Washing machine with water control and associated method

A washing machine and water level technology, applied in the field of washing machines, can solve the problems of energy waste of heating water, wrong reset or adjustment, and inability to estimate the proper water filling level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following preferred embodiments are illustrative in nature and are not intended to limit the invention, its application or use.

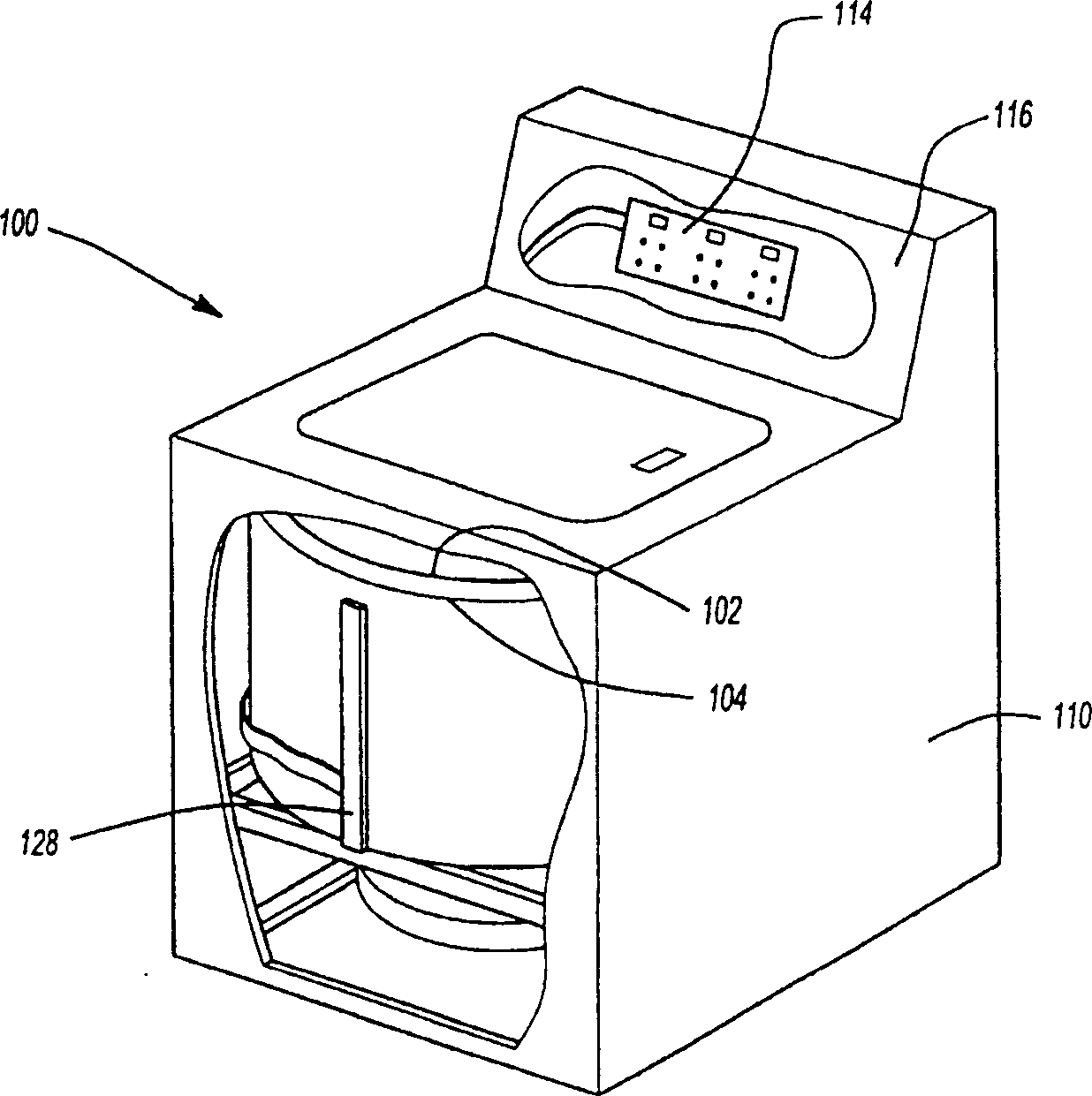

