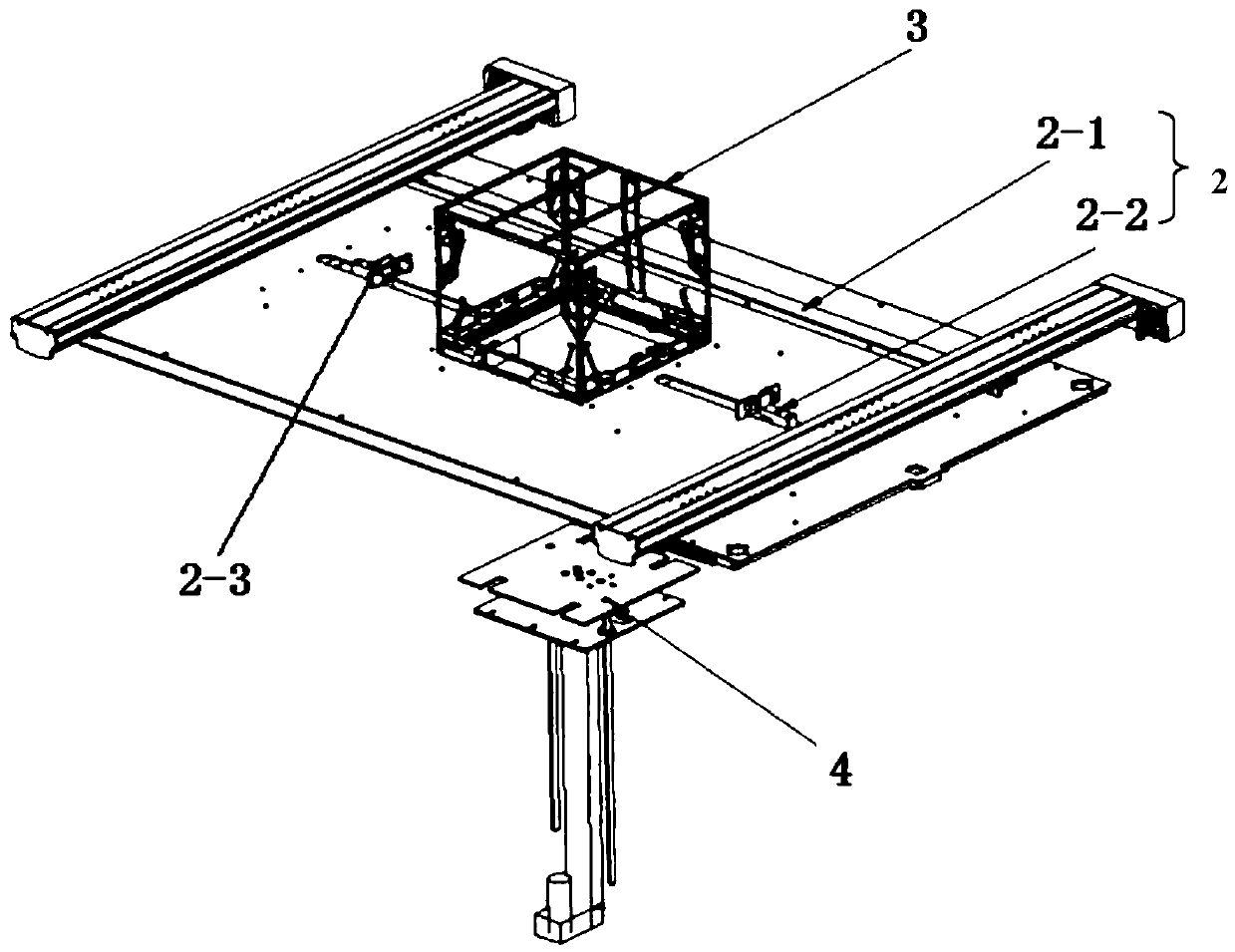

[0039] A cargo box loading and unloading device for a warehouse of a logistics unmanned aerial vehicle, including an apron platform 1 whose center is a parking area, which is driven to move up and down and is provided with a device for adjusting the plane position of the warehouse 3 on the apron platform 1 Upright mechanism 2 and lifting platform 4;

