Method and system for controlling coagulant filling rate by on-line measuring flocculate sedimentation speed

A technology of sedimentation speed and coagulant, which is applied in the control/regulation system, chemical variable control, non-electrical variable control, etc., can solve the problems of low cost, slow sedimentation speed, and can not reflect the lightening of flocs, etc. Direct detection, improved program design, stable online detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

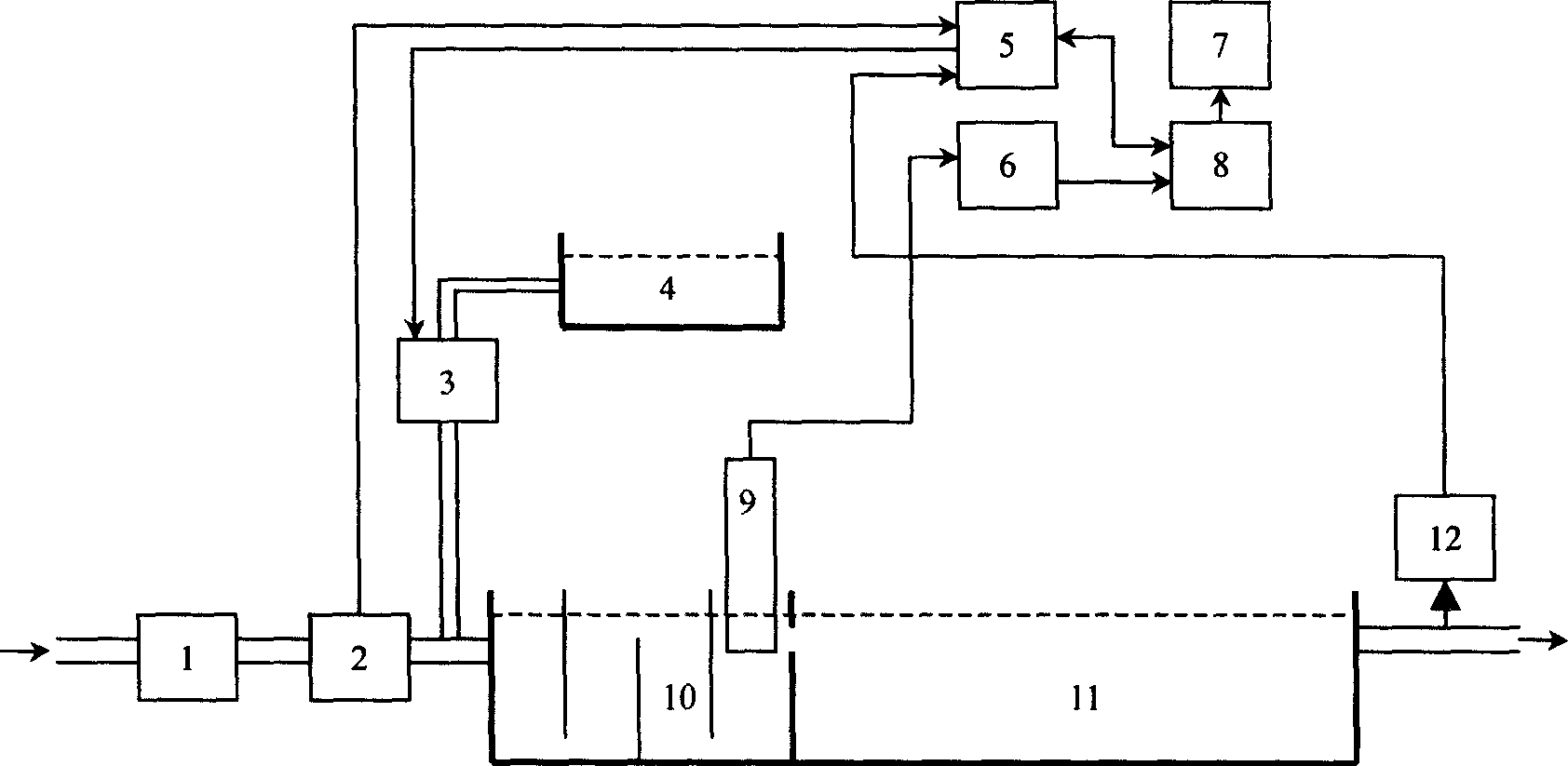

[0035] A preferred implementation of the present invention is described in detail as follows in conjunction with accompanying drawing:

