Patents

Literature

36results about How to "Avoid screwing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

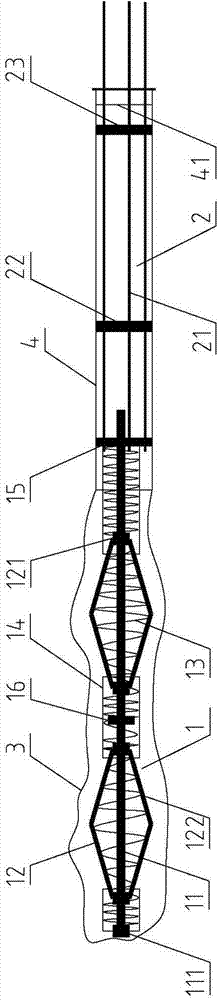

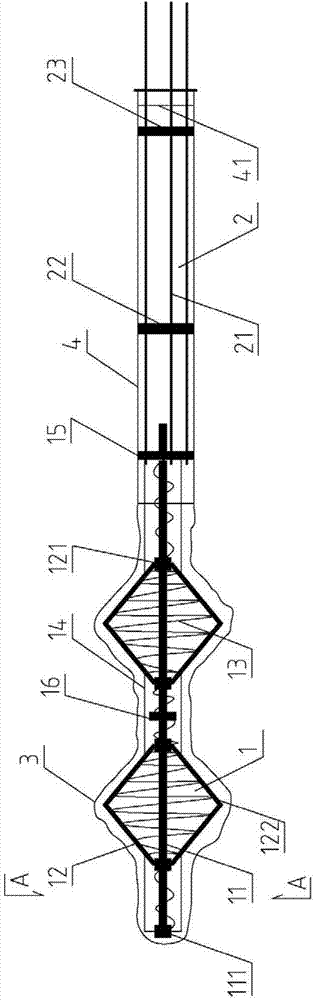

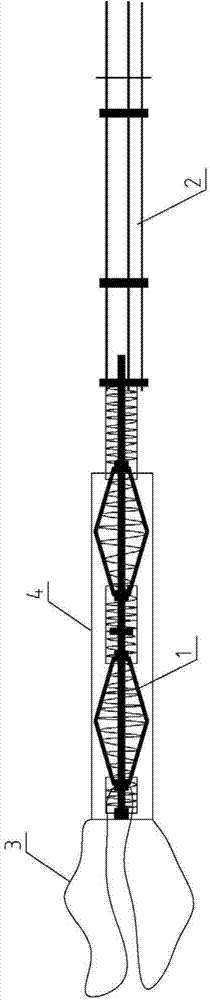

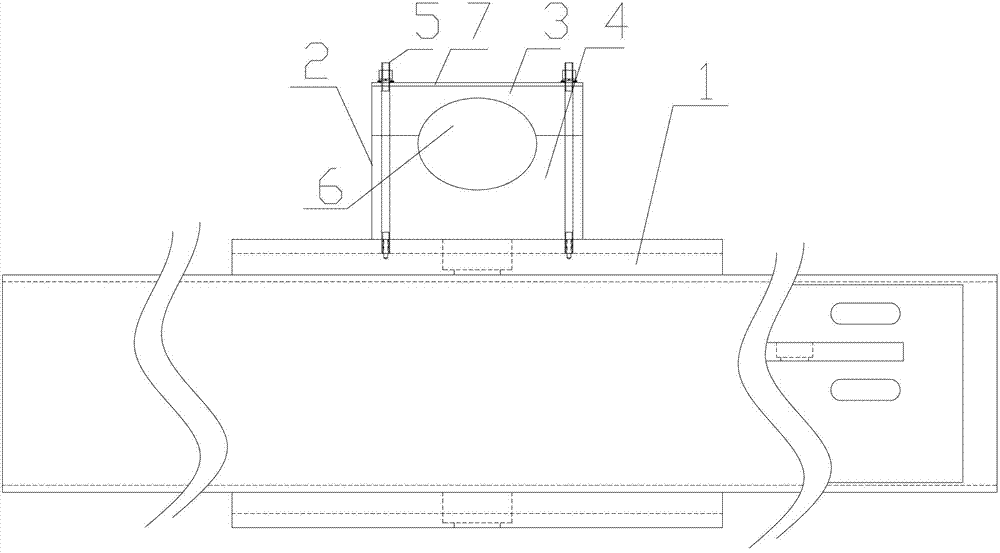

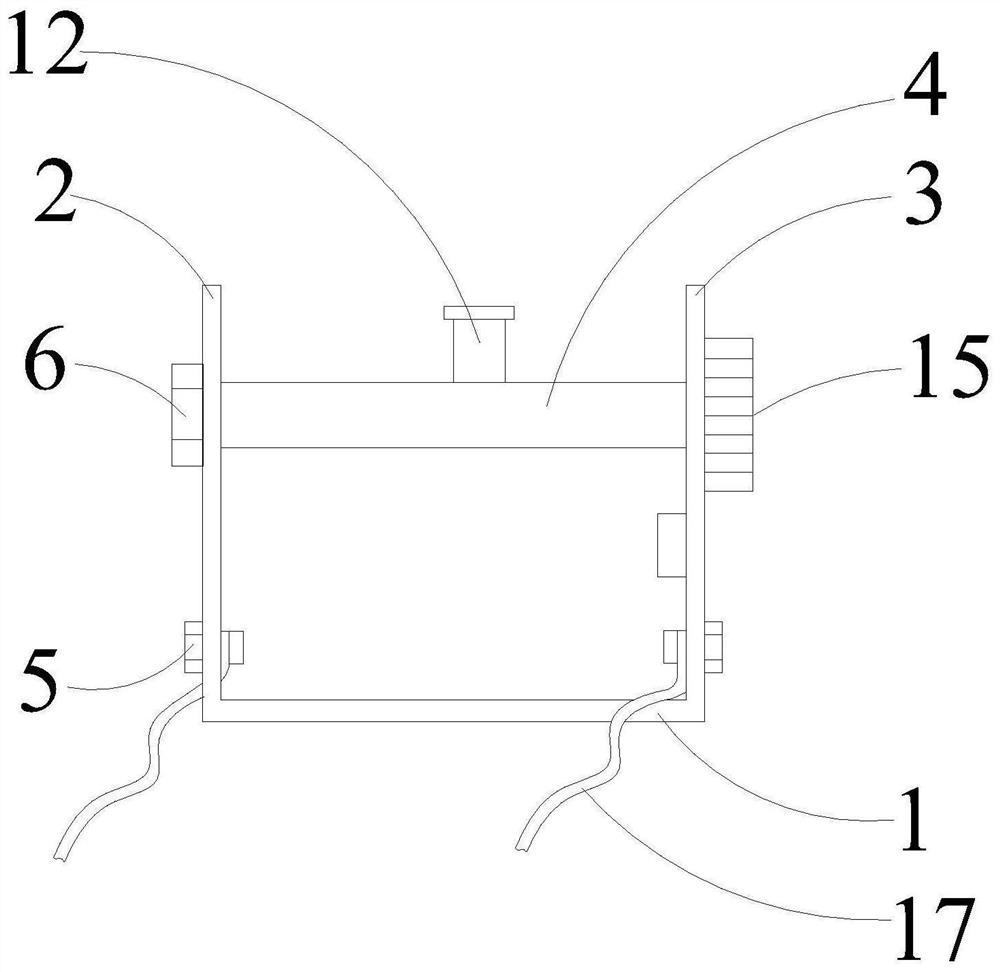

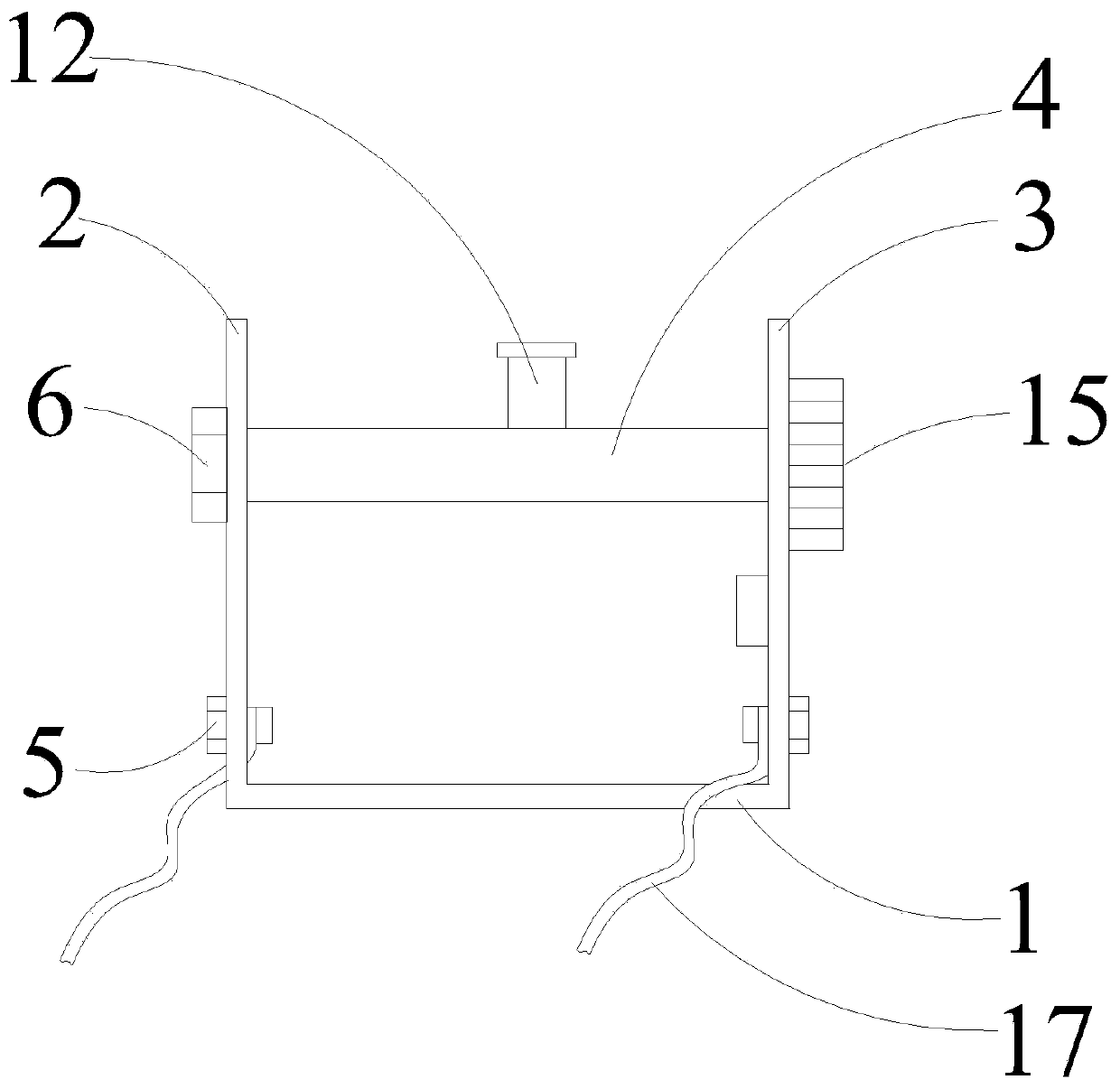

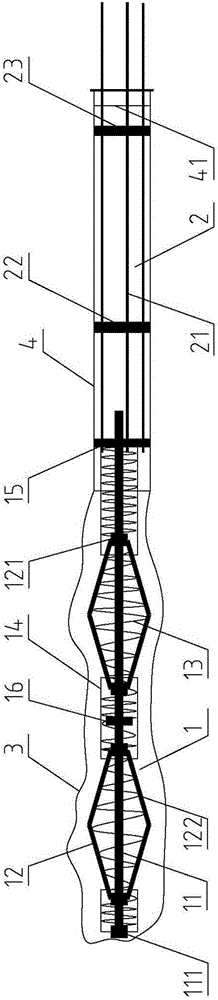

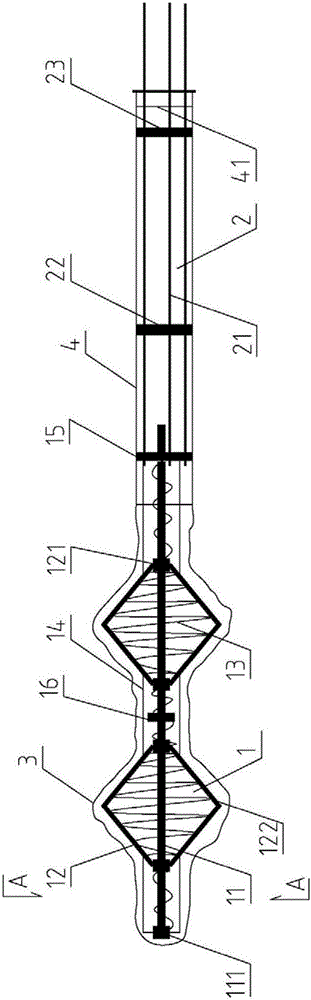

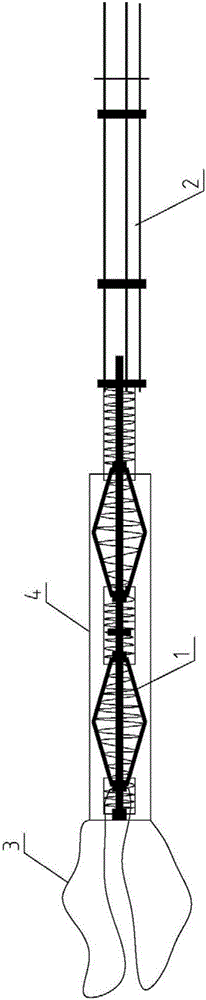

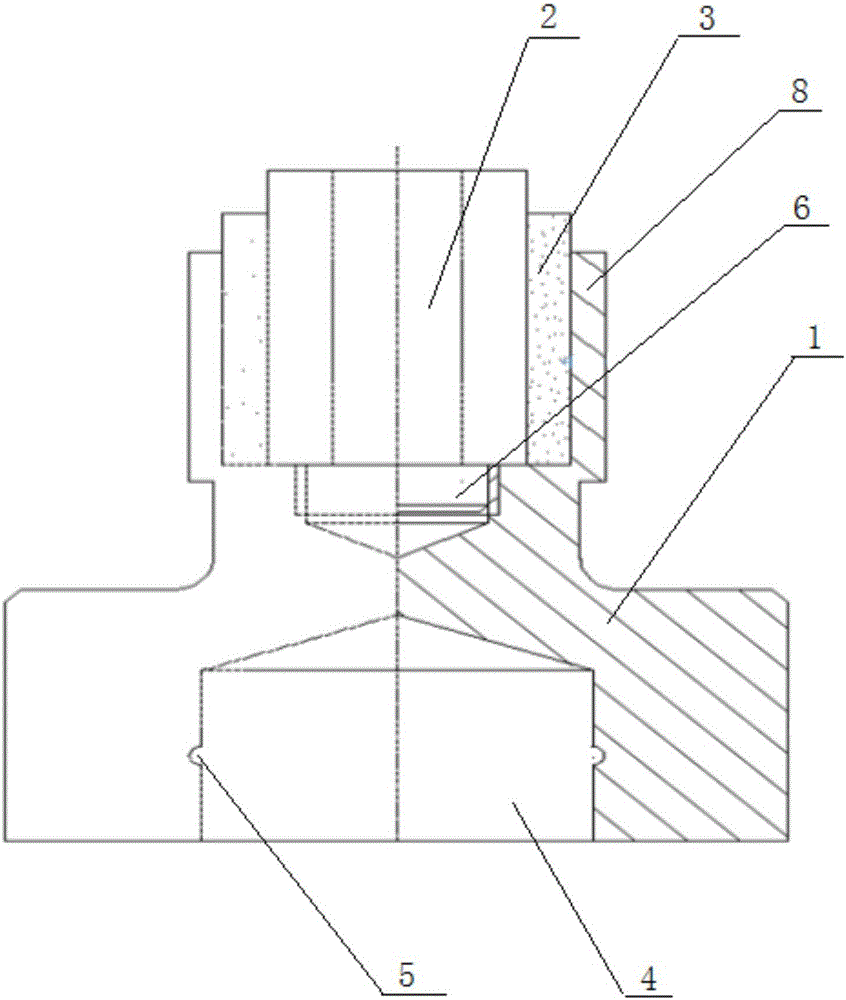

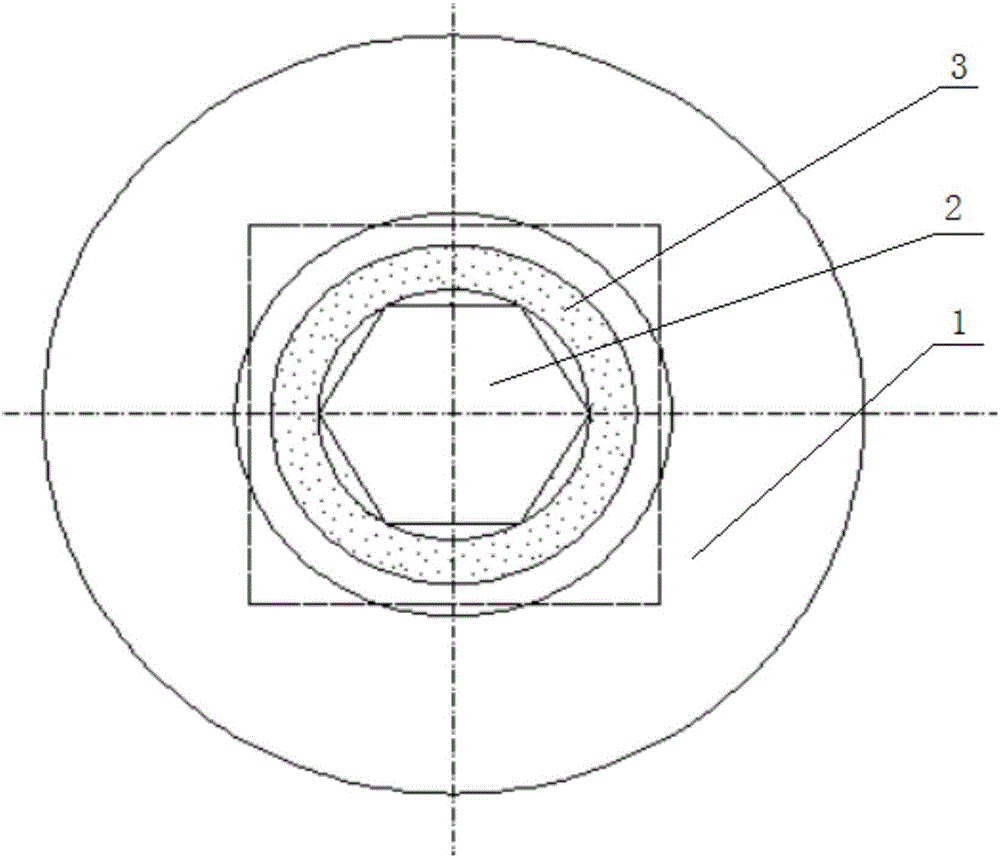

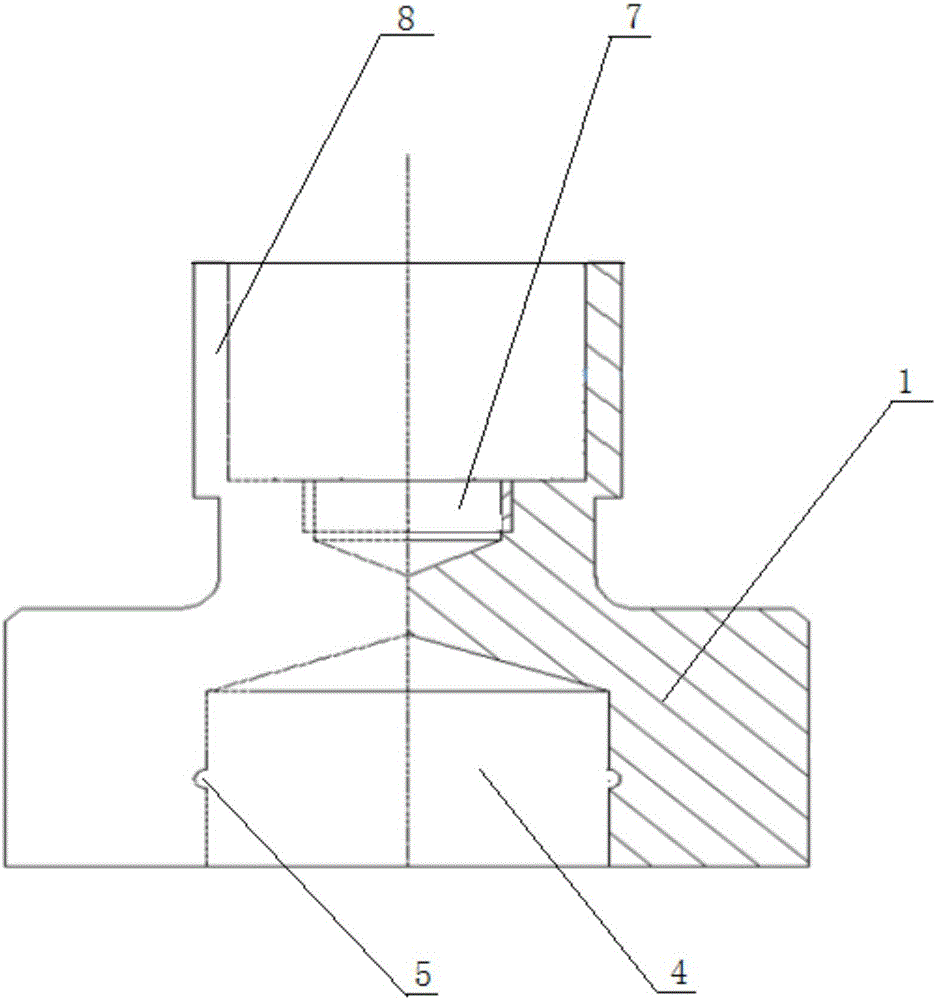

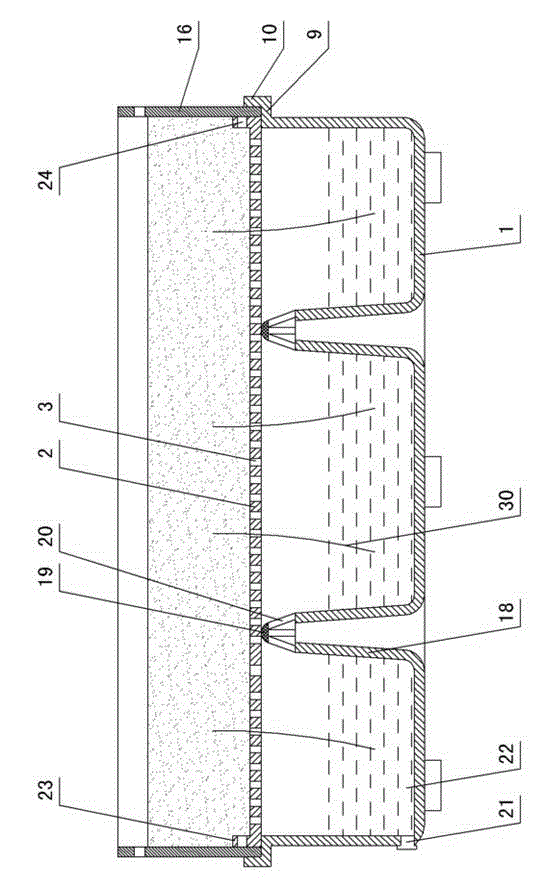

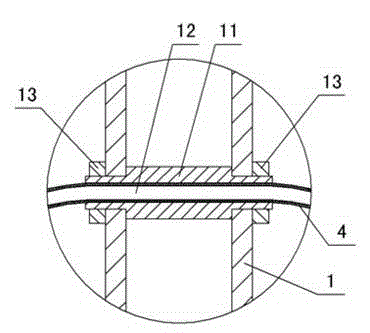

Recyclable expansion anchor rod and construction method thereof

The invention relates to a recyclable expansion anchor rod and a construction method thereof. The recyclable expansion anchor rod comprises an anchor head, a rod body, a protecting bag and a rod body protecting tube; the anchor head is composed of a screw, a herringbone expanding head, a spiral steel wire, a steel wire protecting tube and an anchoring piece; the herringbone expanding head is screwed in the screw; the spiral steel wire penetrates the herringbone expanding head to extend into the steel wire protecting tube; the steel wire protecting tube sleeves the screw; the anchoring piece is mounted at one end of the rod body; the rod body is composed of a plurality of equidistantly arranged steel strands, steel strand position fixing parts and steel strand tensioning parts, and the steel strands are respectively fixed on the anchoring piece, the steel strand position fixing parts and the steel strand tensioning parts; the protecting bag is arranged outside the anchor head; the rod body protecting tube sleeves the rod body and are in butt joint with the protecting bag. The recyclable expansion anchor rod and the construction method thereof have the advantages that simpleness in structure, convenience in mounting, repeated use and low cost are achieved and the like.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

