Patents

Literature

32results about How to "Avoid inconsistent thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

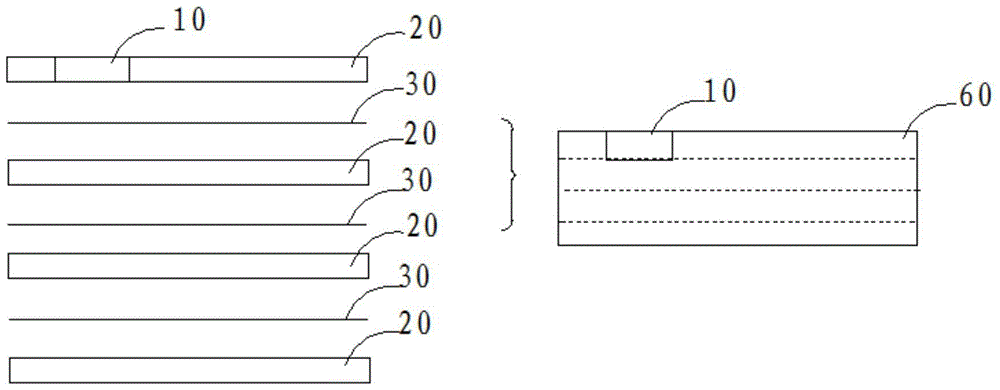

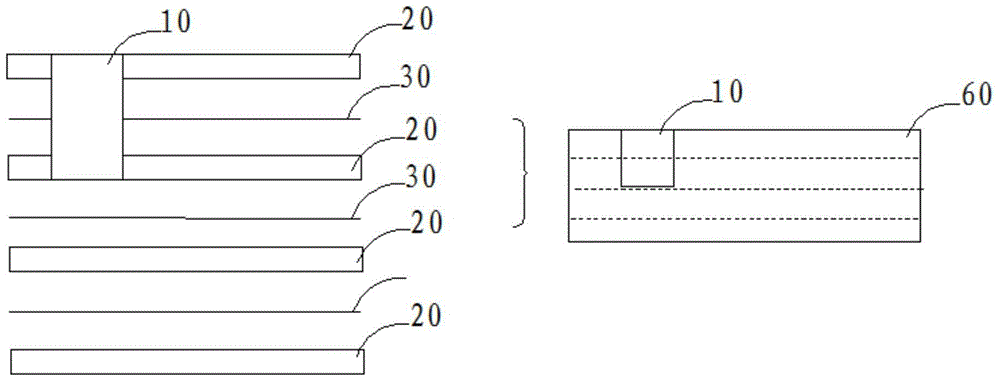

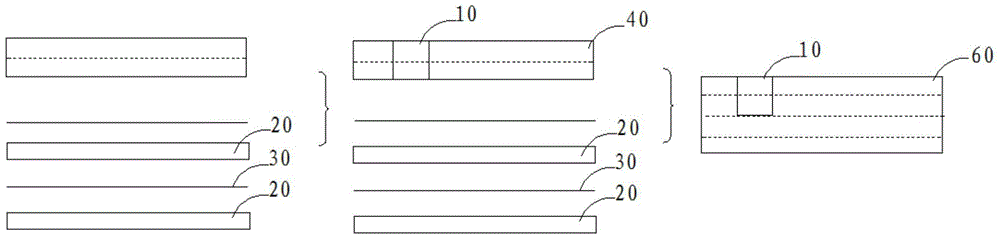

Manufacturing method of partial hybrid printed circuit board

ActiveCN103687347AImprove alignment accuracyAvoid thickness inconsistenciesMultilayer circuit manufacturePrinted circuit boardHigh frequency

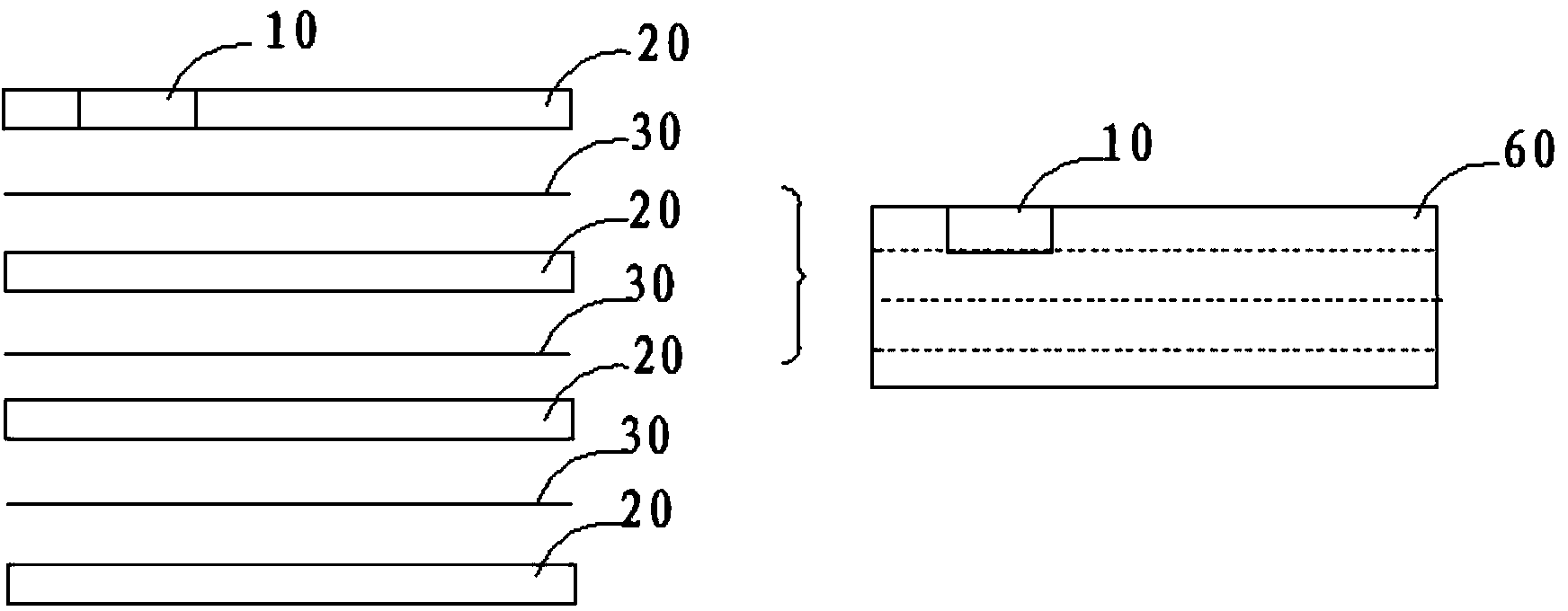

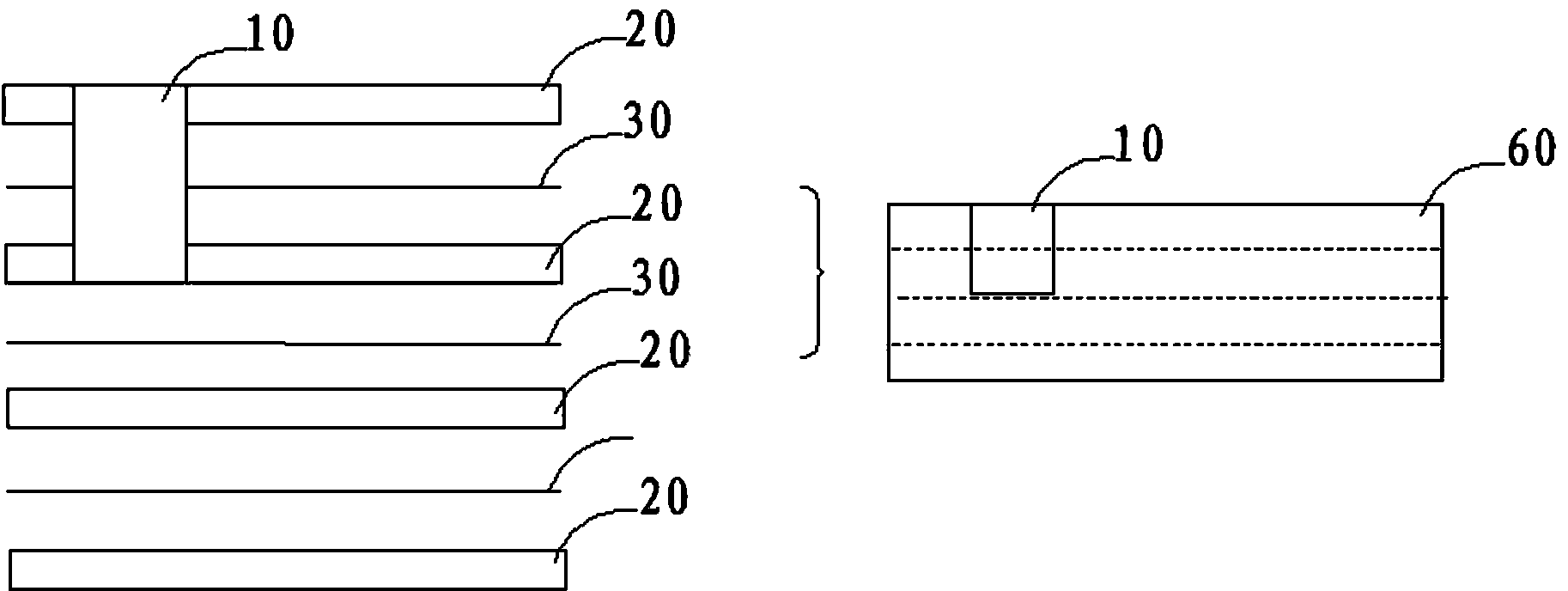

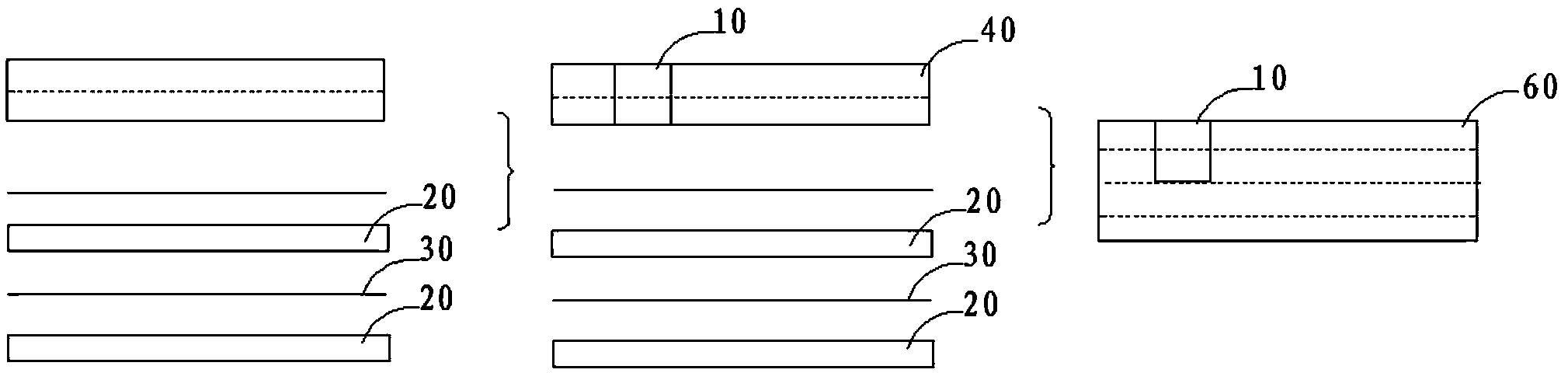

The invention discloses a manufacturing method of a partial hybrid printed circuit board. The manufacturing method comprises the following steps that core boards and prepregs are provided, and the core boards into which a high-frequency material needs to be embedded are correspondingly overlapped according to the positions where the high-frequency material needs to be embedded, wherein each prepreg is arranged between two adjacent core boards into which the high-frequency material needs to be embedded; the overlapped core boards are pressed to form a first multi-layer board; a through groove where the high-frequency material needs to be embedded is milled at the position, where the high-frequency material needs to be embedded, of the first multi-layer board, and the high-frequency material is embedded into the through groove of the first multi-layer board. By the adoption of the manufacturing method, the process of milling the prepregs in the prior art is omitted, the phenomenon that the first multi-layer board is inconsistent in thickness due to the fact that too much glue flows out of the positions close to the through groove, of the core boards into which a high-frequency material needs to be embedded is avoided, the alignment precision between the core boards is improved, the quality of the partial hybrid PCB is improved, and working efficiency is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

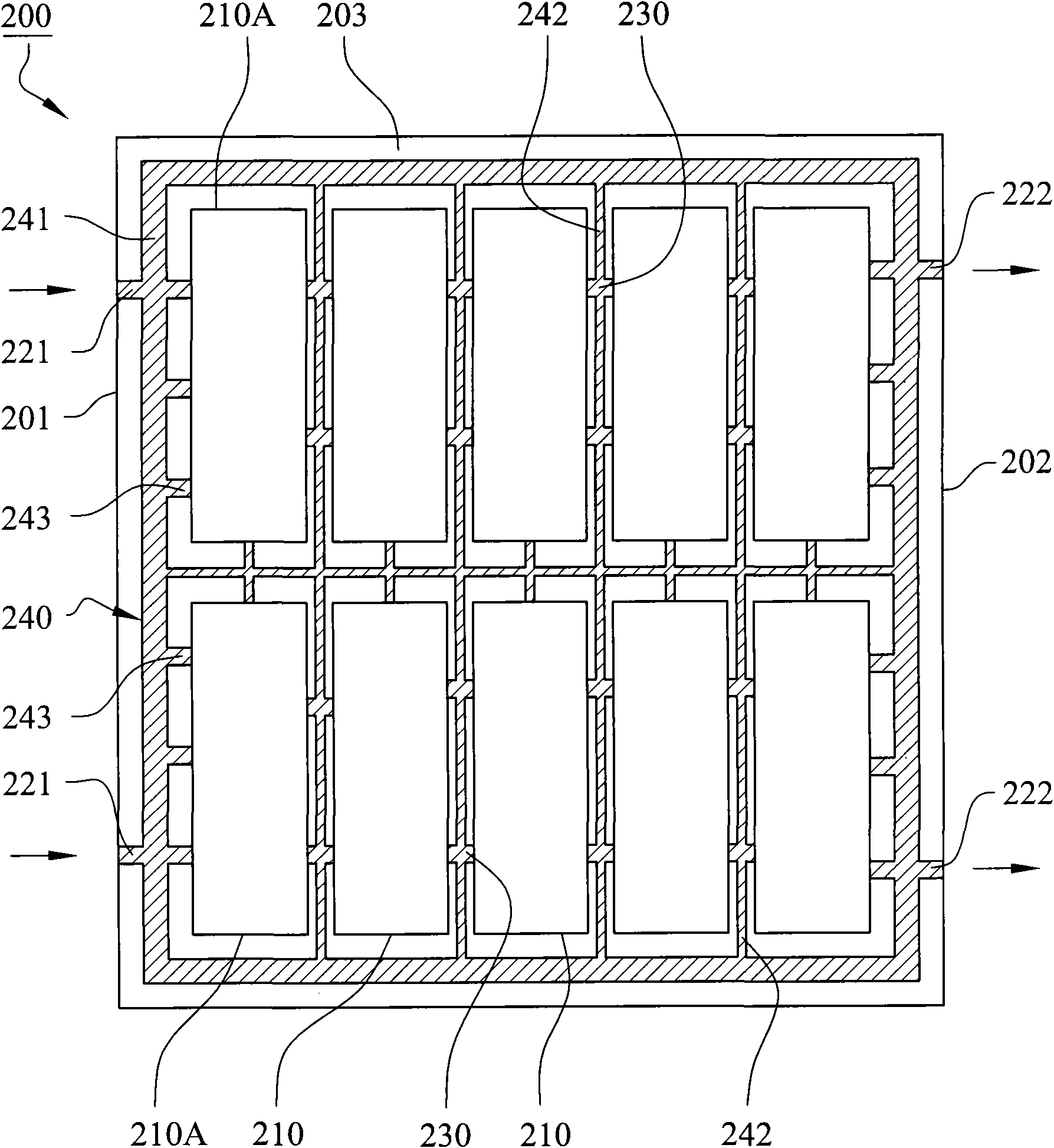

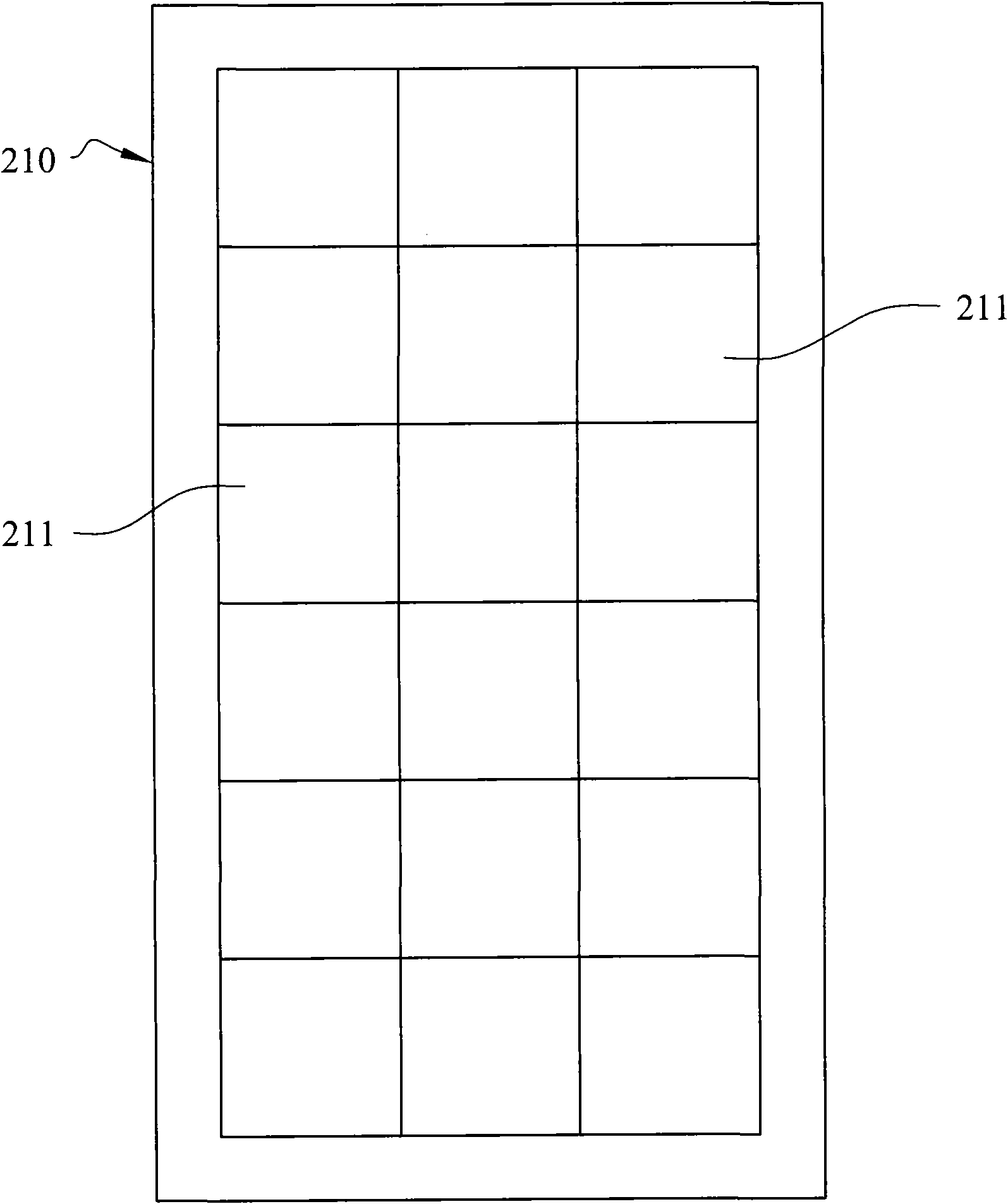

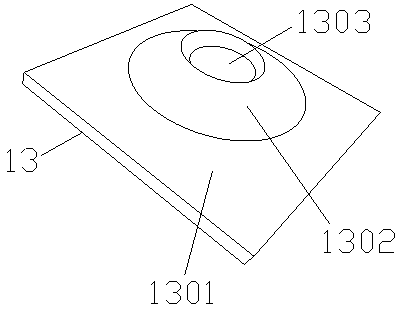

Substrate panel

InactiveCN101626009AAvoid uneven current densityProtect internal circuitsSemiconductor/solid-state device detailsSolid-state devicesCross connectionVoltage

The invention relates to a substrate panel, which mainly comprises two or more than two substrate strips arranged on the substrate panel in an array, two or more than two electroplating buses, two or more than two electroplating string connection wires connected between the substrate strips and connected with two adjacent substrate strips, and a current input gate port buffer area. The electroplating buses connect lateral margins of the substrate panel to the adjacent substrate strips; and the current input gate port buffer area is arranged at a non-substrate strip part of the substrate panel and provided with a current buffer frame and two or more than two net wires, wherein the current buffer frame is in cross connection with the electroplating buses, the net wires are in cross connection with the electroplating string connection wires, and two ends of the net wires are connected to the current buffer frame. Therefore, the current is evenly dispersed to each substrate strip during electroplating, the problem of inconsistent thickness of an electroplating layer due to unevenness of the current density is improved, and instantaneous high current can be buffered and instable voltage can be relaxed to protect internal circuits of the substrate strips.

