Filling rate design and control method for solid filing in coal mining

A technology for solid filling and coal mining, which is applied in the direction of filling, mining equipment, earthwork drilling and mining, etc. It can solve the problems of weakening and lack of an accurate and comprehensive set, and achieves low cost, wide field practicability, and simple design and control methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

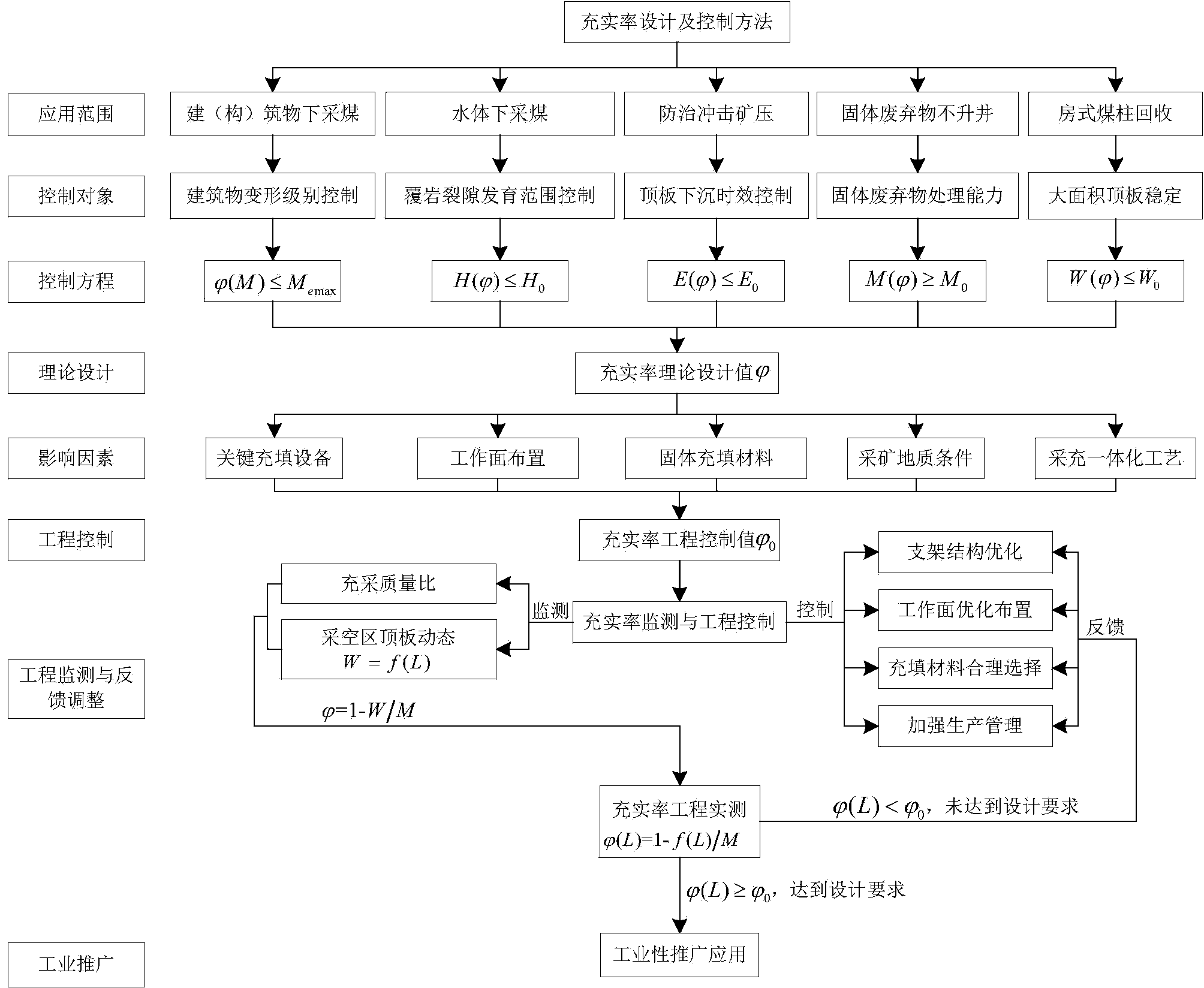

[0027] Embodiment 1: A design and control method of coal filling rate in solid filling mining. Firstly, the theoretical design value of coal filling rate in solid filling mining is obtained according to the purpose of filling mining and the control object Comprehensively analyze the impact of key filling equipment, working face layout, solid filling materials, mining geological conditions, and mining-filling integration process on the filling rate, and design the engineering control value of the filling rate In engineering practice, the actual measurement curves of the filling rate of different advancing positions of the working face are obtained by installing the roof dynamic monitoring equipment in the goaf Compare engineering control values By adjusting the process and management methods to ensure that the measured filling value meets the needs of engineering design and ensure the filling effect; the specific steps are as follows:

[0028] (1) Analyze the purpose of so...