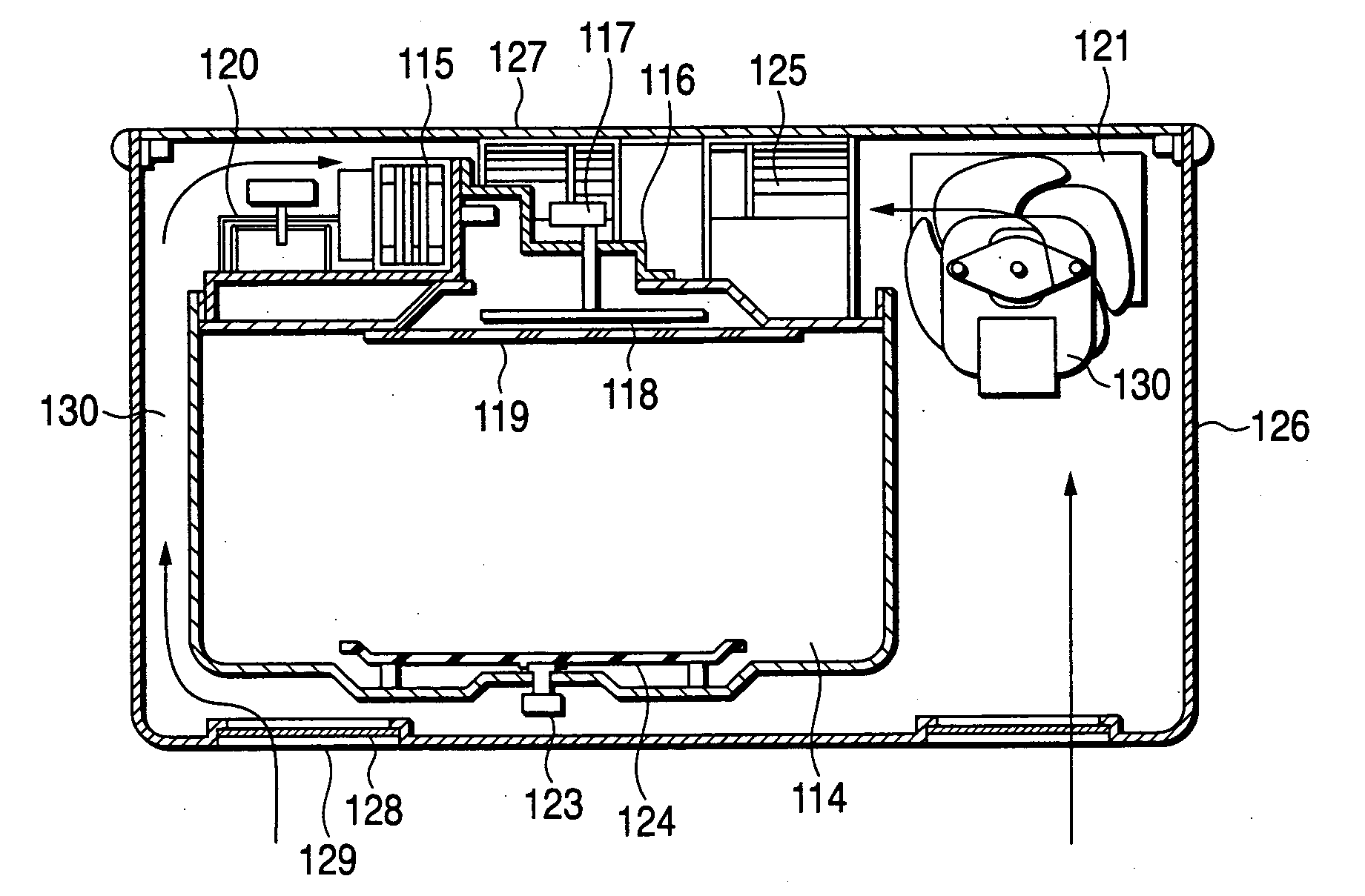

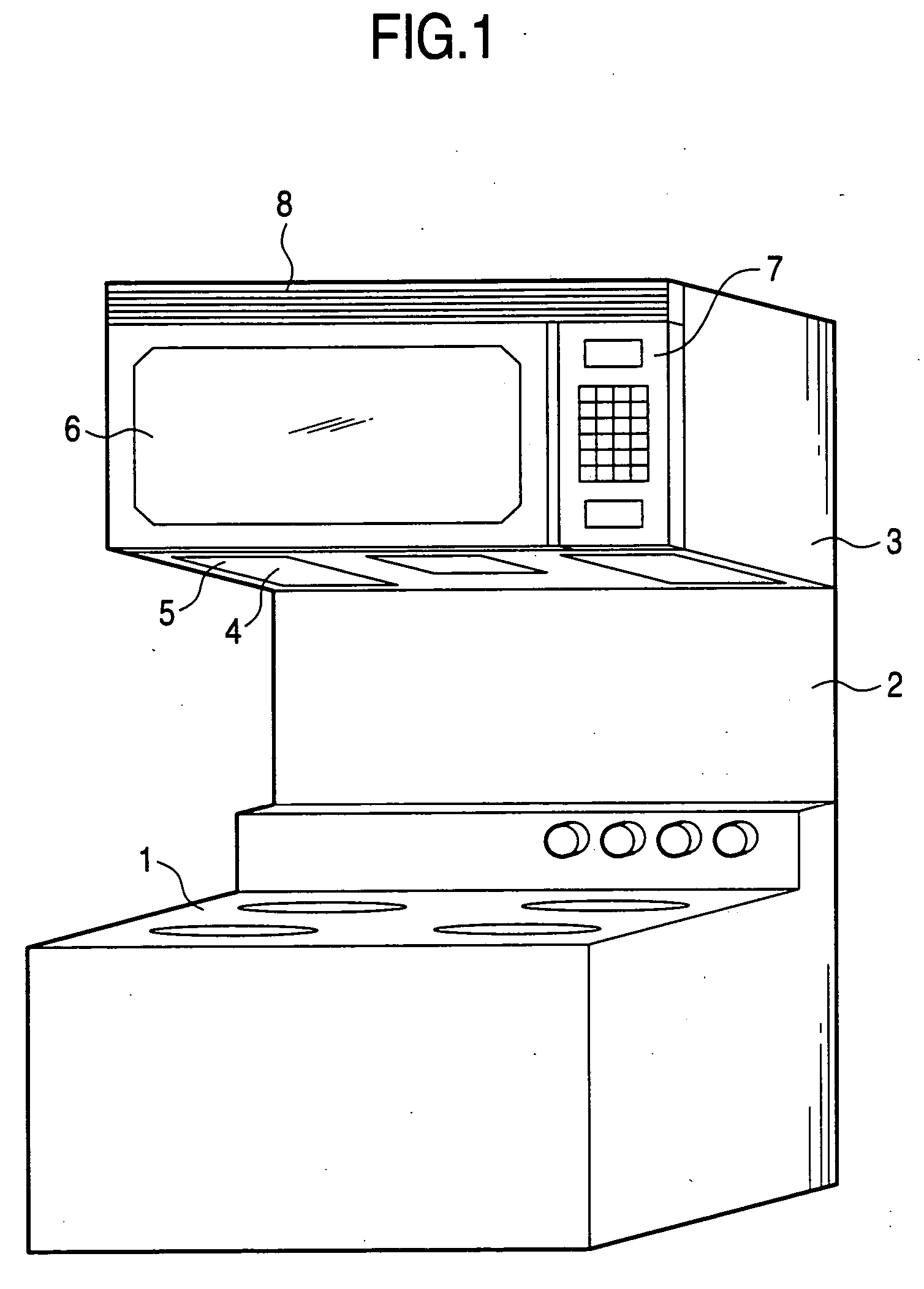

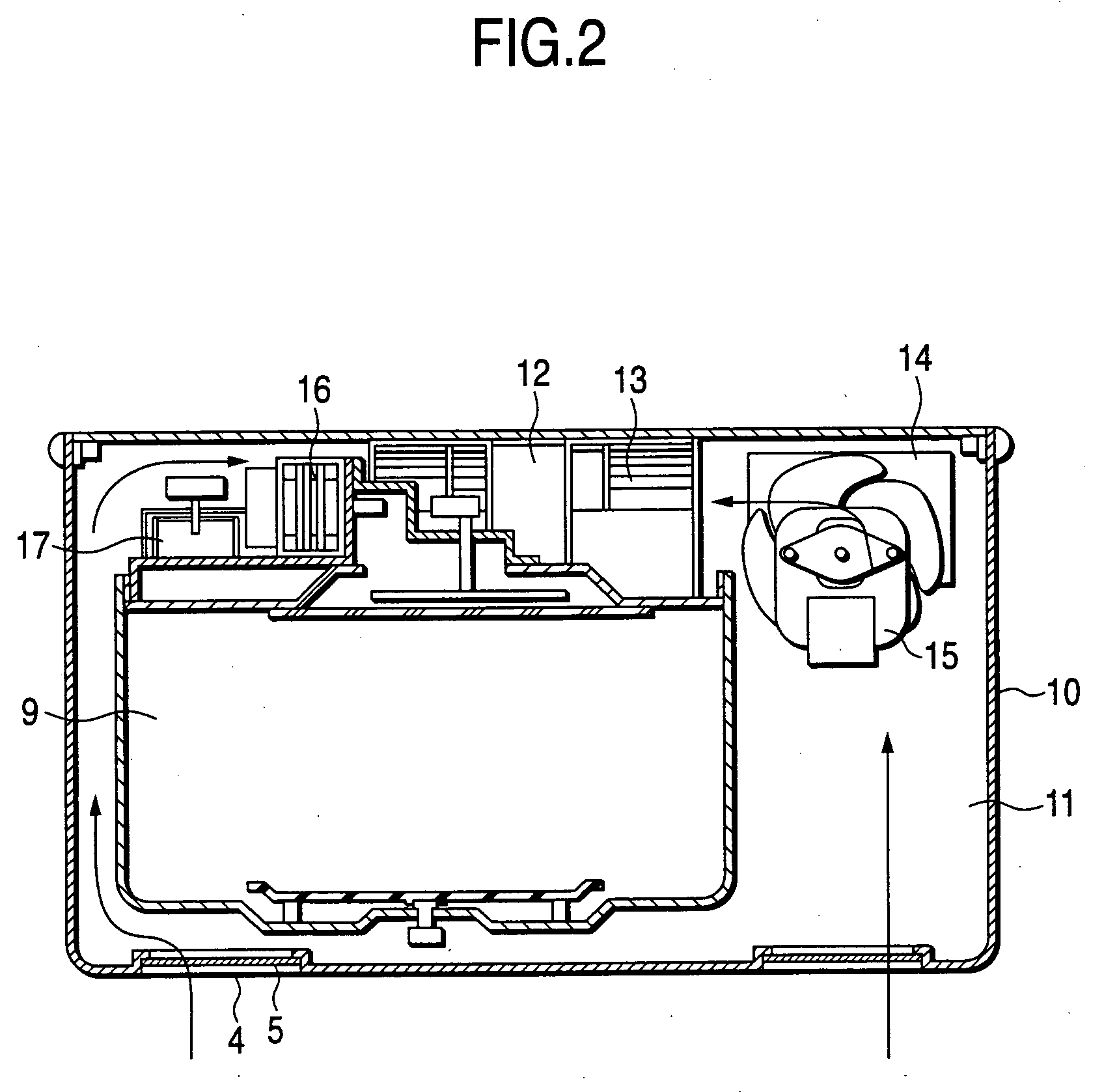

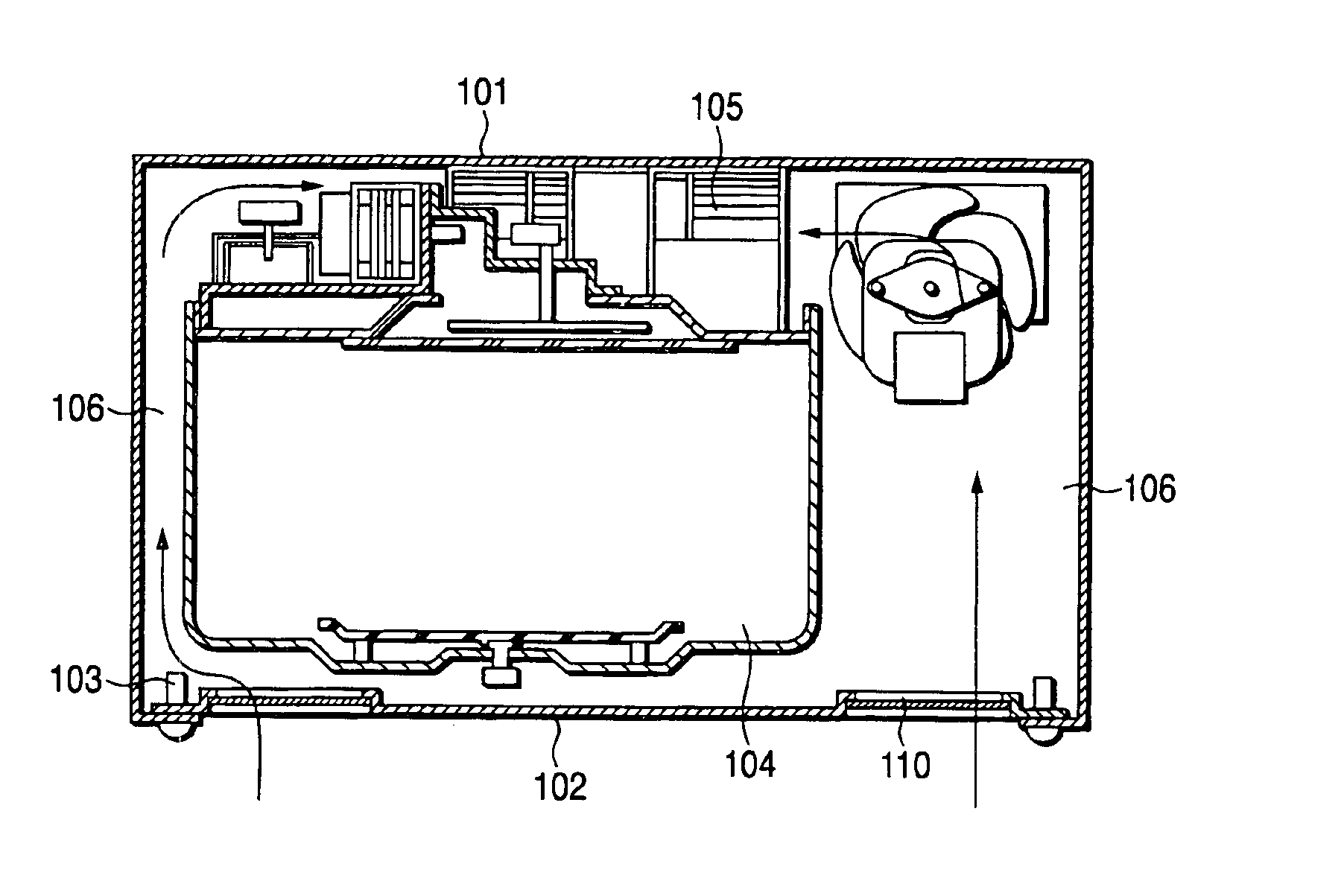

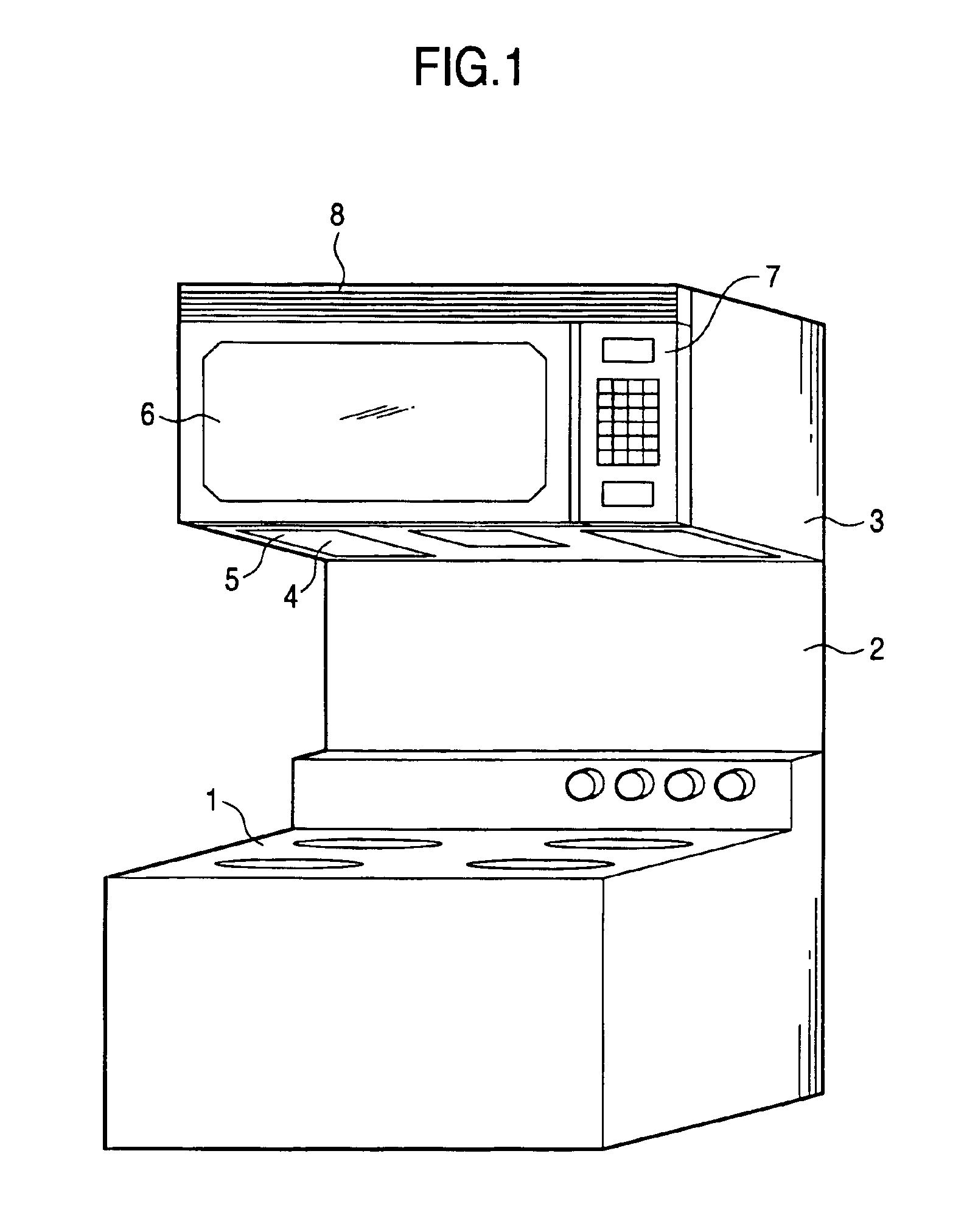

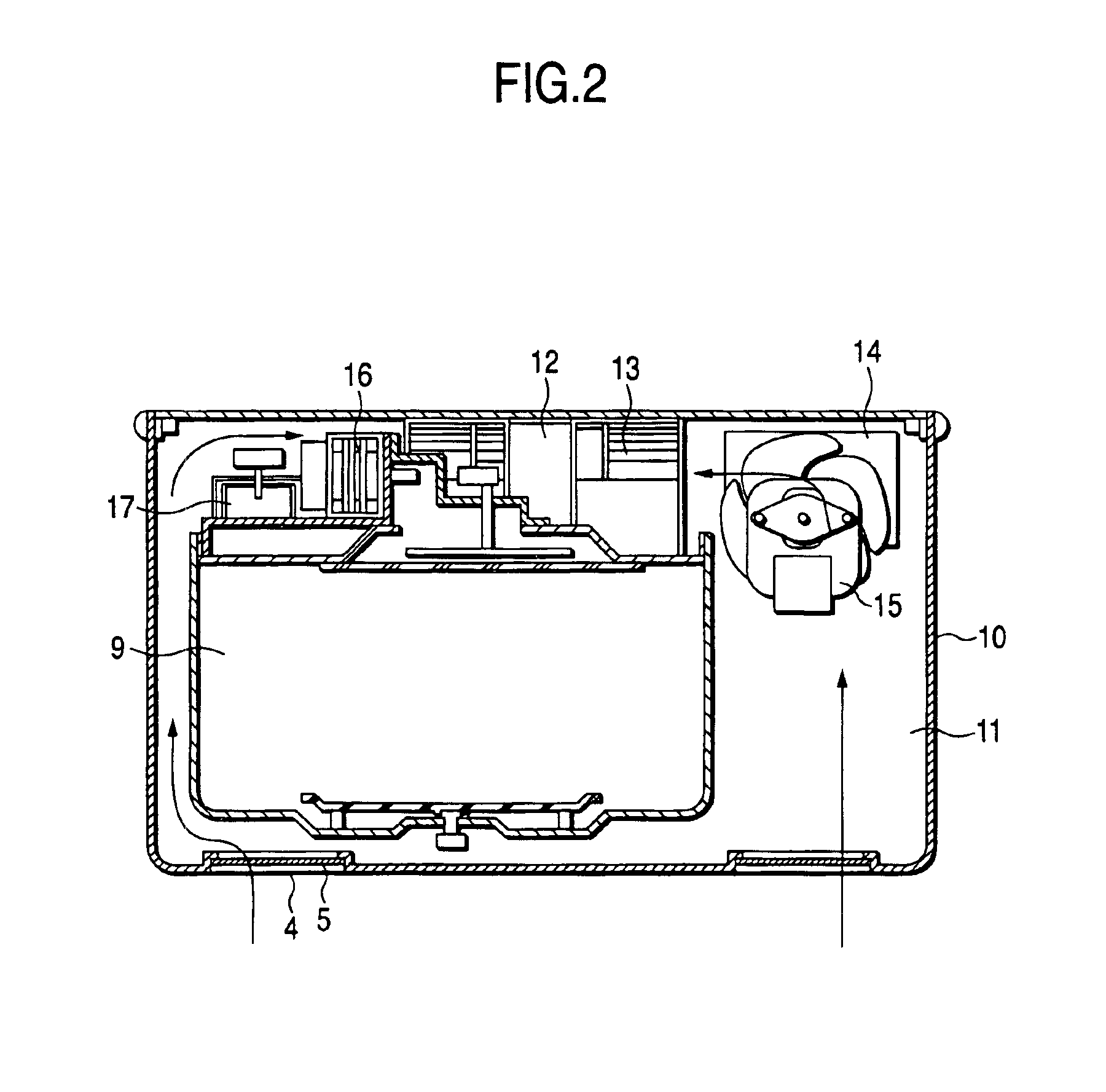

High frequency heating apparatus

InactiveUS20050178763A1Improve detachabilitySimple mannerDomestic stoves or rangesDomestic cooling apparatusEngineeringHooking

The present invention provides a high frequency heating apparatus having a structure, which can be mounted / dismounted an air-exhausting grille without any tools. In this apparatus, an air-exhausting grille is arranged by that a fixing claw portion having a bent Z-shape, a fixing hooking portion having a concave notch, and a magneto joint plate are arranged, whereas a main body located opposite to the air-exhausting grille is arranged by that a slit hole, a hooking flange, and a magneto fixing plate are arranged. As a result, since the magneto joint plate is absorbed with the magneto fixing plate to be fixed with each other, the mounting / dismounting work capability of the air-exhausting grille can be improved without using the tool in a simple manner, and furthermore, a clean cooking appliance can be secured, while the cooking appliance can be readily cleaned.