Owner:POWERTECH TECHNOLOGY

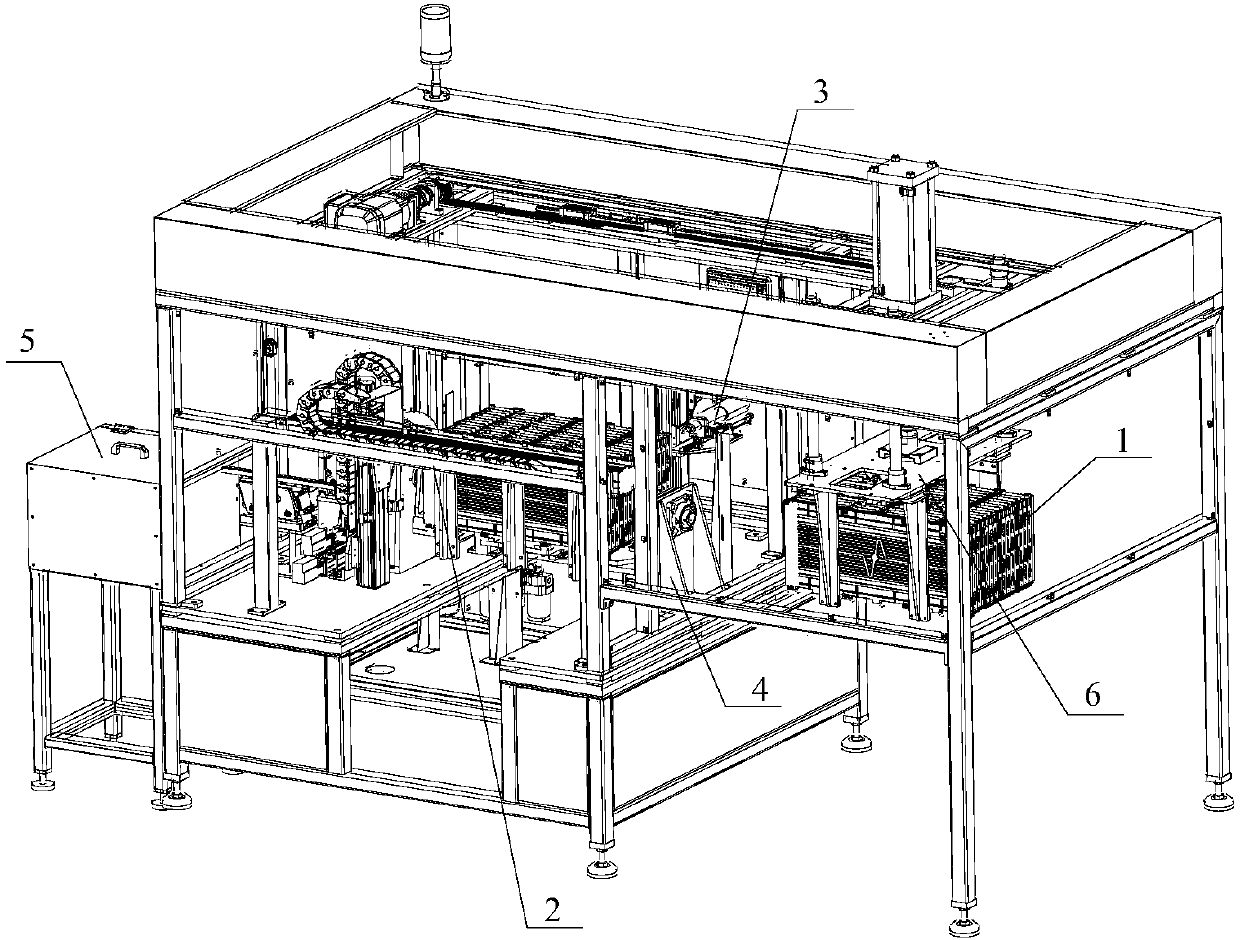

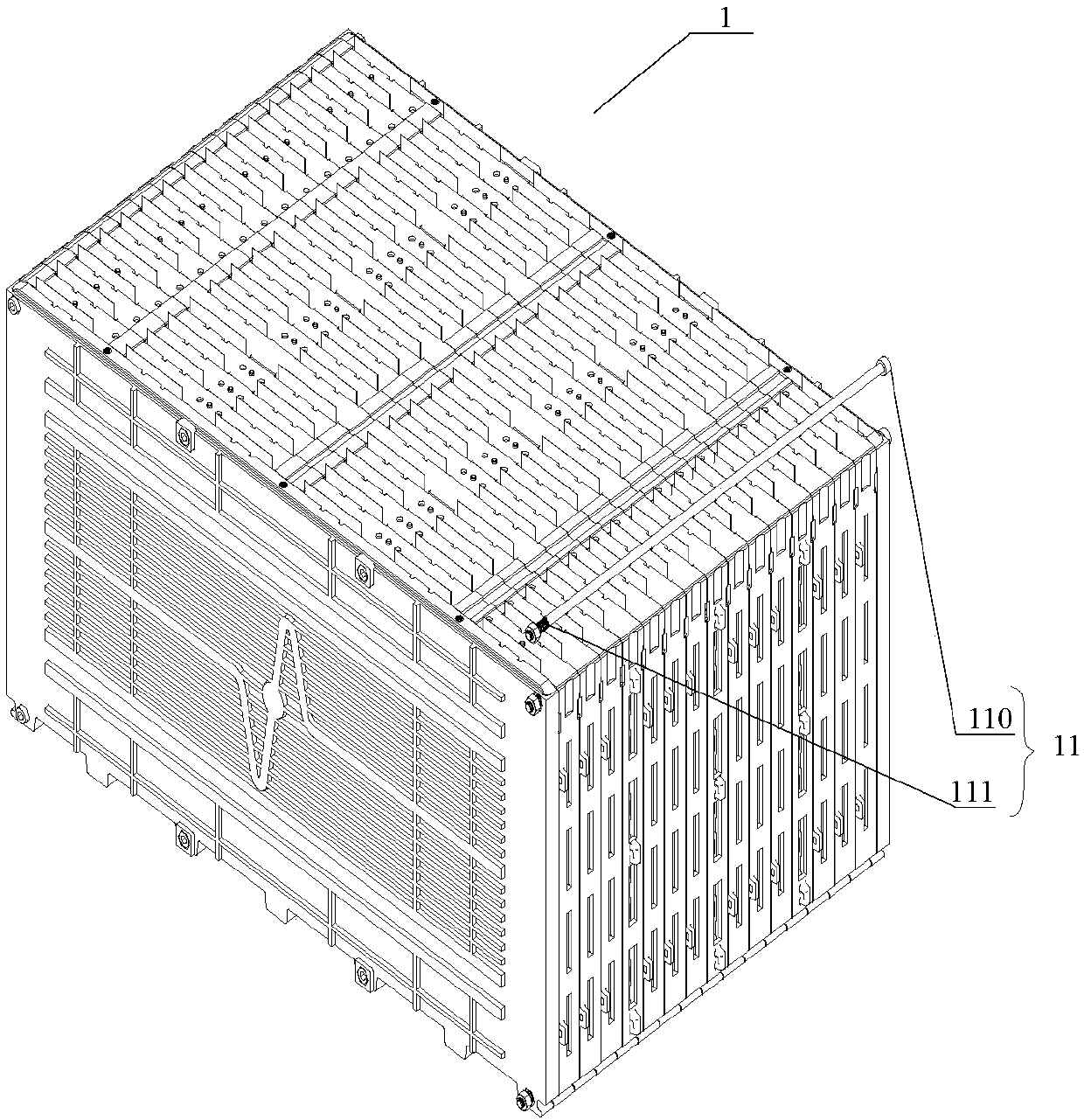

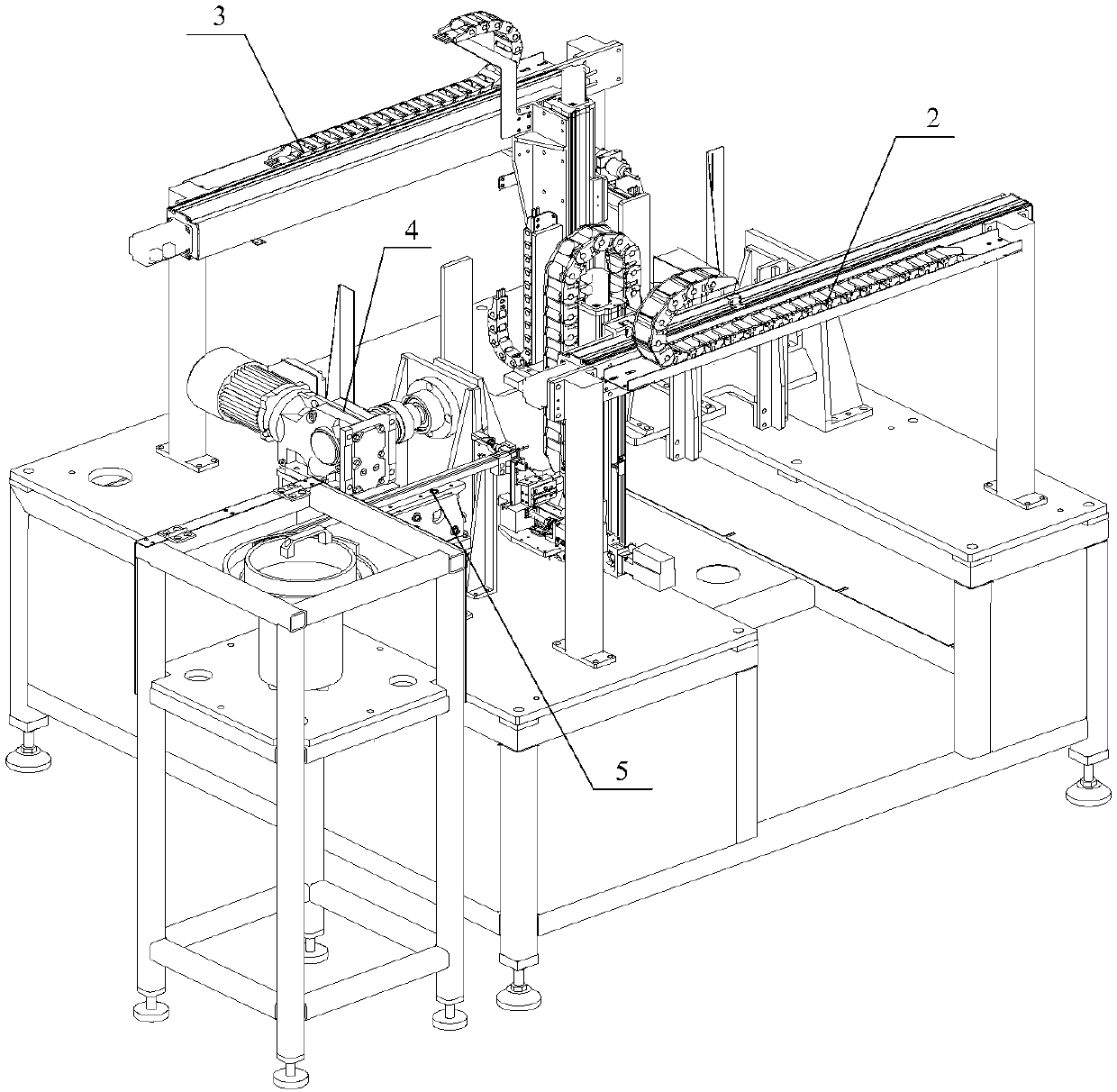

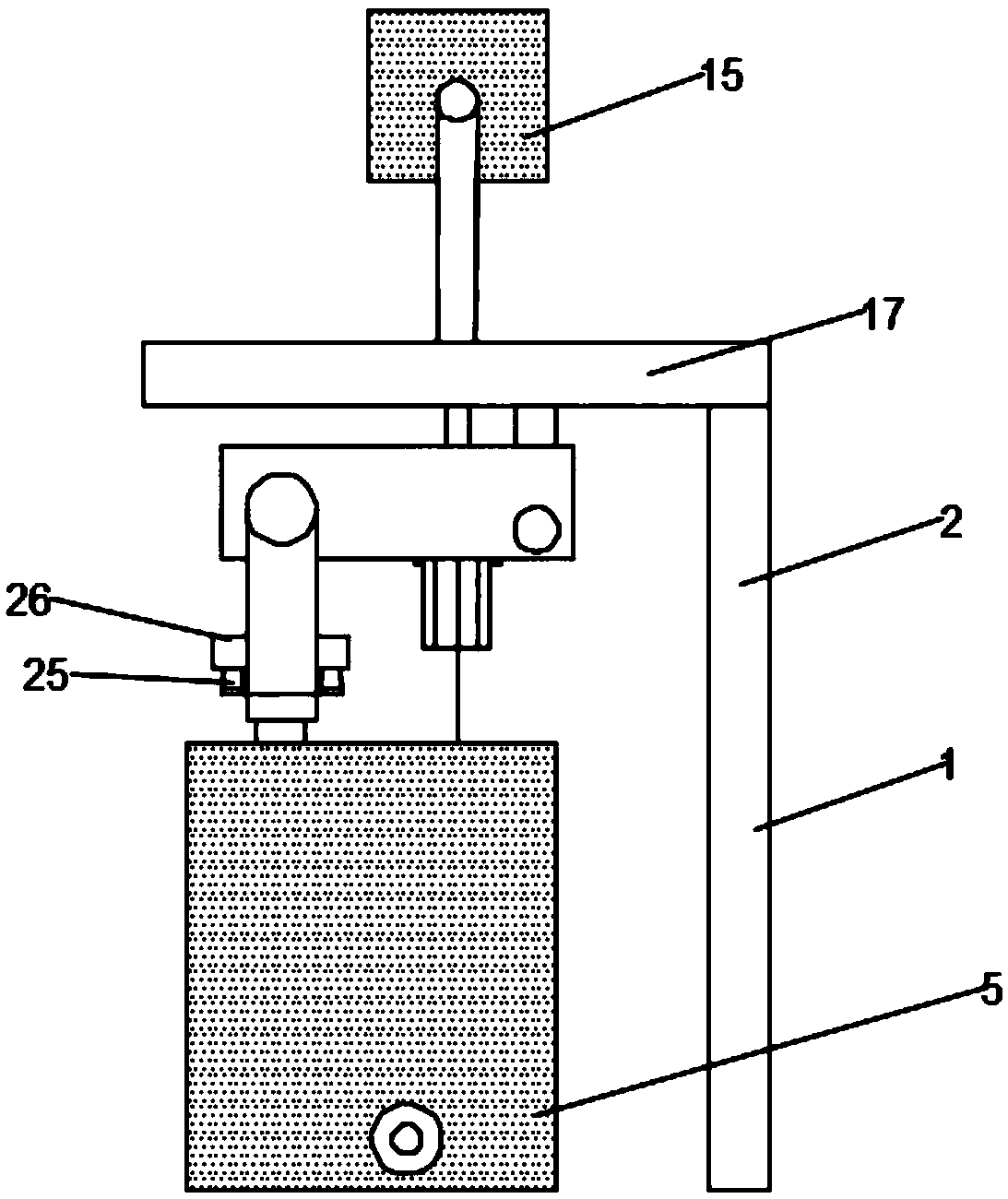

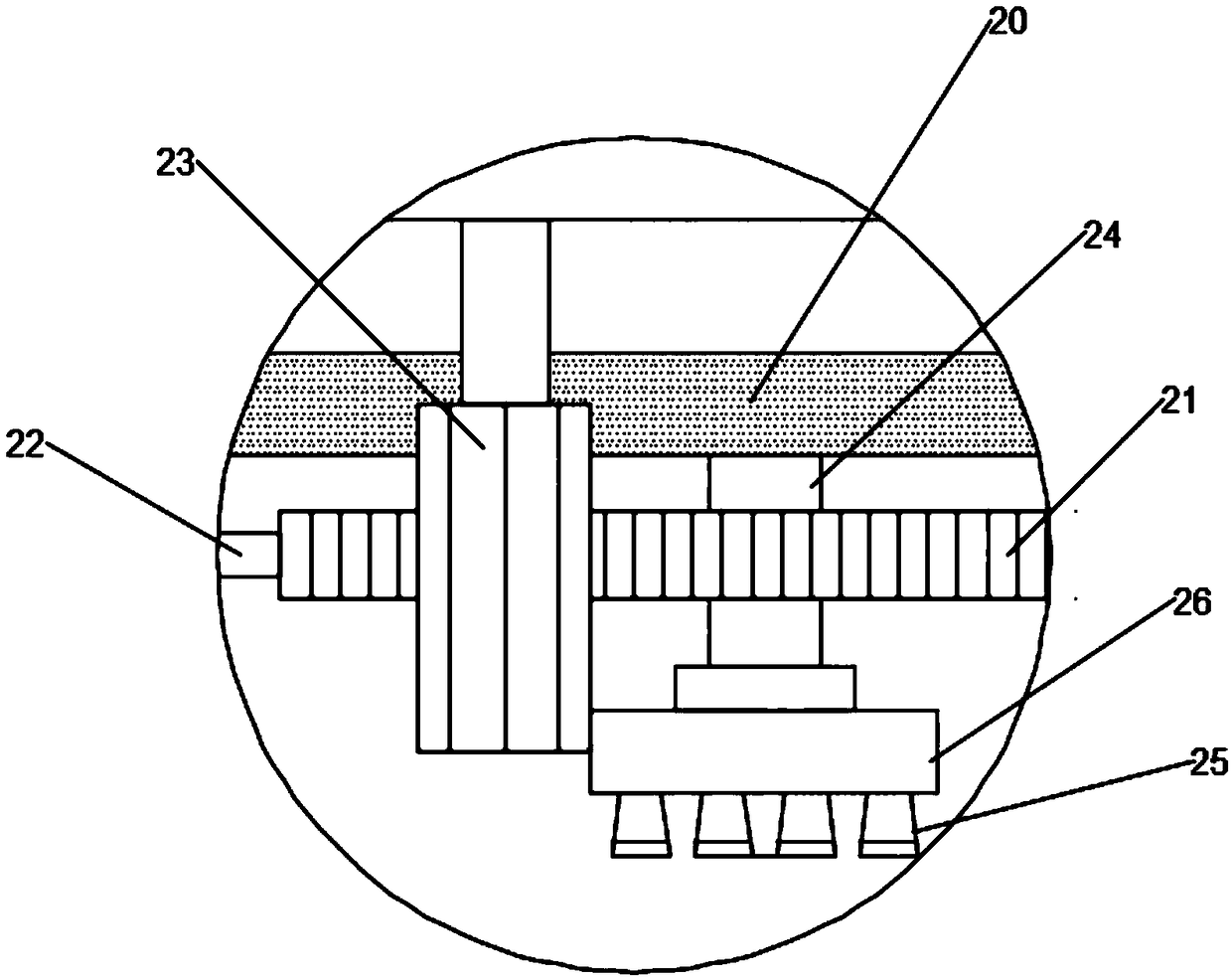

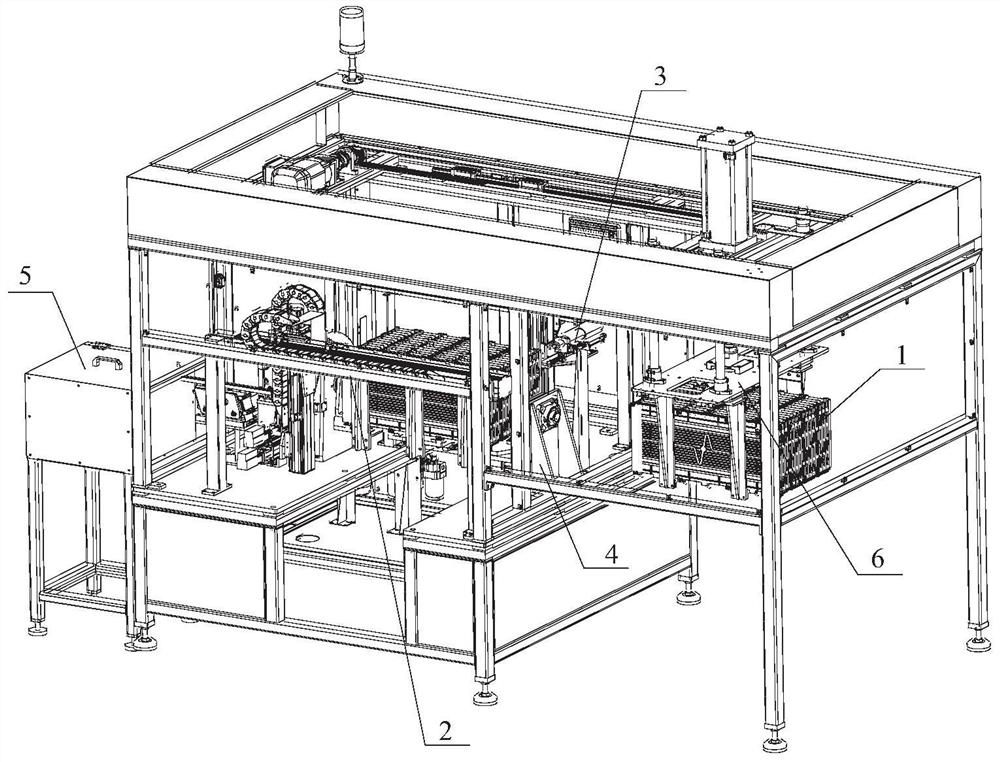

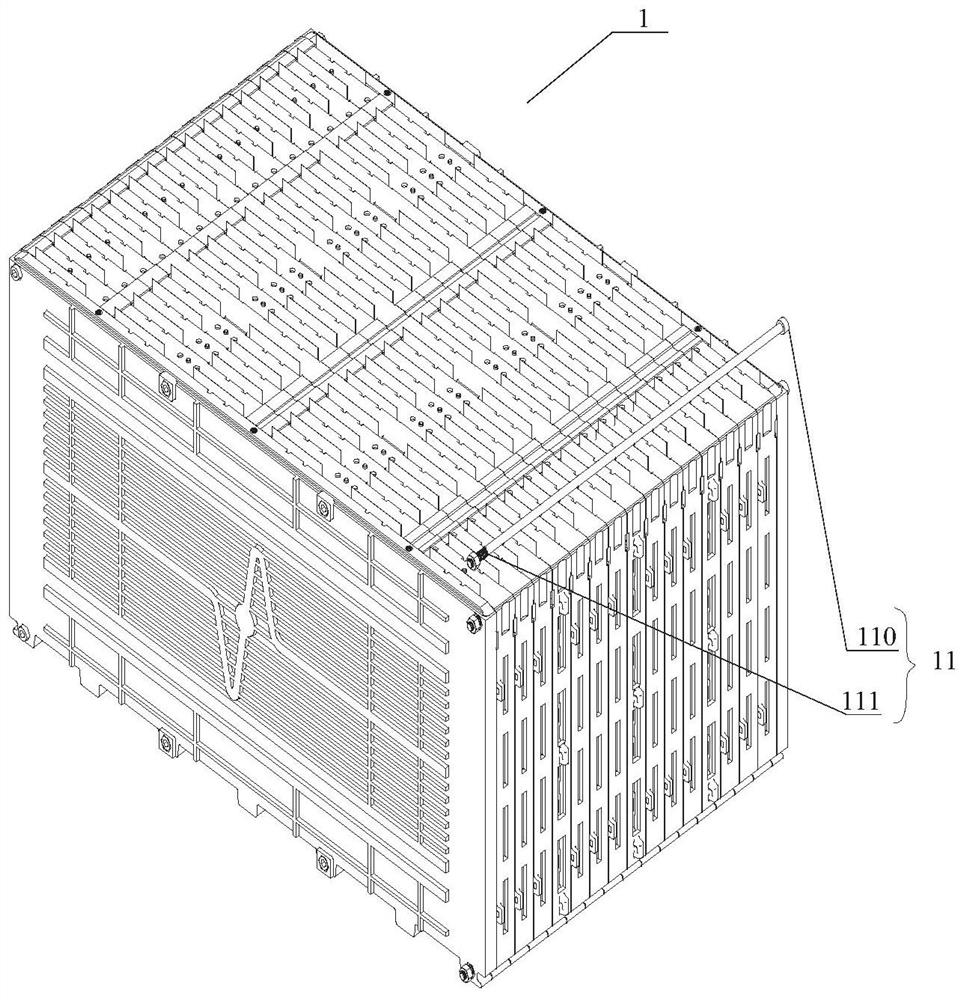

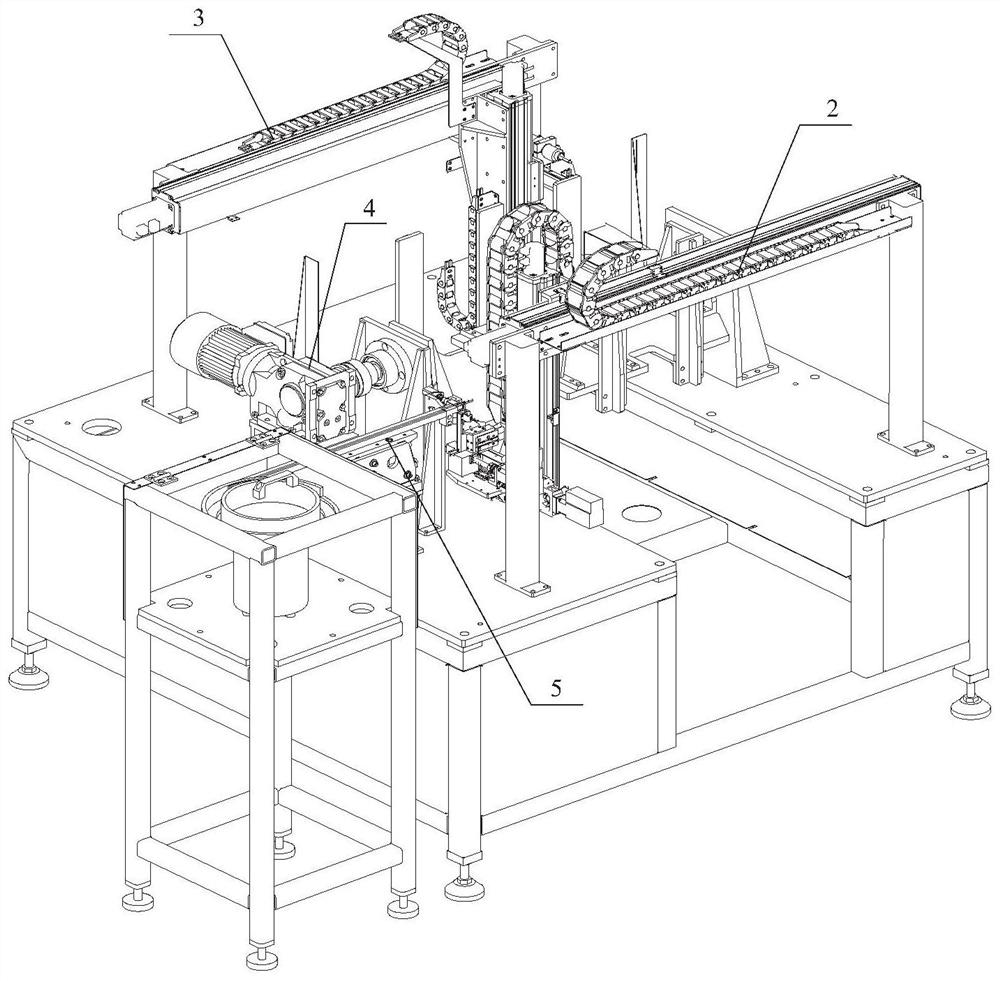

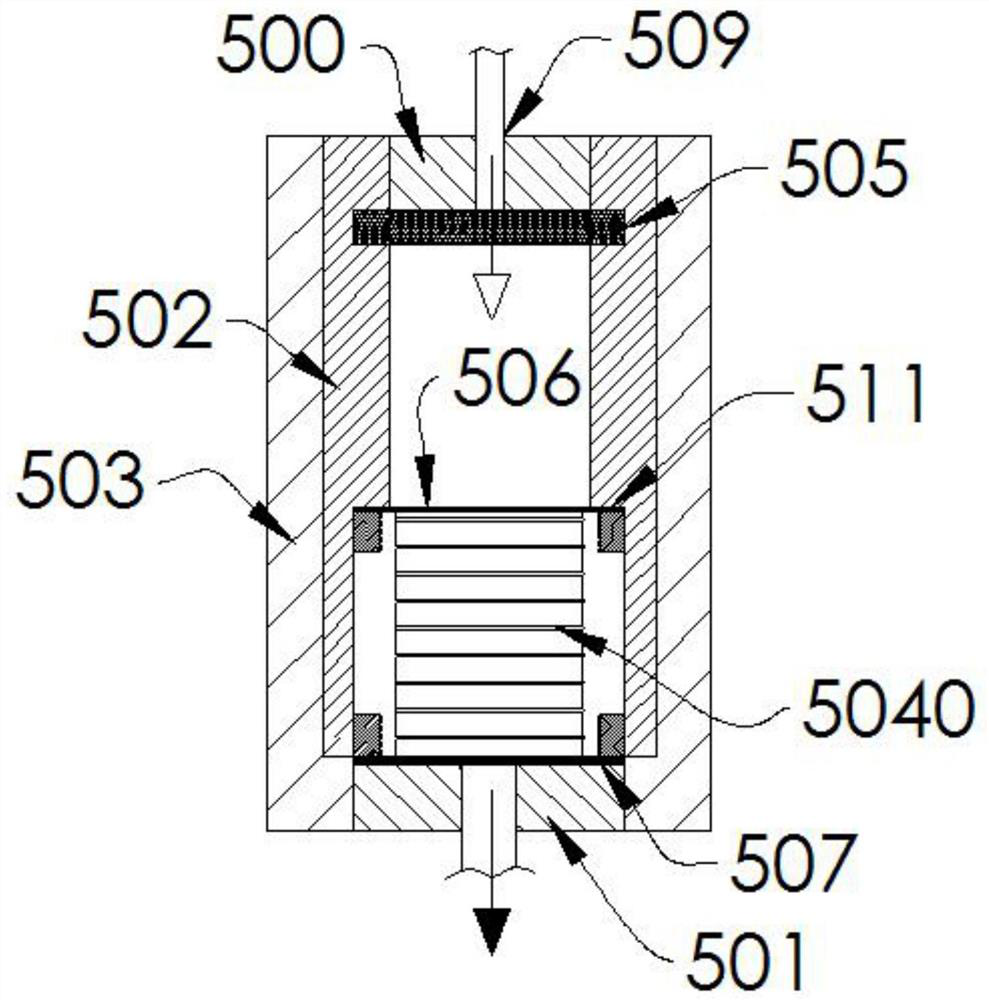

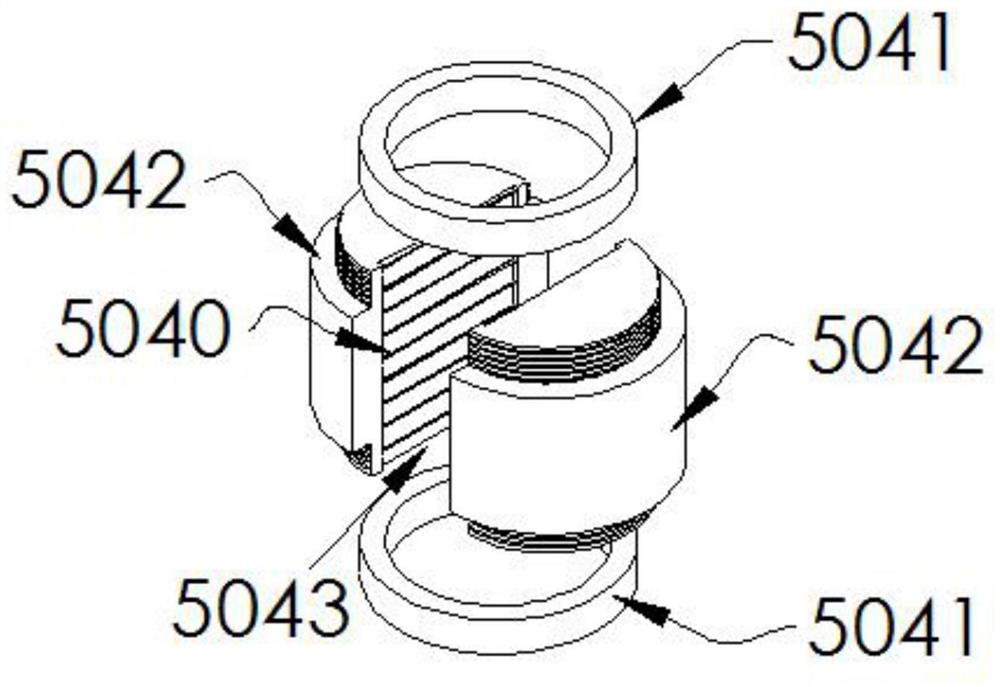

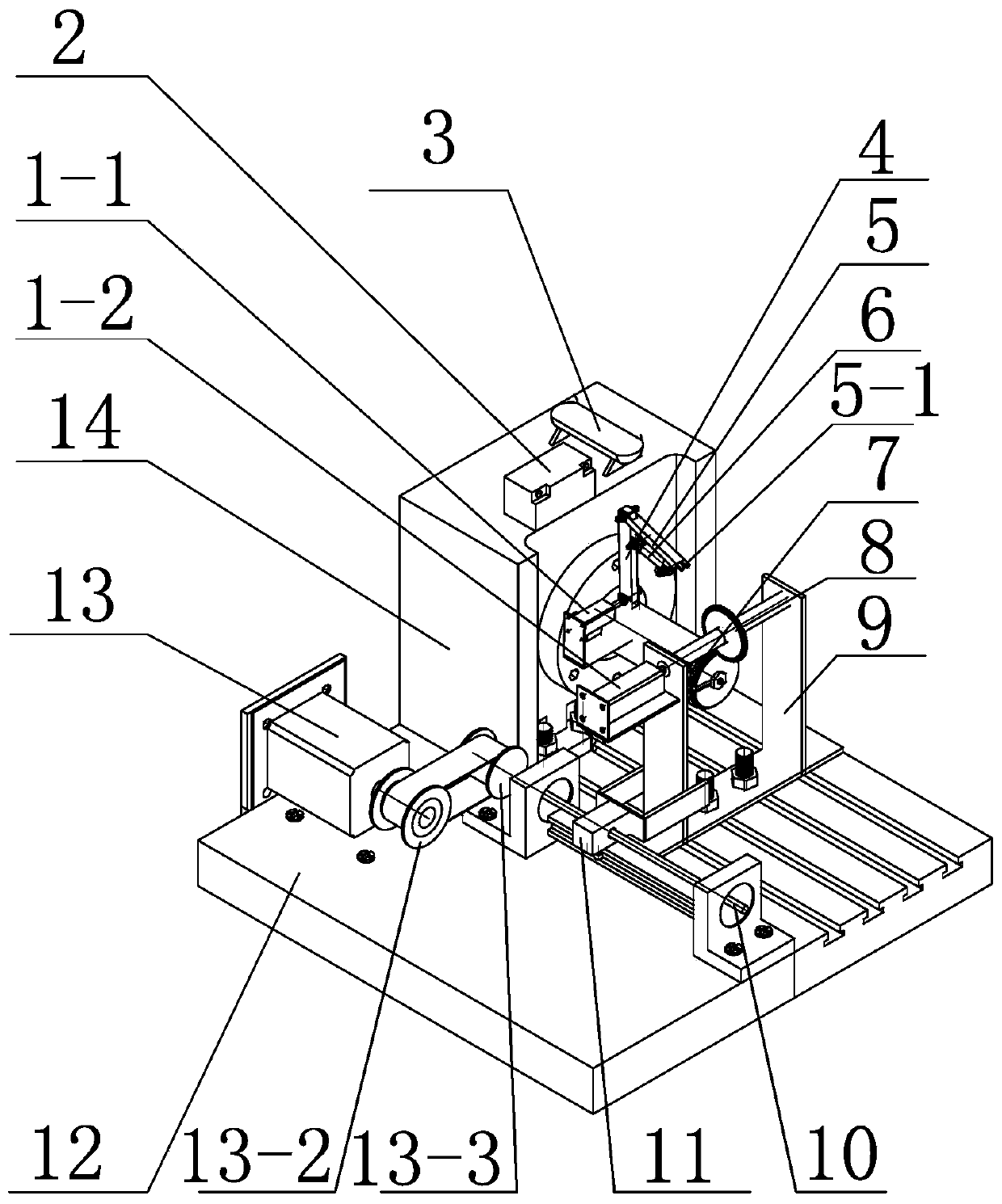

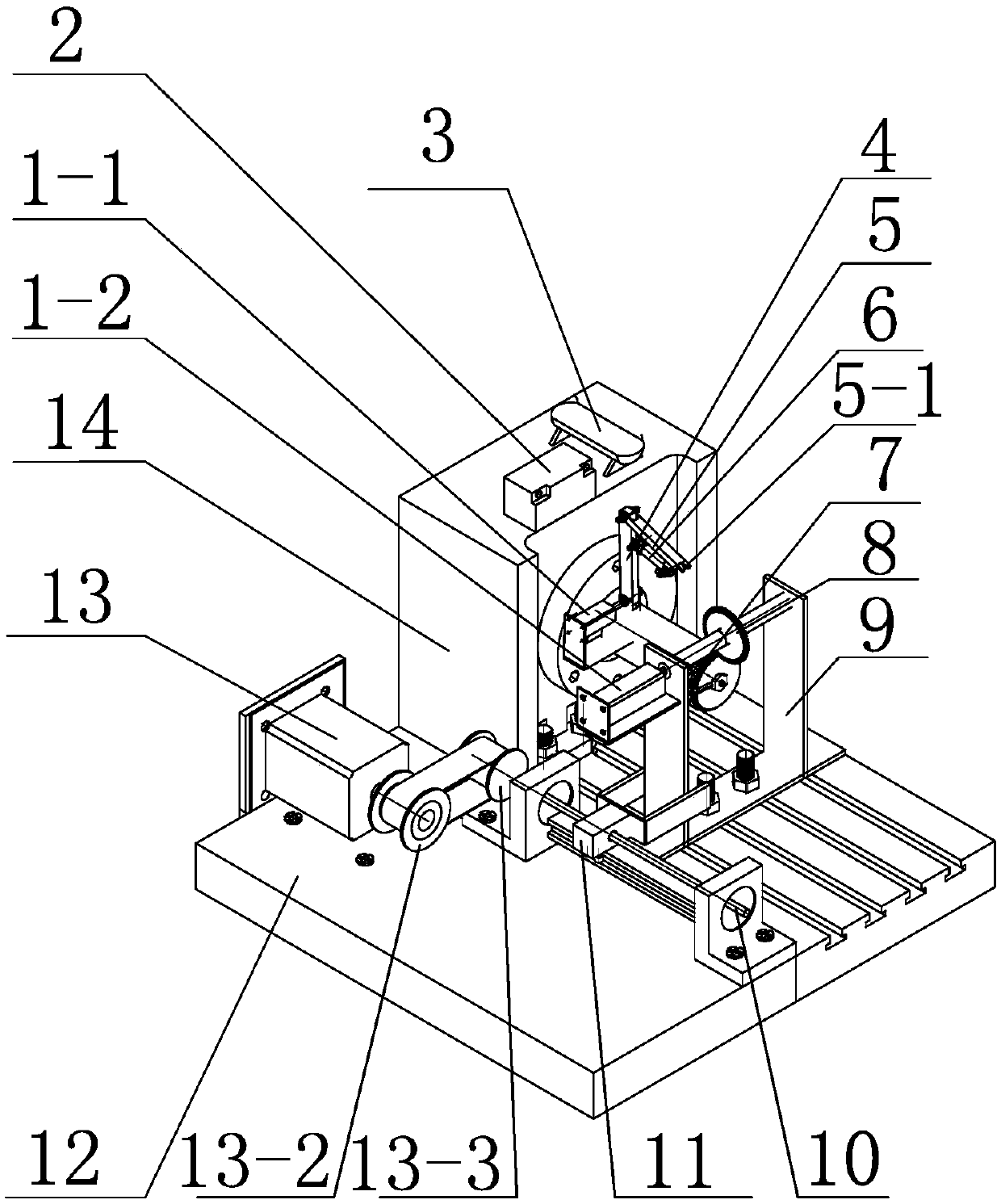

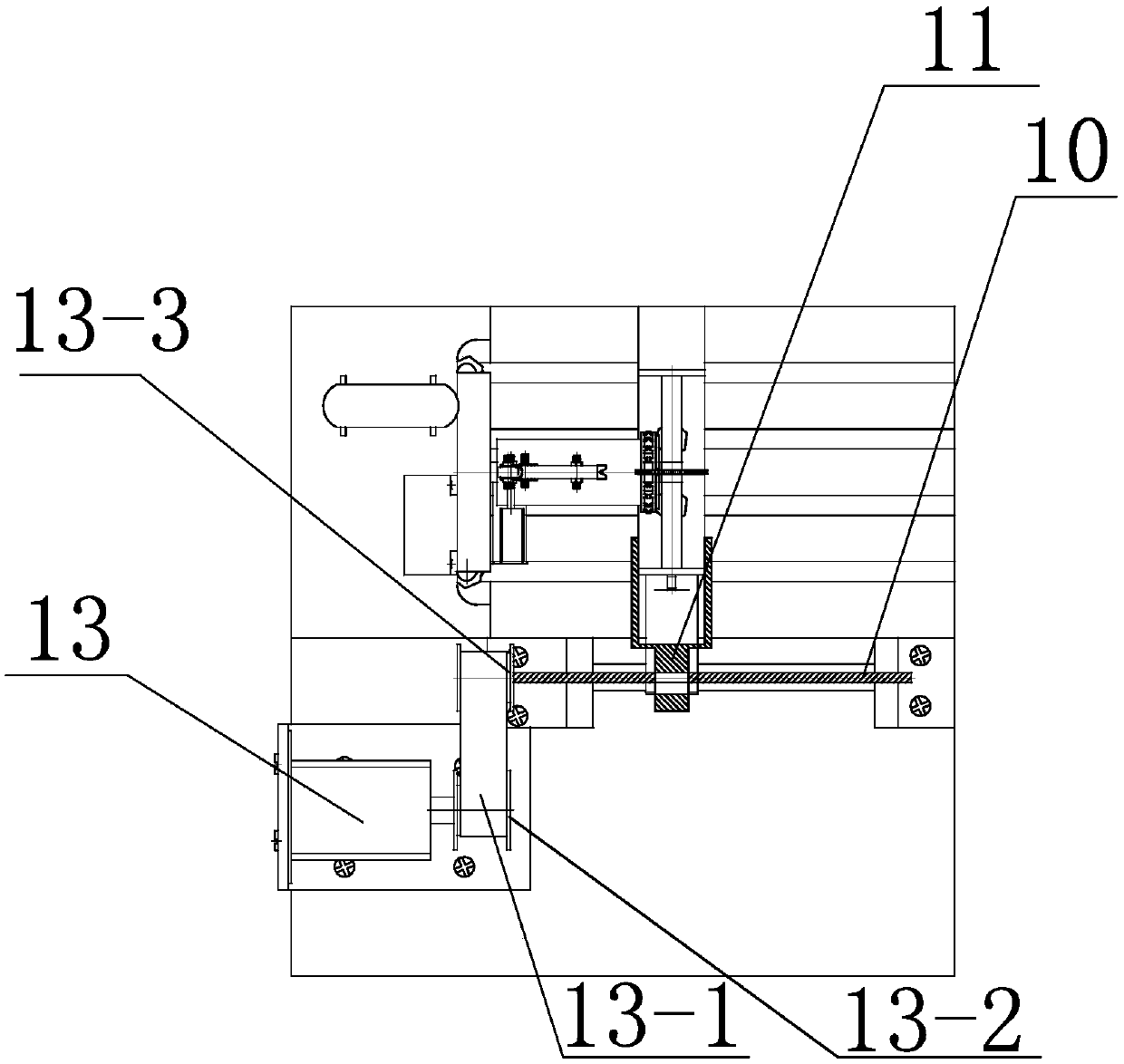

Full-automatic battery module locking device

ActiveCN108054329ARealize automatic tighteningAvoid inconsistent thicknessCell component detailsLocking mechanismEngineering

The invention discloses a full-automatic battery module locking device, which comprises a battery module, a nut positioning mechanism and a torque-adjustable screw locking mechanism, wherein the battery module is provided with a plurality of screws; each screw penetrates through the battery module and comprises a top end part and a thread part; the nut positioning mechanism is arranged at one sideclose to the thread parts and is used for positioning to-be-installed nuts, so that the to-be-installed nuts are overlapped with the axes of the screws; each to-be-installed nut corresponds to one screw; and the torque-adjustable screw locking mechanism is arranged at one side close to the top end parts, and is used for determining locking torque and driving the screws to rotate around the axes of the screws under the action of the locking torque, so that the to-be-installed nuts are arranged at preset positions of the corresponding thread parts. According to the full-automatic battery modulelocking device, automatic tightening of the screws and the nuts is achieved through the nut positioning mechanism and the torque-adjustable screw locking mechanism, tightening missing is avoided, theinconsistency of the locking torque is avoided and the thickness of the locked battery module is consistent, thereby reducing the labor cost and improving the quality and the production efficiency ofthe battery module.

