Parallel hybrid transmission having a single motor/generator

A generator and mechanical transmission technology, applied in the direction of transmission, gear transmission, multi-ratio transmission, etc., can solve the problems of high cost, high weight, energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

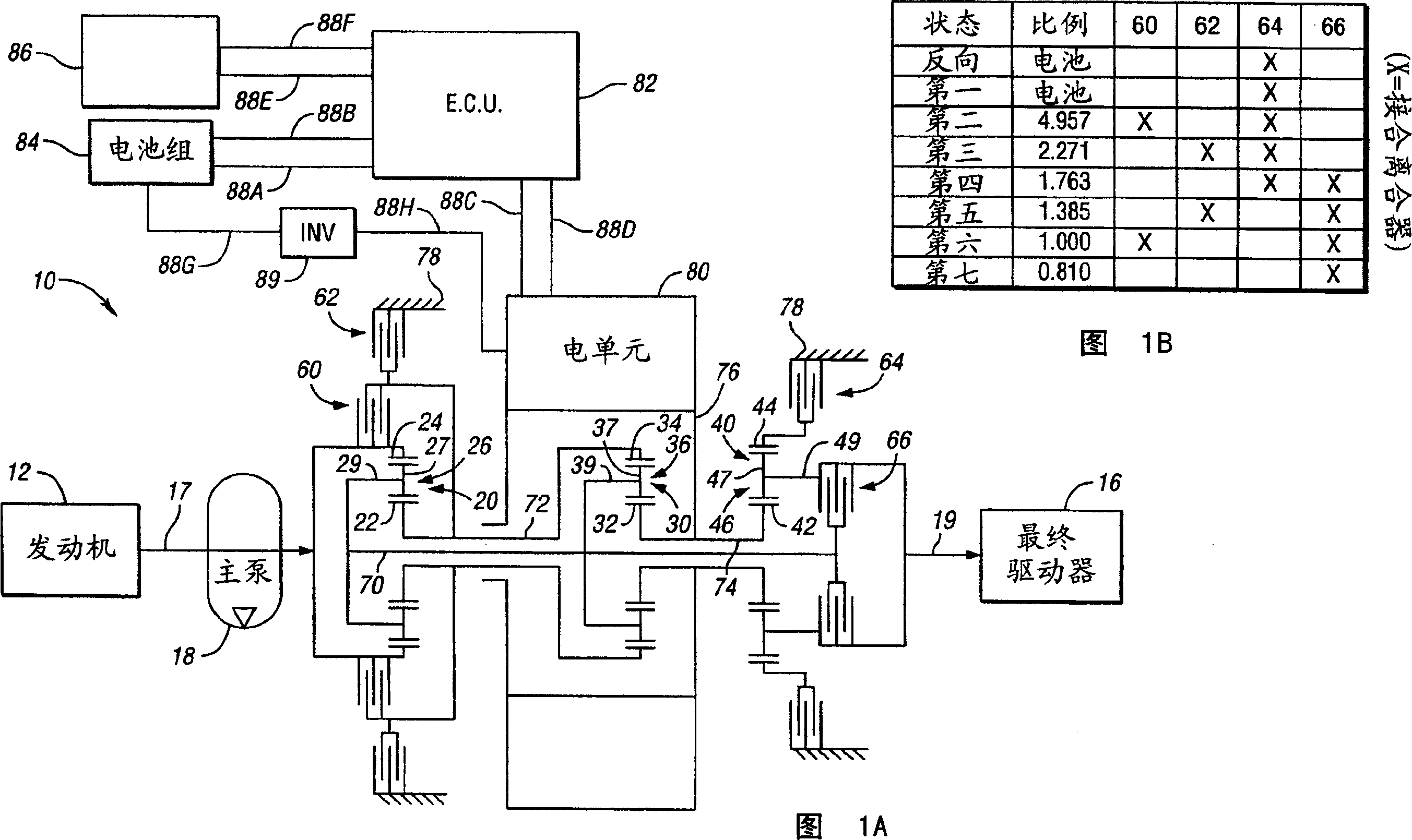

[0025] One representative form of an electro-mechanical transmission with a single motor / generator incorporating the inventive concept is shown in FIG. 1A and is indicated generally by numeral 10 . The hybrid transmission 10 has an input member 17 , which may be a shaft-like body, which may be directly driven by the engine 12 . The engine 12 may be a fossil fuel generator, such as an internal combustion engine or a diesel engine, which is readily adapted to provide a useful power output delivered at a constant revolutions per minute (rpm). A pump 18 for supplying lubrication and cooling fluid to the entire transmission 10 can be detached from the input member 17 . Power flows from the input member 17 through the transmission 10 as described below to the output member 19 which drives the final drive 16 .

[0026]The transmission 10 includes a first planetary gear set 20 that includes a sun gear member 22 , a ring gear member 24 that circumscribes the sun gear member 22 , and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com