Automatic on-line detecting device for welding lines of mast of wind driven generator

A detection device and fan tower technology, which is applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves to analyze materials, etc. It can solve problems that affect inspection quality, safety hazards, and low detection efficiency. , to achieve broad application prospects, improve efficiency and automation level, and achieve the effect of high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

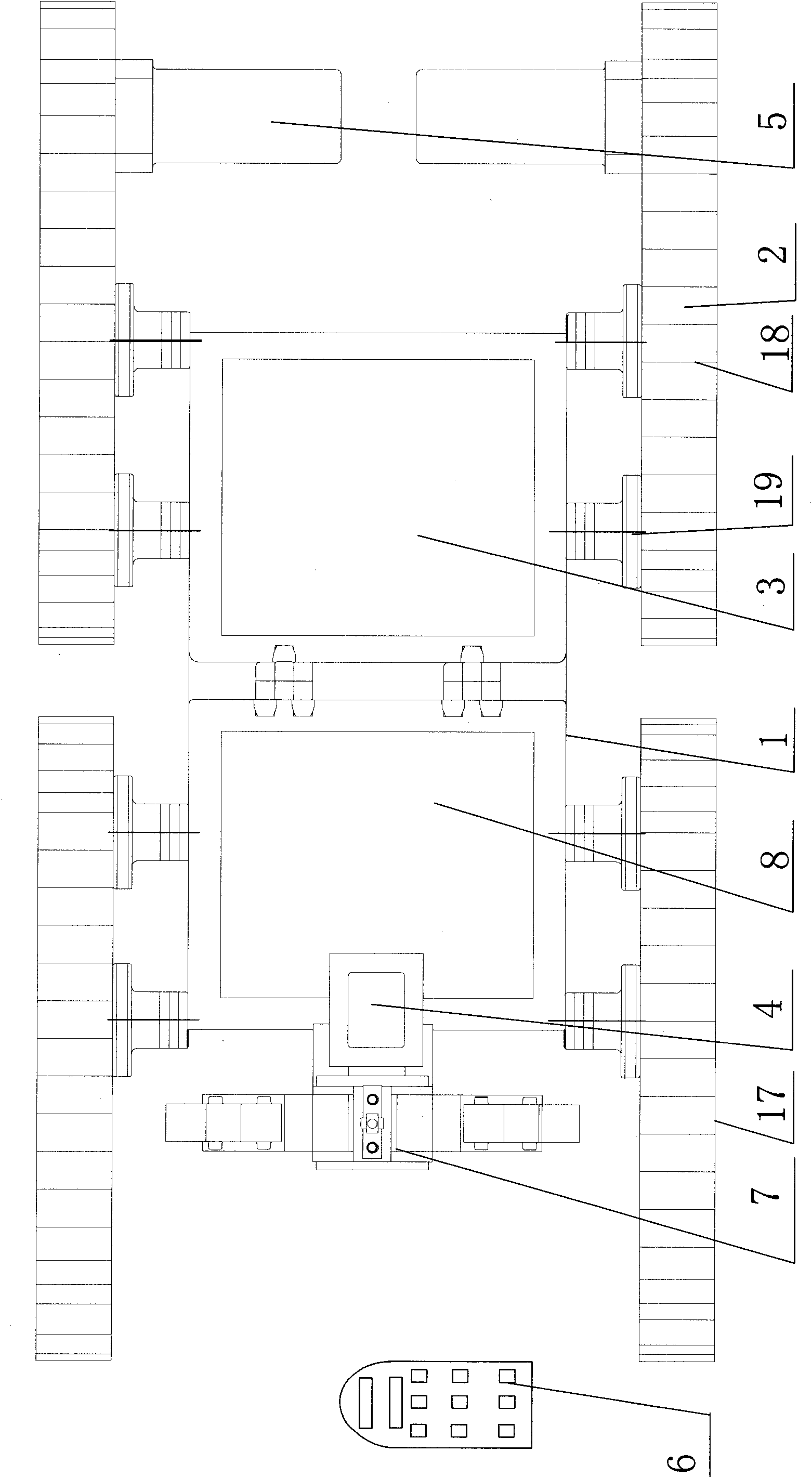

[0026] The automatic on-line detection device for the welding seam of the fan tower comprises: a base frame 1, crawler-type wall climbers 2 are installed on both sides of the base frame 1, an electrical control box 3 is installed on the base frame 1, and the The electrical control box 3 is connected to the industrial camera 4, the motor 5 and the flaw detector 8, the electrical control box 3 is controlled by the remote controller 6, the flaw detector 8 is connected to the probe module 7 through wires, the probe module 7 and the flaw detector Instrument 8 constitutes a phased array ultrasonic nondestructive testing system.