Owner:SHENZHEN CLOU ELECTRONICS

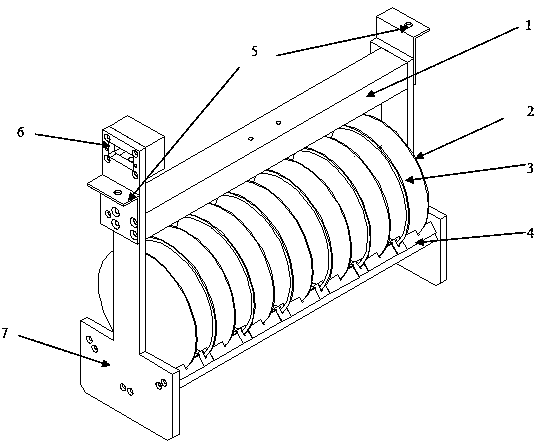

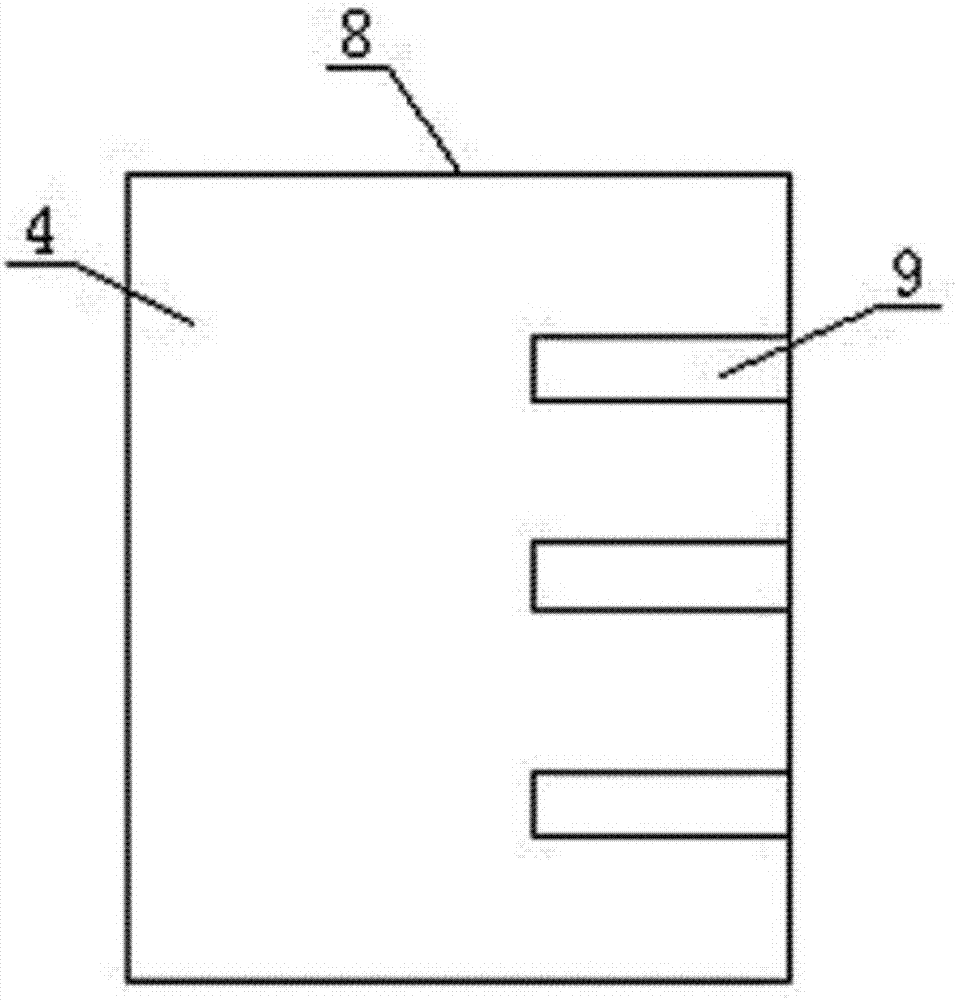

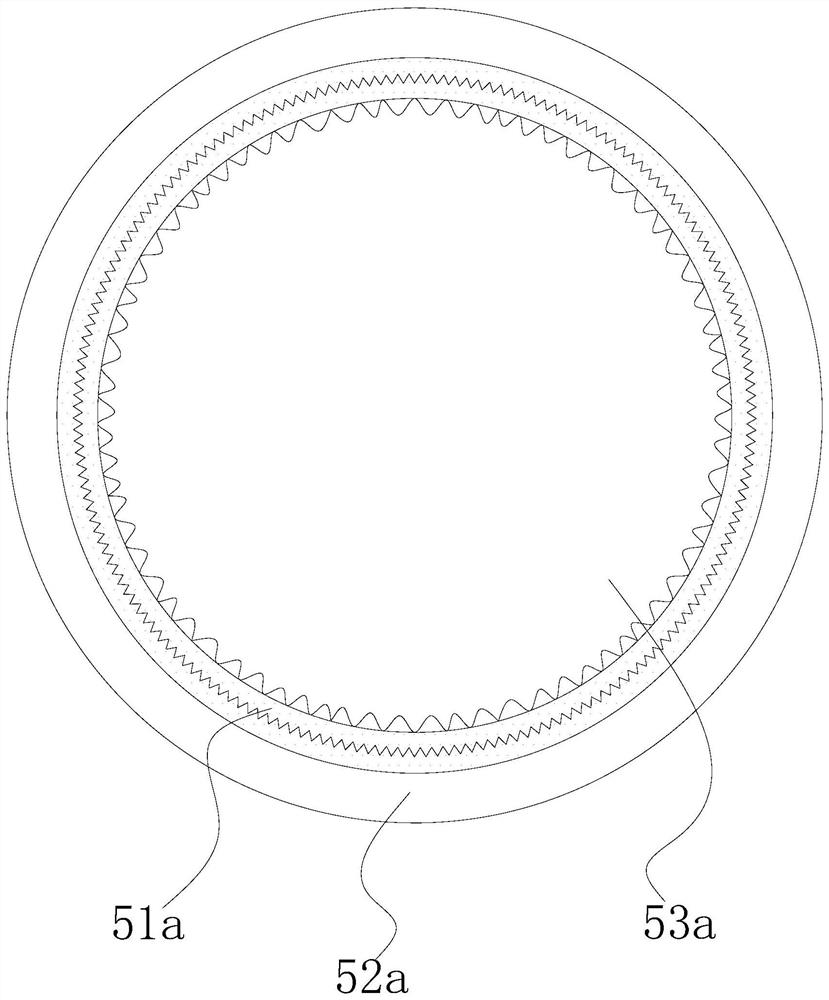

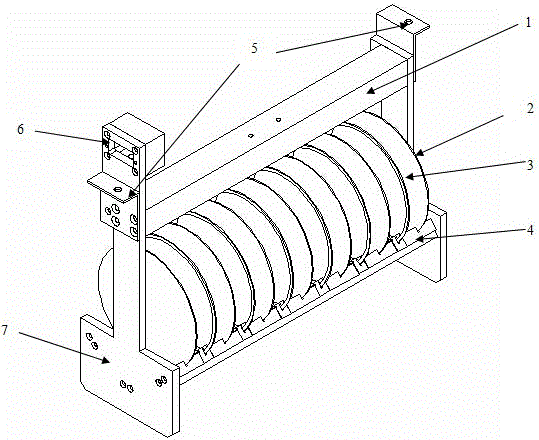

Double-sided electrophoresis frame

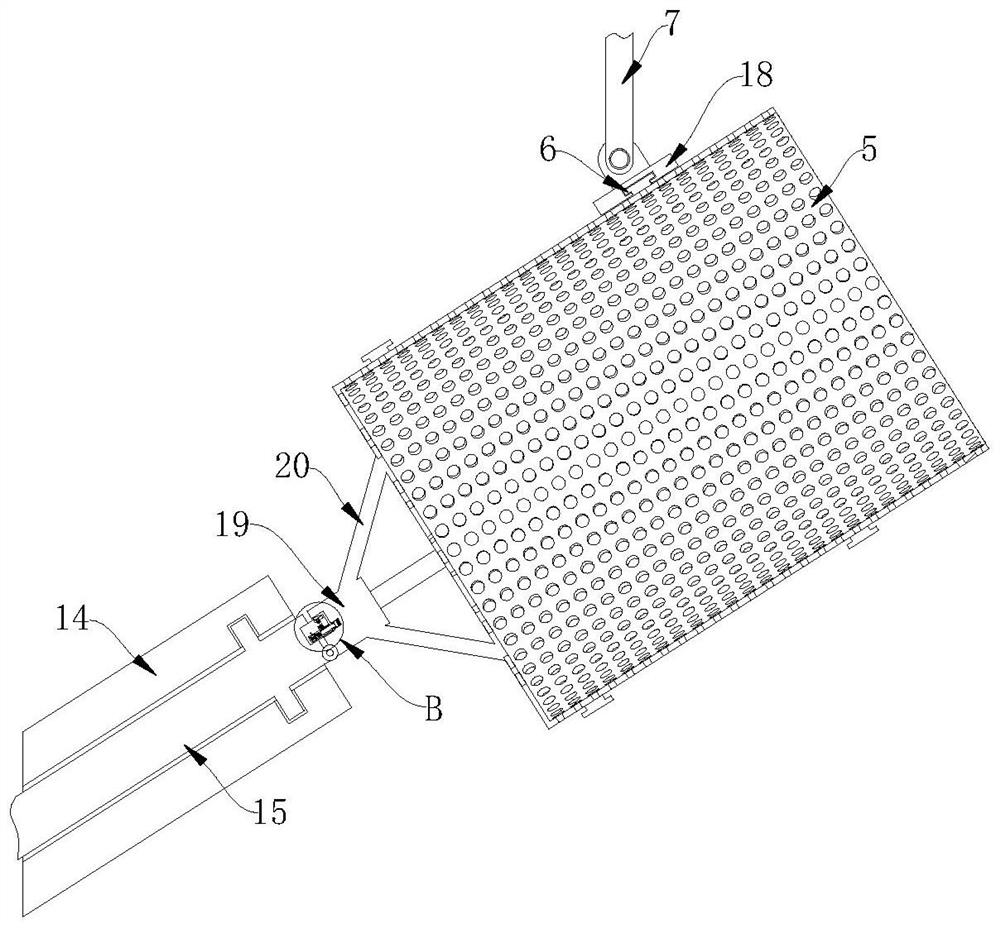

ActiveCN104178793AAvoid inconsistent thicknessGood electrophoresis consistencyElectrophoretic coatingsGeneral purposeElectrophoresis

The invention relates to double-sided production equipment for GPP (general purpose polystyrene) protective transistor chips and particularly relates to a modified double-sided electrophoresis frame for electrophoresis. The double-sided electrophoresis frame comprises a beam, negative electrode plates, positive electrode rings, a supporting plate, positioning plates, an insertion slot and side plates, wherein the two ends of the beam are horizontally fixed at the upper inner sides of the two side plates; the insertion slot which is connected with a power supply of electrophoresis equipment is fixed at the upper end of one side plate; the two ends of the supporting plate are horizontally fixed at the lower inner sides of the two side plates; and a plurality of negative electrode plates and positive electrode rings are alternatively fixedly arranged on the supporting plate in sequence. By using the double-sided electrophoresis frame, the two sides of a silicon wafer are good in electrophoresis consistency, so that the problem that the glass layers on the two sides of the silicon wafer are inconsistent in thickness due to twice single-sided electrophoresis is avoided, and the two sides are unlikely to damage during electrophoresis, so that the product yield and the reliability are improved.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