Owner:PANASONIC CORP

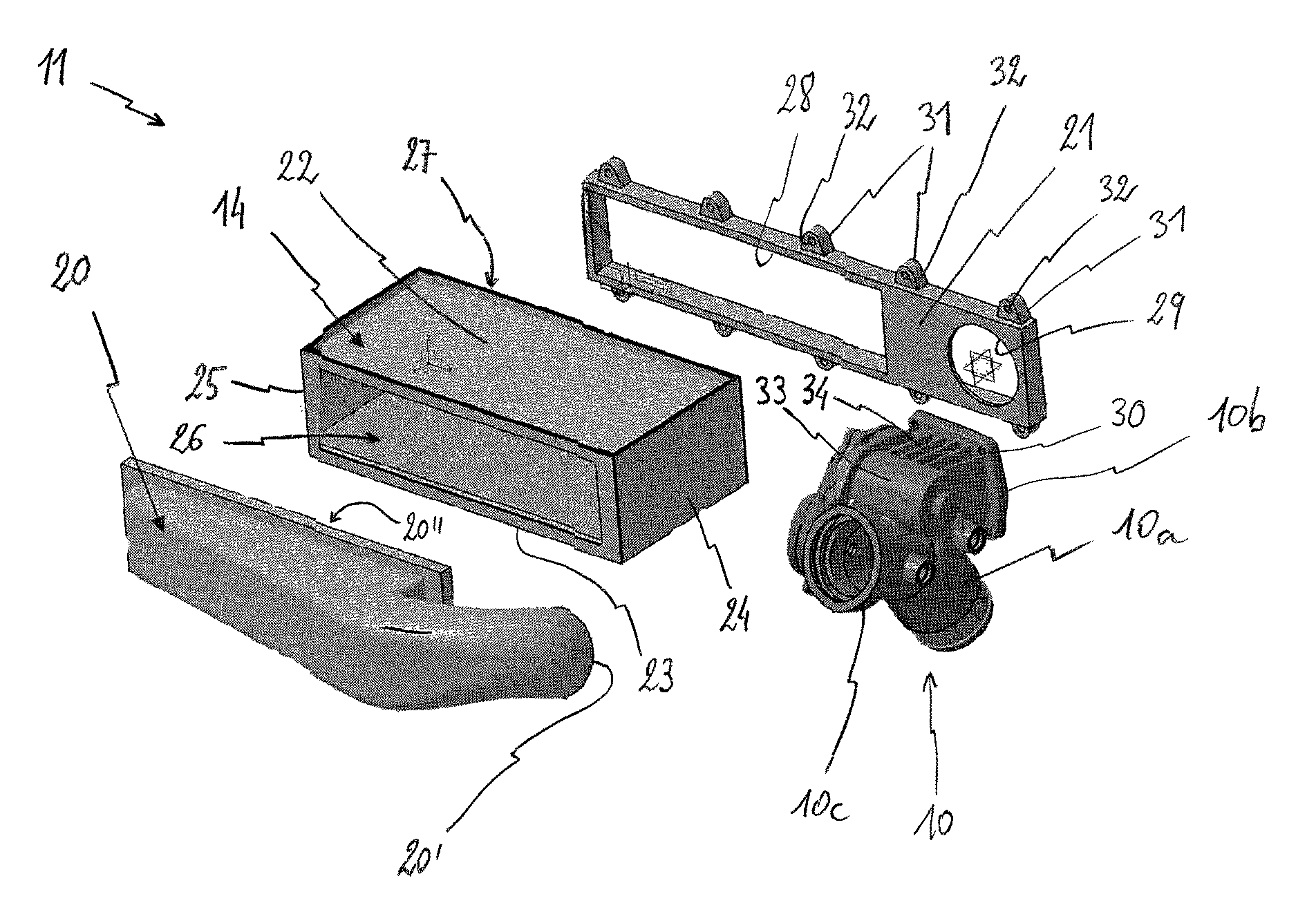

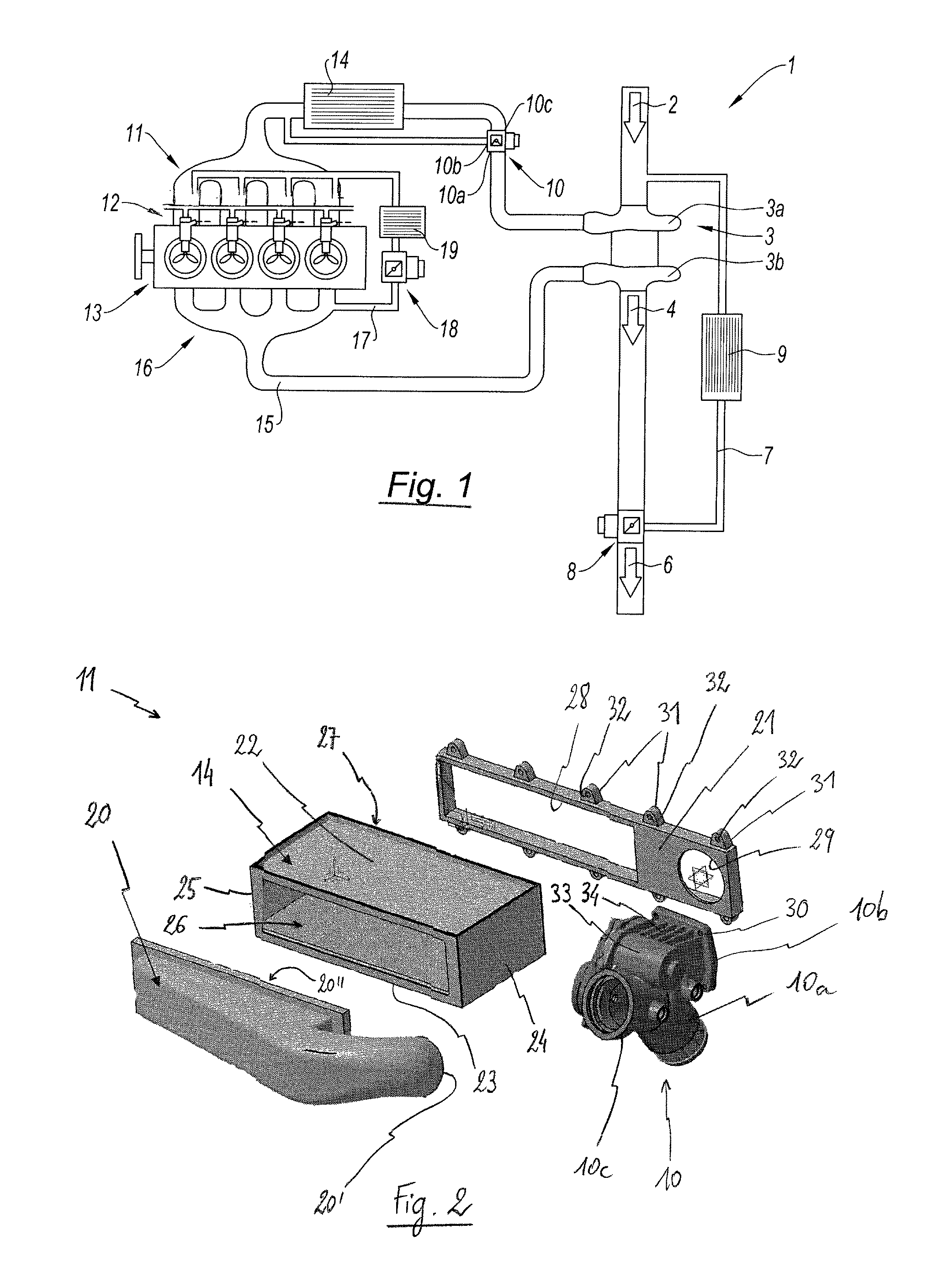

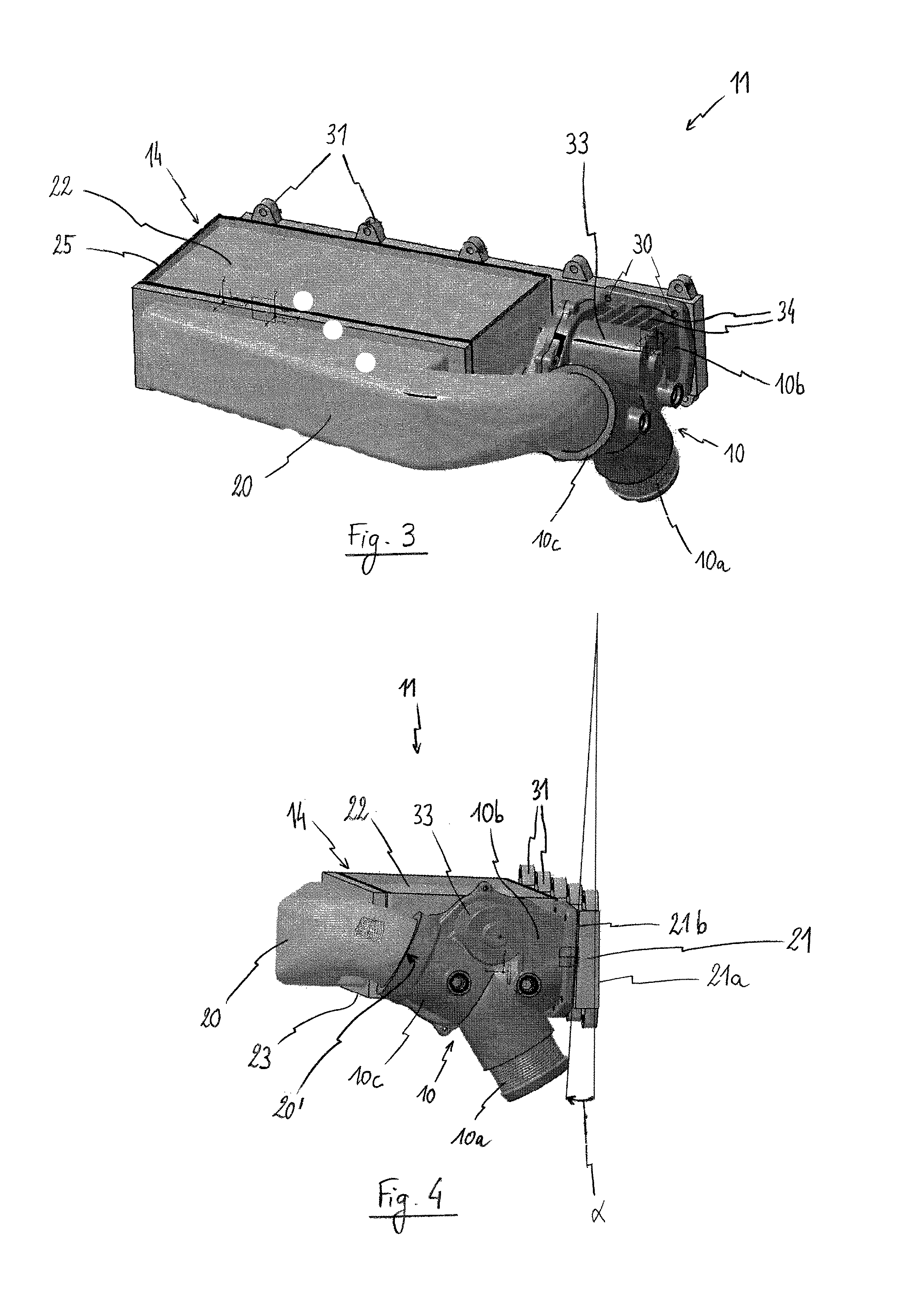

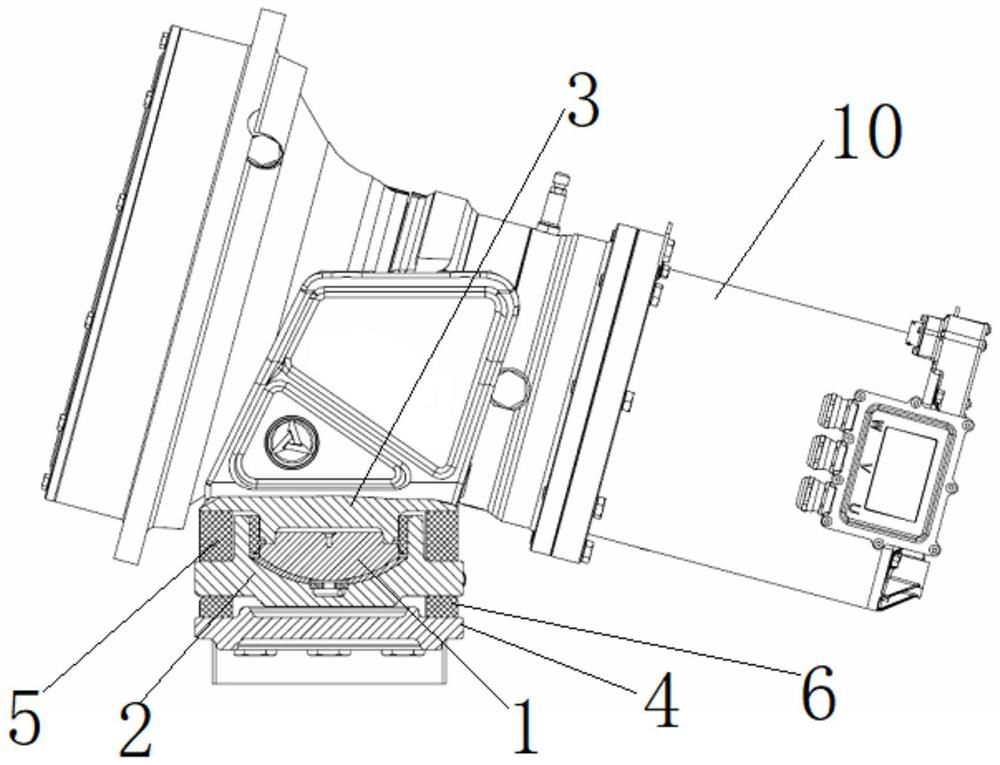

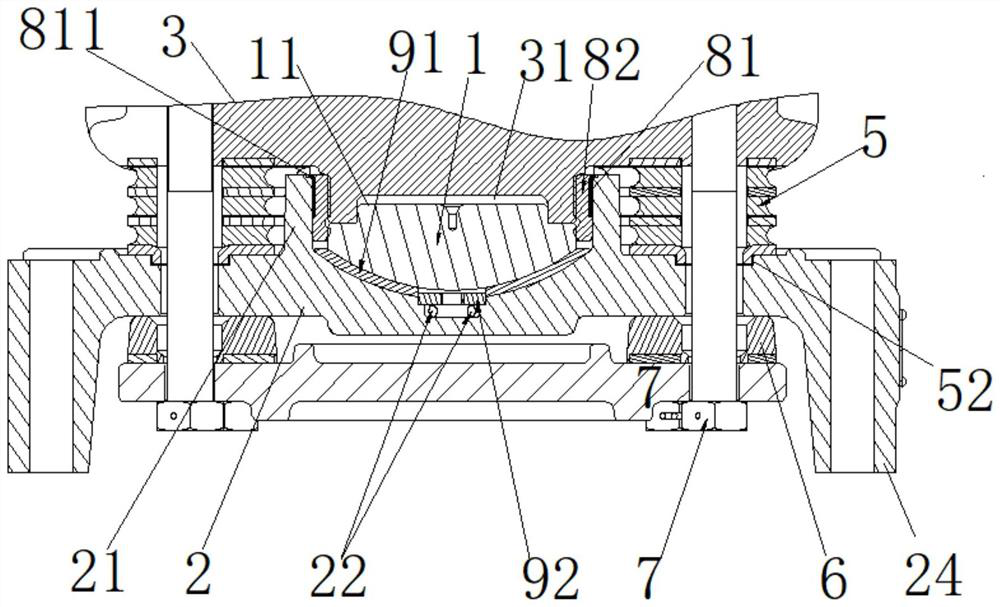

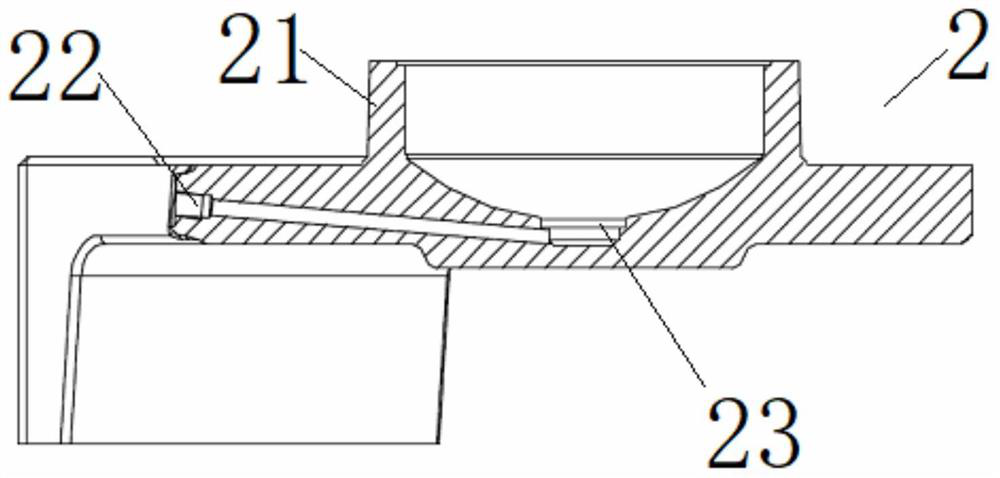

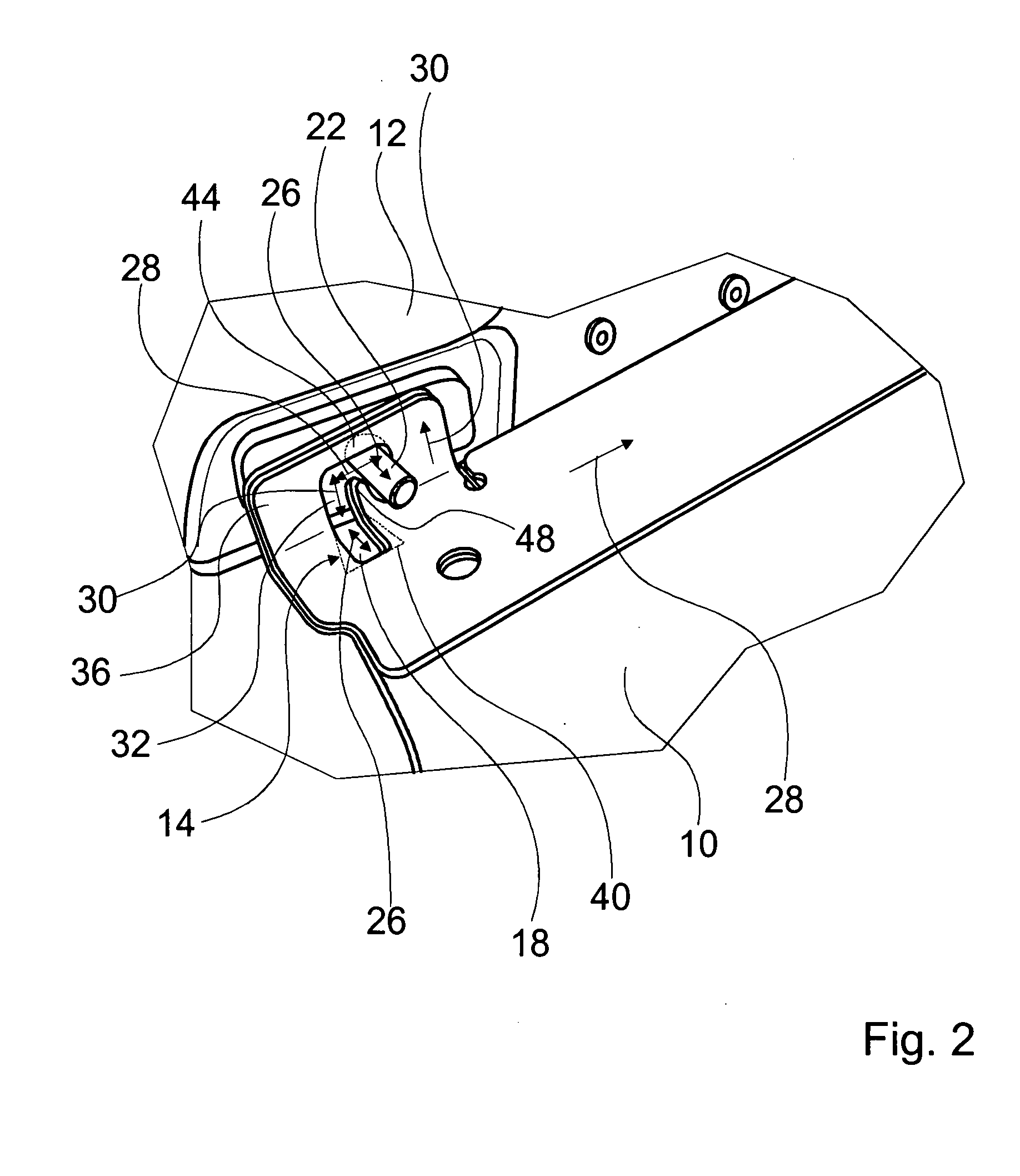

Gas intake device

ActiveUS8656894B2Improve rigidityFulfil structural functionNon-fuel substance addition to fuelInternal combustion piston enginesCombustionCylinder head

A gas intake device for letting gases into an inlet volume of a cylinder head of a motor vehicle combustion engine includes a valve (10) for supplying the cylinder head with gas, this valve communicating with the inlet volume of the cylinder head directly and indirectly via a heat exchanger (14). The valve (10) and the heat exchanger (14) are mounted on a plate (21) intended to be mounted directly on the cylinder head. The device is compact and relatively insensitive to vibration.