Embodiment 2

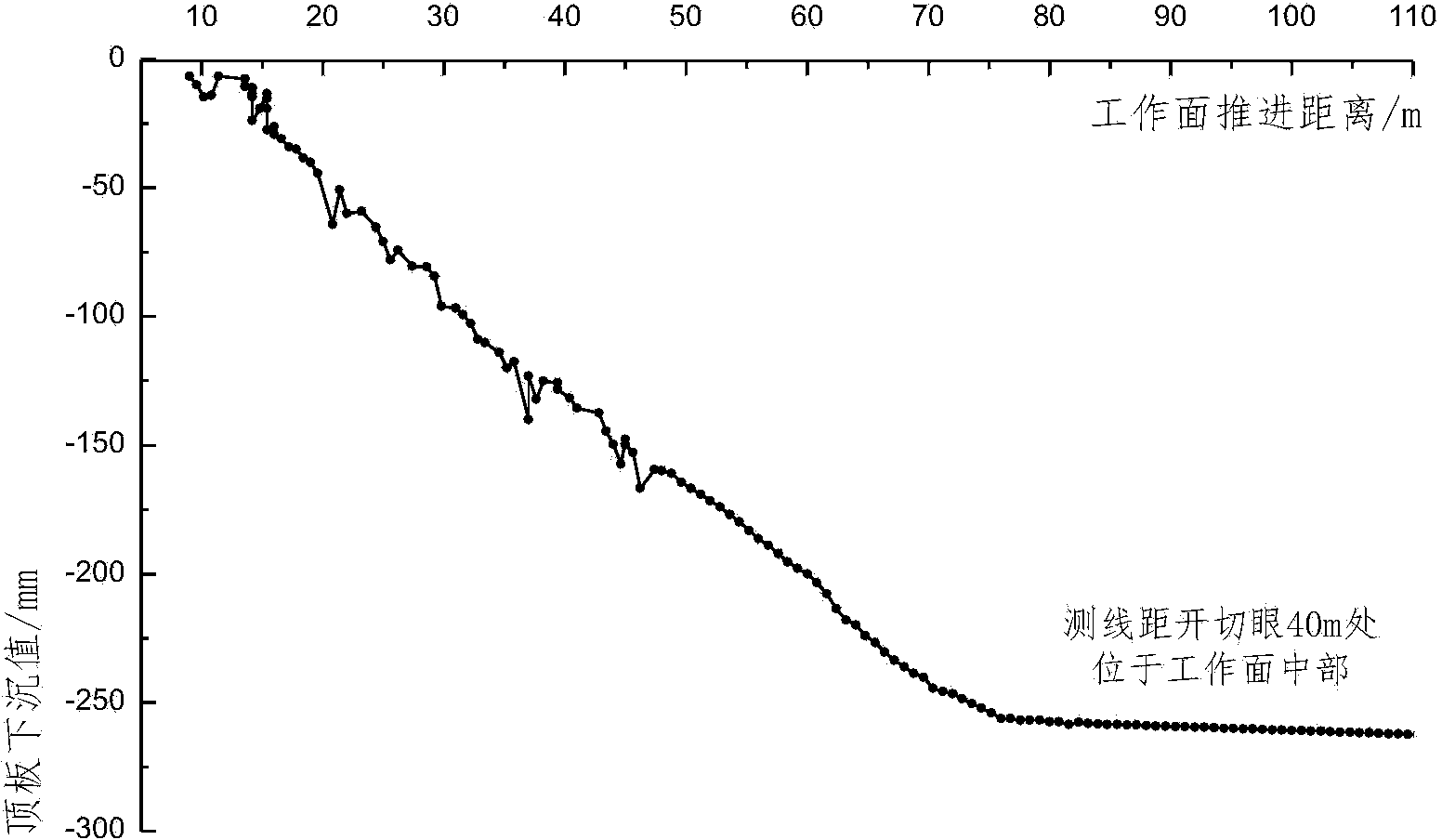

[0045] Example 2: Taking the solid filling coal mining project under a large-scale embankment of a mine as an example, the engineering practice verification of filling rate design and control is carried out. The test filling mining area of this mine is the Nanyang Lake embankment protection coal pillar in the sixth mining area. The designed 6304-1 first mining face has a length of 80m and a advancing length of 518m. m, the average inclination angle is 5°, and the recoverable reserves are 182,000 t. The working