Grenade bottom-row stern screwing device and using method

A stern and bottom row technology, applied in the direction of ammunition, weapon accessories, wrenches, etc., can solve the problems of inability to apply torque, affect product quality, and low efficiency, so as to ensure accuracy and reliability, avoid linear contact surface small, Effect of improving tightening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will be described in detail in conjunction with the technical solutions in the embodiments of the present invention:

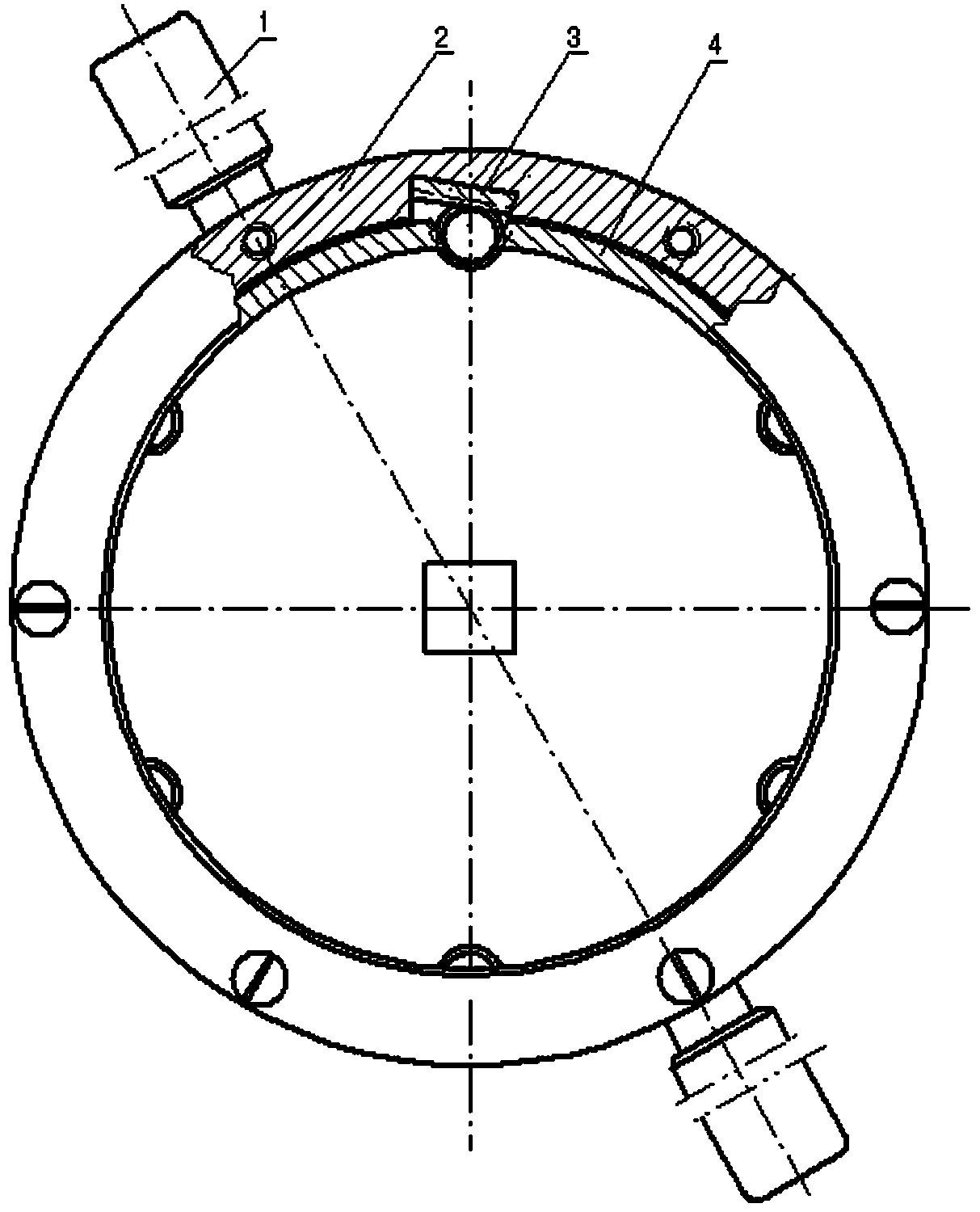

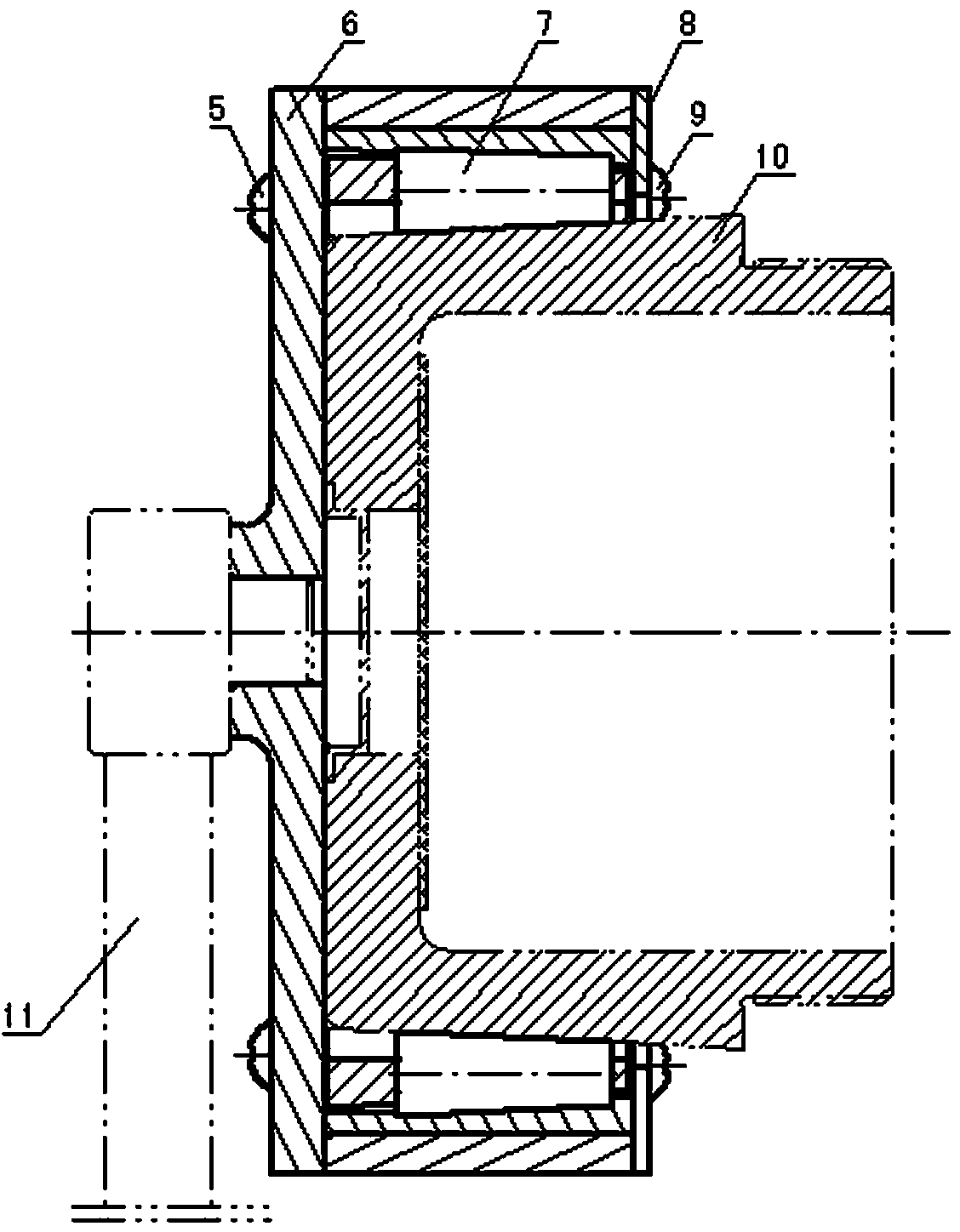

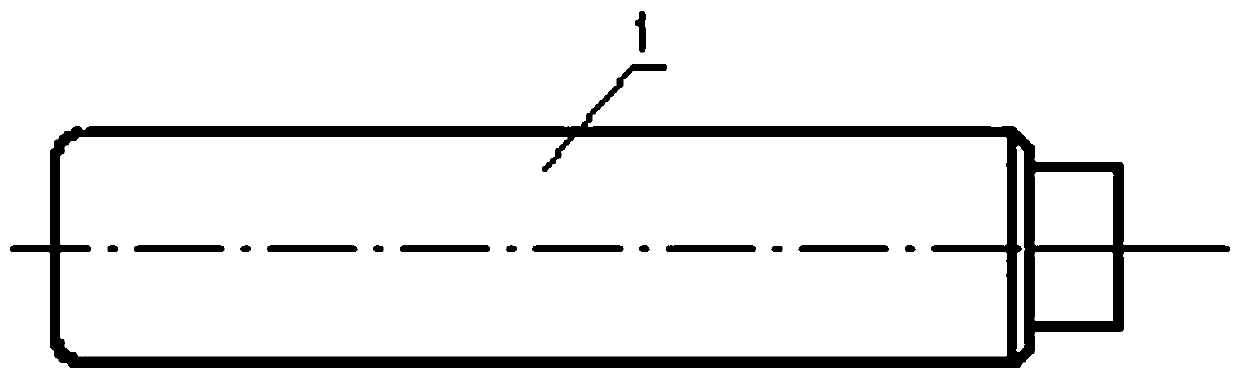

[0038] refer to Figure 1-15 As shown, the present invention proposes a grenade bottom row stern tightening device and its use method. The technical solution is: the conventional grenade bottom row stern tightening device of the present invention includes a frame body 2 and an inclined block 3 with combined assembly, and the retainer 4. Set in the middle of the frame body 2 to evenly distribute and fix the tapered rollers 7. The tapered surface of the tapered rollers 7 is attached to the inclined block 3 of the frame body. The upper end cover 6 and the lower end cover 8 pass through three M6× 16mm screws 5 and six M6×10mm screws 9 are respectively assembled on the upper end surface and the lower end surface of the frame body 2. When in use, the lower end cover 8 faces down and the wrench is inserted into the outer cone of the bottom row of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com