Automatic tightening and mark rolling inspection and assembly system of spline nuts of rear axle main speed reducer

A main reducer and assembly system technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation and backward technology, and achieve the effect of high degree of automation, complex structure and rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

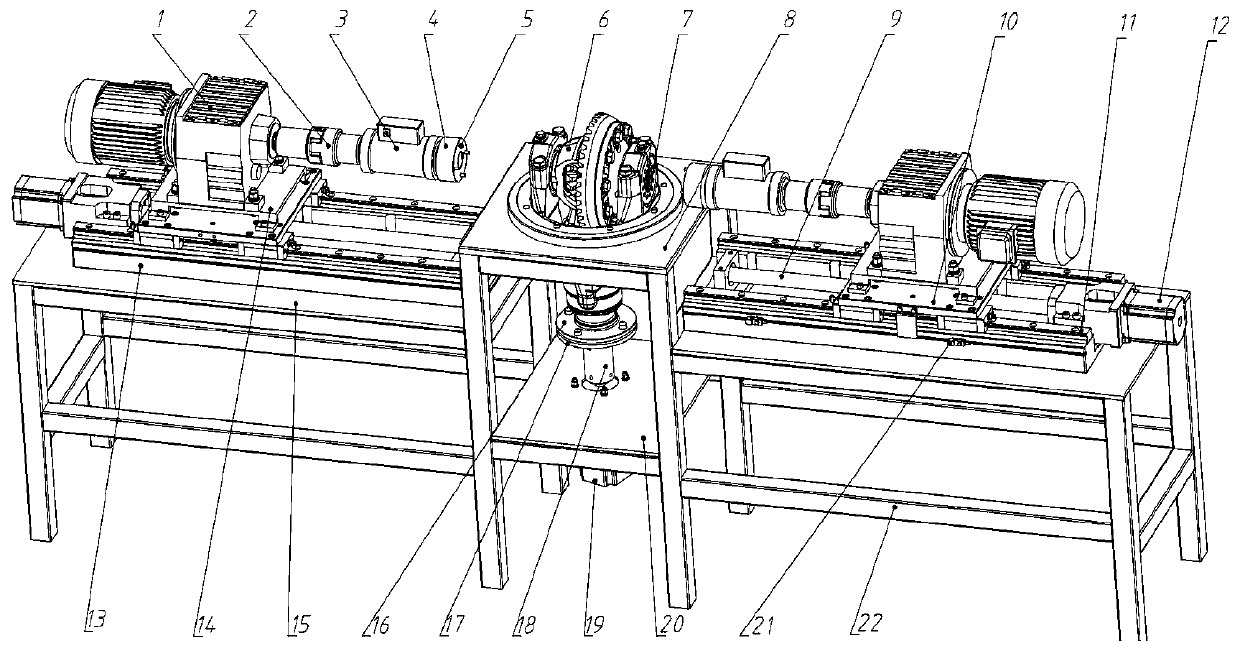

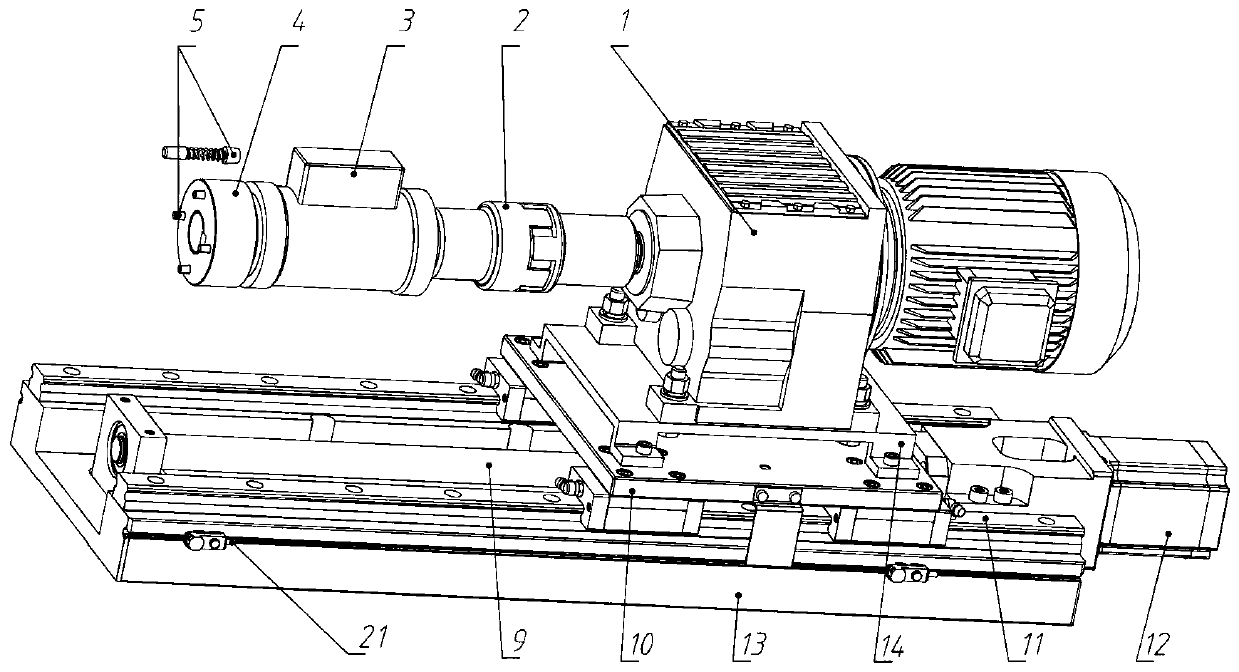

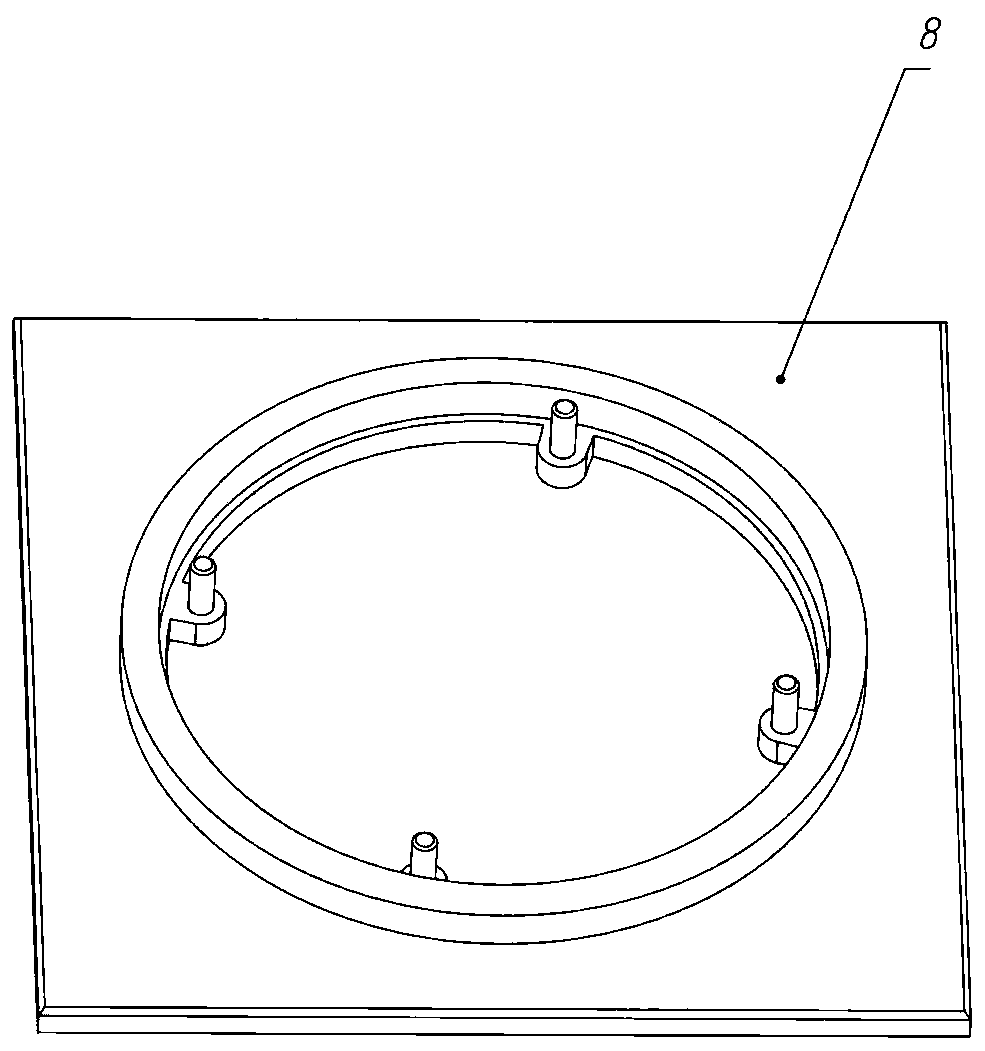

[0023] Such as figure 1 and Figure 5 As shown, the main reducer 6 of the rear axle of the automobile is the assembly object of the whole device, and flower nuts 7 are installed on both sides of the main reducer 6 respectively; The directly below the gear 6.1 is the connecting flange 16 of the driving gear 6.1. Such as figure 1 Shown is an assembly system for automatic tightening and rolling inspection of flower nuts for rear axle main reducers, including a positioning mechanism for installing and fixing the main reducer 6, a tightening device for providing torque for flower nuts 7, and a drive for tightening The device moves along the axis direction of the flower nut 7, the driving device of the imprint rolling inspection, and the supporting servo control system. The main speed reducer 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com