Automatic camshaft shifting device for tightening wrench

A technology of displacement device and camshaft, which is applied in the field of engine manufacturing and engine assembly automatic line to achieve the effect of saving energy, improving productivity and reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

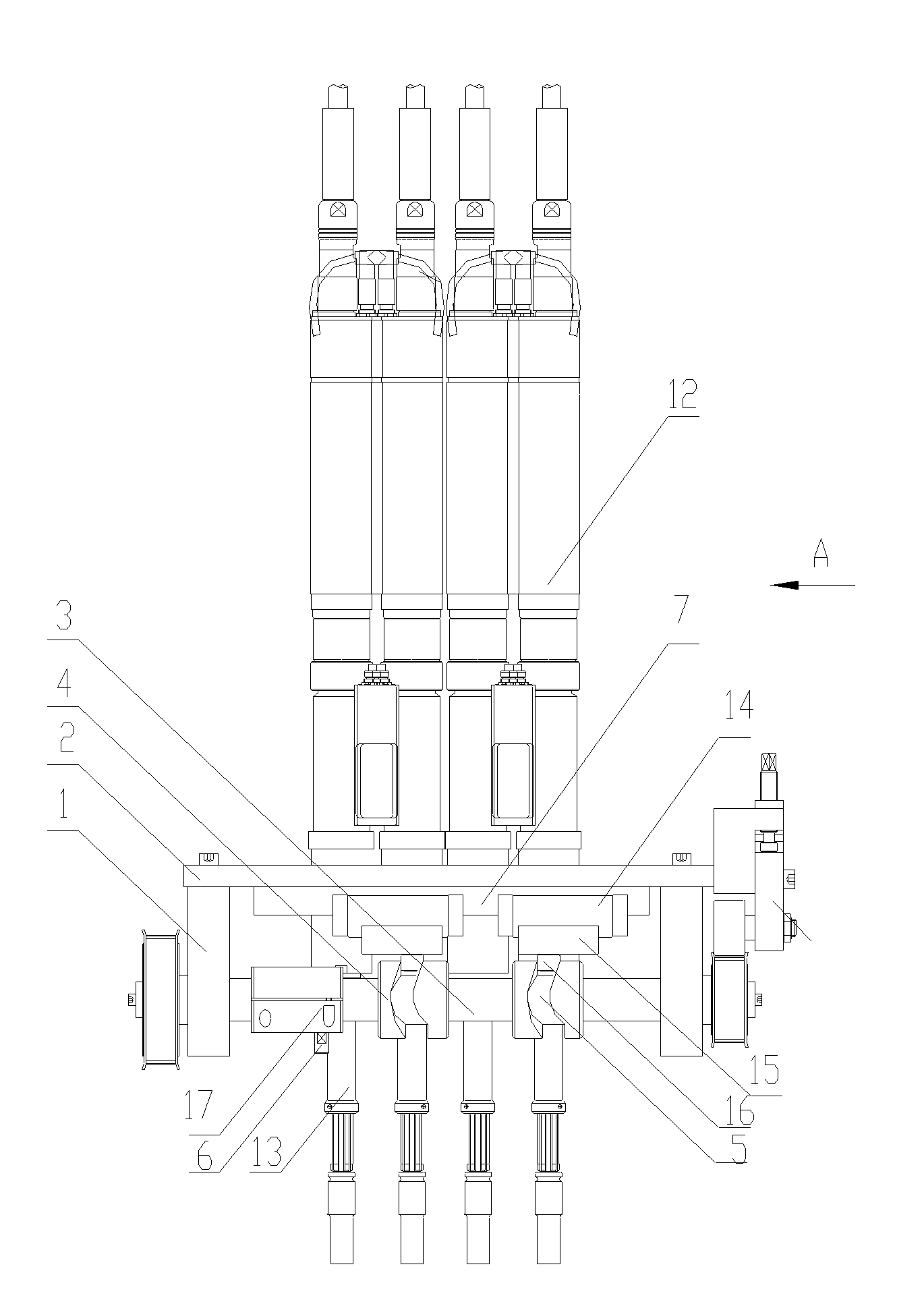

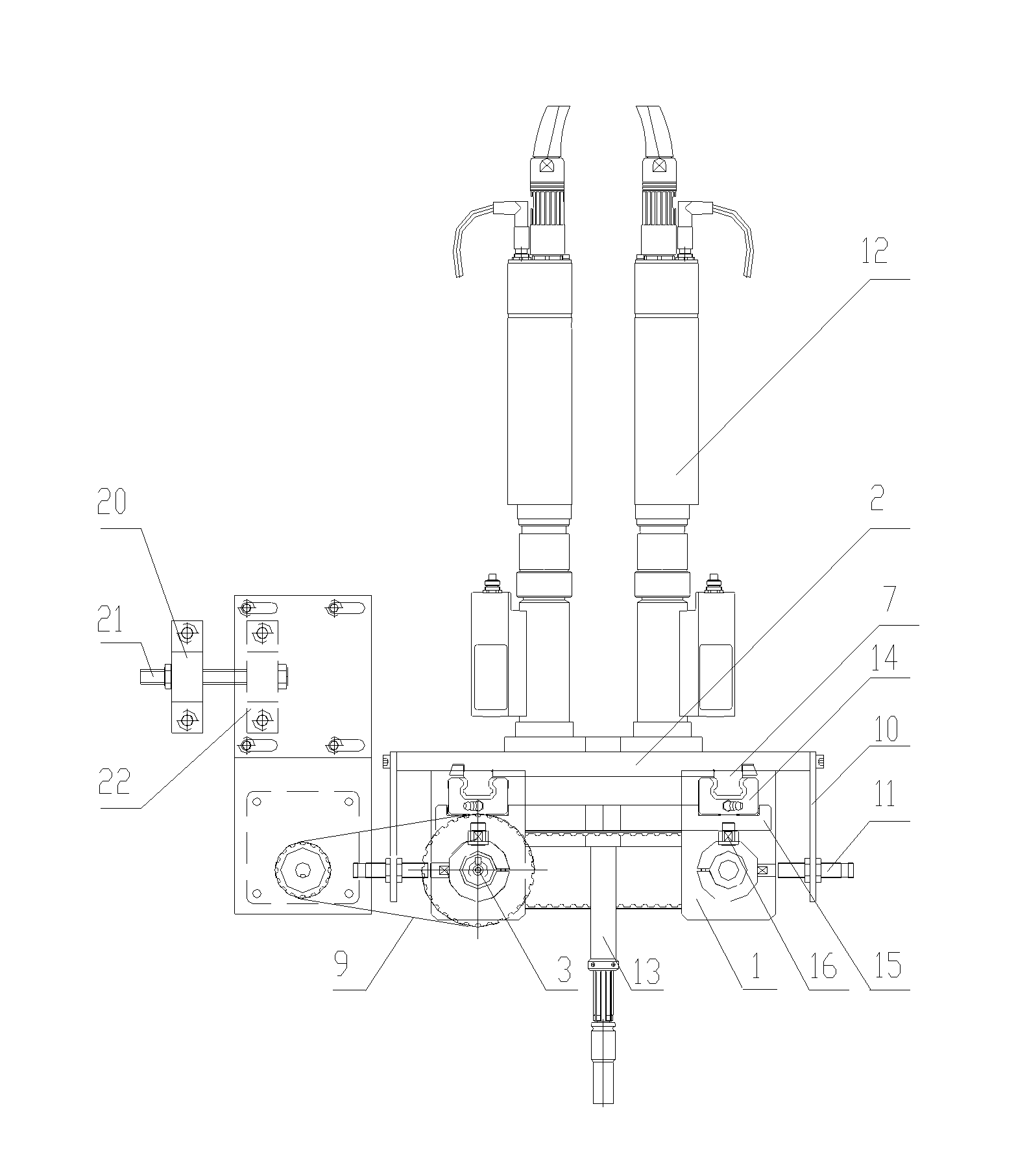

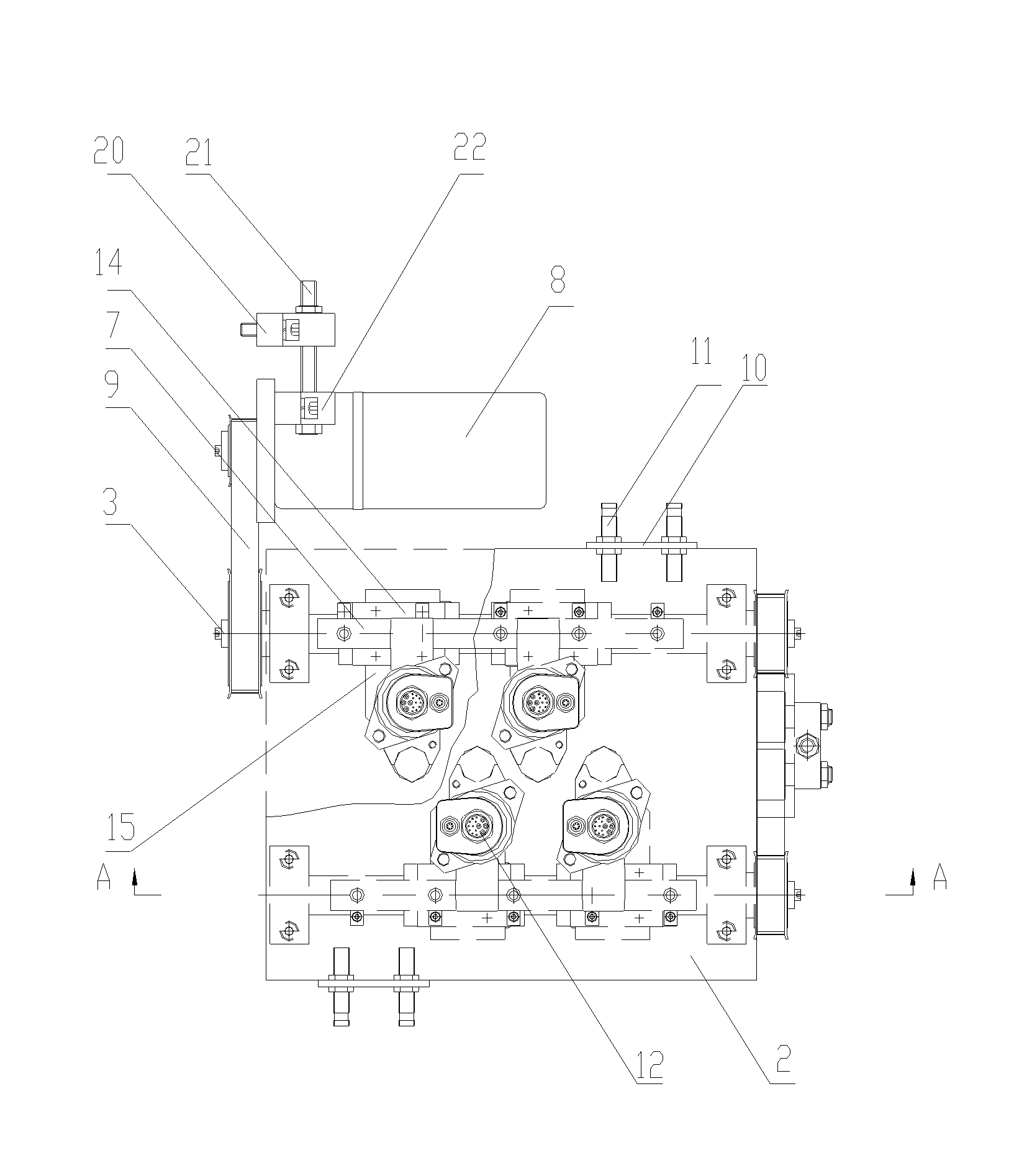

[0015] The present invention includes an upper support plate 2 fastened integrally with the support 1, and at least two camshafts 3 are installed in parallel in the support 1. At least two sections of cams 4 and one induction block 6 are arranged on the camshaft 3 . The induction block 6 can also be installed on the fixed ring 17, and the fixed ring 17 is installed on one end of the camshaft 3. The cam 4 is provided with a circumferential curved groove 5 . At least two linear guide rails 7 are respectively fixed on the lower surface of the upper support plate 2 and located above the camshaft 3 . The motor 8 is connected to one end of the camshaft 3 through a transmission belt 9, and the other end of the camshaft 3 is connected to one end of another adjacent camshaft through another transmission belt. An induction switch bracket 10 is installed on the upper support plate 2, and proximity switches 11 are respectively fixed on the bracket 10. The tightening shaft 12 and the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com