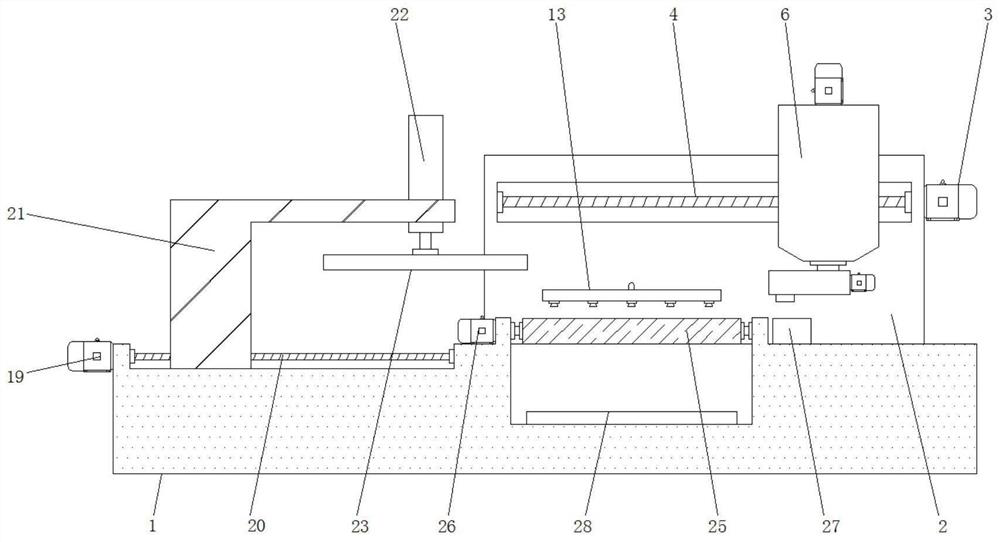

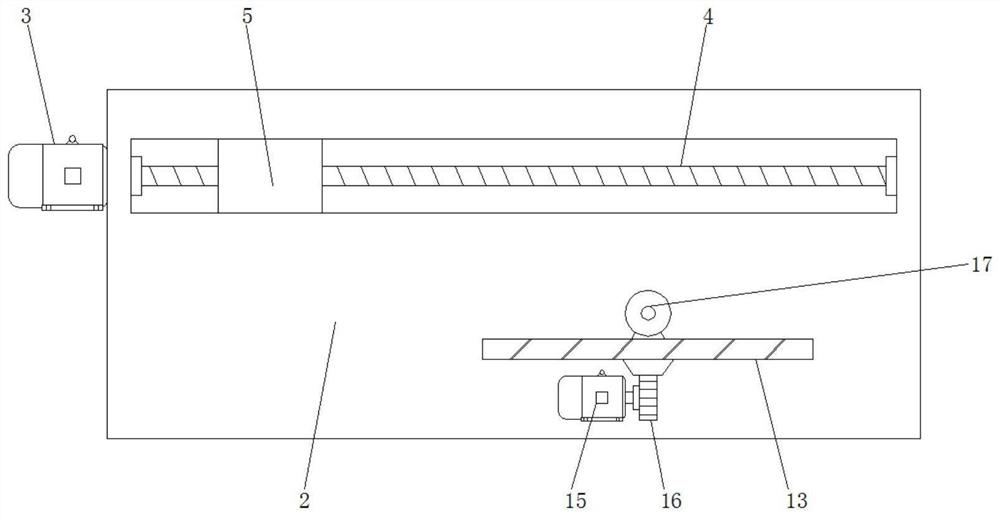

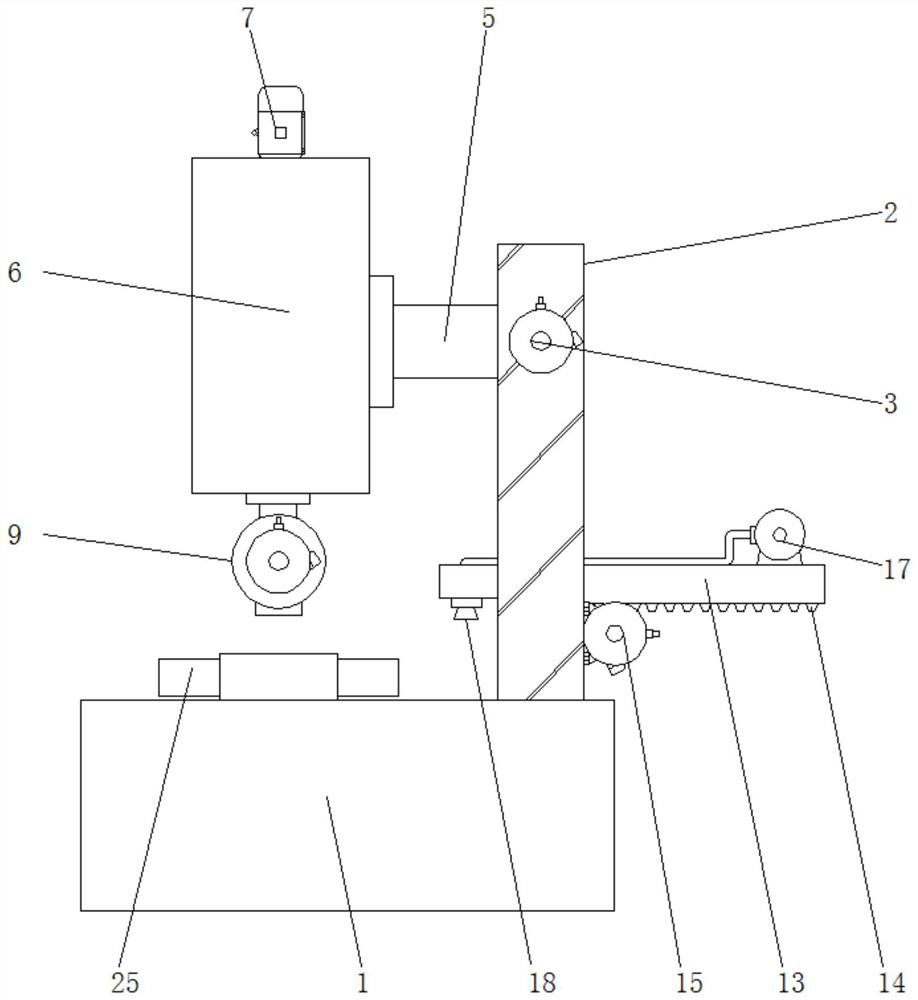

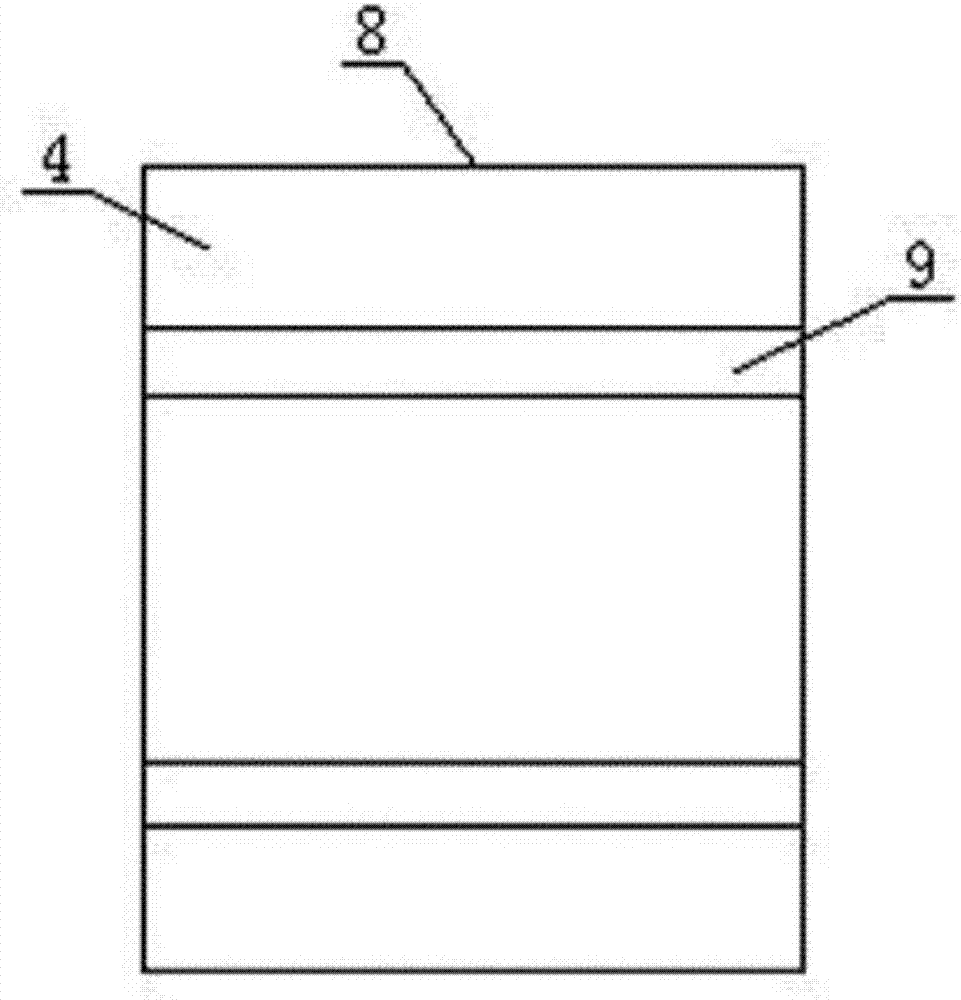

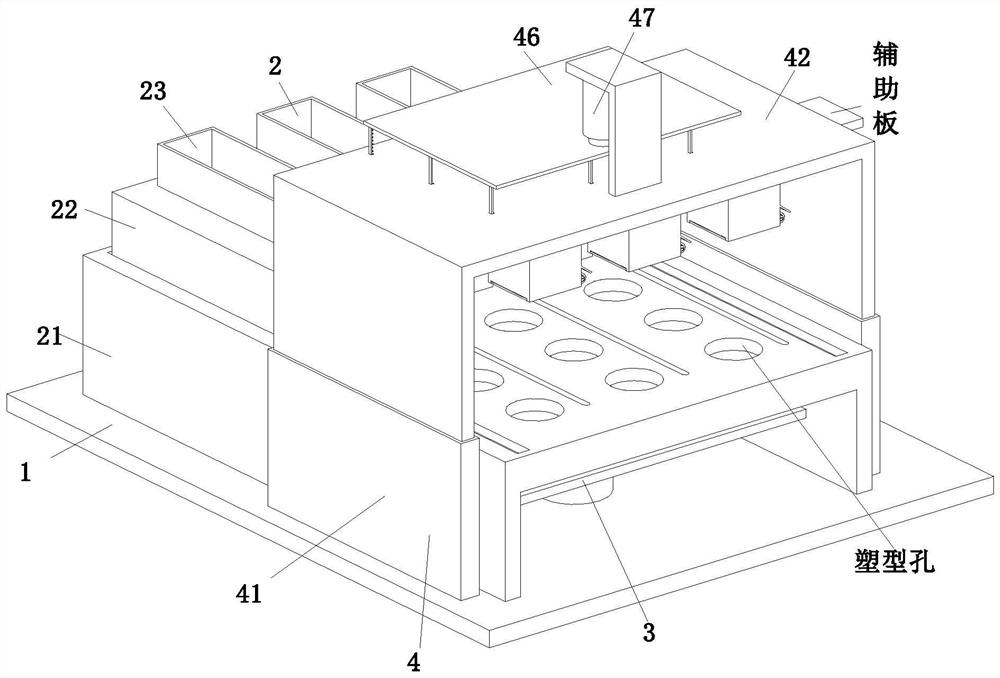

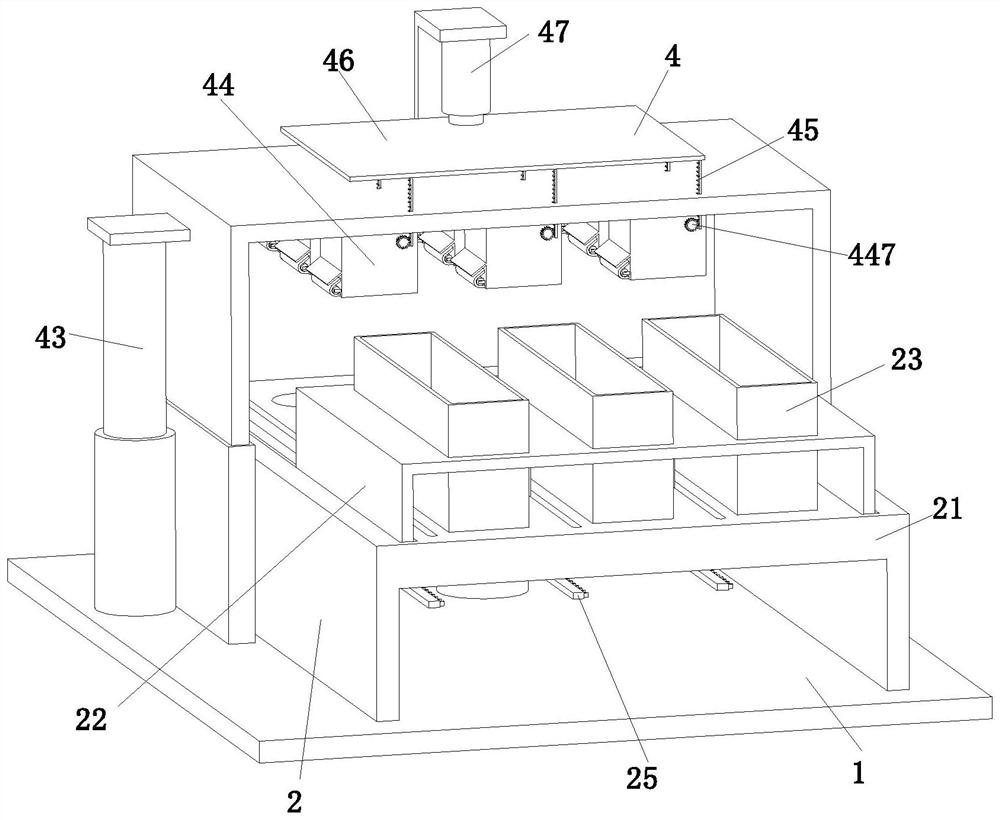

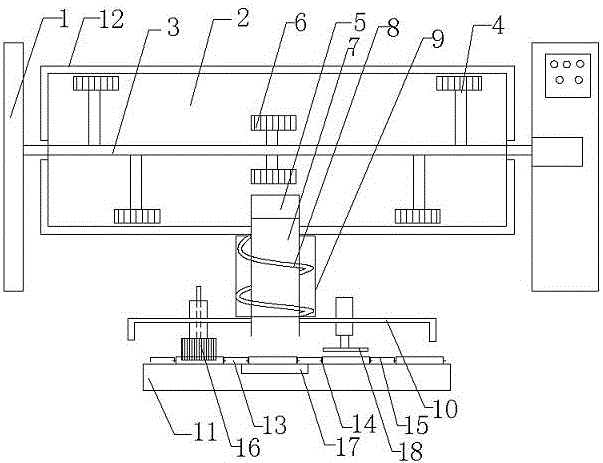

Raw material mixing and die-pressing integrated device for coal ash plate making

PendingCN114516113AEvenly distributedImprove molding qualitySolid waste managementFeeding arrangmentsHydraulic cylinderThermodynamics

The raw material mixing and pressing die integrated device comprises a rack, a transverse plate and a second lead screw, a vertical plate is fixed to the upper portion of the rack, an empty groove is formed in the upper portion of the vertical plate, the surface of the first lead screw is in threaded connection with a movable block, and the transverse plate is arranged below the vertical plate in a penetrating mode; a rack is arranged at the bottom of the transverse plate; the second lead screw is arranged on the left side of the rack, and a hydraulic cylinder is arranged at the top of the L-shaped movable frame in a penetrating mode. The raw material mixing and die-pressing integrated device for coal ash plate making is provided with the first lead screw and the movable block, the first lead screw drives the movable block and the mixing barrel to move, and after coal ash raw materials are mixed, the mixing barrel can be driven to move to the position above the forming die to discharge the coal ash raw materials; therefore, the coal ash raw material can be uniformly distributed in the forming die, the inconsistent thickness of the coal ash plate after compression forming is avoided, and the forming quality of the coal ash plate is improved.

Owner:江苏安普林新材料研究院有限公司

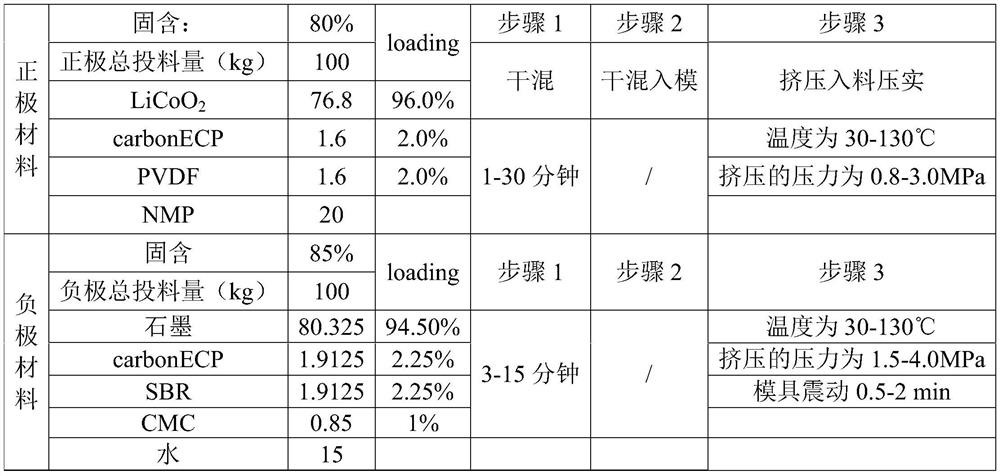

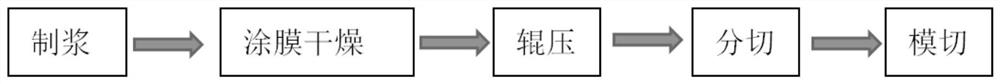

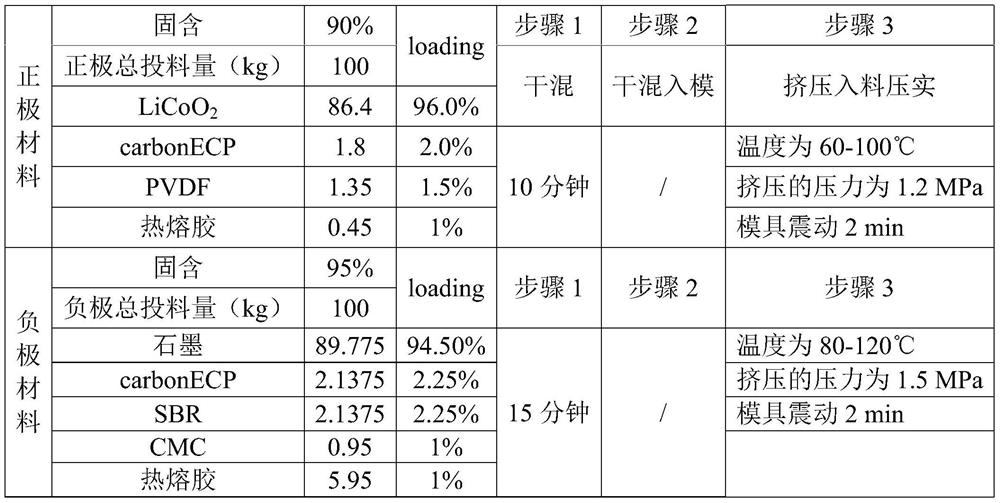

Paste mixing and brick making preparation method of lithium ion battery pole piece

InactiveCN112952042AReduce usageEasy to save energyElectrode thermal treatmentSecondary cellsPower batteryElectrical battery

The invention relates to a paste mixing and brick making preparation method of a lithium ion battery pole piece. The paste mixing and brick making preparation method comprises the following steps of: (1) making material paste preparation, namely carrying out dry mixing on a negative electrode material raw material or a positive electrode material raw material, and adding a solvent into the dry mixed material to obtain the material paste; (2) feeding the paste into a mold, namely adding the prepared paste into a battery pole piece mold which is internally provided with a base material sheet and is divided into an upper mold and a lower mold, placing a base material on the lower mold, and after the paste is coated on the base material, carrying out cavity closing pressing on the upper mold; and (3) performing drying and compaction, namely heating and drying the paste pole piece loaded into the mold cavity, and applying a certain pressure in the drying process to obtain the lithium ion battery pole piece. Compared with the prior art, the paste mixing and brick making preparation method has the advantages of simple process, low investment cost, high investment benefit, great reduction of the cost of the power battery, facilitation of popularization and application of the electric automobile and the like.

Owner:BATTERO TECH CORP LTD

Method for quick glazing of ceramic multicolor glaze

InactiveCN106565279AAchieve multi-color decoration effectImprove operational efficiencyWater basedWax

The invention relates to the technical field of ceramics, in particular to a method for quick glazing of a ceramic multicolor glaze. The method can greatly reduce the operation control difficulty, simplify the technological process and improve production efficiency, stabilize the product quality and reduce the production cost, and can ensure clear patterns and smooth lines. The method for quick glazing of a ceramic multicolor glaze provided by the invention includes the steps of: 1) preparation of water-based wax; 2) glazing; 3) waxing; 4) cleaning after curing of water-based wax; and 5) repeating the step 2)-step 4).

Owner:陕西火凤凰艺术陶瓷有限责任公司

Boron doping method, solar cell and manufacturing method thereof

PendingCN113972130AModerate thicknessEnhanced Laser AbsorptionSemiconductor/solid-state device manufacturingEngineeringSolar cell

The invention discloses a boron doping method, a solar cell and a manufacturing method of the solar cell, relates to the technical field of photovoltaics, and aims to enable boron to be easily doped into a silicon wafer and reduce the boron doping difficulty. The boron doping method comprises the following steps: providing a silicon substrate; forming an auxiliary layer on the silicon substrate, wherein the material of the auxiliary layer comprises titanium dioxide; forming a boron-containing slurry layer on the auxiliary layer; propelling boron impurities in the boron-containing slurry layer through the auxiliary layer into the silicon substrate by using a laser to dope the silicon substrate. The boron doping method, the solar cell and the manufacturing method of the solar cell are used for manufacturing the solar cell.

Owner:LONGI SOLAR TECH (XIAN) CO LTD

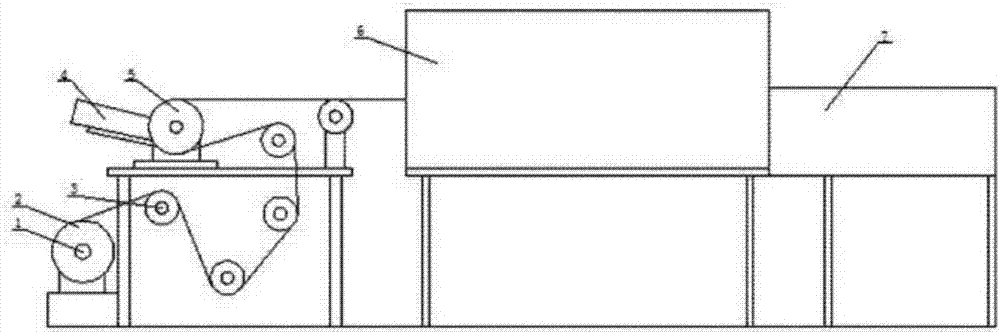

Automatic lithium battery pole piece coating machine

InactiveCN107486370AEasy to operateQuality assuranceLiquid surface applicatorsCoatingsElectrical batterySlurry coating

The invention discloses an automatic lithium battery pole piece coating machine used for solving the problems that the conventional continuous coating machine is labor-hour-consuming and wastes resources and a batch-type coating machine is complicated in structure, difficult in operation and difficultly controllable in quality. The automatic lithium battery pole piece coating machine disclosed by the invention comprises an unwinding device, wherein a tension adjustment device is arranged at the rear end of the unwinding device; a slurry coating device is arranged at the rear end of the tension adjustment device; a drying device is arranged at the rear end of the slurry coating device; a winding device is arranged at the rear end of the drying device; the unwinding device mainly comprises unwinding rollers; pole piece coils are arranged on the unwinding rollers; the tension adjustment device mainly comprises a group of tension adjustment rollers; the slurry coating device comprises a coating roller and a die head; the coating roller is used for coating battery slurry onto the pole piece; the die head is matched with one side of the coating roller in parallel; the outlet of the die head is aligned at the coating roller; a gasket for partitioning the battery slurry is arranged at the outlet in the die head; and the height of the gasket is lower than the depth of the battery slurry in the die head. According to the automatic lithium battery pole piece coating machine disclosed by the invention, the problem that the quality of the batch-type coating machine is difficultly ensured is solved, and the problem that the continuous coating machine wastes resources is overcome.

Owner:四川泰锂新能源科技有限公司

Surface treatment device used in automobile brake pad production process

The invention discloses a surface treatment device used in an automobile brake pad production process. The surface treatment device comprises a device body, a stand column, a placement plate, a horizontal sliding rod, a paint discharge box and a horizontal support arm, wherein the horizontal support arm is arranged on the upper portion of the device body, the stand column is welded to the right side of the lower surface of the horizontal support arm, the horizontal sliding rod is horizontally arranged on the lower portion of the device body, the placement plate is movably installed on the horizontal sliding rod, the right end of the horizontal sliding rod is welded to the stand column, and the paint discharge box is arranged on the lower left portion of the device body. The surface treatment device is characterized in that the interior of the horizontal support arm is arranged into a hollow structure, a servo motor is fixedly installed above the horizontal support arm, the servo motoris arranged into a forward and backward rotation motor, and a first rotating shaft is welded to the lower side of the servo motor. The surface treatment device can guarantee that paint sprayed onto the surface of a brake pad is uniformly distributed, and the situation is avoided that the surface thickness of the brake pad is not uniform due to nonuniform distribution of paint, and consequently normal use of the brake pad is affected.

Owner:WUHAN MATENG TECH DEV

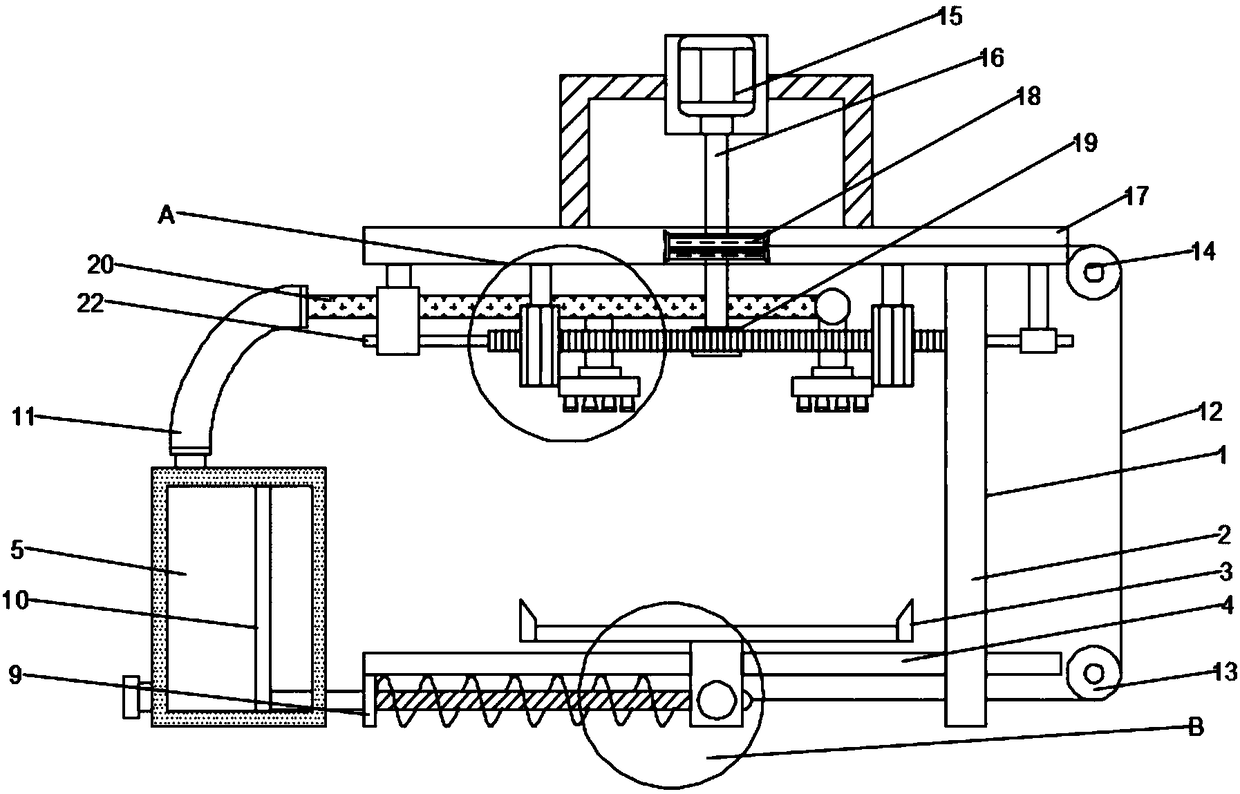

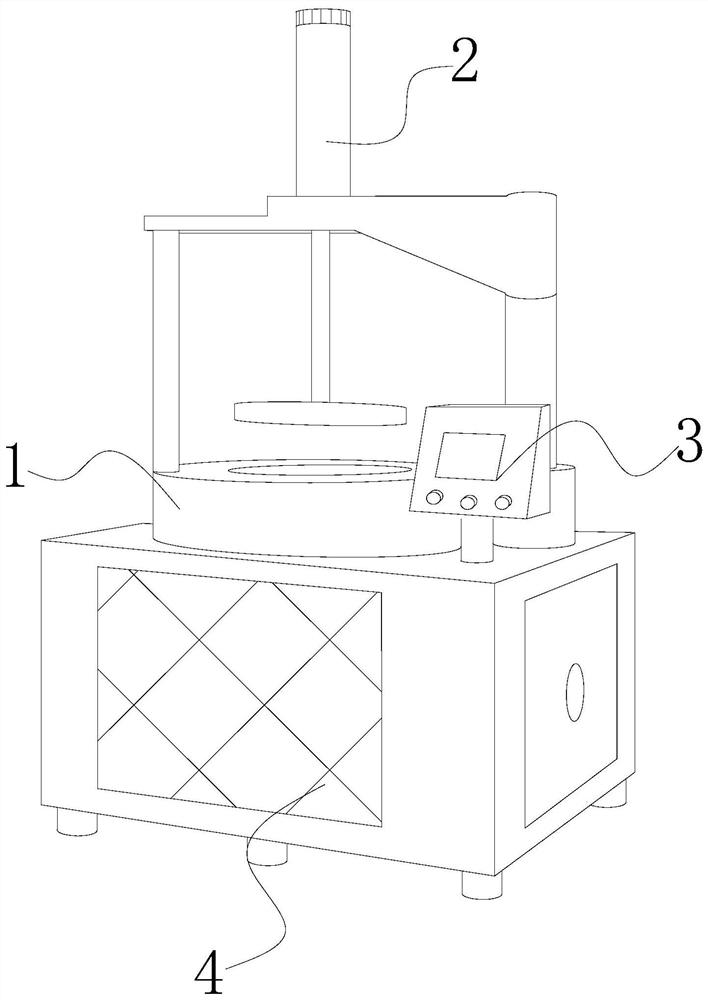

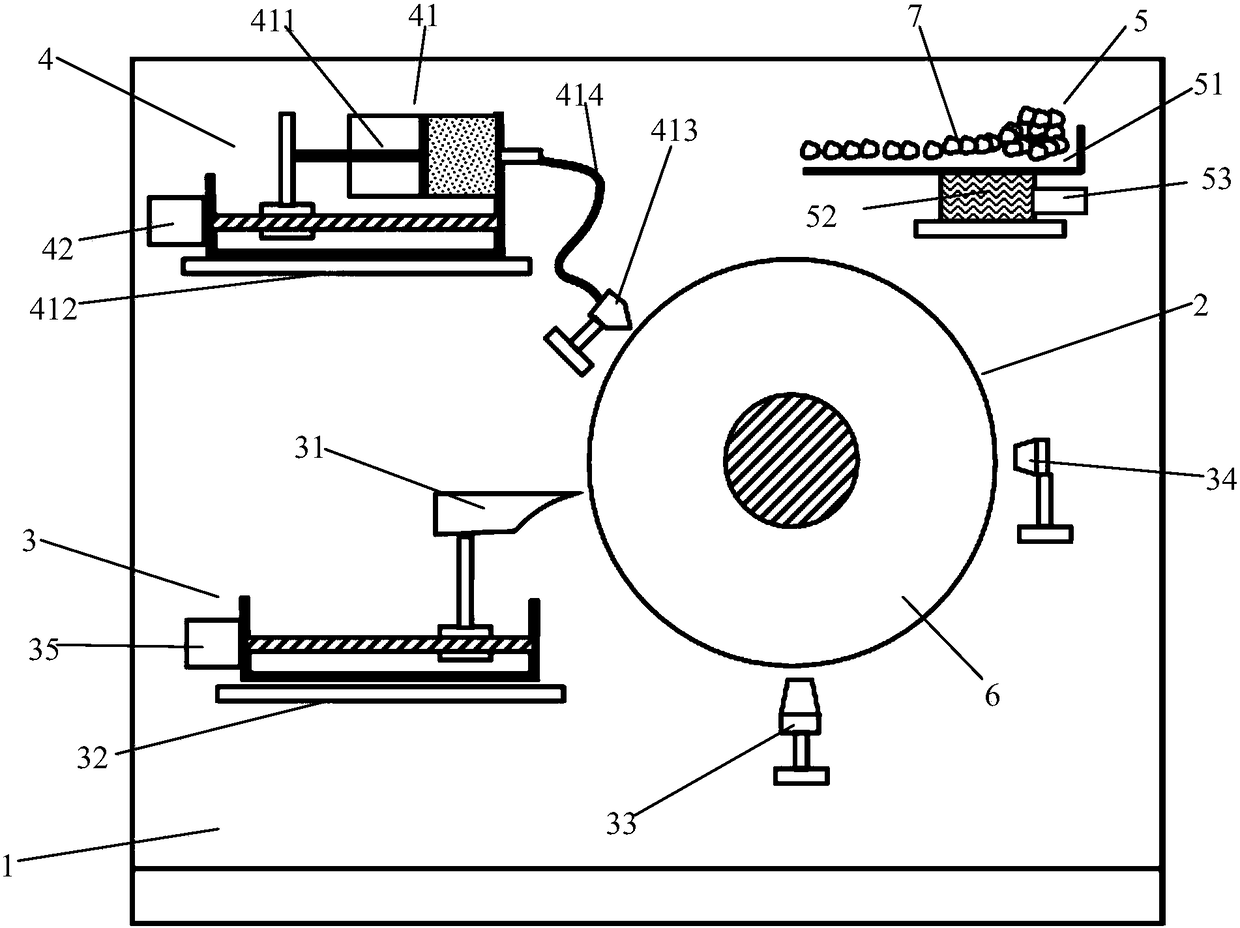

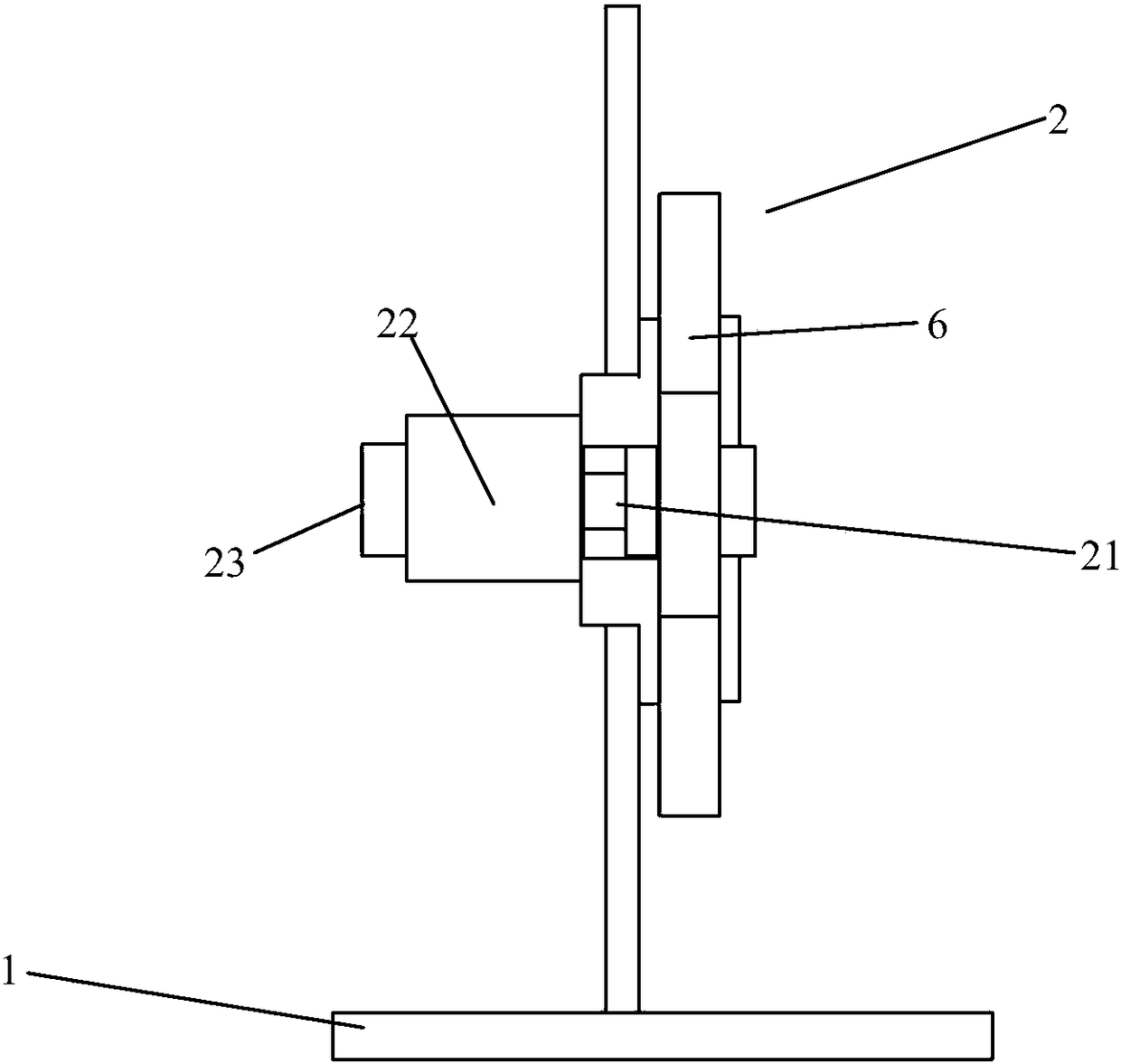

Ultrathin wafer processing device

ActiveCN112497051AImprove smoothnessAvoid inconsistent thicknessGrinding machine componentsSemiconductor/solid-state device manufacturingWaferStructural engineering