face is arranged in an upward mining, downward filling and retreating style. ZZC10000 / 20 / 40 six-column supporting filling coal mining hydraulic support is adopted, and the filling material is gangue from underground excavation.

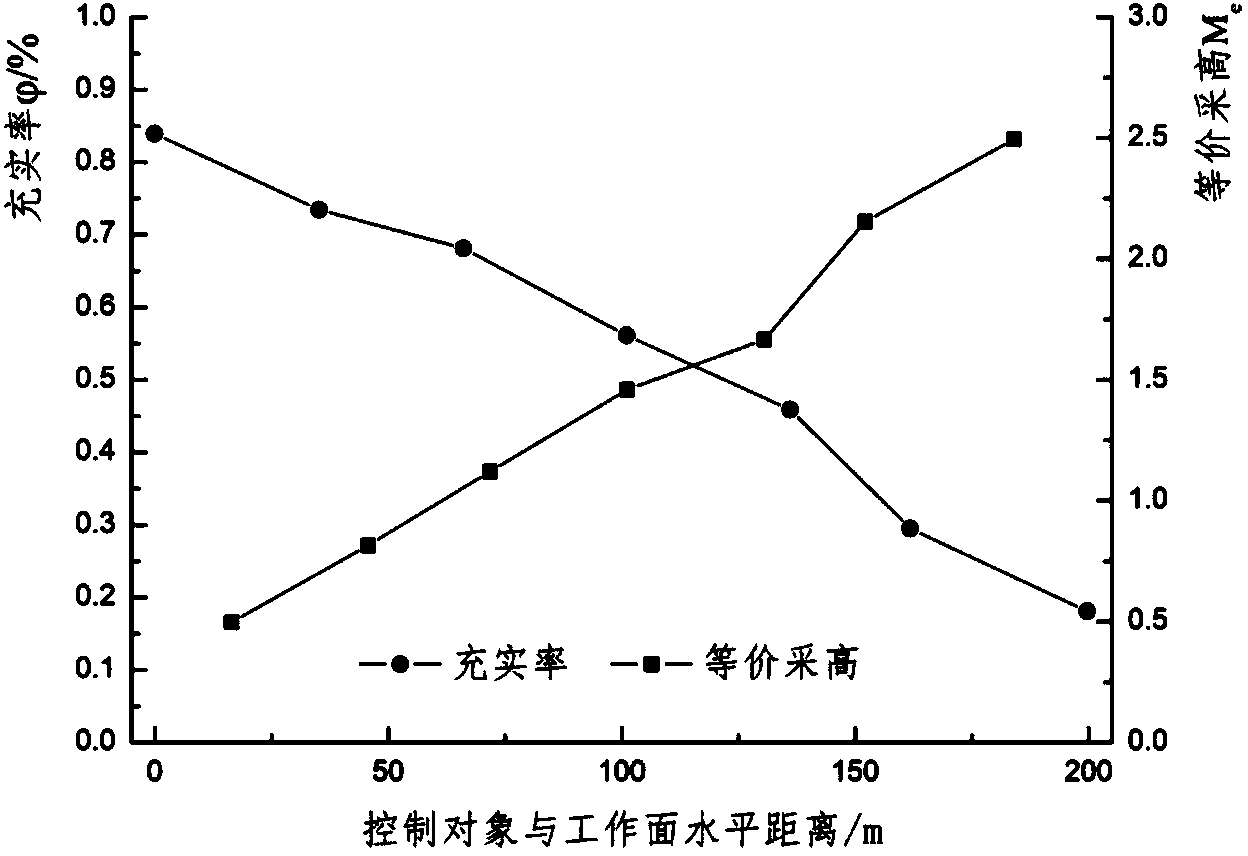

[0046] (1) The purpose of solid filling mining in this coal mine is to mine coal under the embankment of Nanyang Lake, and the objects that need to be controlled are large-scale embankments on the ground. The deformation control level of large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com