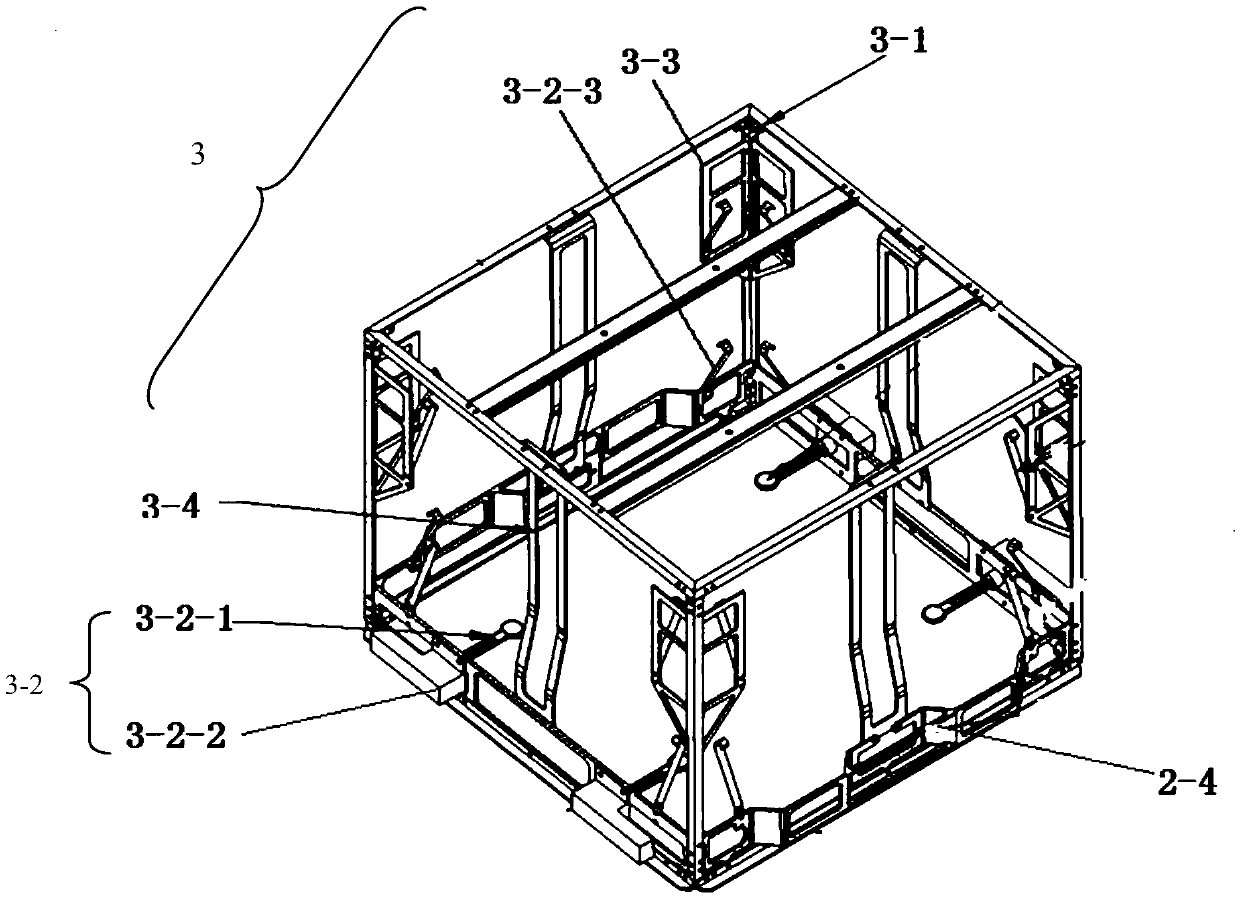

[0040] The warehouse 3 is a box-type structure with a bottom opening; the warehouse 3 includes a box body 3-1 and a lifting mechanism 3-2 for loading and unloading cargo boxes, and a loading and unloading hole that allows cargo boxes to pass is formed in the middle of the parking area;

[0041] Lifting platform 4, which is driven to move up and down to enter the warehouse 3 through the loading and unloading hole from below for delivery to the warehouse 3 or unloading cargo boxes from the warehouse 3;

[0042] The lifting platform is provided with an escape groove corresponding to the lifting platform 4 of the lifting mechanism 3-...

Embodiment 2

[0046] Based on Embodiment 1, the alignment mechanism 2 includes a front and rear alignment mechanism and a left and right alignment mechanism. The board 2-1 is used for front and rear alignment of the warehouse 3; the left and right alignment mechanism includes two push blocks 2-2 which are arranged on the apron platform 1 and are located on the left and right sides of the parking area and are driven to move in opposite directions left and right for use In the right position about the warehouse 3.

[0047] Wherein, a butt joint 2-3 is formed on the push block 2-2, and a butt joint recess 2-4 is correspondingly provided at the bottom of the warehouse 3 to realize the butt joint positioning.

[0048] Further, the front and rear positive position mechanism 2 also includes two first screw drive mechanisms arranged symmetrically on the basis of the front and rear median lines of the apron platform 1, and the two first screw drive mechanisms are arranged on the upper surface of the...

