Automatic quick-change adsorption tightening device

An automatic, tightening head technology, used in electric vehicles, transportation and packaging, manufacturing tools, etc., can solve the problems of mechanical collision affecting the service life of tools, inability to automatically pick up screws, and screws falling off, so as to improve service life and compact devices. , reduce the effect of mechanical collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

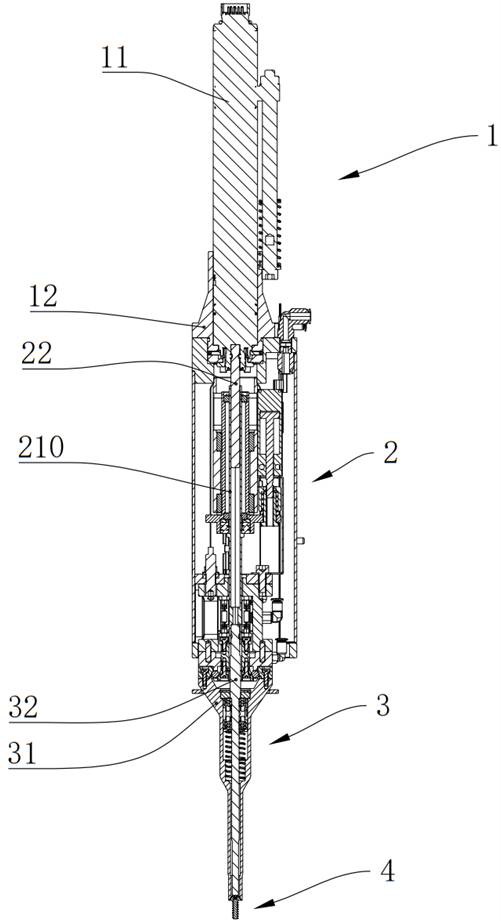

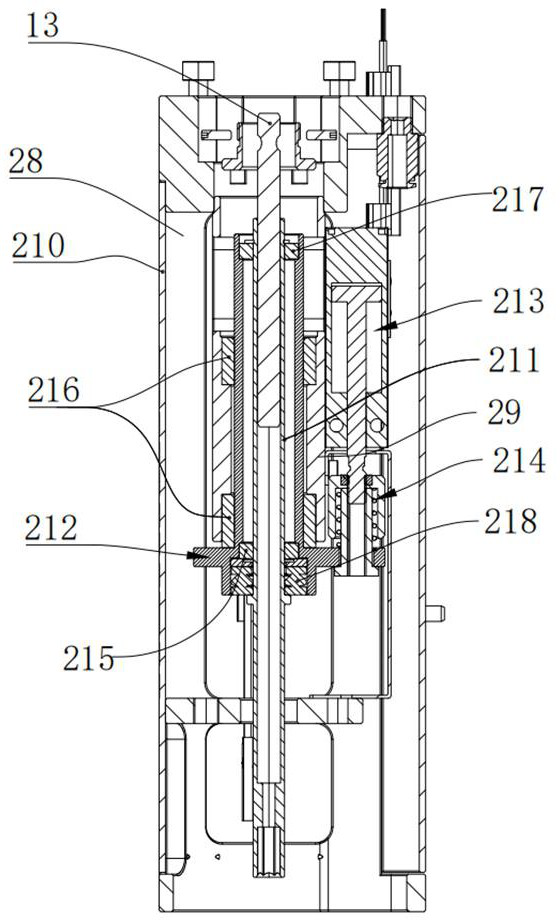

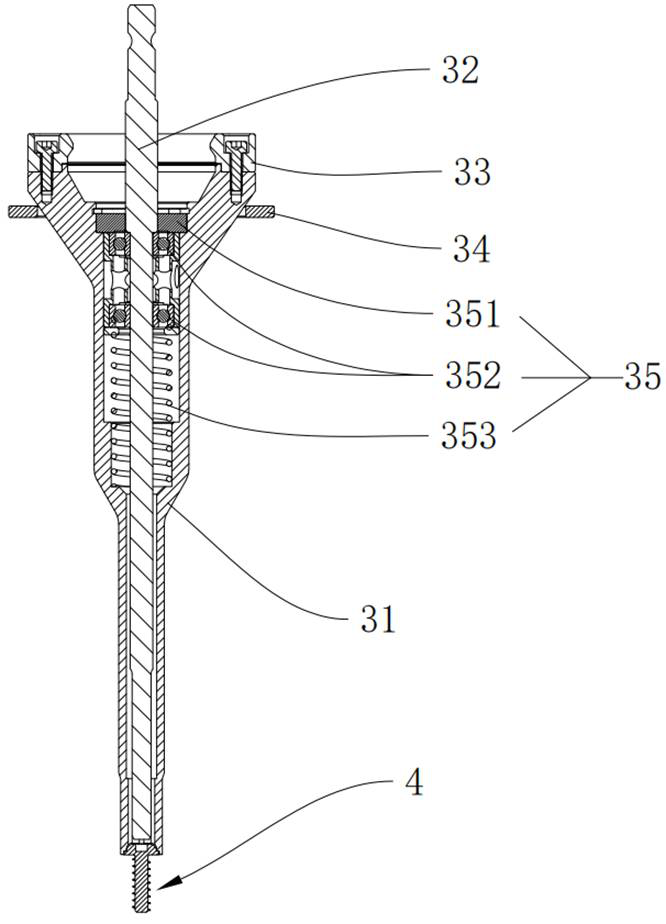

[0030] like Figure 1-5 As shown, an automatic quick-change adsorption and tightening device includes a tightening gun mounting module 1 for tightening, an adsorption and tightening head 3 for adsorbing or tightening screws 4, and a quick-change connection mechanism 2 for quickly replacing the adsorption and tightening head 3 The described tightening gun installation module 1 includes a transmission connecting rod 13 and a tightening gun 11 that are connected to each other by transmission; the suction tightening head 3 includes a hollow suction nail tube 31 and a screw bit head 32 arranged in the suction nail tube 31; The quick-change connection mechanism 2 includes a mounting bracket 21, a movable limit assembly, a sliding traction assembly and a pneumatic connecting pipe; specifically, the upper end of the screw bit 32 is hexagonal, and correspondingly, the tightening gun 11 is provided with a hexagonal prism shaped drive connection holes.

[0031] The transmission connecti...

Embodiment 2

[0054] The difference from the first embodiment is that the nailing cylinder 213 or the driving cylinder 24 is replaced with a linear motor or a rotary motor to cooperate with the lead screw and the lead screw nut, and the output end of the linear motor or the lead screw nut is fixedly connected to the transmission shaft 211. , the drive shaft 211 is driven to move by a linear motor or a rotary motor, and then the screw bit head 32 is controlled to move to achieve nailing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com