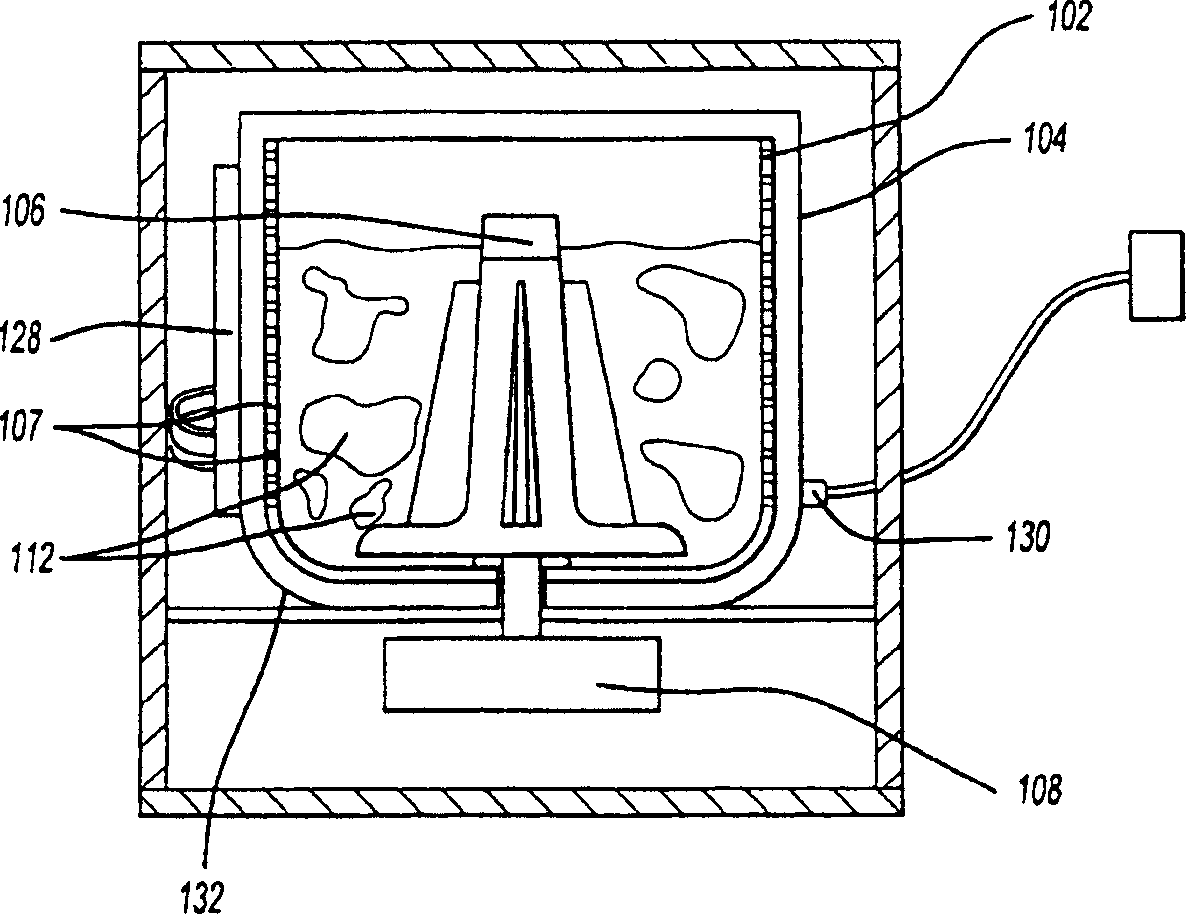

[0018] figure 1 and figure 2 One embodiment of a washing machine 100 according to the invention is shown. The washing machine includes a housing 110 , an inner tub 102 and an outer tub 104 . The inner tub 102 includes perforations 107 through which water flows from the outer tub 104 into the inner tub 102 . The inner tub includes an agitator 106 connected to a motor and transmission system 108 . The washing load 112 is introduced into the inner tub 102 for washing.

