Bolt pre-tightening device and bolt tightening method on draught fan tower barrel

A technology for fan towers and bolts, applied in the direction of torque/torsional force measurement, metal processing, metal processing equipment, etc. during tightening, can solve problems such as time-consuming and energy-consuming, economic loss, and bolt loosening, and reduce the intensity of manual labor. , Guarantee reliability, solve the effect of time-consuming and laborious and inaccurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

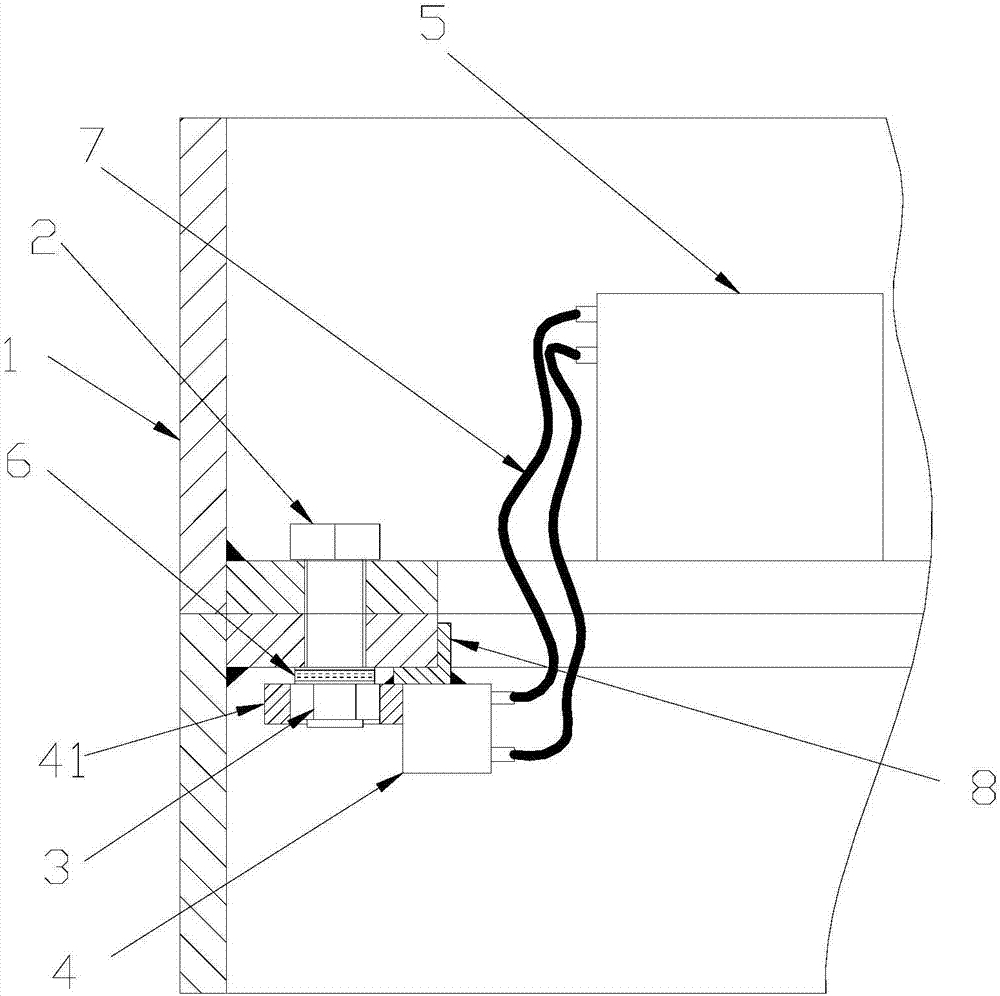

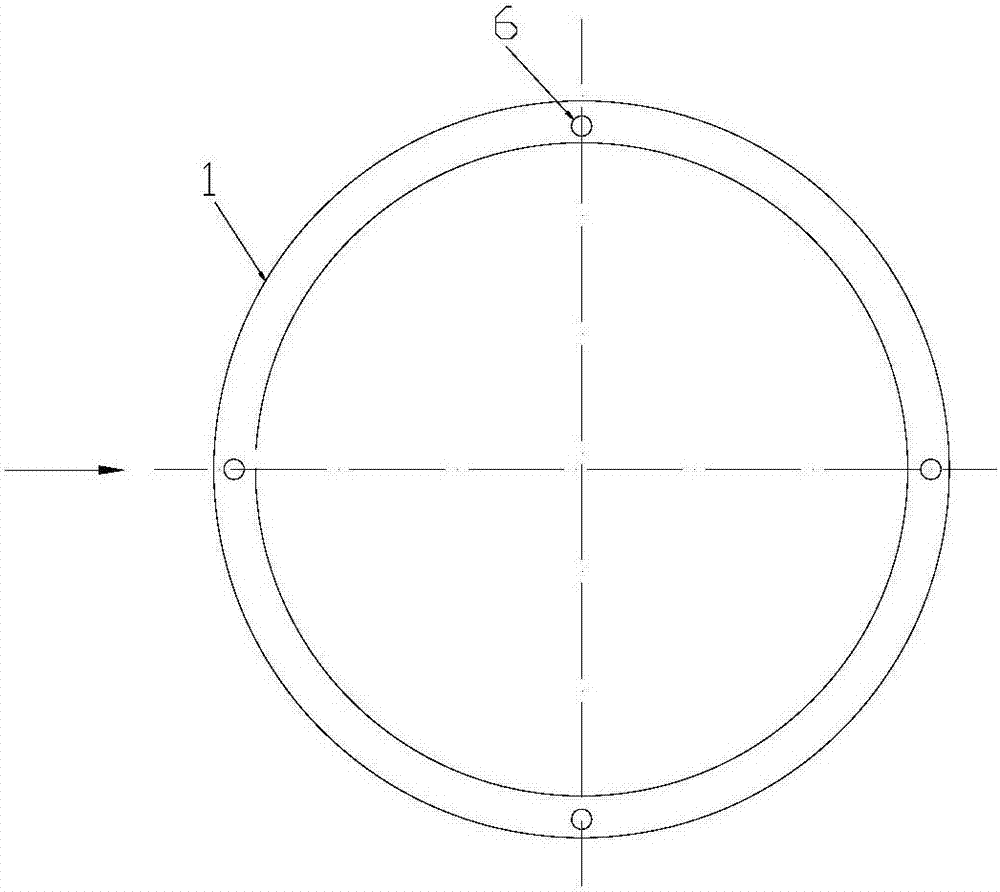

[0032] Such as figure 1 As shown, a bolt pre-tightening device on a wind turbine tower includes a stress detection device installed at the joint of the tower 1 and a bolt tightening device. The stress detection device includes a plurality of The pressure sensor 6, the pressure sensor 6 is arranged on the side where the end of the bolt 2 is in contact with the tower tube 1, and the bolt 2 is pressed against the surface of the tower tube 1 to detect the pressure between the bolt 2 and the tower tube 1 ; The pressure sensor 6 is connected with the bolt tightening device to generate electrical signals for controlling the action of the bolt tightening device. When the detection value of the pressure sensor 6 is less than the set