The invention discloses an ultrathin wafer processing device. The structurally of the device comprises a processing mechanism, a rotator, a control switch and a workbench, the rotator and the processing mechanism are located on the same central axis, the control switch is fixedly embedded in the surface of the upper end of the workbench, the processing mechanism is installed at the upper end of the workbench, and the rotator is fixed to the upper end of the workbench. The extending part of the outer side of the wafer acts on a friction block, the wafer rotates reversely to act on a continuousbending structure of the friction block and a bending plate, attaching force is generated on the wafer, the smoothness of the outer side of the wafer is enhanced while the outer side of the wafer is prevented from extending, the problem that the thickness of the outer side of the wafer is inconsistent is solved, after the wafer is lost, a grinding structure is controlled to ascend and descend, a fixing ring drives a grinding plate to ascend and descend, so that a stress structure and a attaching plate are exposed through a gap groove, the length of the stress structure is increased, the attaching friction force of an arc-shaped knife edge in a supporting rod to the wafer is enhanced, frequent disassembly and replacement after grinding loss are avoided, and the situation that the accuracy of the grinding structure is affected by frequent disassembly and installation is prevented.

Owner:临漳县澳皇网络科技有限公司

A fully automatic battery module locking device

ActiveCN108054329BRealize automatic tighteningAvoid inconsistent thicknessCell component detailsMetal working apparatusControl engineeringMechanical engineering

Owner:SHENZHEN CLOU ELECTRONICS

An ultra-thin wafer processing device

ActiveCN112497051BImprove smoothnessAvoid inconsistent thicknessGrinding machine componentsSemiconductor/solid-state device manufacturingWaferEngineering

The invention discloses an ultra-thin wafer processing device, the structure of which comprises a processing mechanism, a rotator, a control switch, and a workbench. The mechanism is installed on the upper end of the workbench, and the rotator is fixed on the upper end of the workbench. The extended part of the wafer acts on the friction block. Under the reverse rotation of the wafer, it acts on the continuous bending structure of the friction block and the bending plate, causing a sticking effect on the wafer. Combined force, avoiding the extension of the outer side of the wafer while enhancing the smoothness of the outer side of the wafer, and preventing the problem of inconsistent thickness on the outer side of the wafer. After the wafer is lost, the grinding structure is controlled to lift up and down, so that the fixed ring drives the grinding plate up and down, so that the stressed structure and the sticking The plywood is exposed through the gap groove, which increases the length of the stressed structure and enhances the friction force of the arc-shaped knife edge in the support rod against the wafer, avoiding the need for frequent disassembly and replacement after grinding loss, and preventing frequent disassembly and installation from affecting the accuracy of the grinding structure.

Owner:临漳县澳皇网络科技有限公司

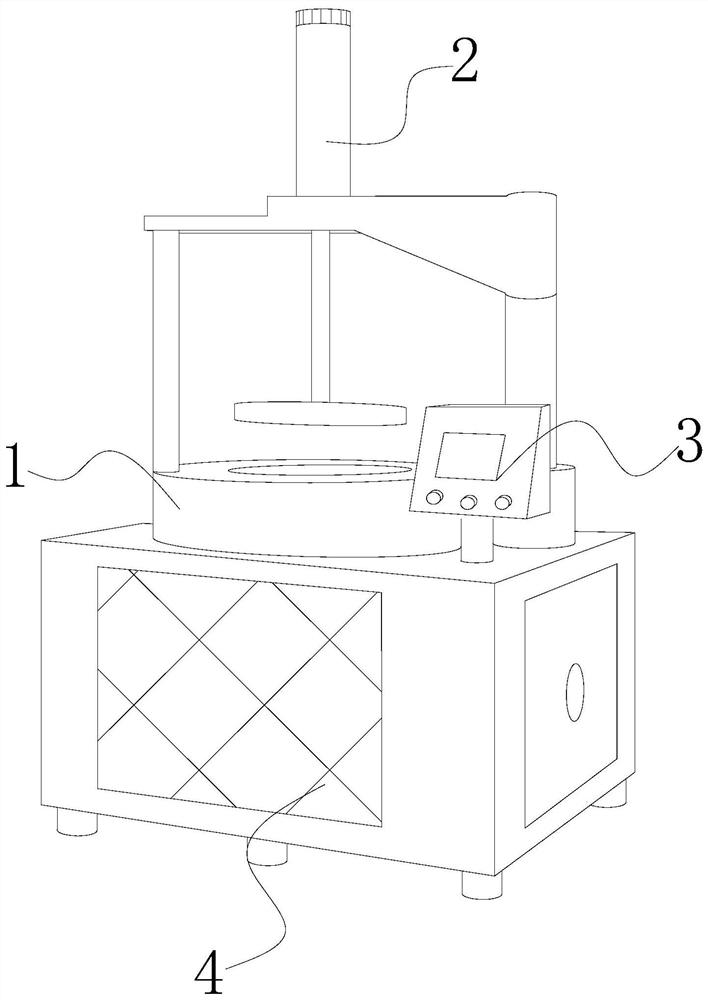

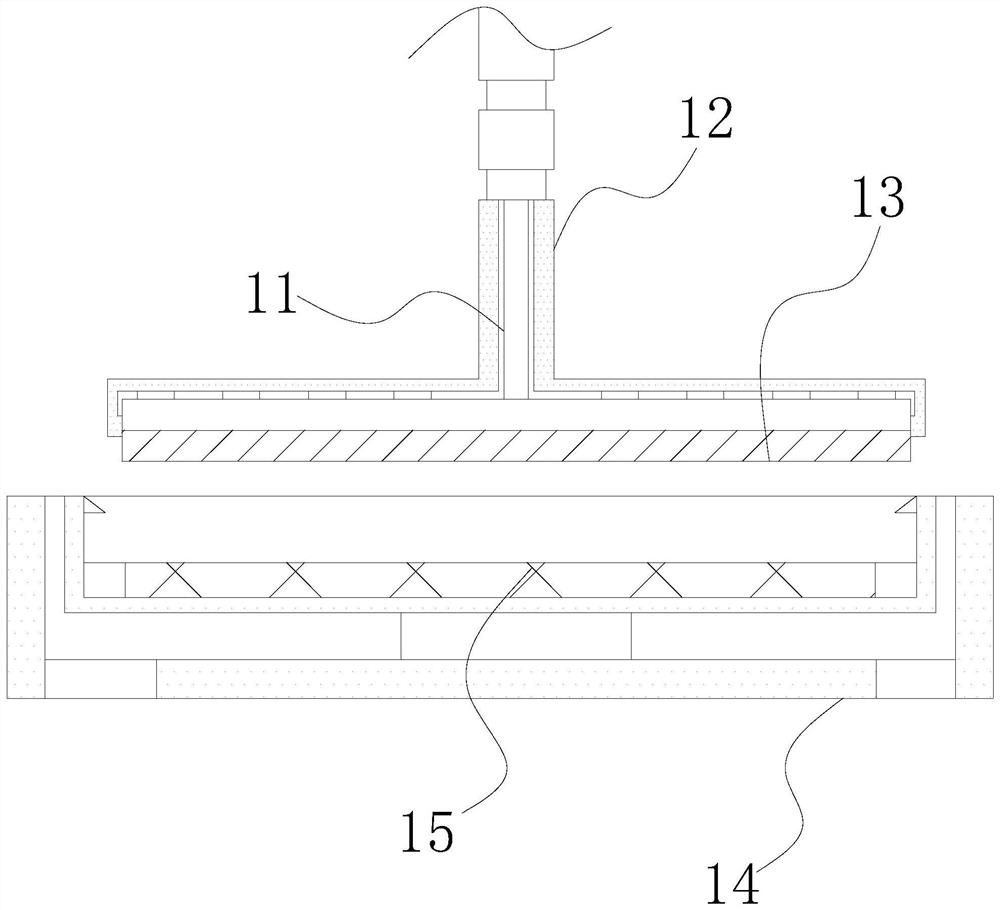

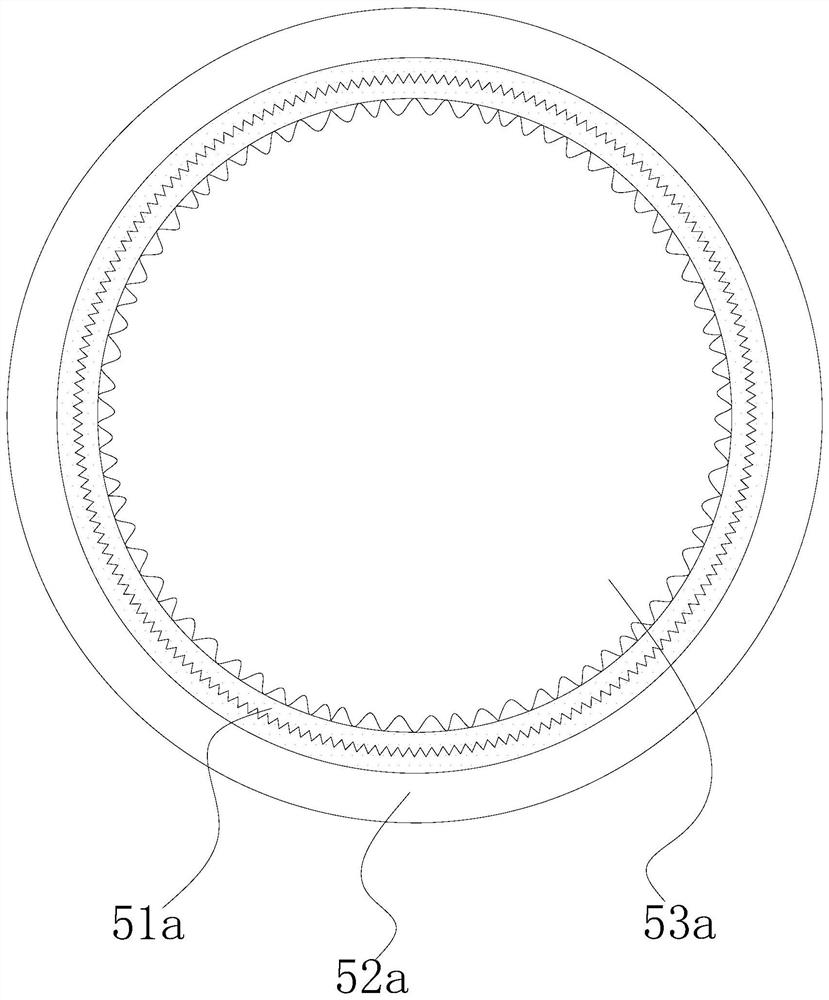

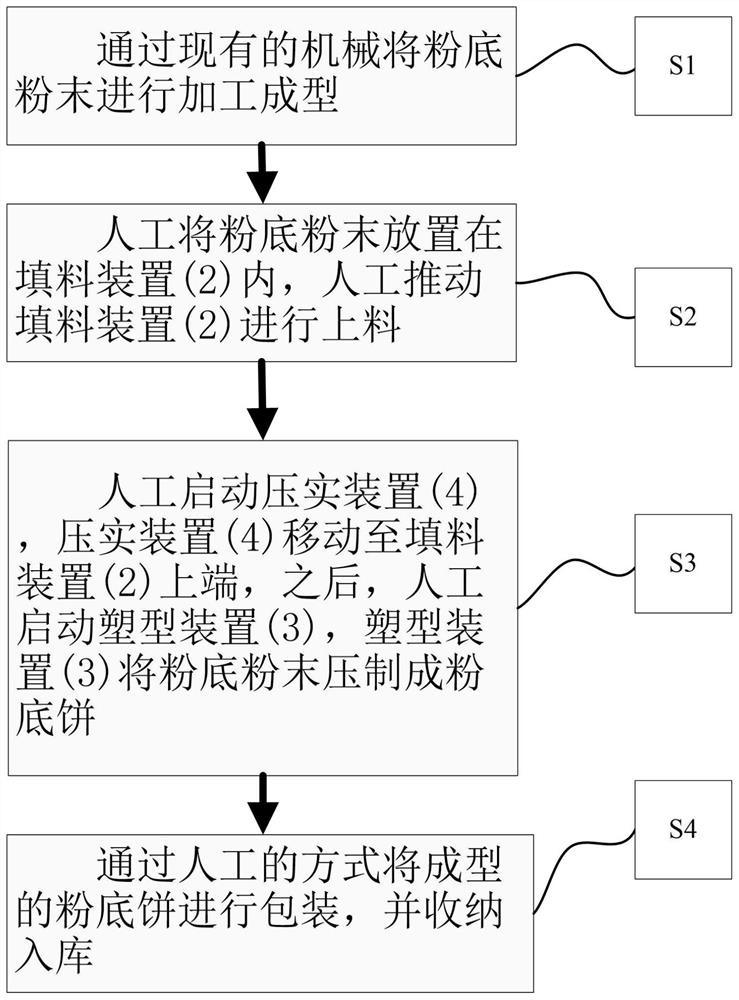

Preparation method of freckle-removing and whitening cosmetic

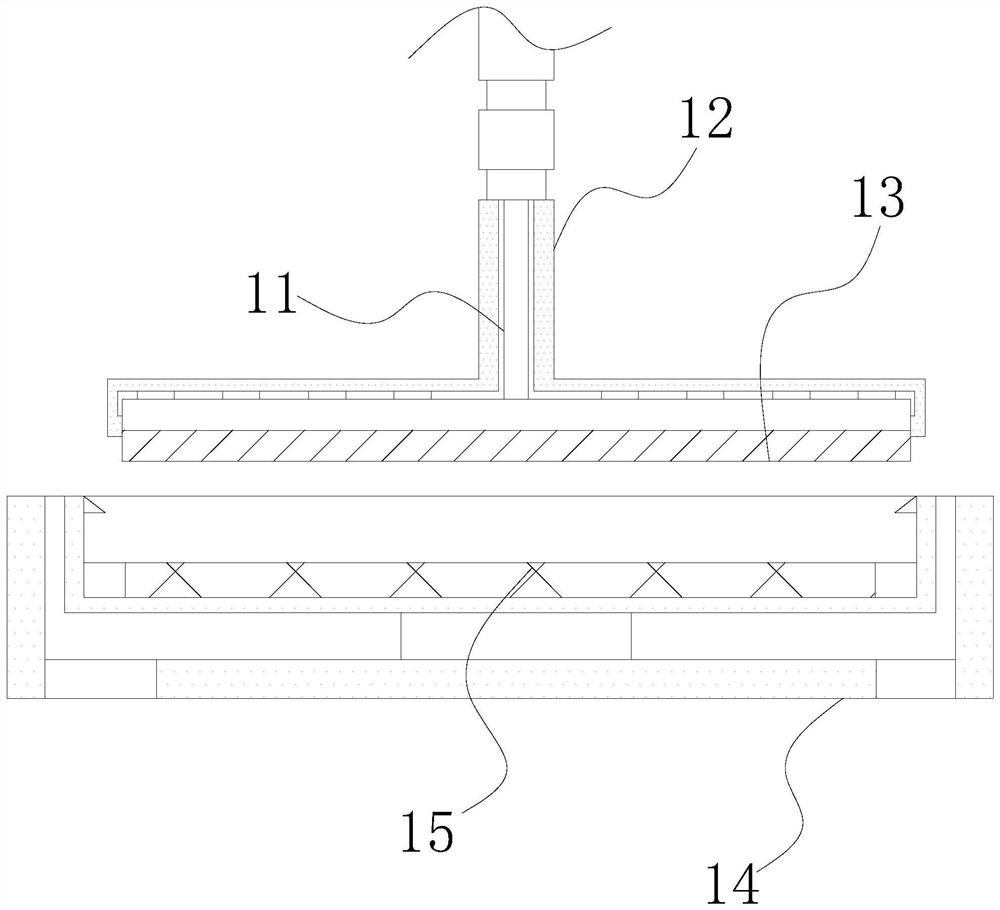

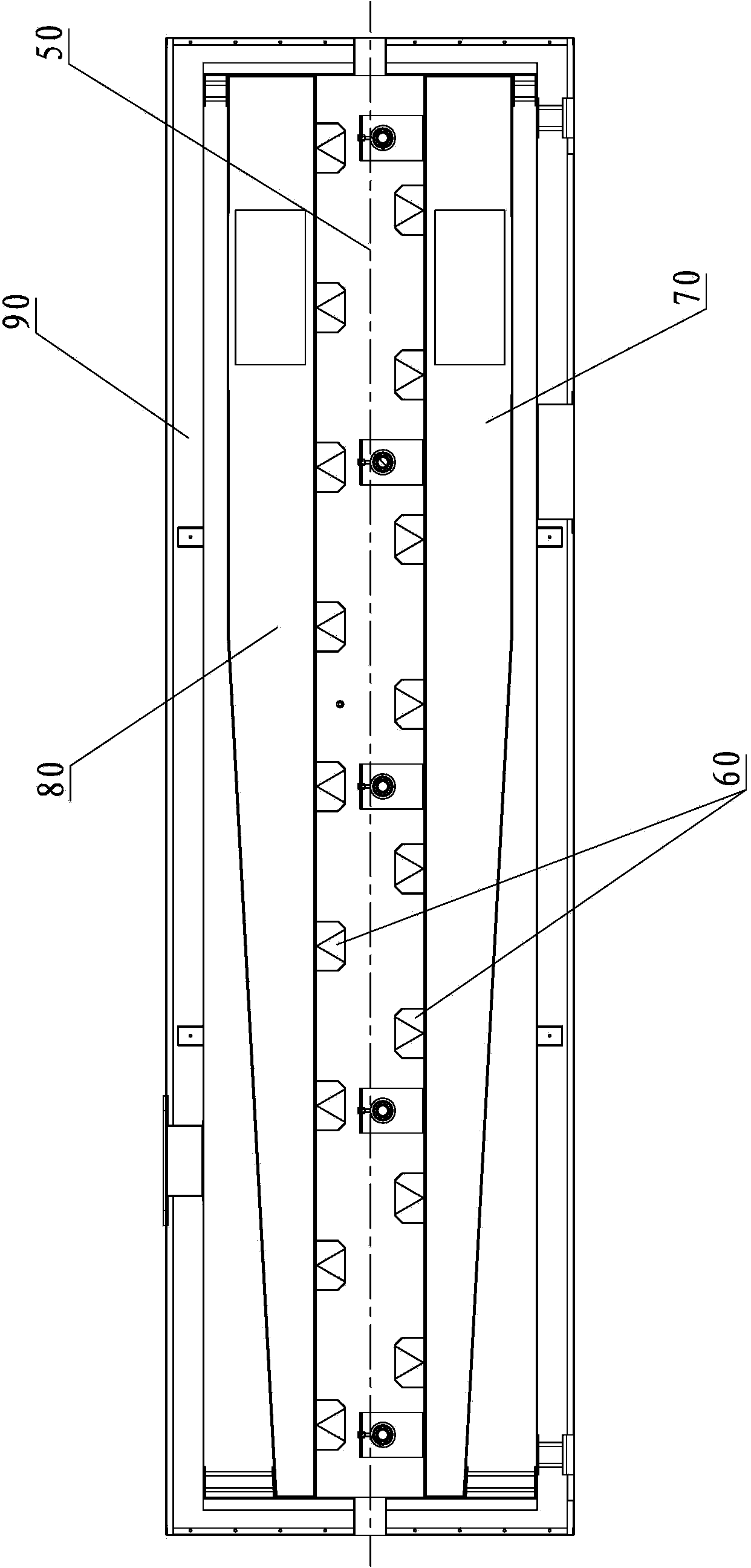

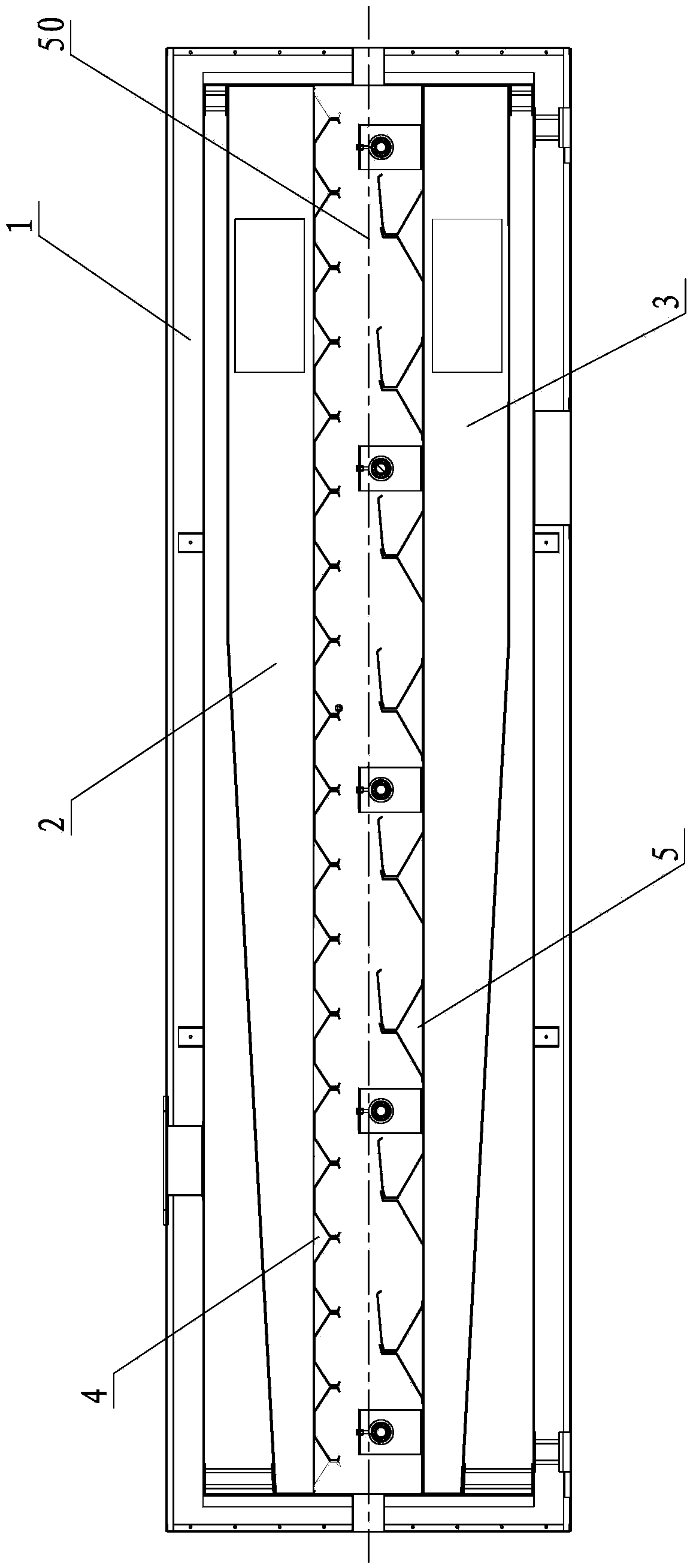

ActiveCN113352678AAvoid excessive gapsAvoid inconsistent thicknessShaping pressArchitectural engineeringMechanical engineering

The invention relates to a preparation method of freckle-removing and whitening cosmetics. A bottom plate, a filling device, a molding device and a compaction device are included, the filling device is mounted at the upper end of the bottom plate, the molding device is arranged below the filling device, the lower end of the molding device is fixedly connected with the bottom plate, and the compaction device is arranged above the filling device. The problems that when foundation make-up powder is pressed into cakes by existing equipment, the foundation make-up powder is generally directly poured into a pressing position, the pressing position cannot be beaten, too large gaps are prone to occurring among the foundation make-up powder, the thicknesses of the formed foundation make-up cakes are different, the dosages of foundation make-up are not consistent, the quality of the foundation make-up cakes is reduced, and meanwhile, when the foundation make-up cakes are separated from the surfaces of the foundation make-up cakes after being formed, the phenomenon that the surfaces of the foundation make-up cakes are sticky and uneven easily occurs on the surfaces of the foundation make-up cakes, so that the smoothness of the surfaces of the foundation make-up cakes is reduced, and the forming effect of the foundation make-up cakes is reduced can be solved.

