Double-spindle turn-milling compound numerical control machine

A compound CNC machine tool and dual-spindle technology, applied in the field of CNC machine tools, can solve the problems of low transmission power and slow processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

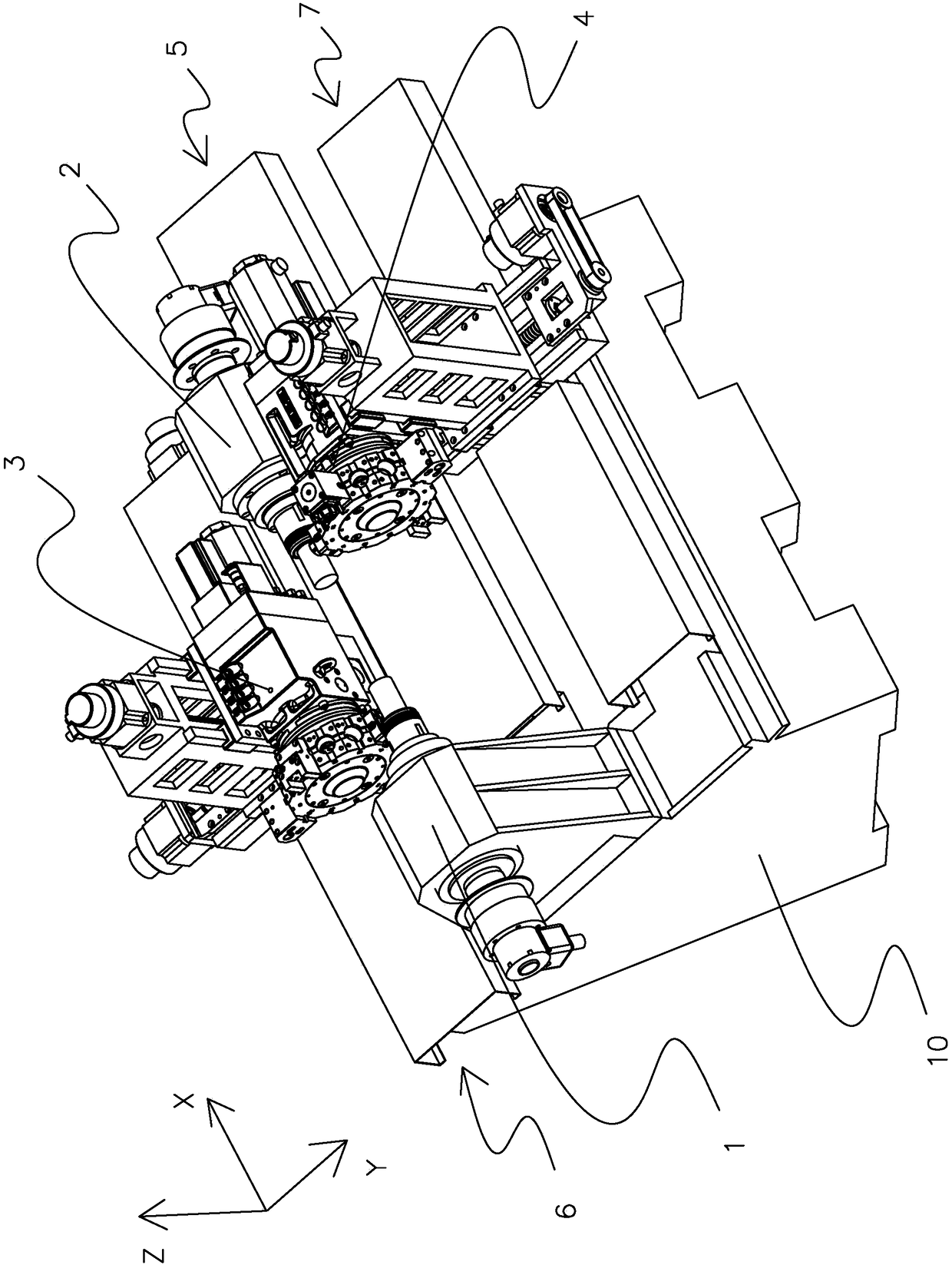

[0028] A double-spindle turning-milling compound numerical control machine tool, comprising: a machine base 10;

