A desktop robot automatic locking screw machine

A robot and automatic locking technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as reducing the efficiency of screw machining, reducing the functionality and scope of application of screw machines, and inability to tighten screws. performance and scope of application, and the effect of improving practicability and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

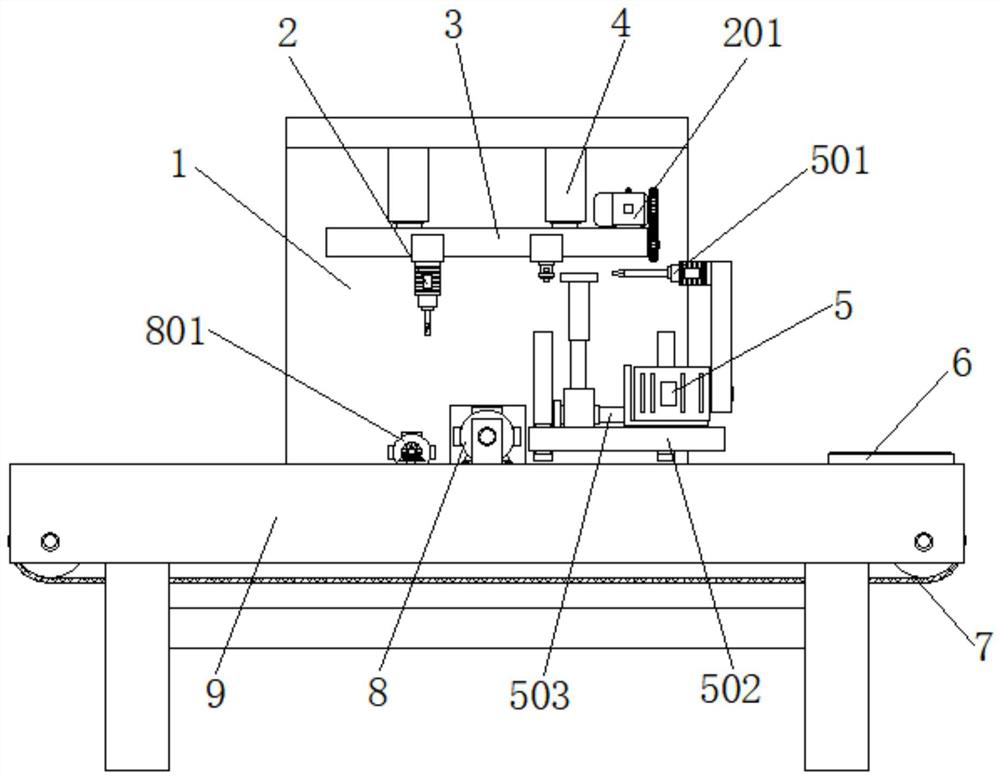

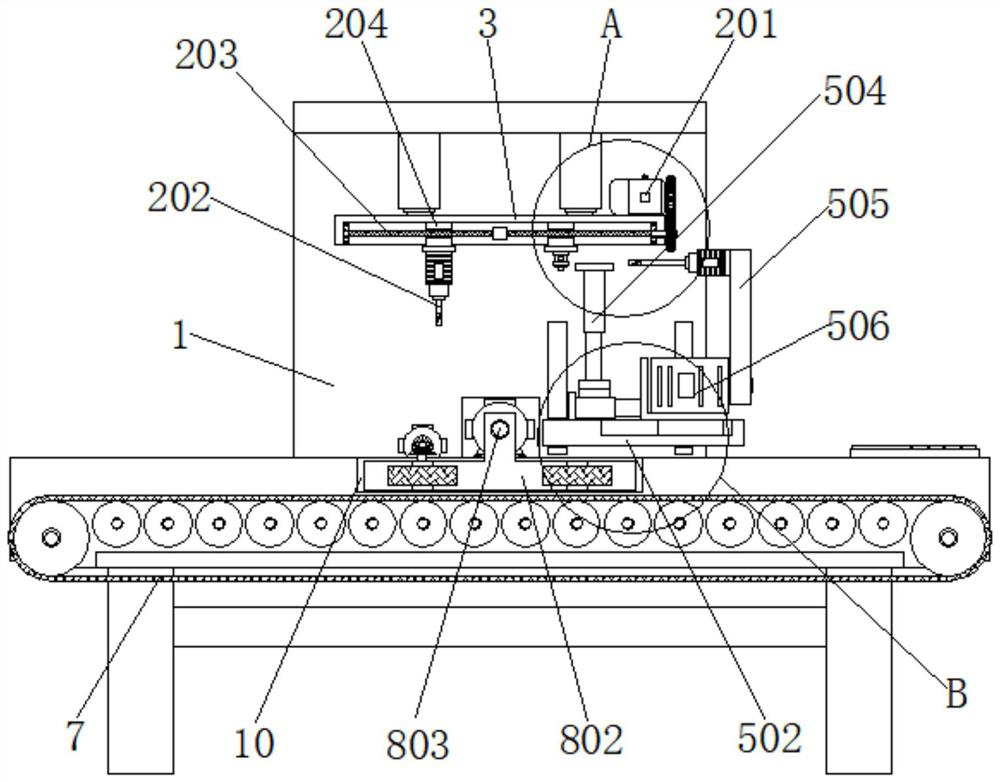

[0045] Example 1, such as figure 1 , 2 , 3, 4 and 7, when starting to tighten the screws on the top of the part, first control the first driving device 201 to drive the first threaded rod 203 to rotate, so that the two groups of sliding blocks 204 are close to or far away from each other until the infrared laser light The infrared rays emitted by 205 irradiate the screw on the top of the part, and then the second driving device 801 drives a set of scroll wheels 804 to rotate, and four sets of scroll wheels 804 are used to drive the part to rotate until the screw irradiated by the infrared laser lamp 205 turns to Directly below the first screw gun 202 , then control the extension of the first electric lifting rod 4 , and use the first screw gun 202 to tighten the screws on the parts.