Owner:JIANGXI YONGTONG TECH

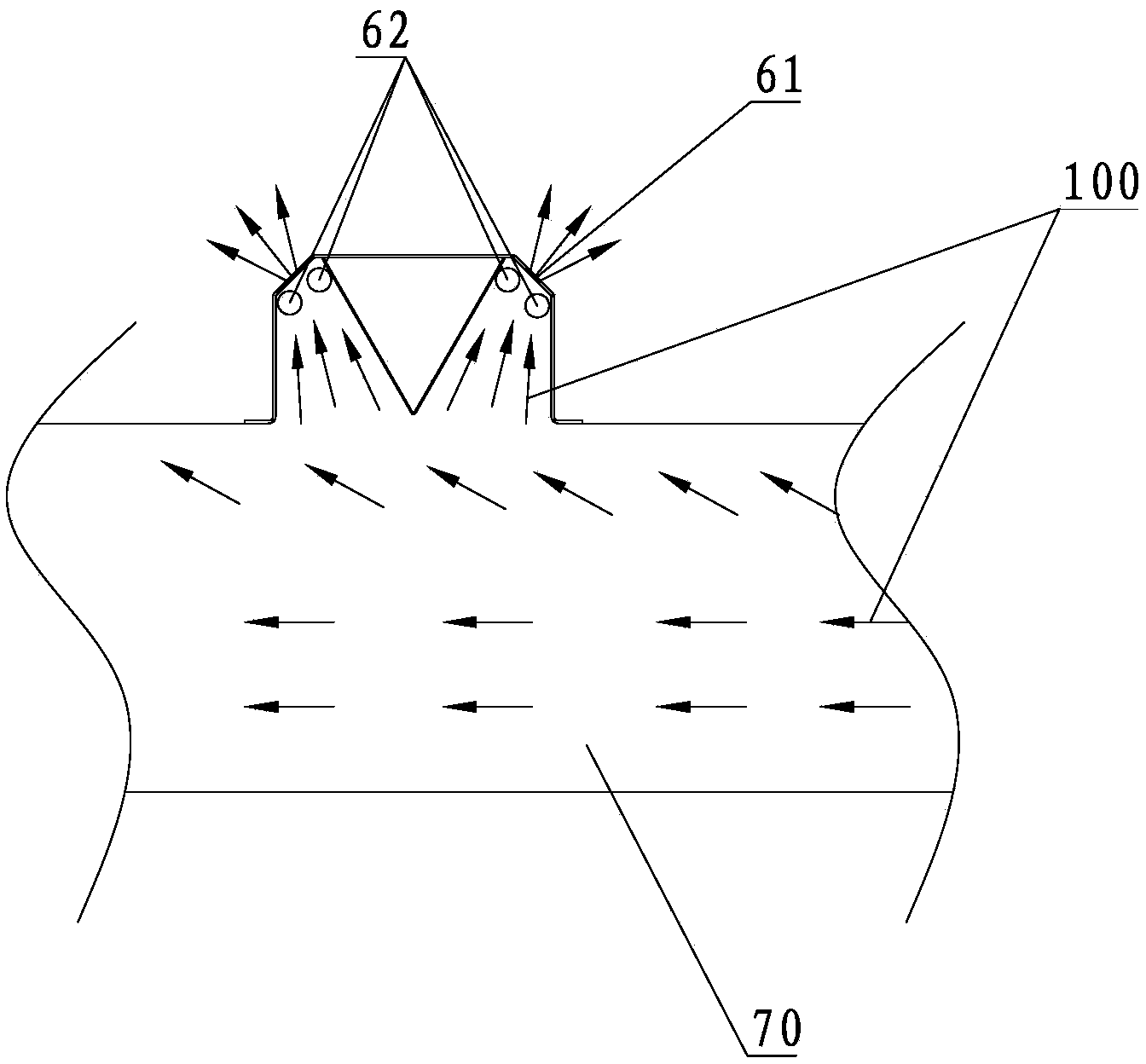

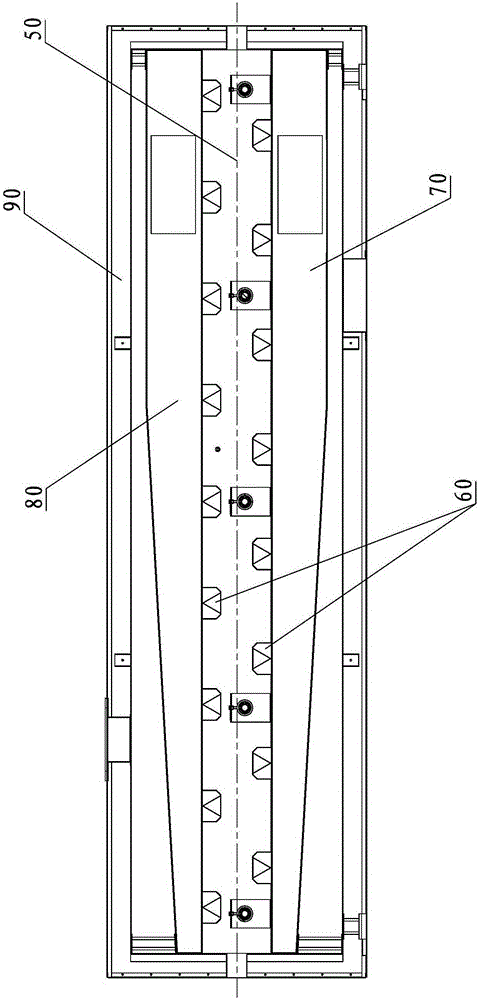

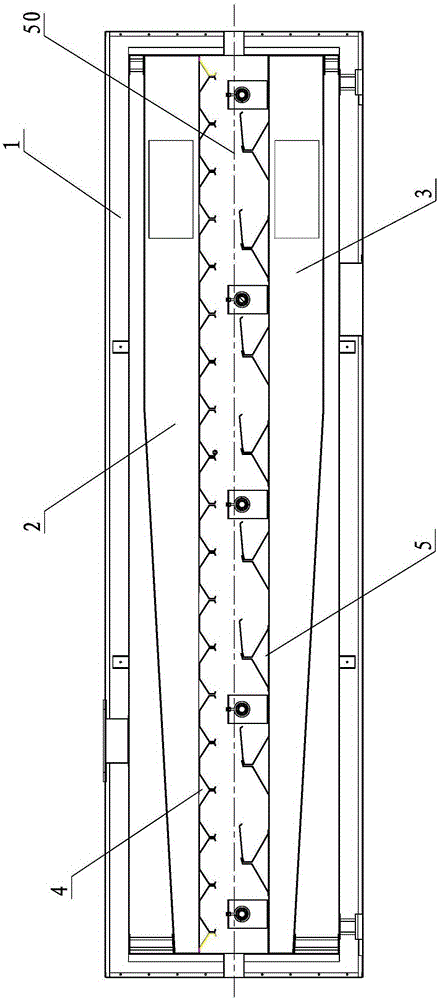

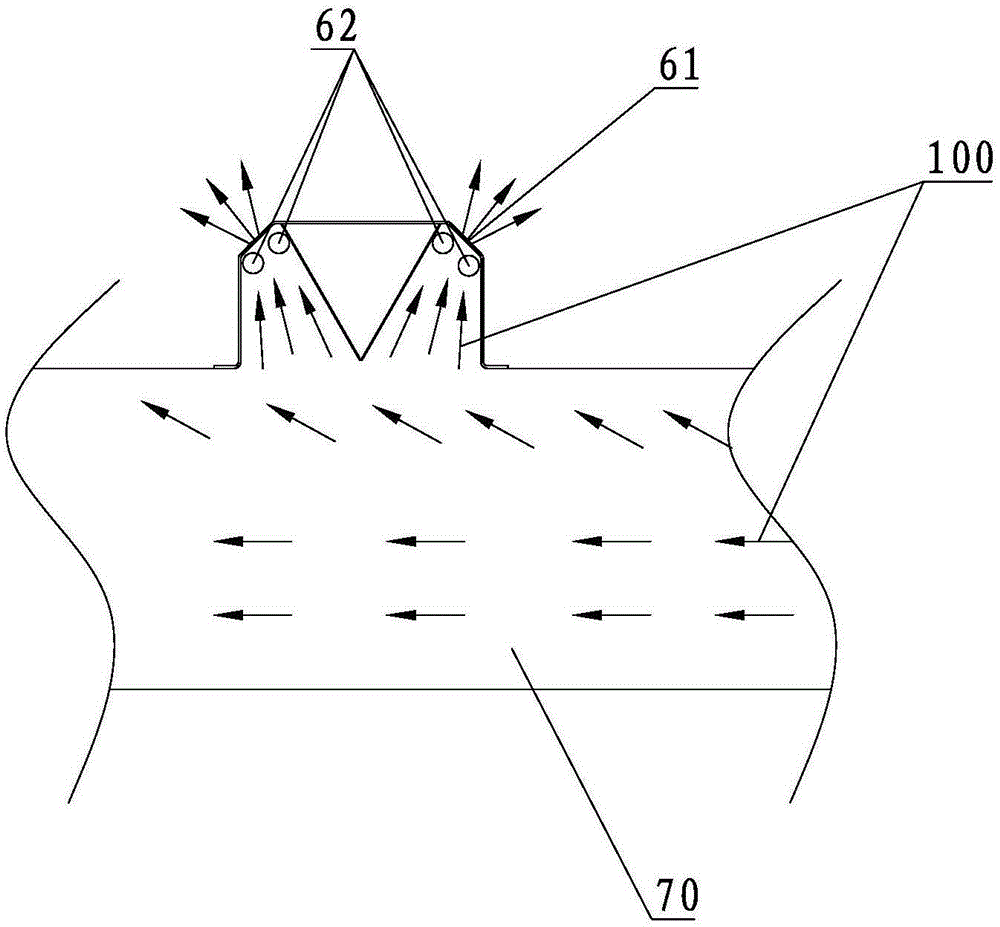

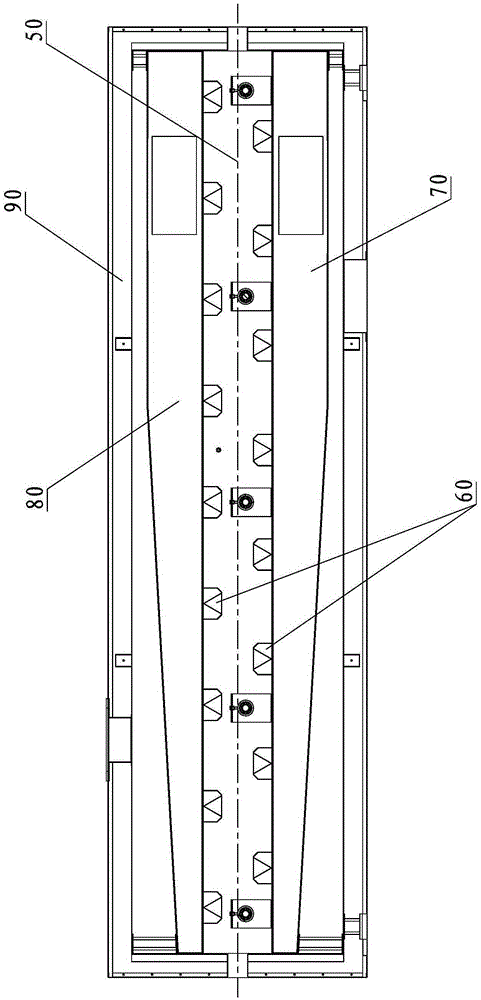

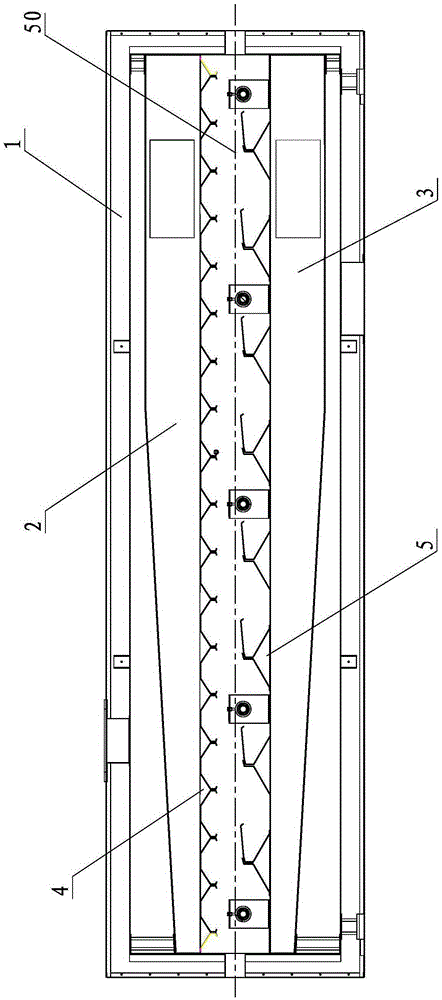

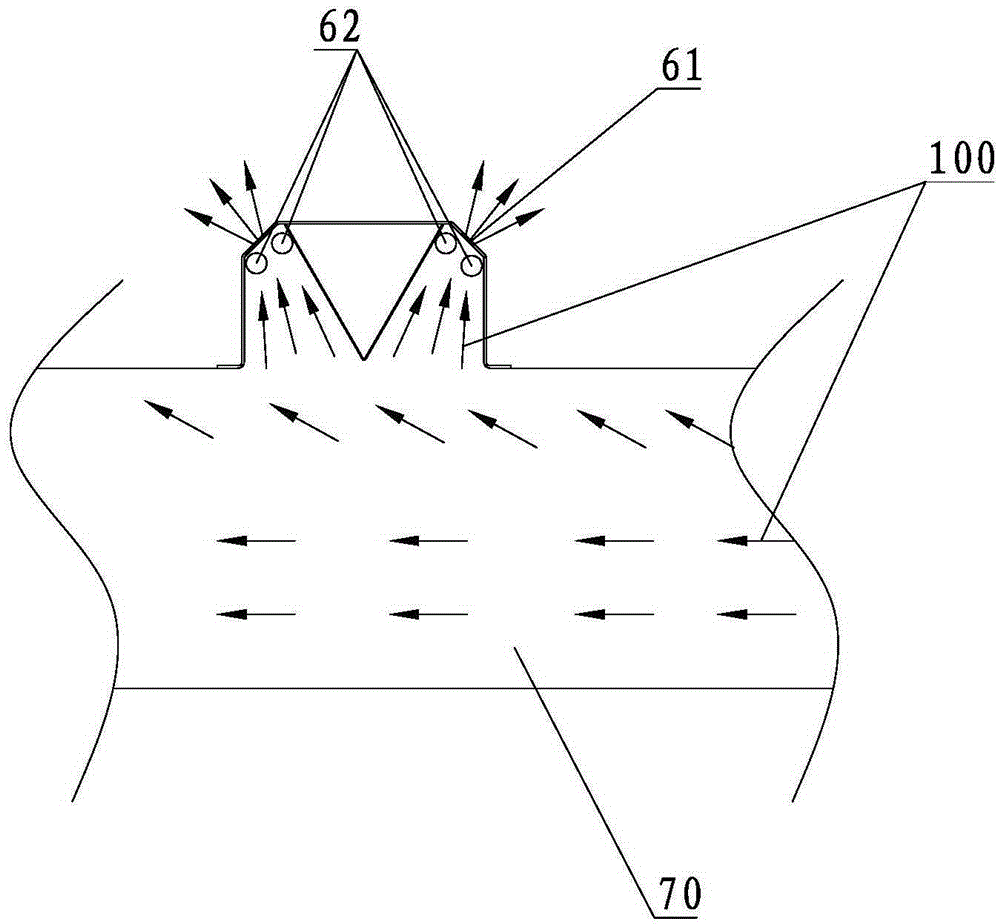

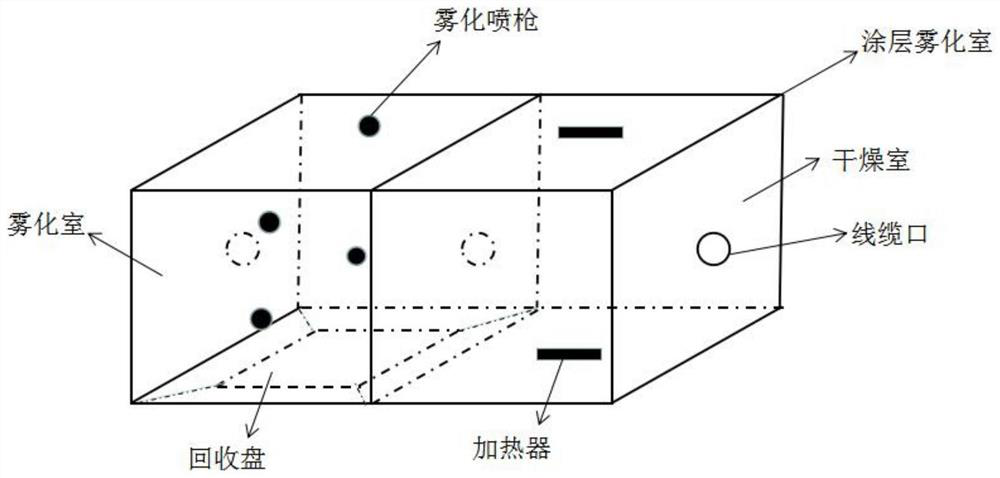

Coating dryer and air nozzle special for coating dryer

The invention provides a coating dryer and an air nozzle special for the coating dryer. The air nozzle special for the coating dryer comprises an air chamber and a straight section, one end of the straight section is communicated with the air chamber, and an air outlet is formed in the other end of the straight section. Compared with a scattered air outlet mode used in an air outlet of a common air nozzle, the coating dryer and the air nozzle special for the coating dryer have the advantages that the straight section is arranged in front of the air outlet of the air nozzle, so that fluid is led to pass through a section of flat channel, due to the fact that sudden size variation of the ventilation section area does not exist in the straight section, eddies can not be caused, a pressure equalizing area can be formed in the straight section instead, and the stability of the speed of air blown out from the air outlet finally is guaranteed. When the air nozzle is applied to the coating dryer, due to the fact that the air speed after pressure equalizing is stable, the air speed enables upward pushing force formed by the air blown out from the air nozzle to foil materials to be stable, the chattering phenomenon of the foil materials can not happen in a drying oven, and the problem that the thicknesses of coatings are not consistent is solved.

Owner:SHENZHEN HAONENG TECH

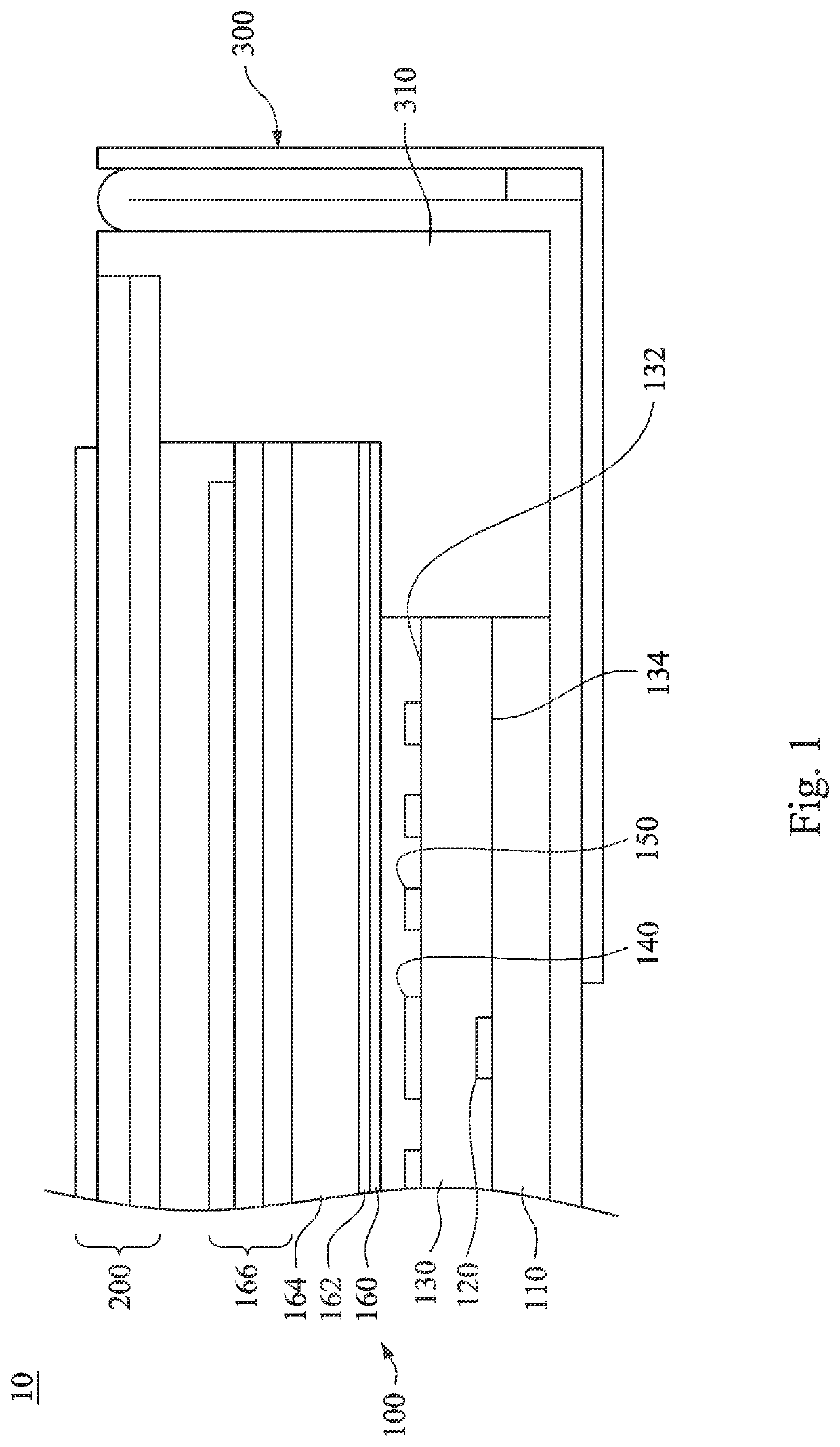

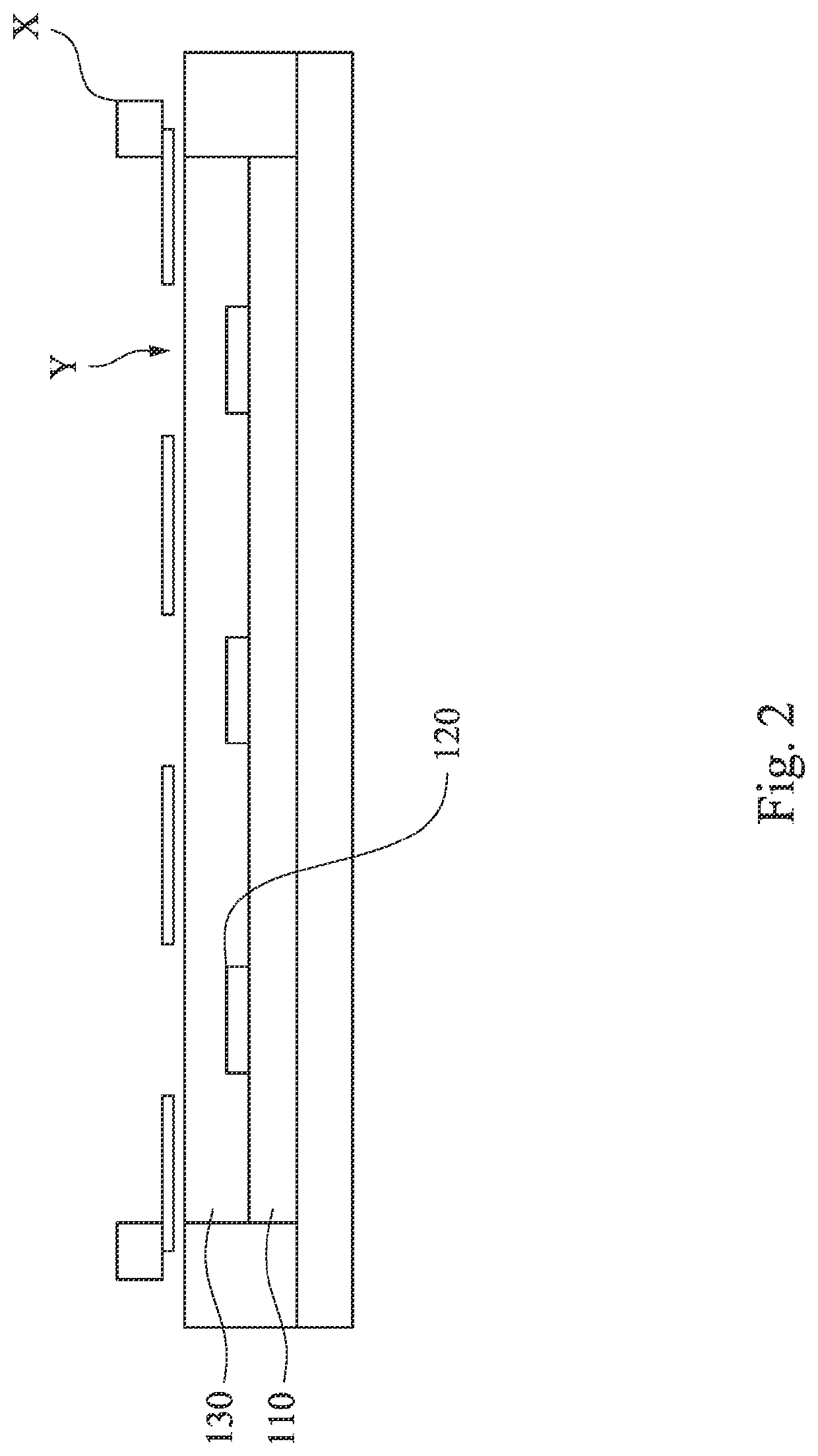

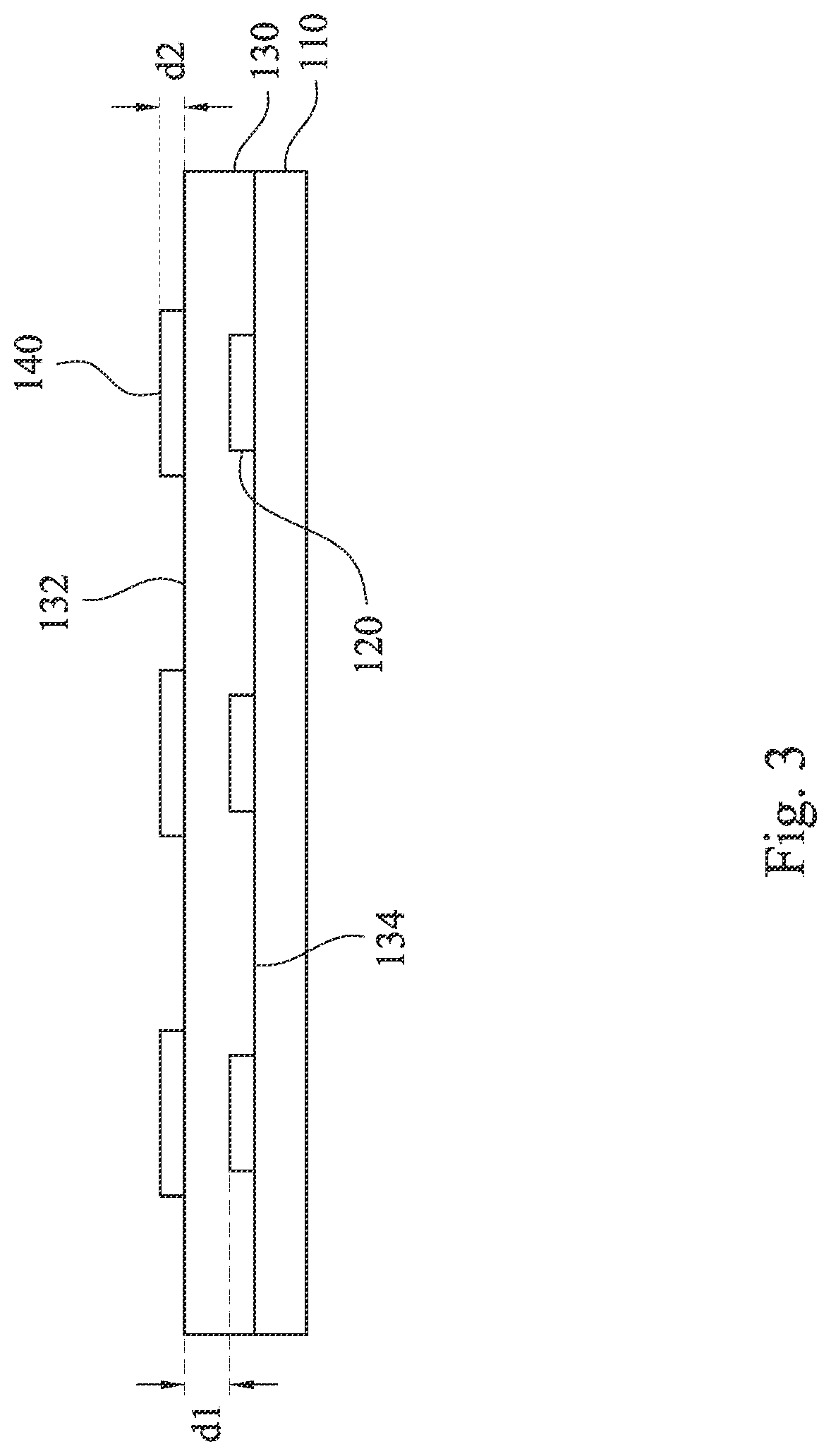

Backlight module and display device using the same

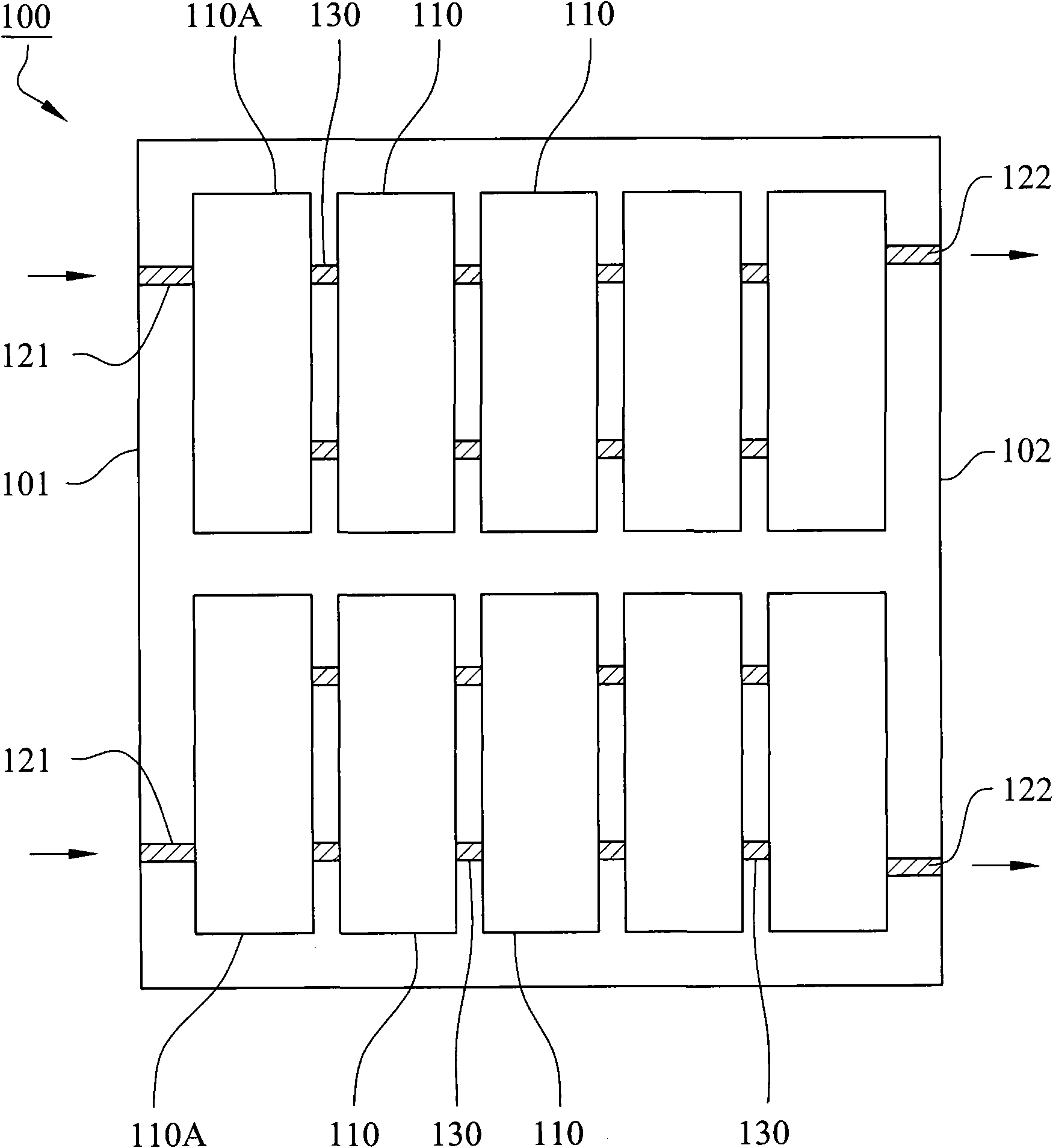

PendingUS20220206211A1Avoid inconsistent thicknessUneven light distributionMechanical apparatusPlanar/plate-like light guidesVertical projectionDisplay device