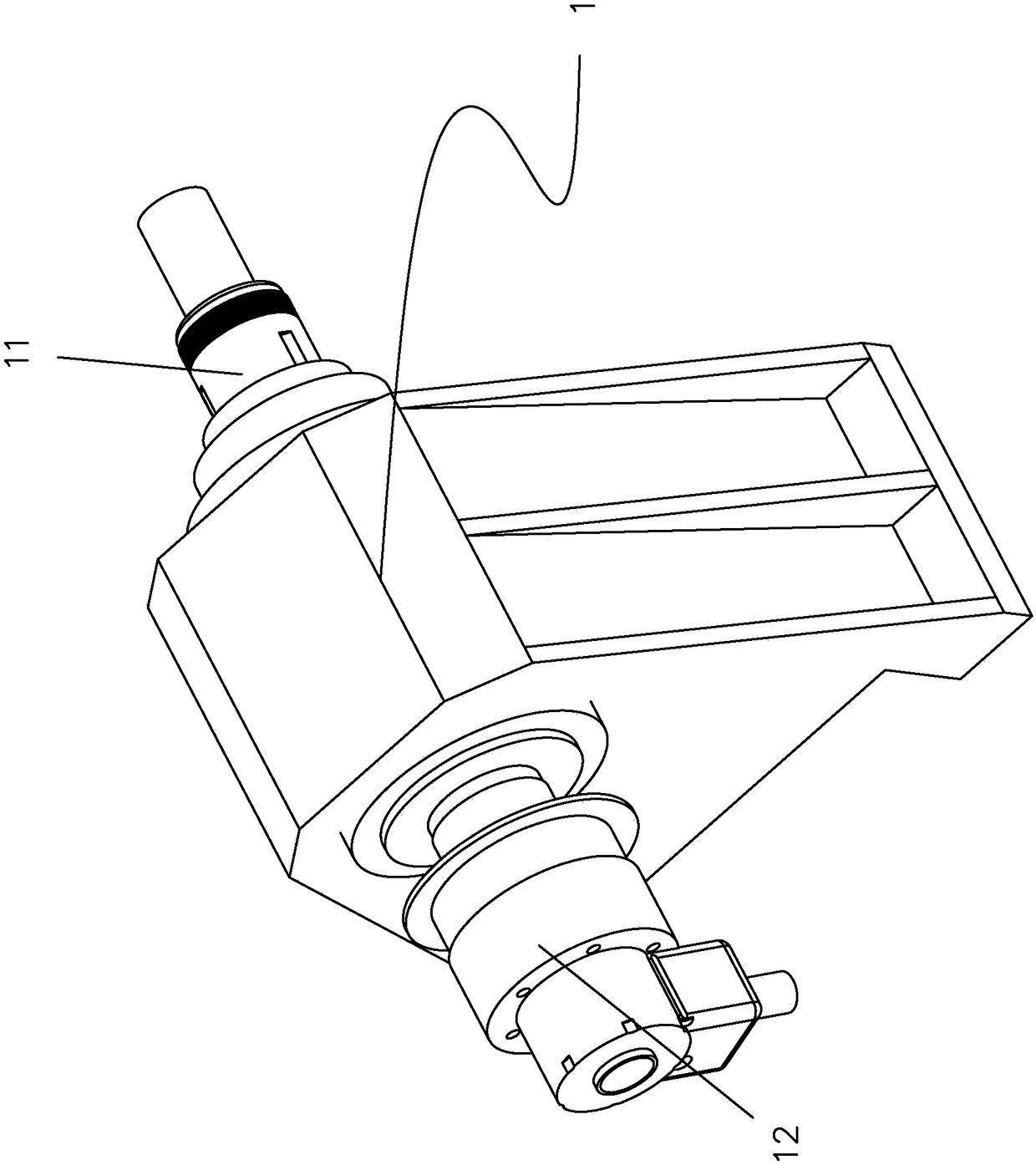

[0029] The first spindle 1, the first spindle 1 is located on the machine base 10 and it is a built-in electric spindle, the output end of the first spindle 1 is provided with a first jacket 11 for clamping the workpiece, the other of the first spindle 1 One end is provided with a first driving cylinder 12 for driving the first jacket 11 to be tight;