Embodiment 2

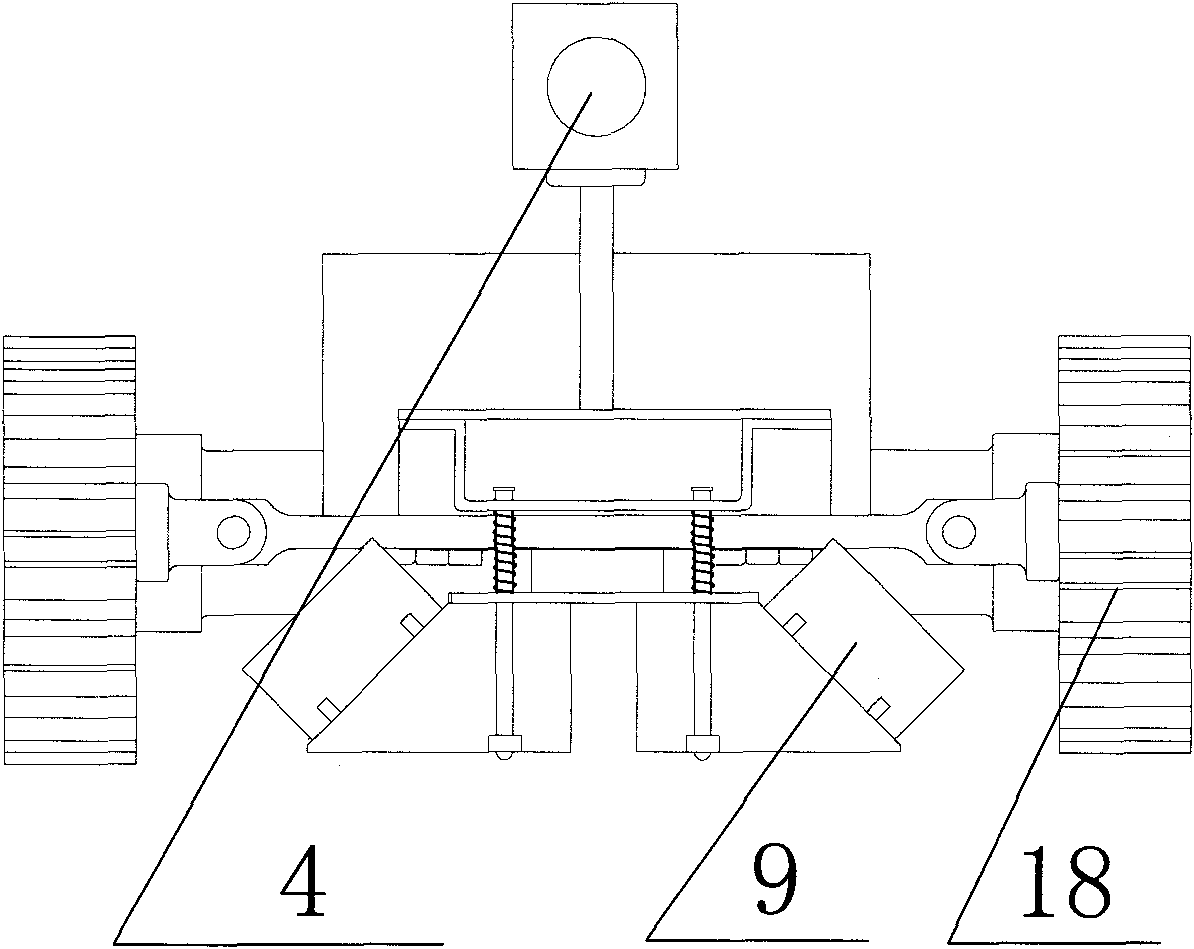

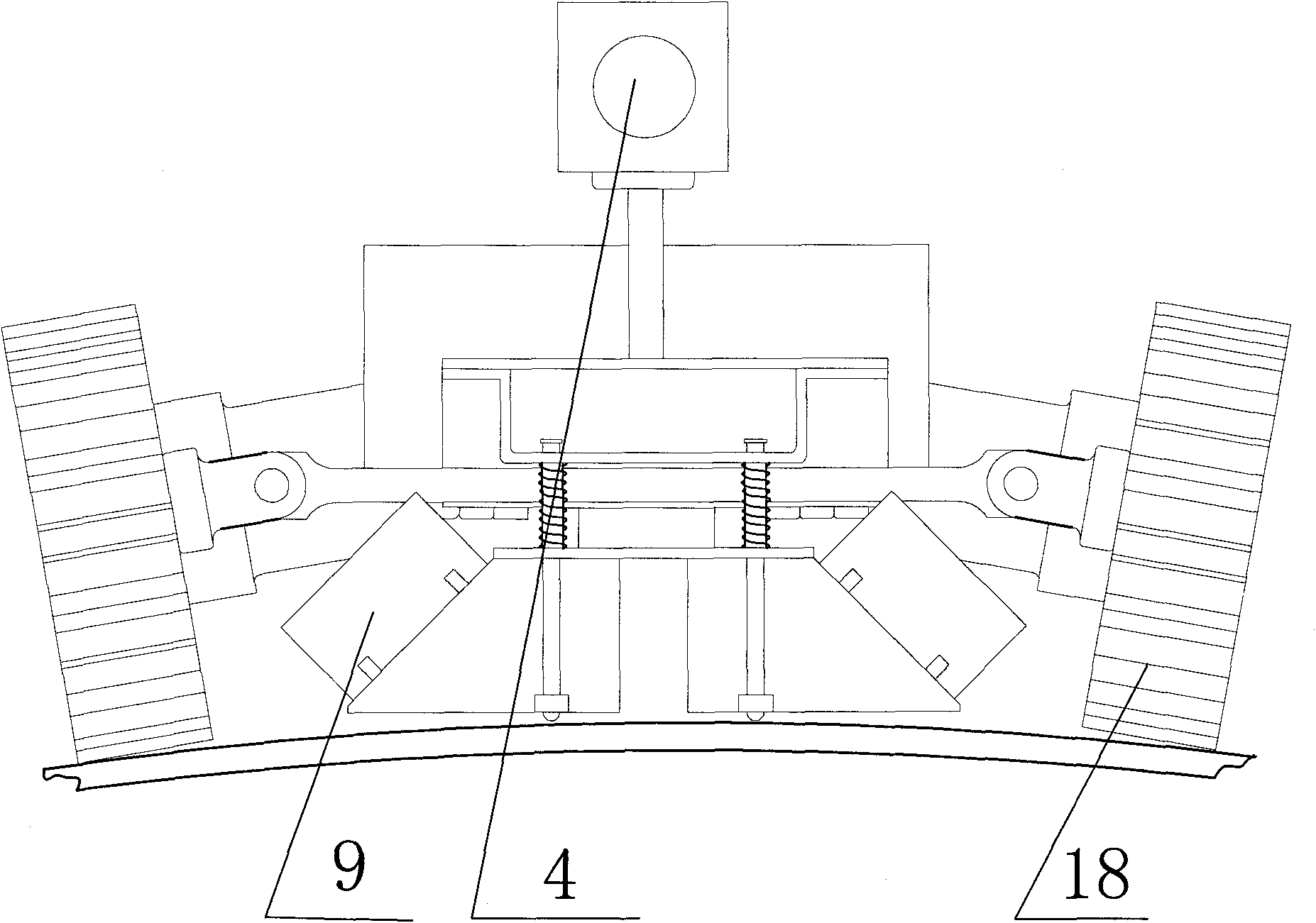

[0028] In the automatic on-line detection device for the weld seam of the fan tower described in Embodiment 1, the probe module 7 includes a probe 9, and the probe 9 is installed on a wedge 10, and the wedge 10 is connected to the middle plate 11 by screws One side of the middle plate 11 is connected to the support plate 13 through the spring 12, the bracket 14 is installed on the support plate 13, and the other side of the middle plate 11 is connected to the universal ball 16 through the guide rod 15.

Embodiment 3

[0030] In the automatic on-line detection device for wind turbine tower welds described in Embodiment 1, the crawler-type wall climber 2 includes track wheels 17 and crawler belts 18 surrounding the track wheels; the track-type wall climber is a cross Symmetrical structure.

[0031] The automatic on-line detection device for the weld seam of the fan tower, the industrial camera 4, the electrical control box 3, the probe module 7, and the flaw detector 8 are all installed on the chassis 1 and fixed with screws; the track wheels 17 and Connect with hinge 19 between underframe 1, described underframe is made up of two base plates, pin shaft connection between described two base plates, described crawler wheel and crawler have a group.

[0032] The automatic on-line detection device for the weld seam of the fan tower, the wall climber can carry out various operations by carrying different equipment and instruments;

[0033] (1) Inspection, flaw detection or sand blasting, rust re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com