The present disclosure provides a backlight module, including a substrate, a plurality of light-emitting elements, a protective layer and a plurality of first dots. These light-emitting elements are disposed on the substrate. The protective layer is disposed on the substrate and the light-emitting elements, the protective layer has an upper surface and a lower surface opposite to the upper surface, and the upper surface of the protective layer is flat. The first dots are disposed on the upper surface of the protective layer and cover the light-emitting elements. A vertical projection area of each of the first dots on the substrate is larger than a vertical projection area of each of the light-emitting elements on the substrate, so as to reduce the thickness of the backlight module and reduce the dots alignment process.

Owner:AU OPTRONICS CORP

Coating dryer and its special air nozzle with buffer structure

The invention provides a coating dryer and an air nozzle with a buffer structure special for the coating dryer. The air nozzle comprises an air chamber, a straight section and a bending section, one end of the straight section is communicated with the air chamber, the other end of the straight section is connected with one end of the bending section, the other end of the bending section is provided with an air outlet, and the bending section and the straight section are arranged in an obtuse angle mode. The straight section is arranged in front of an air outlet of the air nozzle, so that flow is led to pass through a section of flat channel. Due to the fact that sudden size variation of the ventilation area does not happen, eddies can not be caused, a pressure equalizing area can be formed in the straight section instead, and the stability of the air speed is guaranteed. The bending section is additionally arranged in front of the air outlet, so that the air does not directly blow a foil band, and the air slowly blows the foil band with an angle. Accordingly, when the air nozzle is applied to the coating dryer, the air speed after pressure equalizing is stable so that upward pushing force formed by the air blown out from the air nozzle to foil materials can be stable, the chattering phenomenon of the foil materials can not happen in a drying oven, and the problem that the thicknesses of coatings are not consistent is solved.

Owner:SHENZHEN HAONENG TECH

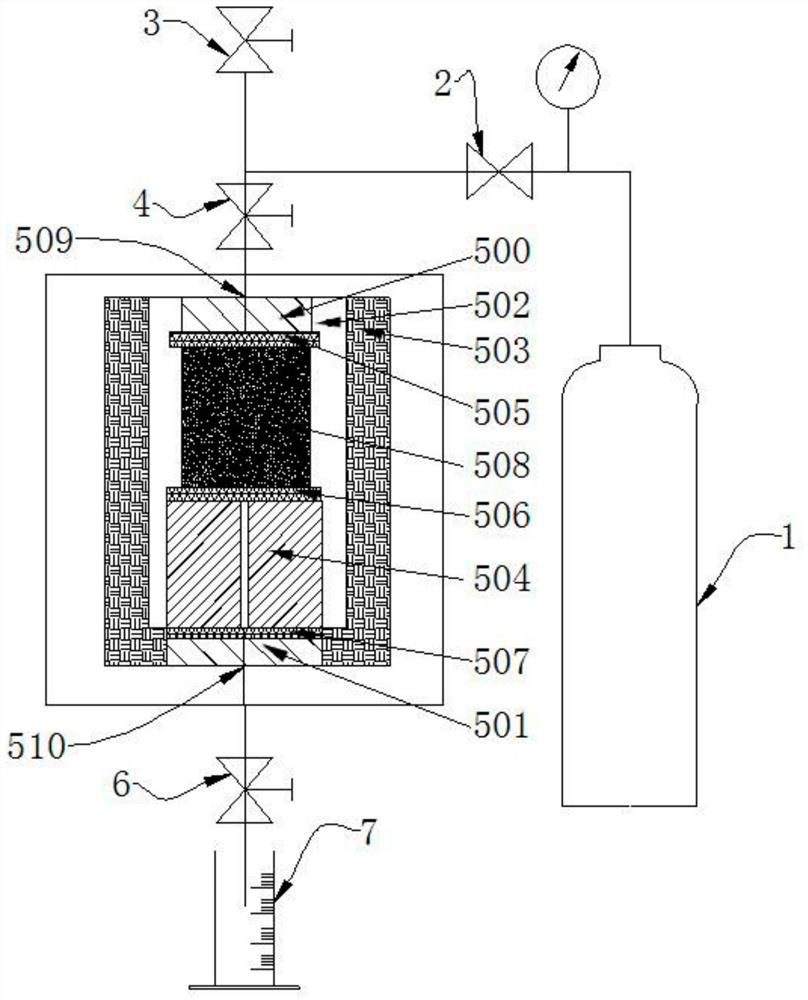

Drilling fluid leak prevention and plugging effect evaluation experimental system

The invention relates to the technical field of drilling fluid leakage prevention and plugging, and discloses an experimental system for evaluating the effect of drilling fluid leakage prevention and plugging, including: a pressurizing device, which is suitable for outputting compressed gas to form a predetermined experimental pressure; Cup, which includes a cup body with an inner cavity, the upper end of the cup body is connected with a pressurizing device, and the lower end of the cup body is provided with a liquid discharge port; the leakage model includes a permeable leakage model and a crack type leakage model selectively installed in the cup body The model is suitable for dividing the cup body into a pressurized chamber connected with the pressurizing device and a liquid leakage chamber connected with the liquid discharge port at the installation position, wherein the permeable leakage model is a columnar sand plate; It includes a columnar model body, the columnar model body has a crack suitable for connecting the pressurized chamber and the leakage chamber, and multiple seams are formed on the inner wall of the crack. The invention can more realistically simulate formation fracture type leakage and seepage type leakage.

Owner:CHINA NAT OFFSHORE OIL CORP +1

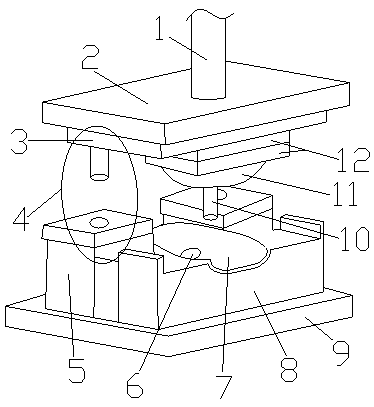

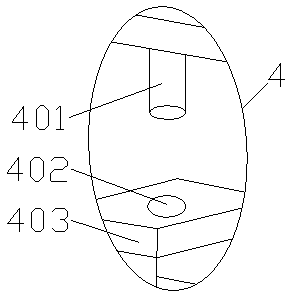

Anchor rod tray processing compound die

InactiveCN111036769AAvoid inconsistent thicknessImprove product qualityShaping toolsPunchingSteel tube

The invention discloses an anchor rod tray processing compound die which structurally comprises a stainless steel tube, a panel, a stress plate, a profile fixing device, a supporting seat, an inner groove, a groove, a die seat, a base, an extension pipe, a convex model, double reinforcing plates and an intact model. The stainless steel tube is mounted at the right center of the surface of the panel, the stress plate is mounted at the bottom of the panel, the stress plate is connected to the supporting seat through the profile fixing device, the supporting seat is connected to the die seat, thegroove is connected to the die seat, the inner groove is connected to the die seat through the groove, and the base is arranged at the bottom of the die seat. The anchor rod tray processing compounddie has the beneficial effects that as the profile fixing device, the inner groove, the groove, the extension pipe and the convex model are arranged, the inner groove, the groove, the extension pipe and the convex model can be used for pressing and punching an anchor rod tray at one time; and the profile fixing device can avoid inconsistence of thickness caused by mechanical failures or improper mechanical force application in the pressing and punching processes, so that the product quality is improved.

Owner:宿迁市郑品家具股份有限公司

A method of manufacturing a local mixed pressure printed circuit board

ActiveCN103687347BImprove alignment accuracyAvoid inconsistent thicknessMultilayer circuit manufactureState of artPrinted circuit board

The invention discloses a manufacturing method of a partial hybrid printed circuit board. The manufacturing method comprises the following steps that core boards and prepregs are provided, and the core boards into which a high-frequency material needs to be embedded are correspondingly overlapped according to the positions where the high-frequency material needs to be embedded, wherein each prepreg is arranged between two adjacent core boards into which the high-frequency material needs to be embedded; the overlapped core boards are pressed to form a first multi-layer board; a through groove where the high-frequency material needs to be embedded is milled at the position, where the high-frequency material needs to be embedded, of the first multi-layer board, and the high-frequency material is embedded into the through groove of the first multi-layer board. By the adoption of the manufacturing method, the process of milling the prepregs in the prior art is omitted, the phenomenon that the first multi-layer board is inconsistent in thickness due to the fact that too much glue flows out of the positions close to the through groove, of the core boards into which a high-frequency material needs to be embedded is avoided, the alignment precision between the core boards is improved, the quality of the partial hybrid PCB is improved, and working efficiency is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Coating dryer and its special nozzle

The invention provides a coating dryer and an air nozzle special for the coating dryer. The air nozzle special for the coating dryer comprises an air chamber and a straight section, one end of the straight section is communicated with the air chamber, and an air outlet is formed in the other end of the straight section. Compared with a scattered air outlet mode used in an air outlet of a common air nozzle, the coating dryer and the air nozzle special for the coating dryer have the advantages that the straight section is arranged in front of the air outlet of the air nozzle, so that fluid is led to pass through a section of flat channel, due to the fact that sudden size variation of the ventilation section area does not exist in the straight section, eddies can not be caused, a pressure equalizing area can be formed in the straight section instead, and the stability of the speed of air blown out from the air outlet finally is guaranteed. When the air nozzle is applied to the coating dryer, due to the fact that the air speed after pressure equalizing is stable, the air speed enables upward pushing force formed by the air blown out from the air nozzle to foil materials to be stable, the chattering phenomenon of the foil materials can not happen in a drying oven, and the problem that the thicknesses of coatings are not consistent is solved.

Owner:SHENZHEN HAONENG TECH

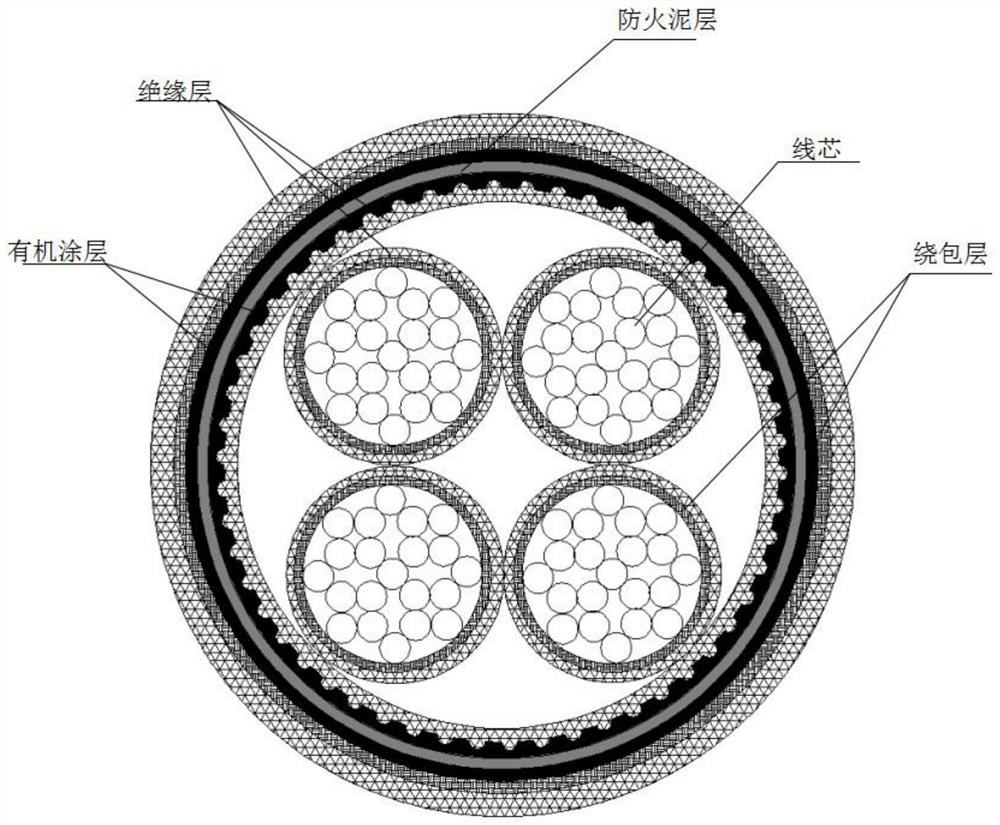

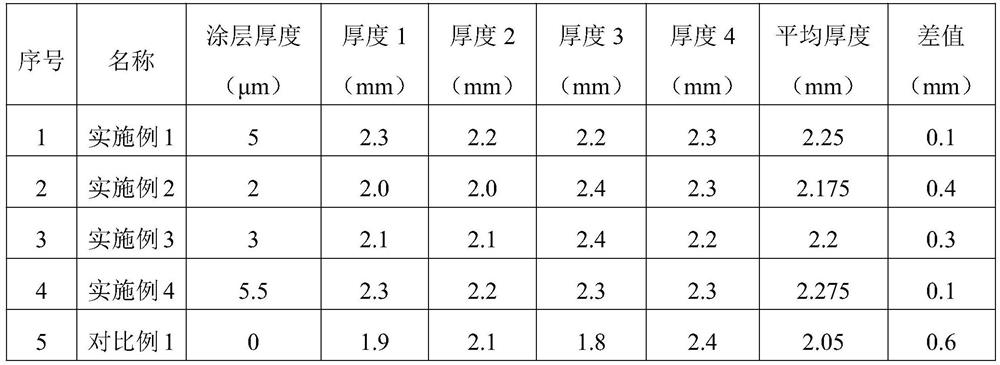

Preparation method of high-flame-retardant fireproof cable

PendingCN114596998AAvoid crackingReduce eccentricityFireproof paintsClimate change adaptationInsulation layerElectric cables

The invention discloses a preparation method of a high-flame-retardant fireproof cable. The preparation method comprises the following steps: 1) wire drawing and twisting of a wire core; 2) stranded wire insulation; (3) twisting the cable; (4) preparing an organic coating; (5) fireproof mud is extruded and coated; (6) re-preparing the organic coating; and 7) cable insulation. By optimizing the components and proportion of the fireproof mud, the flowability and adhesion of the fireproof mud are ensured; and the special organic coating is pre-coated on the surface of the cable, so that the bonding effect of the fireproof mud and the cable is improved, and meanwhile, moisture in the fireproof mud is prevented from permeating into the internal conductive cable. And a specific organic coating is further sprayed on the outer layer of the coated fireproof mud, so that evaporation of water is prevented, and cracking of the fireproof mud due to drying is avoided. In the insulation extrusion molding process of the cable containing the composite coating, small-angle reciprocating rotation is applied to the cable, the situation that the thicknesses of insulation layers on the upper surface and the lower surface of the cable are inconsistent due to gravity is avoided, and the eccentricity of the cable is reduced.

Owner:金龙电缆科技有限公司

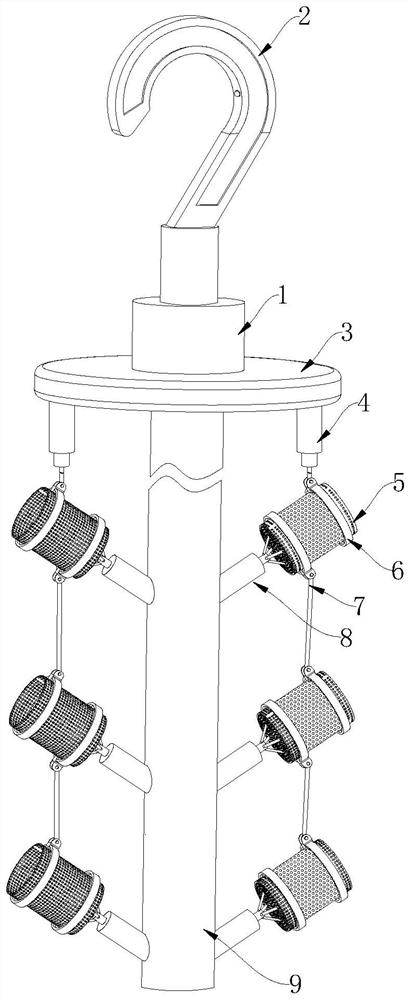

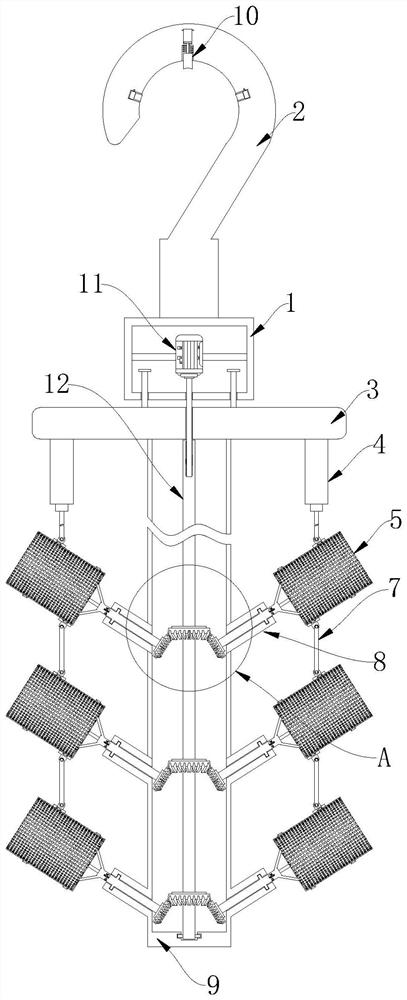

Clamp for nickel plating protection

InactiveCN114293239AAvoid incomplete nickel platingNickel plating is beneficialElectrolysis componentsMetallurgyReciprocating motion

The invention relates to the technical field of nickel plating clamps, in particular to a nickel plating protection clamp which comprises a mounting table, a hook is fixedly connected to the top wall of the mounting table, a servo motor is fixedly mounted in the mounting table and electrically connected with a power source, and a supporting frame is movably mounted at the bottom end of the mounting table. A supporting column is fixedly connected to the center of the bottom wall of the supporting frame, and a rotating shaft driven by a servo motor is rotationally installed in the supporting column. According to the nickel plating device, each part is correspondingly placed in one part containing barrel, the parts of different shapes can be stored in the part containing barrels, nickel plating can be conveniently conducted on the parts of different sizes and shapes, and vertical reciprocating motion of a supporting frame and a supporting column can be achieved through forward and reverse rotation of a servo motor; the air bubbles adsorbed on the surface of the part can be diffused to the liquid level along with movement of the part, meanwhile, nickel ions in the plating solution pool can move and are evenly distributed, and the phenomenon that the thickness of a plating layer is inconsistent is avoided.

Owner:蒋昊良

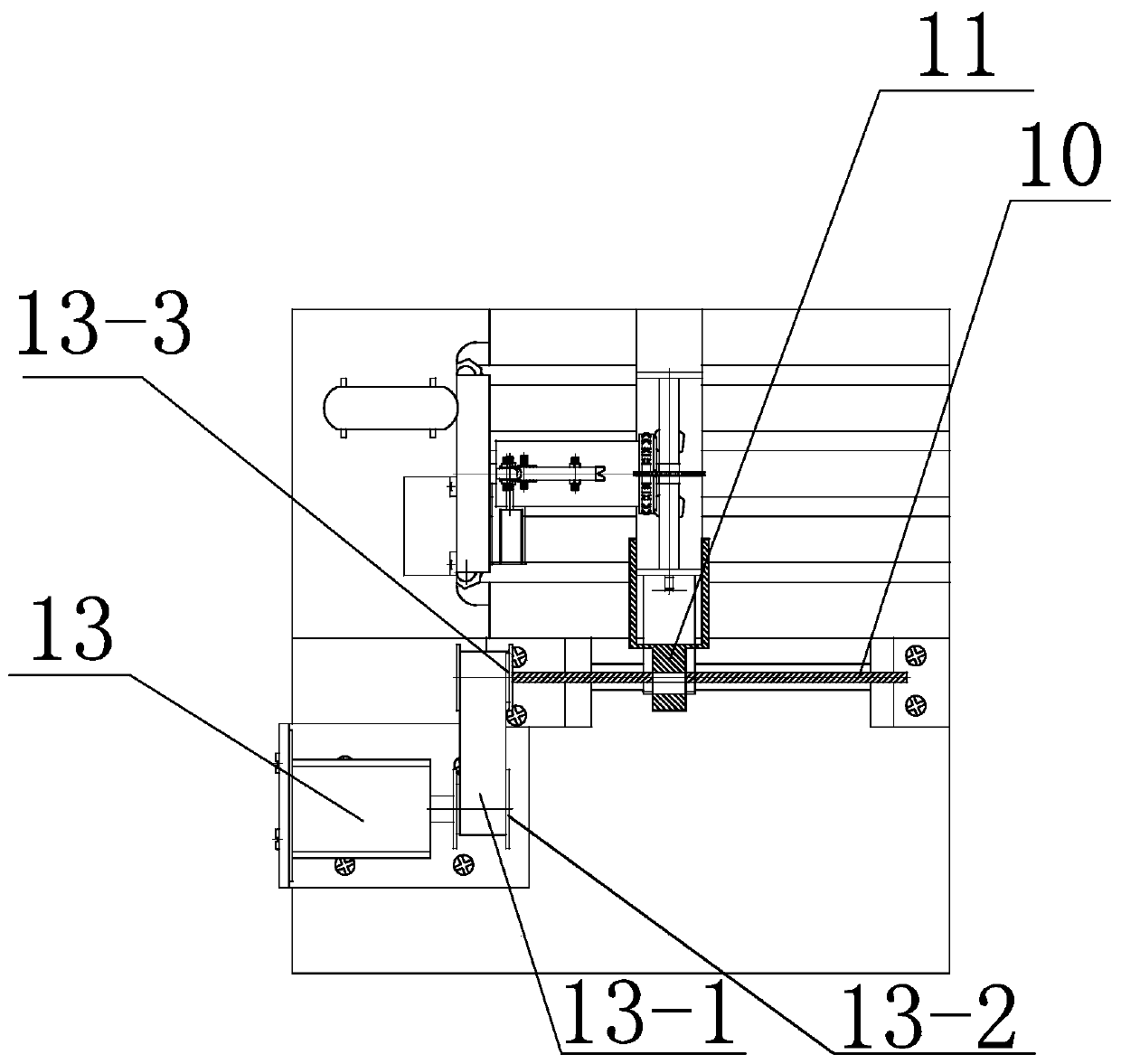

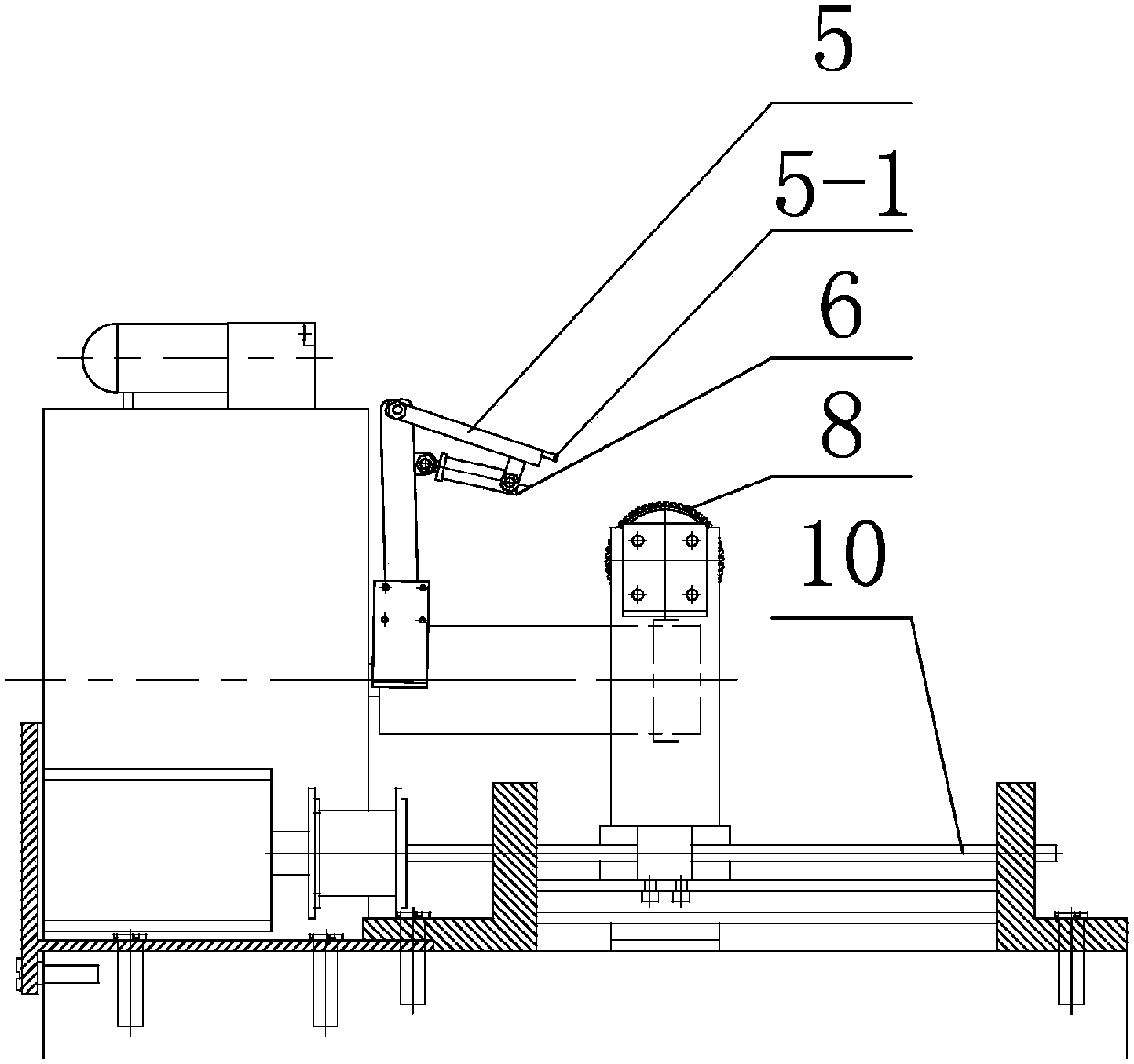

A device and method for making the thickness of the locking claw of the cage consistent

ActiveCN109648149BAvoid the situation where there is inconsistent thickness on both sidesAvoid inconsistent thicknessAutomatic control devicesMeasurement/indication equipmentsRobotic armElectric machinery

The invention discloses a device and method for enabling the thickness of retainer locking claws to be consistent, and relates to the technical field of bearing structure machining. For solving the problem that when the cutter is aligned with the centers of the retainer locking claws manually, and the thicknesses of two sides of a part of the locking claws of 12 pairs of the locking claws in the machined single retainer are inconsistent, the device comprises a second control motor, a power supply, the retainer, the cutter, a bottom base, a machine base, a first control motor, an air pump, a first mechanical arm, a second mechanical arm, an alignment mechanism, a telescopic air cylinder and a cutter bar, wherein before the bearing retainer is machined, centering and positioning are carriedout on the cutter and the retainer through the alignment mechanism, after the centering and positioning is confirmed, the locking claws of the bearing retainer is machined, and the situation that dueto the fact that the cutter is not consistent with the centers of the retainer locking claws, the thickness of the two sides of the part of the locking claws of the machining completed retainer are caused to be inconsistent is avoided. The device and the method are suitable for the centering and positioning the cutter and the retainer locking claws and enabling the thickness of the two sides of the machined retainer locking claws to be consistent.