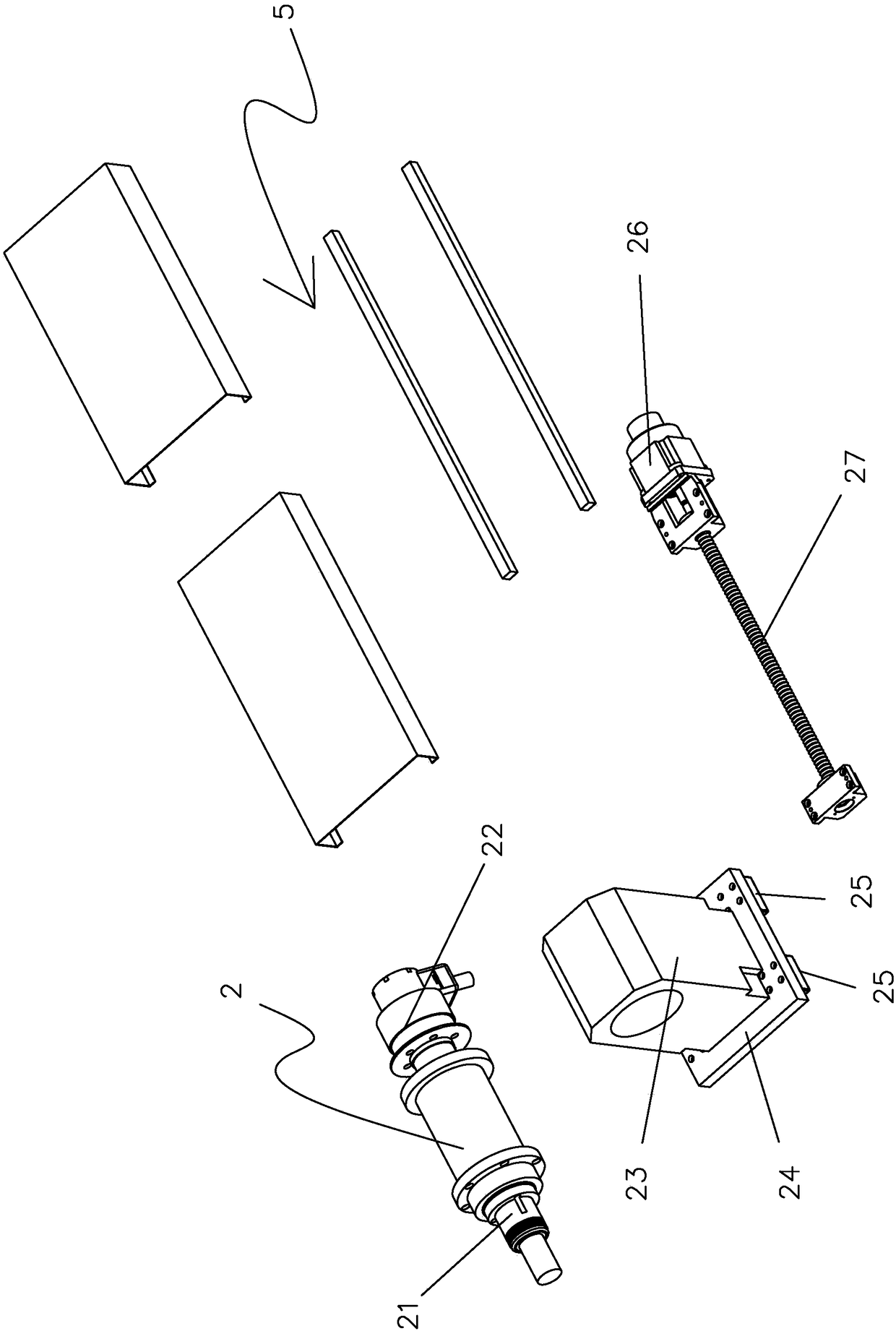

[0030] The second spindle 2, the second spindle 2 is located on the base 10 and it is also a built-in electric spindle, the output end of the second spindle 2 is provided with a second jacket 21 for clamping the workpiece, the second spindle 2 The other end is provided with a second driving oil cylinder 22 for driving the second jacket 21 to be loose and tight, and the second main shaft 2 can slide to the first main shaft 1 along the machine base 10 so that the first jacket 11 and the second jacket 21 can interact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com