Embodiment 3

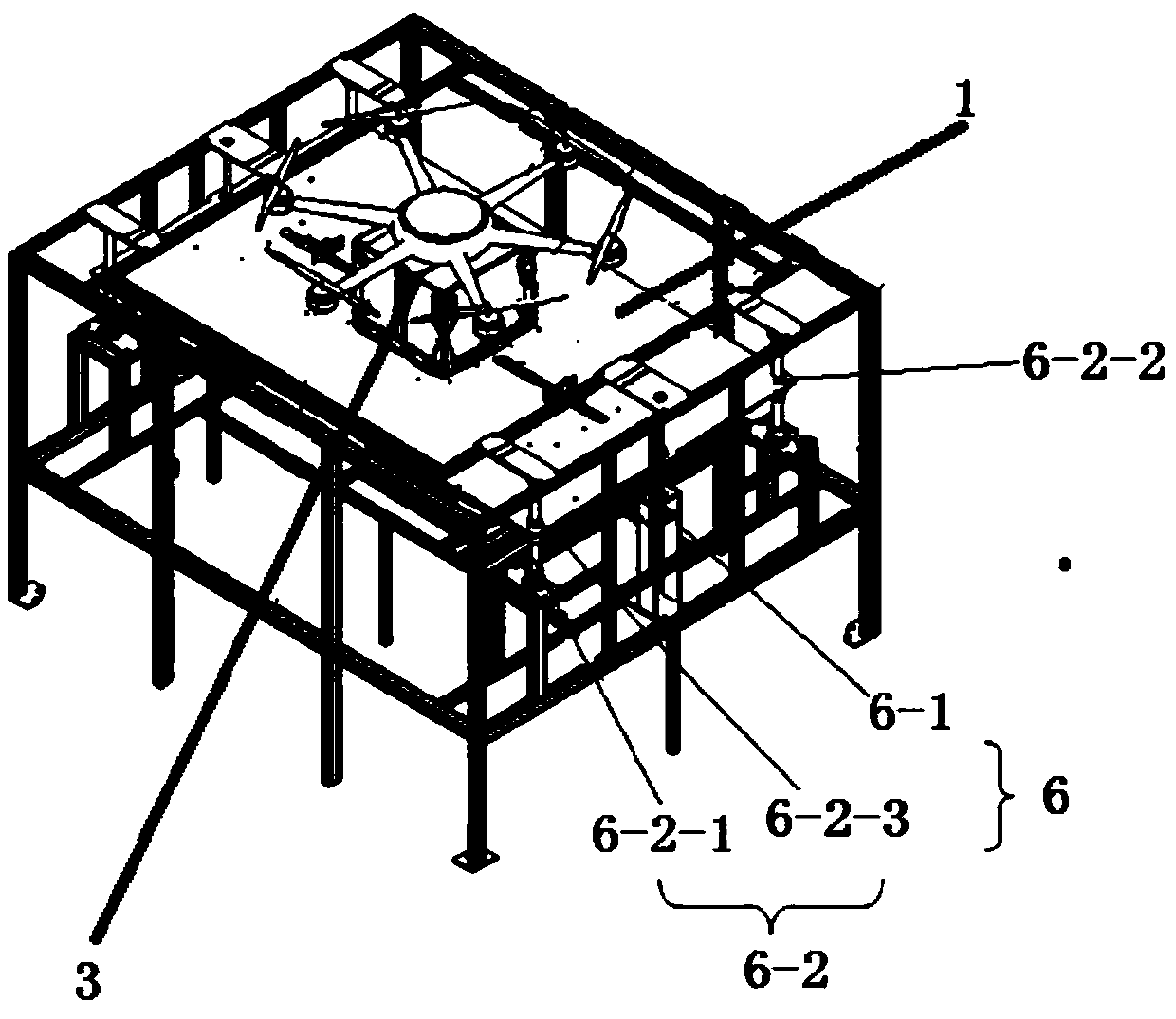

[0051] Based on Embodiment 2, the cargo box loading and unloading device of the logistics UAV loading warehouse 3 also includes a lifting mechanism 66 for driving the apron platform 1 to move up and down. The lifting mechanism 66 includes two lead screw lifting mechanisms 6-1 and The guide module 6-26-2 that is used to guide the movement of the lead screw lifting mechanism 6-1, the leading screws of the two lead screw lifting mechanisms 6-1 are installed vertically on the left center position and the right side of the apron platform 1 respectively. At the side center position, the nut of the screw lifting mechanism 6-1 is fixedly connected with the apron platform 1, and the guide module 6-26-2 is a corresponding vertical guide rod 6-2-1 that runs through the apron platform 1. The platform 1 is provided with a guide hole 6-2-2 corresponding to the guide rod 6-2-1, and a guide sleeve 6-2-3 is inserted in the guide hole 6-2-2.

[0052] The left and right ends of the apron platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com