Embodiment 2

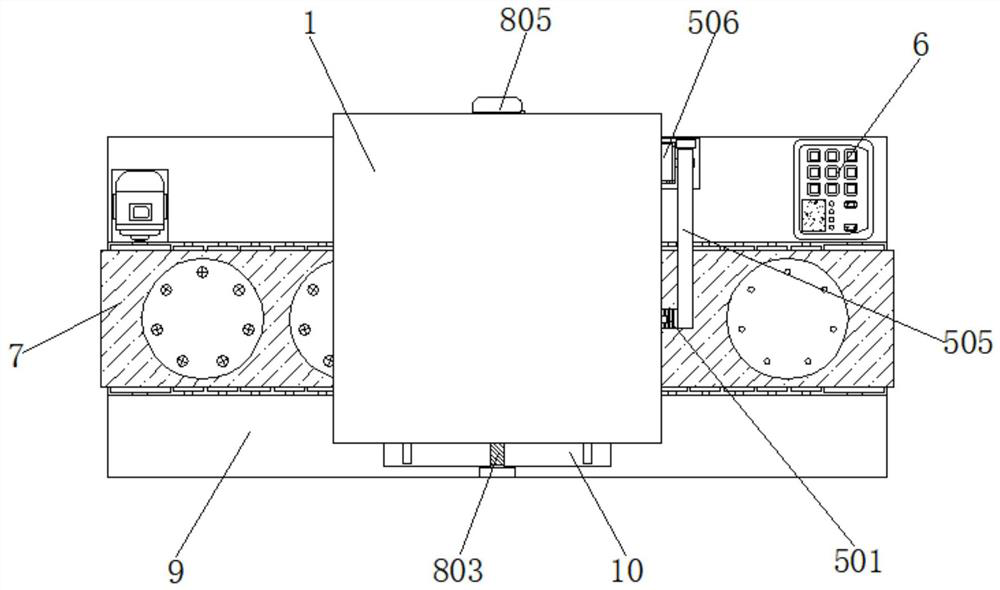

[0046] Example 2, such as figure 1 , 2 , 3, 4, 5, 6 and 8, when starting to tighten the screws around the cylindrical part, control the first servo motor 506 to rotate counterclockwise 90°, so that the second screw gun 501 moves to the top of the conveyor belt device 7 At the middle position, use the clamping assembly 8 to drive the parts to rotate, so that the screws around the parts can face the second screw gun 501 one by one, and then control the electric push rod 503 to shorten, so that the second screw gun 501 can tighten the screws around the parts, And if the screws around the part are located above the outside of the part, the height of the second screw gun 501 can be controlled by shortening the second electric lifting rod 504 .

[0047] Working principle: The device is powered on before use, the operator stands at the end close to the control panel 6, and manually places the cylindrical processed parts on the top of the conveyor belt device 7, and the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com