Special embroidery box for embroidered cloth

An embroidery frame and piece of cloth technology, applied in the field of embroidery machines, can solve problems such as inability to embroider, and achieve the effect of simple embroidery process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

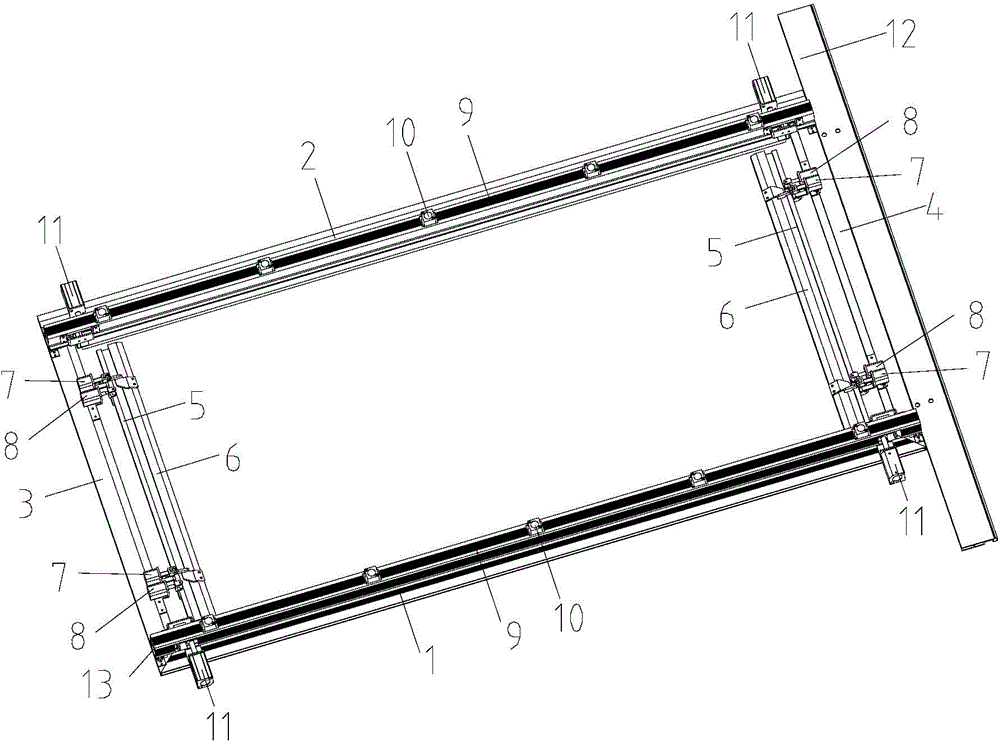

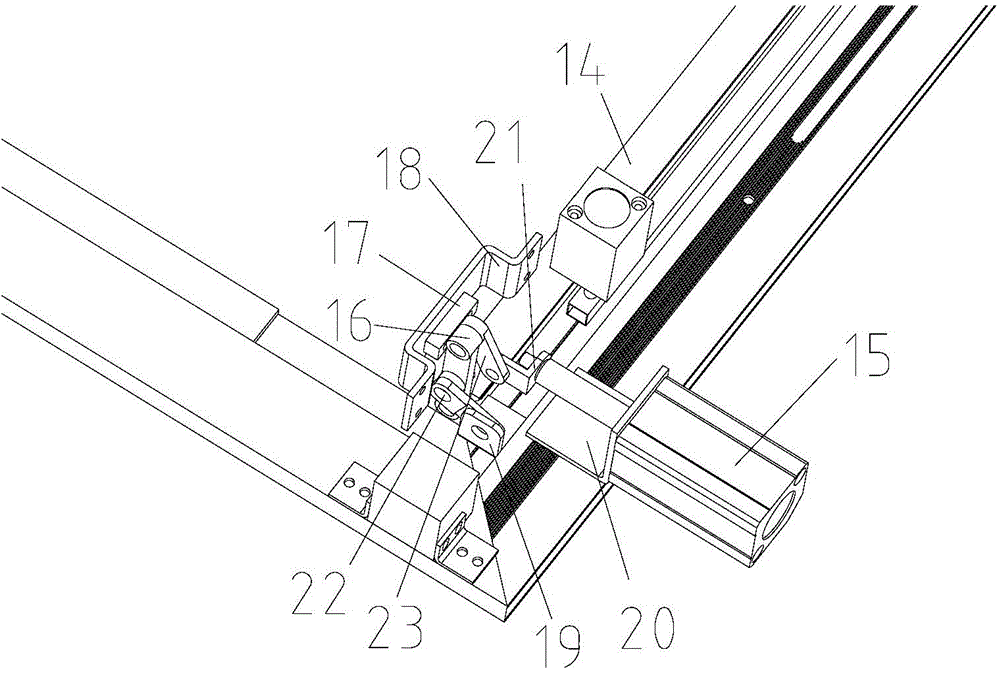

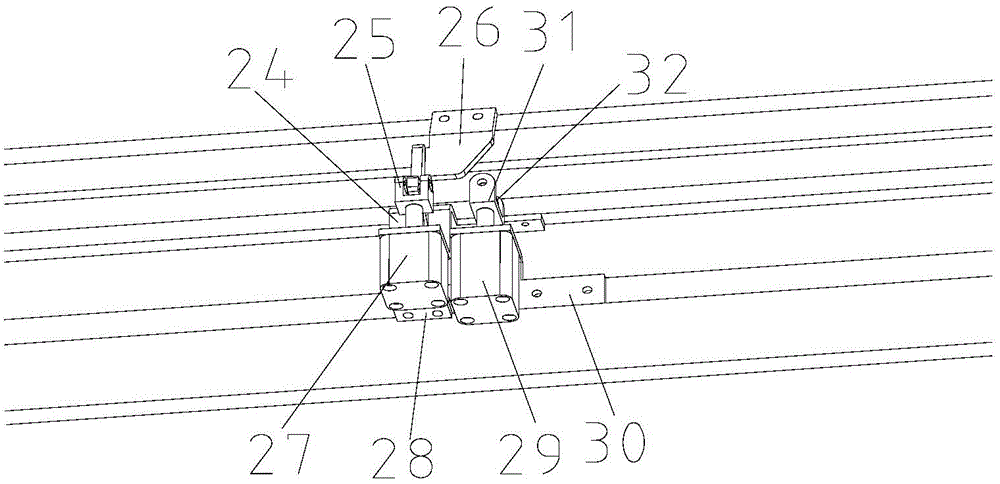

[0015] The following will be further described in conjunction with the accompanying drawings and specific implementation methods: A special embroidery frame for cloth embroidery, including: a front beam 1, a rear beam 2, a left beam 3, and a right beam 4 constituting the embroidery frame frame; Support beam 9 on 2, five pneumatic devices c10, two cylinder linkages 11; pneumatic devices a7, pneumatic device b8, rear side bars 5, left and right beam cover plates 6 installed on left beam 3 and right beam 4; The cylinder a15 of the cylinder linkage mechanism 11 is fixed on the front beam 1 through the angle plate 20, the cylinder joint 21 is located at the threaded end of the piston rod of the cylinder a15, and the cylinder linkage mechanism 11 is installed on the On the front beam 1; and the two-eye connecting rod 22 is located on the left side of the three-eye connecting rod 16 and connected with the middle hole of the three-eye connecting rod 16 with a pin shaft; and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com