Owner:AVIC HARBIN BEARING

Device and method for enabling thickness of retainer locking claw to be consistent

ActiveCN109648149AReduce material costsImprove work efficiencyAutomatic control devicesMeasurement/indication equipmentsEngineeringMachining

The invention discloses a device and method for enabling the thickness of retainer locking claws to be consistent, and relates to the technical field of bearing structure machining. For solving the problem that when the cutter is aligned with the centers of the retainer locking claws manually, and the thicknesses of two sides of a part of the locking claws of 12 pairs of the locking claws in the machined single retainer are inconsistent, the device comprises a second control motor, a power supply, the retainer, the cutter, a bottom base, a machine base, a first control motor, an air pump, a first mechanical arm, a second mechanical arm, an alignment mechanism, a telescopic air cylinder and a cutter bar, wherein before the bearing retainer is machined, centering and positioning are carriedout on the cutter and the retainer through the alignment mechanism, after the centering and positioning is confirmed, the locking claws of the bearing retainer is machined, and the situation that dueto the fact that the cutter is not consistent with the centers of the retainer locking claws, the thickness of the two sides of the part of the locking claws of the machining completed retainer are caused to be inconsistent is avoided. The device and the method are suitable for the centering and positioning the cutter and the retainer locking claws and enabling the thickness of the two sides of the machined retainer locking claws to be consistent.

Owner:AVIC HARBIN BEARING

A double-sided electrophoresis rack

ActiveCN104178793BAvoid inconsistent thicknessGood electrophoresis consistencyElectrophoretic coatingsElectrophoresisEngineering

The invention relates to double-sided GPP protection transistor chip production equipment, in particular to a modified double-sided electrophoresis rack for electrophoresis. The double-sided electrophoresis frame includes a beam, a negative plate, a positive ring, a support plate, a positioning plate, a slot and a side plate. On the outer side of the upper part, the slot for connecting with the power supply of the electrophoresis equipment is fixed on the upper end of one of the side plates, the two ends of the supporting plate are horizontally fixed on the lower inner side of the two side plates, and several negative plates and positive rings are alternately fixed on the supporting plate. board. Using a double-sided electrophoresis frame, the consistency of electrophoresis on both sides of the silicon wafer at the same time is good, avoiding the problem of inconsistent thickness of the glass layers on both sides of the silicon wafer caused by two single-sided electrophoresis, and the simultaneous electrophoresis on both sides is not easy to be damaged, thereby improving product yield and reliability.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

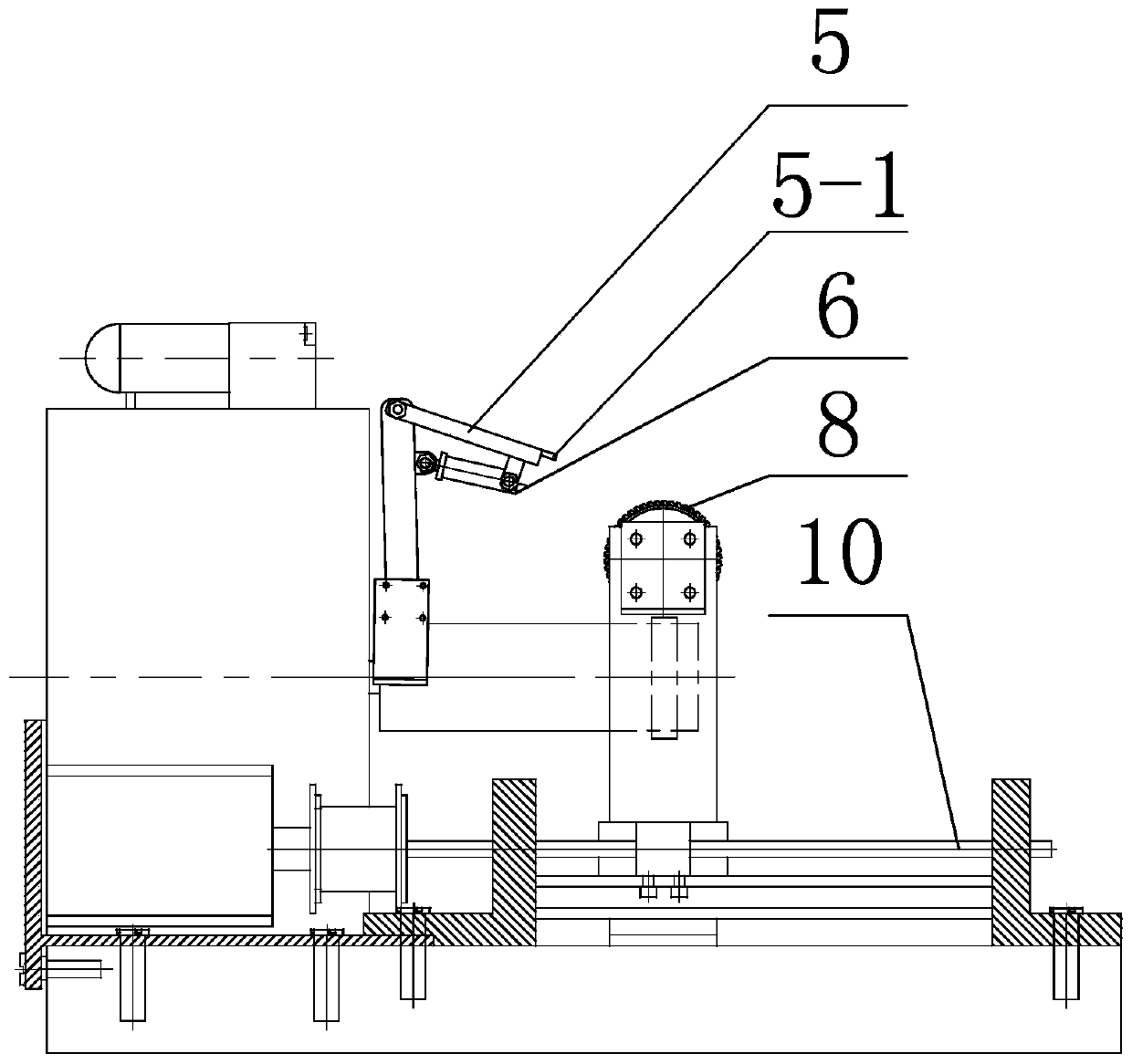

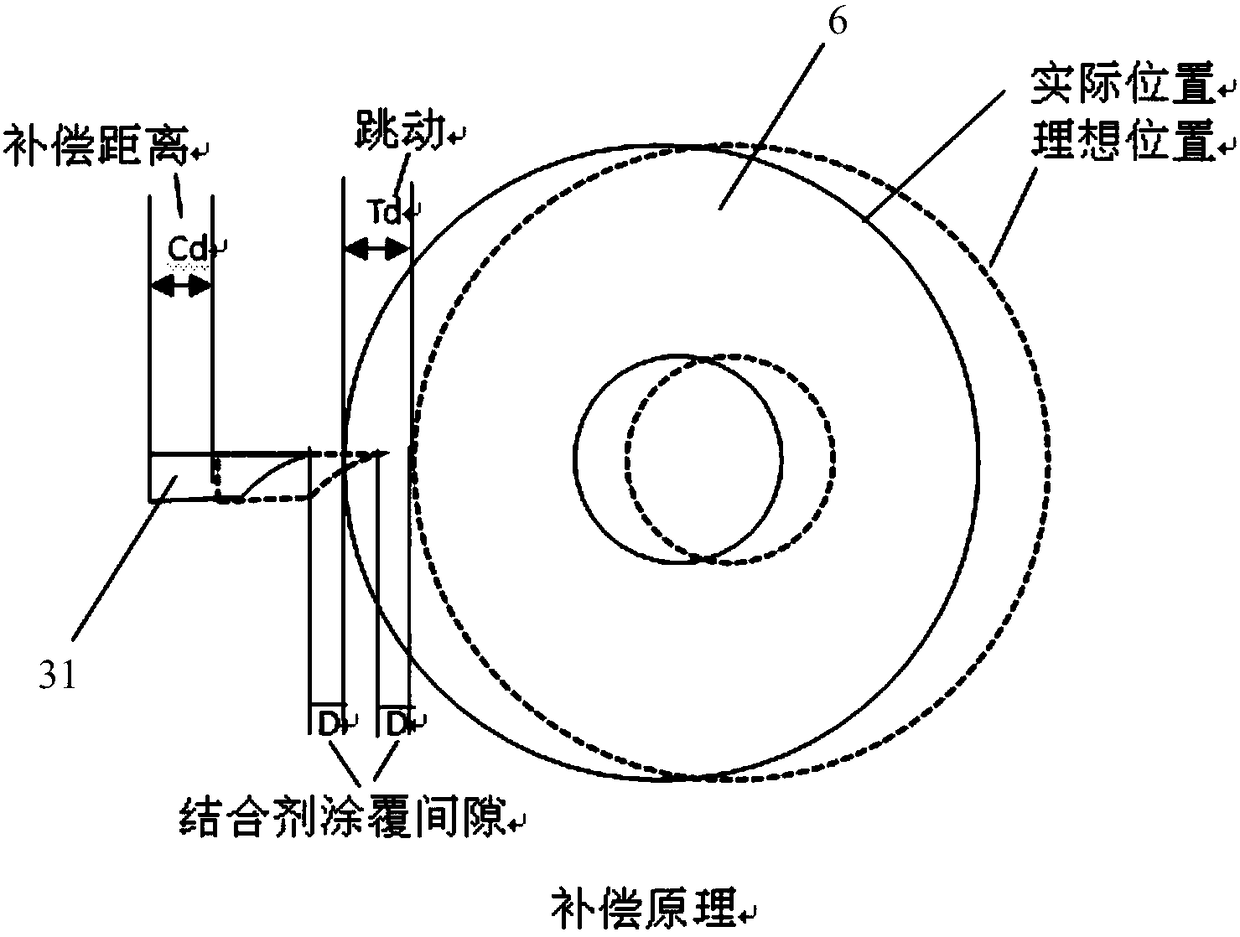

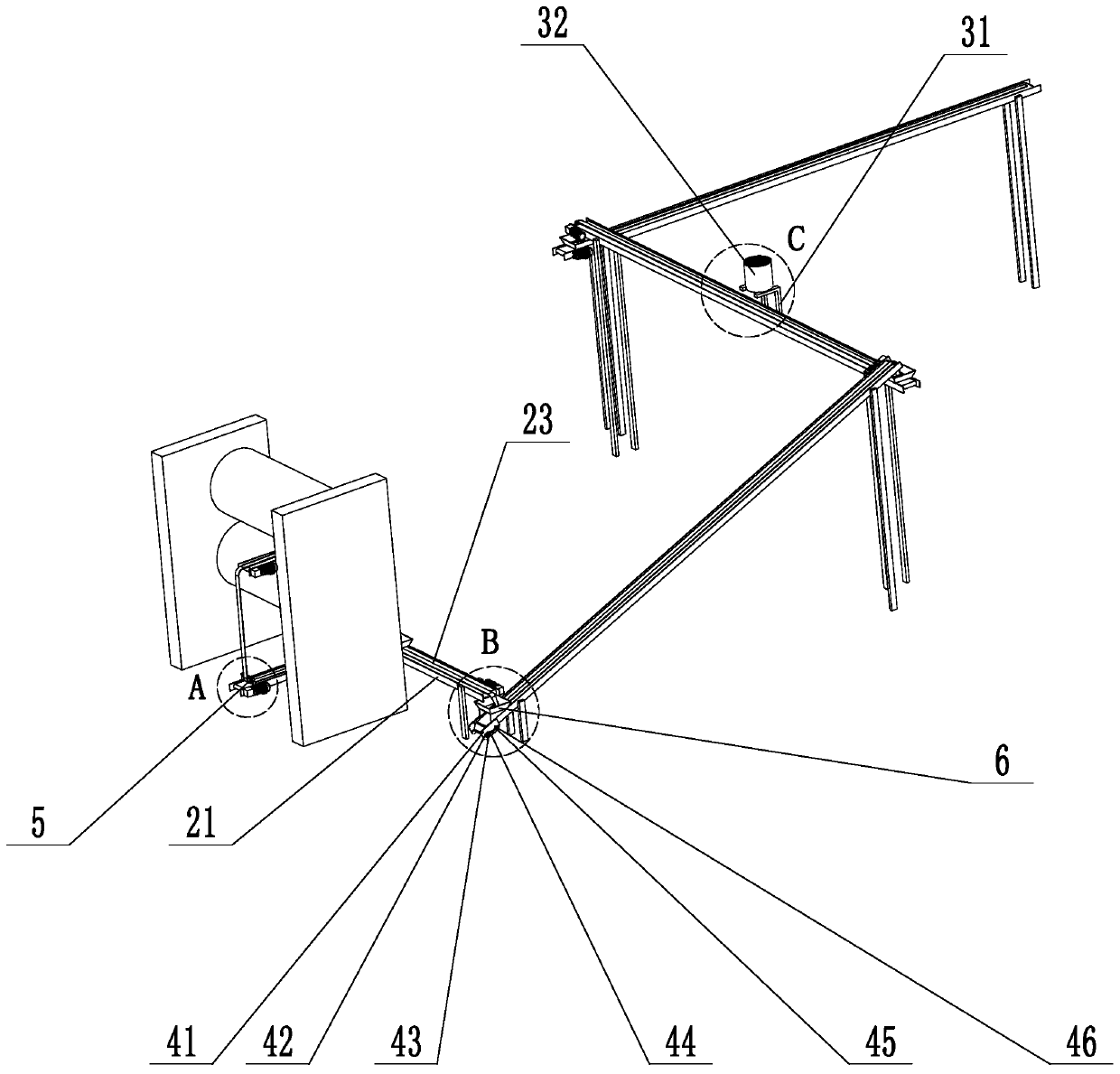

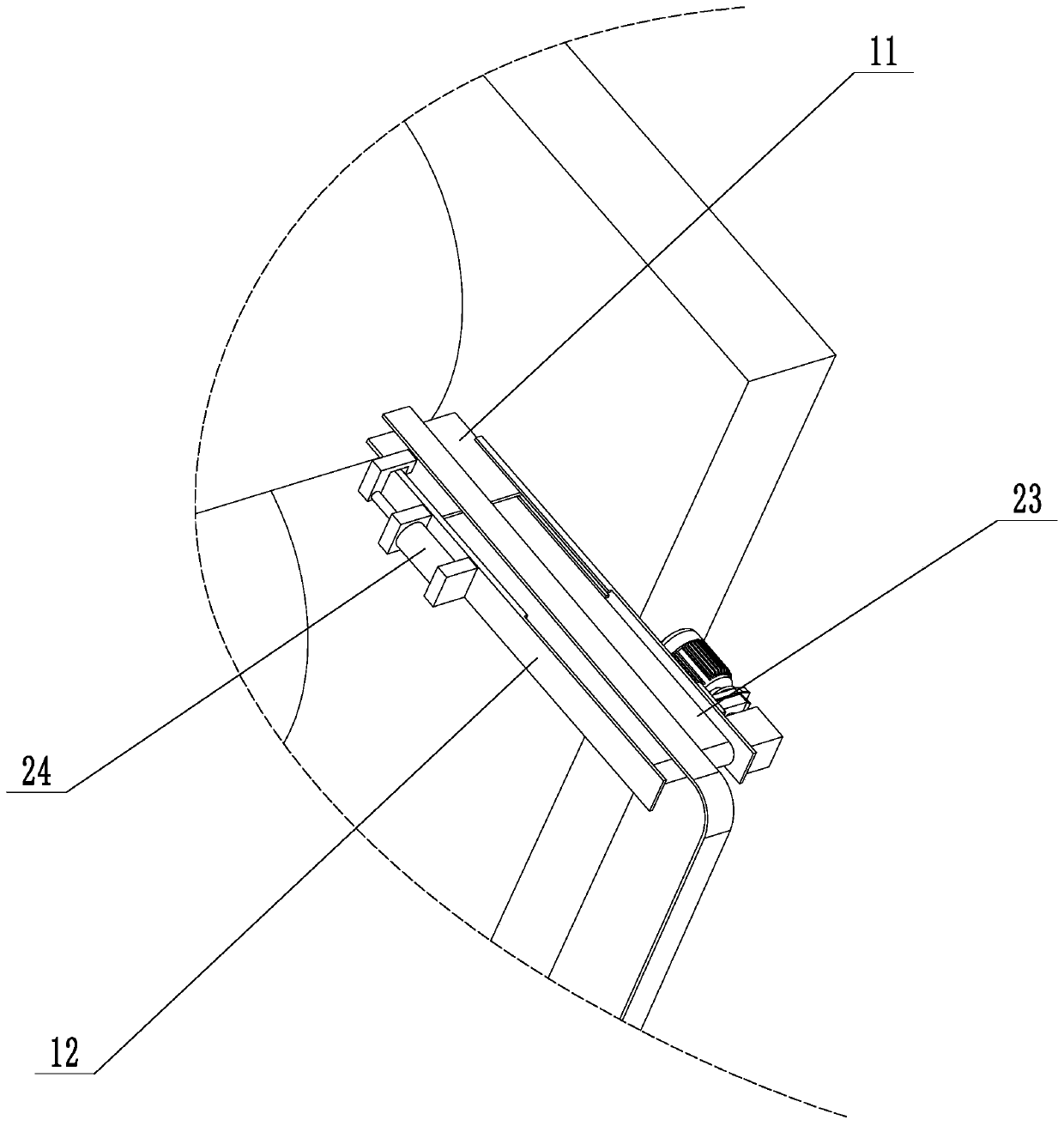

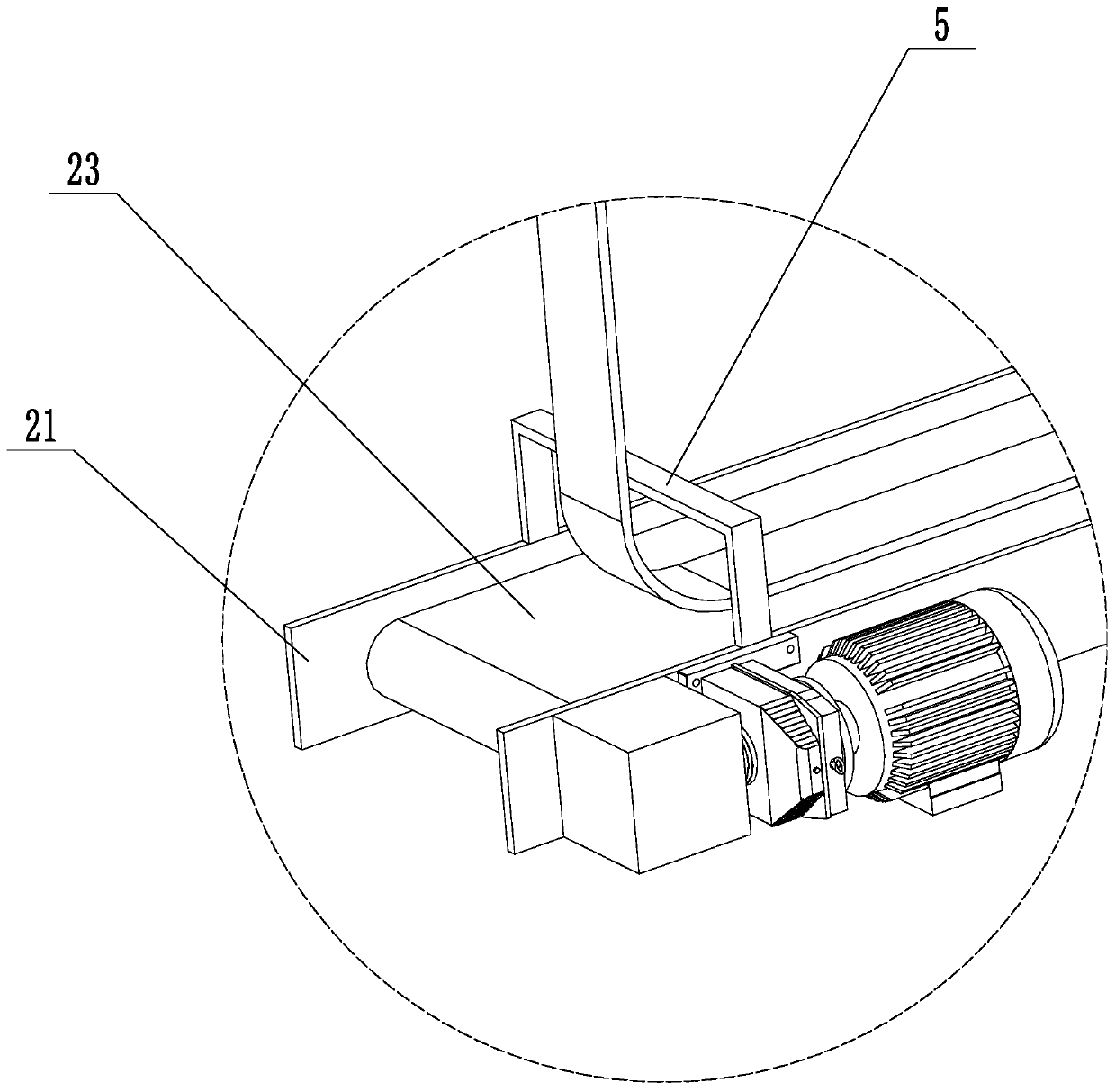

Method and device for manufacturing a single-layer abrasive wheel

ActiveCN105965408BUniform coatingAvoid inconsistent thicknessGrinding devicesGrinding wheelFixed position

The invention discloses a manufacturing method and device for a single-layer abrasive particle grinding wheel. The method includes the following steps that firstly, a fixed-thickness structure is adjusted so that an unchangeable binding agent coating gap can be formed by the fixed-thickness structure and a to-be-coated work face of a grinding wheel base body; secondly, the to-be-coated work face of the rotating grinding wheel base body is coated with a binding agent, the binding agent is smeared to the whole grinding wheel base body through the rotation movement of the grinding wheel base body, meanwhile, the excessive binding agent smeared to the surface of the grinding wheel is spread and removed through the fixed-thickness structure under the restraint of the binding agent coating gap between the fixed-thickness structure and the grinding wheel base body; thirdly, after the binding agent is smeared, the grinding wheel base body rotates continuously, abrasive particles fall at a uniform speed from the fixed position above the grinding wheel base body, and the abrasive particles can be evenly scattered on the surface of the binding agent of the grinding wheel base body by means of the rotation movement of the grinding wheel base body; and fourthly, binding agent curing is conducted on the grinding wheel base body coated with the binding agent and the abrasive particles, and the brazing abrasive particle grinding wheel is formed.

Owner:HUAQIAO UNIVERSITY

Novel rubber inverting device for tire cord calendaring machine

The invention relates to a novel rubber inverting device for a tire cord calendaring machine. The novel rubber inverting device comprises a plurality of transporting machines which are sequentially connected end to end for transporting edge rubber, and a rubber scraping part which is arranged on the first transporting machine and is used for collecting edge rubber from a roller of the calendaringmachine, wherein the output end of the last transporting machine is positioned above the input end of the next transporting machine; the rubber scraping part comprises a scraping plate which is arranged on the first transporting machine and is used for scraping edge rubber on the roller of the calendaring machine; each transporting machine comprises a transporting slot and a belt transporting mechanism arranged in the transporting slot, the belt transporting mechanism comprises two or more transmission rollers which are rotatably connected to the transporting slot, a conveyor belt which is used for sequentially connecting two or more transmission rollers, and a power device arranged on the transporting slot, and the output end of the power device is connected to one transmission roller. The novel rubber inverting device is used for collecting edge rubber on the roller of the calendaring machine, can effectively reduce vulcanized rubber particles in a product, and improves product quality.

Owner:HEBEI WANDA TIRE CO LTD

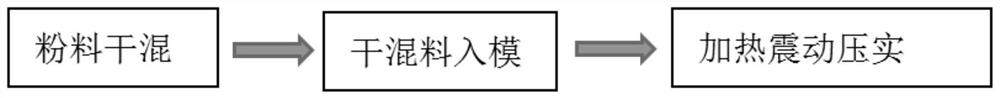

Dry powder brick pressing preparation method of lithium ion battery pole piece

PendingCN112952043ASolve the difficulty of slurry transportationSolve the problem of sedimentation and agglomerationElectrode thermal treatmentSecondary cellsComposite materialElectrical battery

The invention relates to a dry powder brick pressing preparation method of a lithium ion battery pole piece. The dry powder brick pressing preparation method comprises the following steps of: (1) preparing a dry mixed material, namely performing dry mixing on a negative electrode material raw material or a positive electrode material raw material, and adding a hot melt adhesive into the dry mixture to obtain the dry mixed material; (2) feeding the dry mixed material into a mold, namely adding the prepared dry mixed material into a battery pole piece mold which is internally provided with a base material sheet and is divided into an upper mold and a lower mold, placing the base material on the lower mold, and after the dry mixed material is placed on the base material, carrying out cavity closing pressing on the upper mold; and (3) conducting compaction, namely extruding the pole piece dry mixed material containing the hot melt adhesive in the die cavity, and heating the dry mixed material in the extrusion process to obtain the lithium ion battery pole piece. Compared with the prior art, the dry powder brick pressing preparation method has the advantages of being simple in process, low in investment cost, high in investment benefit, capable of greatly reducing the cost of the power battery, beneficial to electric automobiles and the like.

Owner:BATTERO TECH CORP LTD

A rice laying device for making crispy rice

Owner:蚌埠启邦科技信息咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com