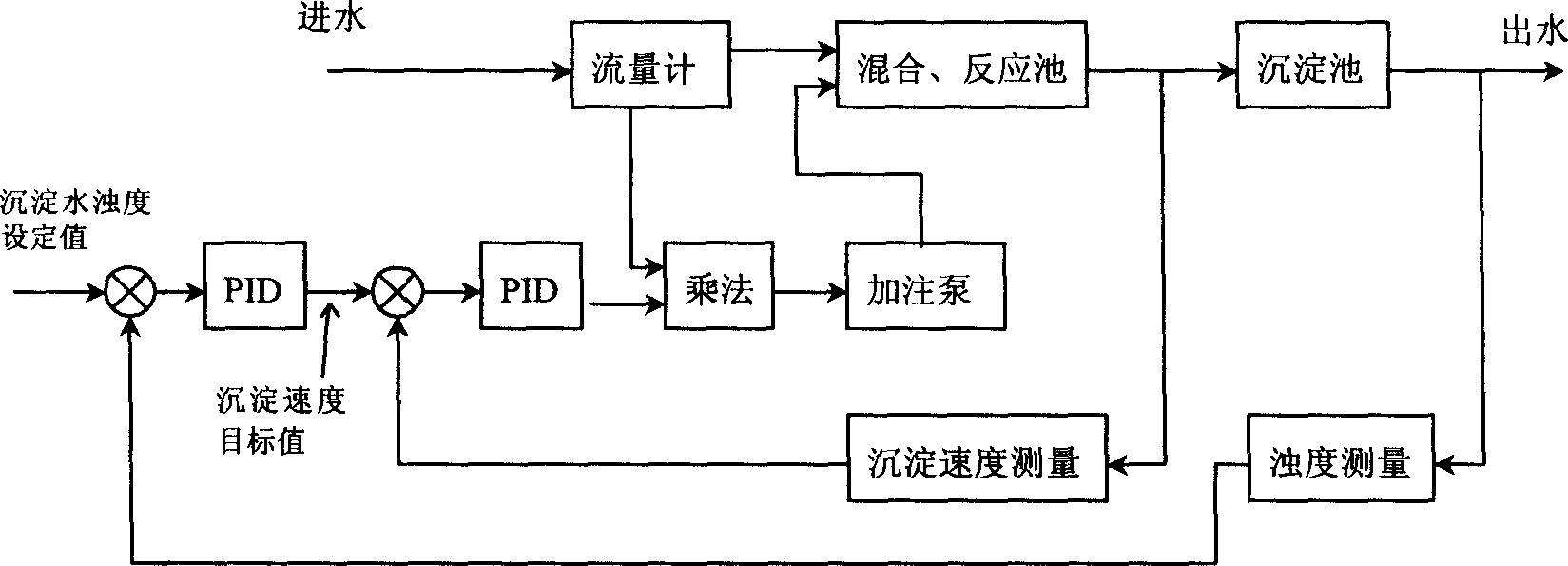

[0036] The method of controlling the amount of coagulant injection by measuring the floc sedimentation speed online is introduced as follows.

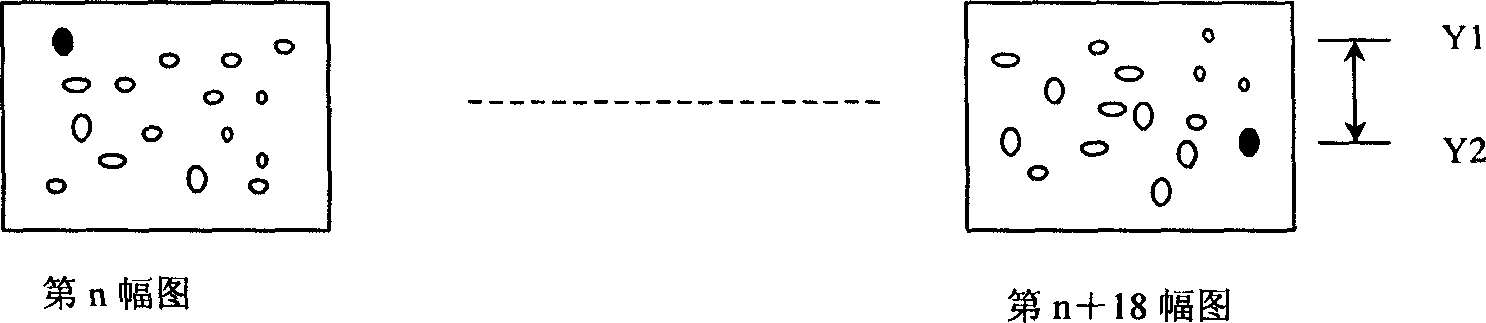

[0037] 1. The raw water enters the mixing reaction tank, mixes, reacts, and flocculates with the added coagulant to produce flocs. In the method, the moving images of the flocs are collected in real time by a floc image acquisition sensor under water at the end of the mixing reaction tank.

[0038] 2. The sensor head contains a specially designed underwater water flow guide and deceleration mechanism, so that the water flow is slow, stable (flocs will not be broken), and horizontal (no vertical flow component) flows through the sampling window in the sensor head.

[0039] 3. The area of the sampling window is about 30*20mm, and the thickness is 3mm, so as to avoid the overlapping of flocs in the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com