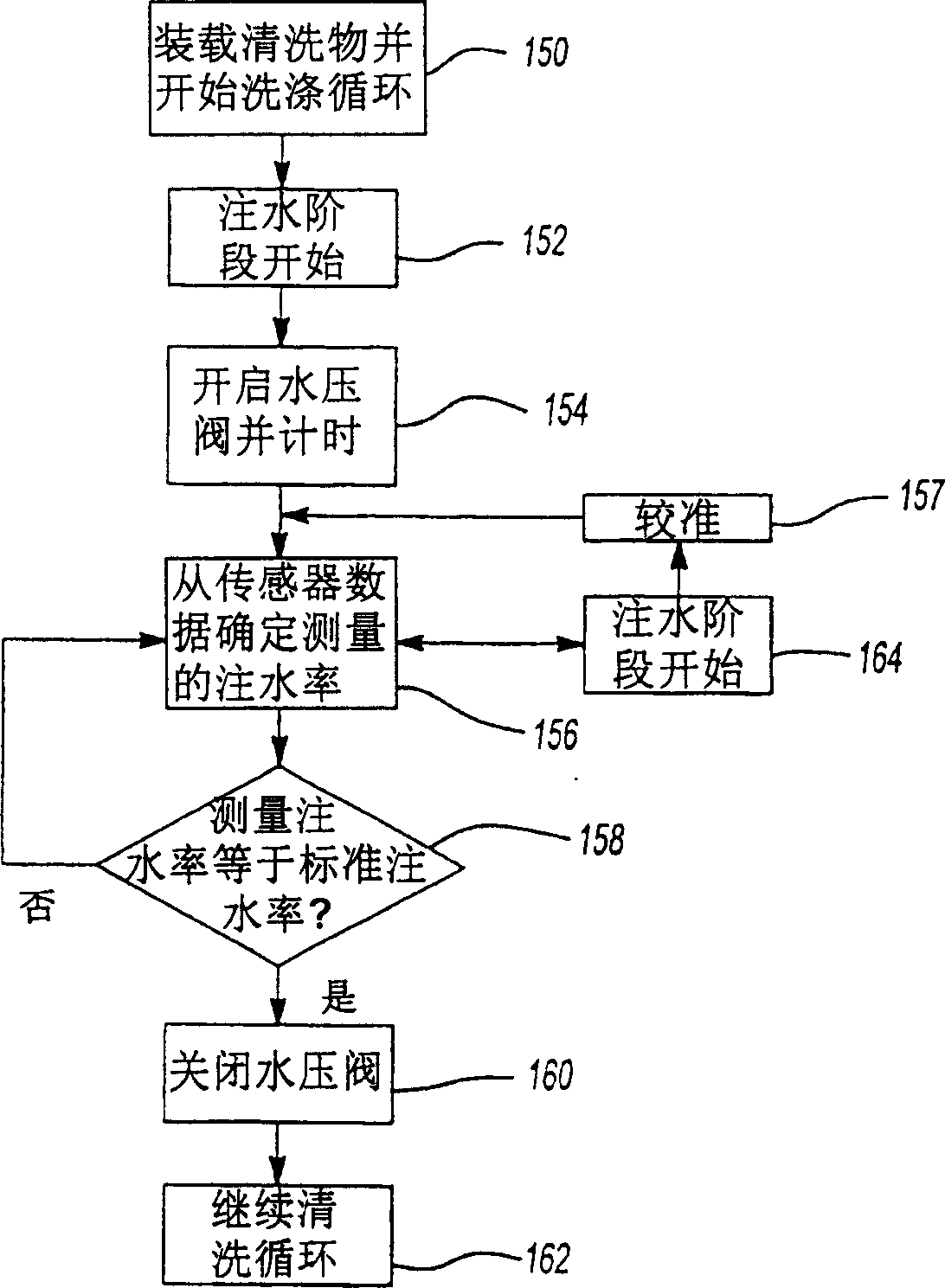

[0019] refer to figure 1 and Figure 4 , the washing machine includes a console 116 with a user-operable control panel 114 . Console 116 overlays controller 118 , which includes microprocessor 120 , stored memory 140 and timer 142 . The controller 118 receives user inputs 122 via the control panel 114, including wash cycle selections and wash cycle adjustments, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com