value, the bolt tightening device works to tighten the bolts, and when the detection value of the pressure sensor 6 is equal to or greater than the set value, the bolt tightening device stops working. The bolt tightening device includes a hydraulic wrench ...

Embodiment 2

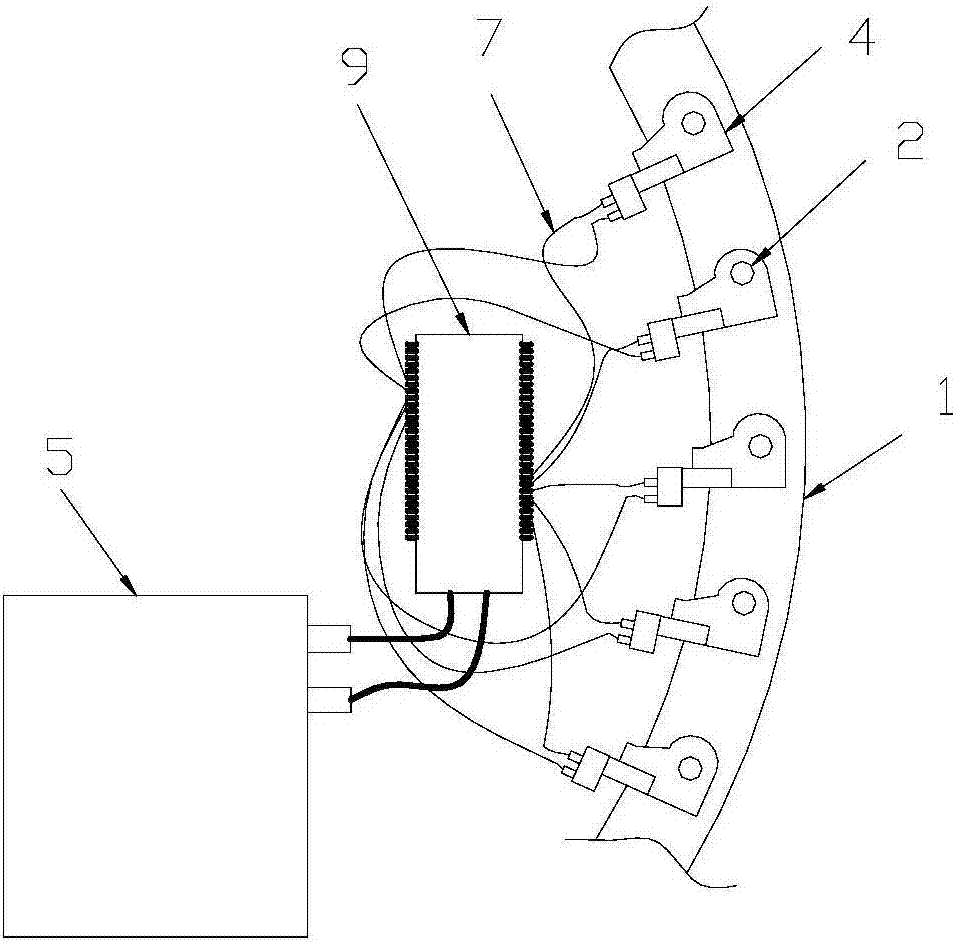

[0047] Such as Figure 5 and Figure 6 As shown, the difference between the present embodiment and the first embodiment is that the connection mode between the electric pump 5 and the hydraulic wrench 4 of the present embodiment is different from that of the first embodiment, and correspondingly, the tightening method of the bolt 2 is also different. Specifically, the electric pump 5 is connected to each hydraulic wrench 4 through the main oil supply pipe and the main oil return pipe. The main oil supply pipe and the main oil return pipe are double high-pressure oil pipes. There are multiple interfaces, and each interface is correspondingly connected with a hydraulic wrench 4 , that is, each hydraulic wrench 4 is supplied with oil by the electric pump 5 at the same time.

[0048] Since the bolts 2 at the joints of each tower tube 1 have the same specifications and rated torque values, the method of simultaneously supplying oil to each hydraulic wrench 4 by the electric pump 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com