Owner:VALEO SYST DE CONTROLE MOTEUR +1

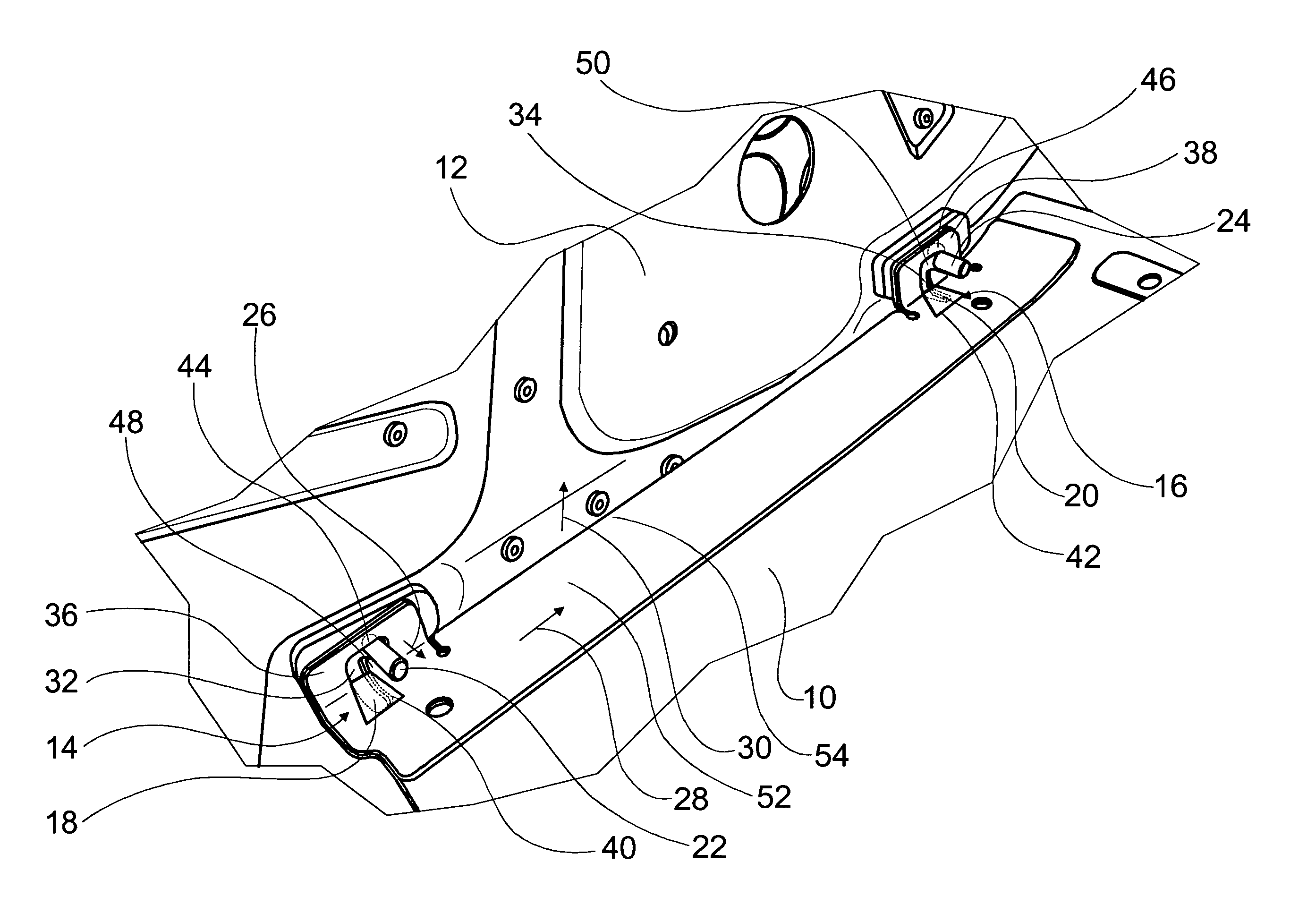

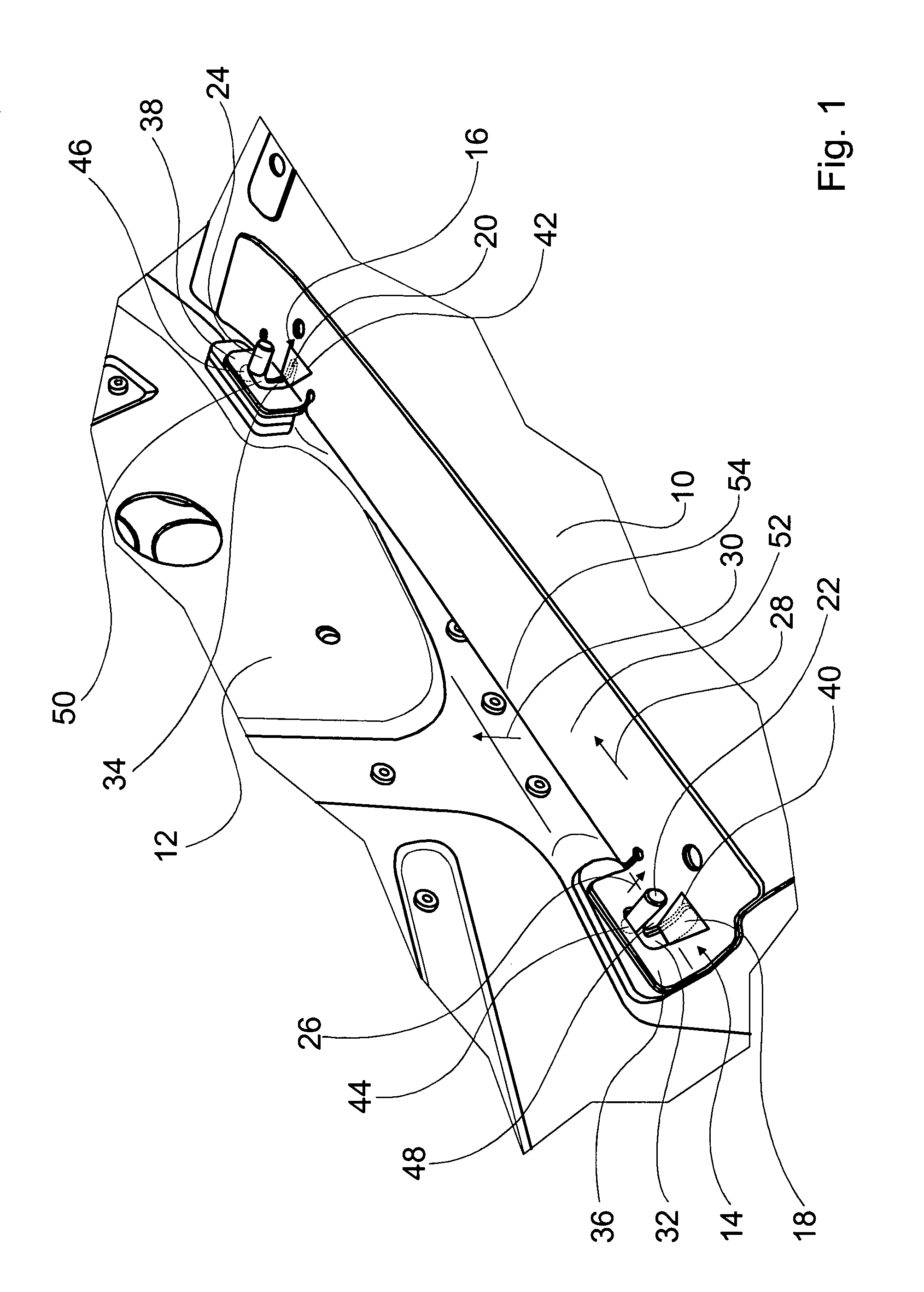

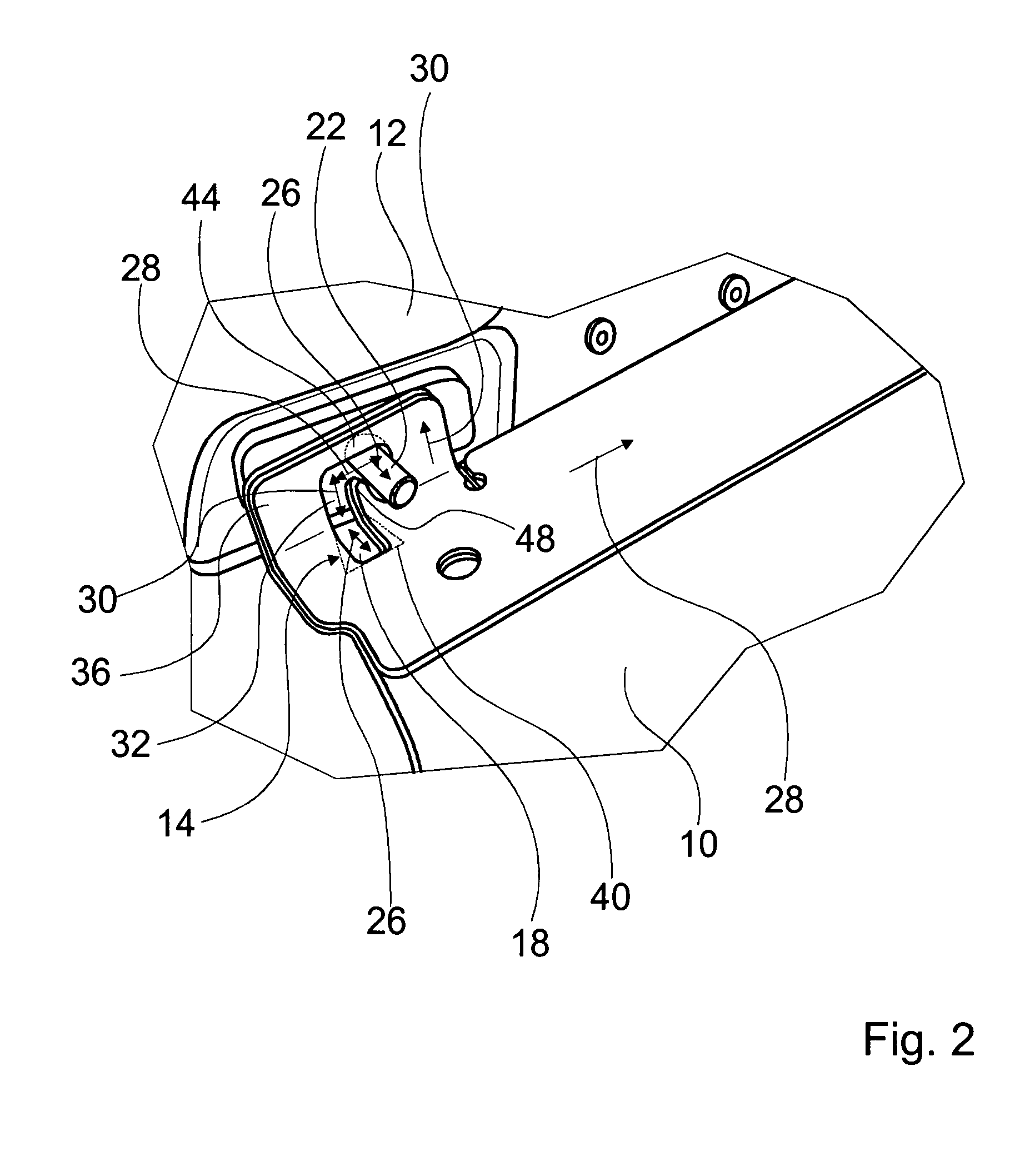

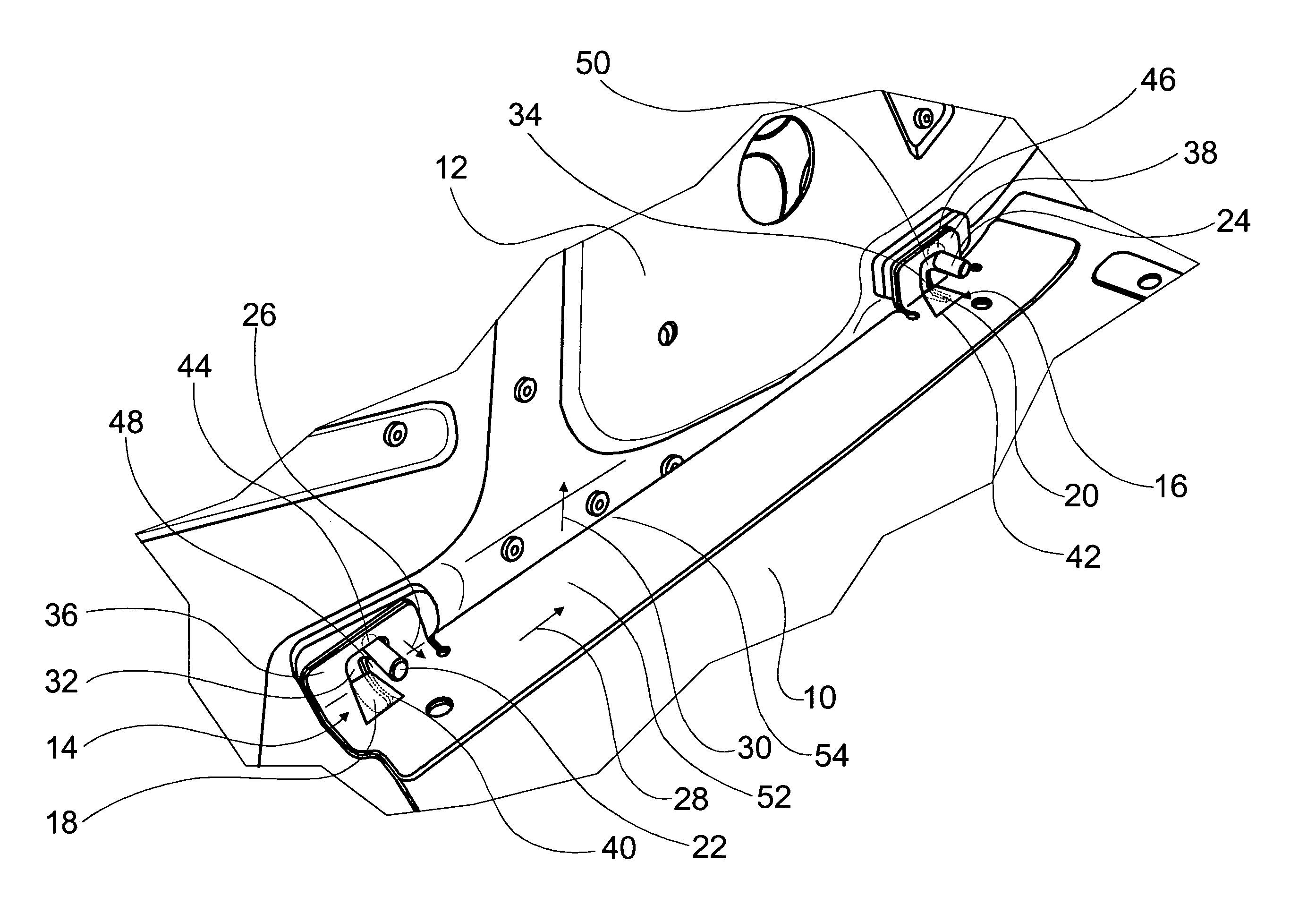

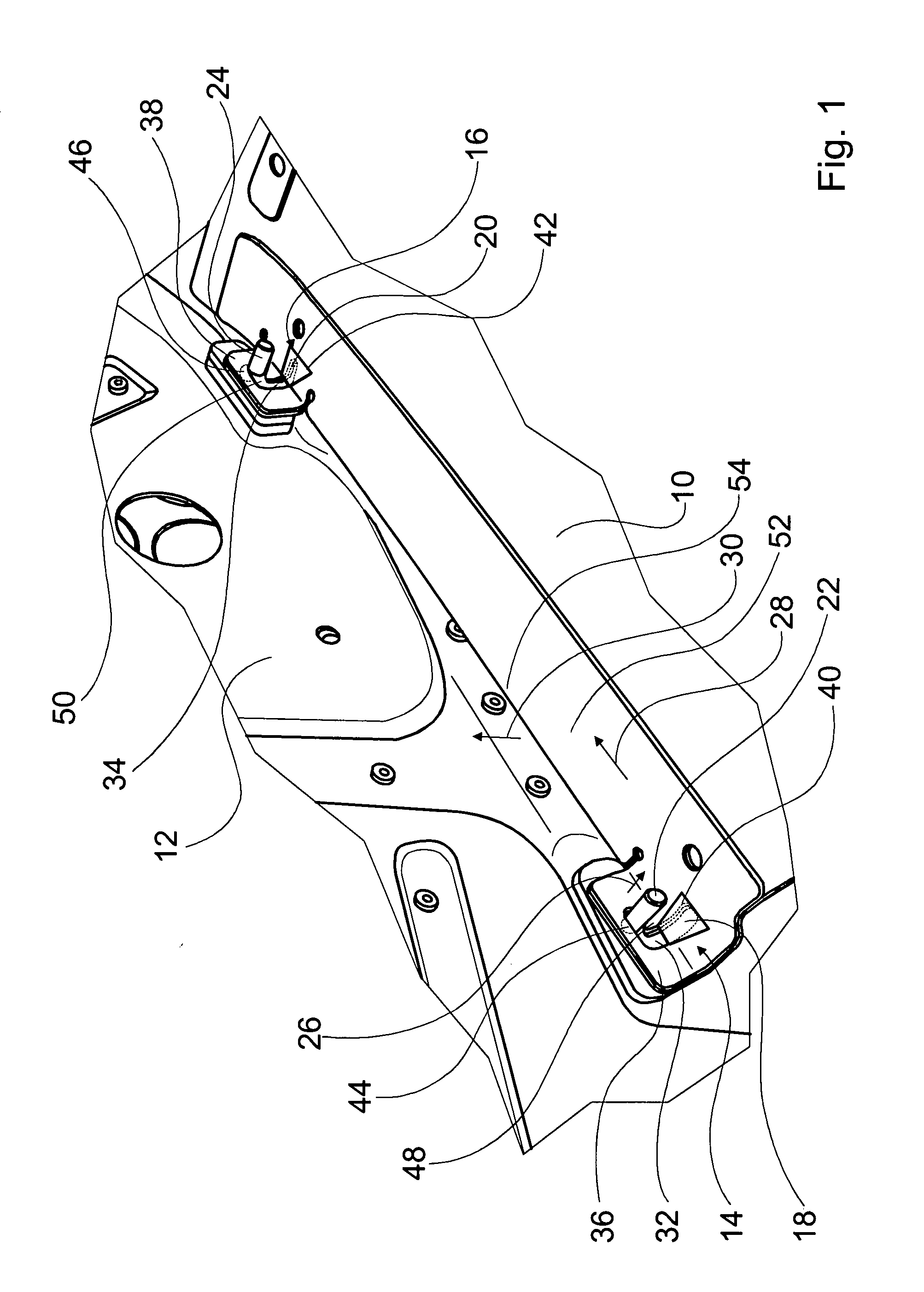

Aircraft seat fixing apparatus

InactiveUS7396084B2Simple and time-saving installationAvoid screwingSeating arrangementsSeat framesEngineeringMechanical engineering

An aircraft seat fixing apparatus includes at least one insertion region and at least one retaining element, both of which are provided for fixing a shell half to a bracket. The insertion region comprises a recess for enabling the retaining element to be inserted into the insertion region by means of an insertion movement which has a component perpendicular to a main direction of the extent of the retaining element.

Owner:RECARO AIRCRAFT SEATING GMBH & CO KG

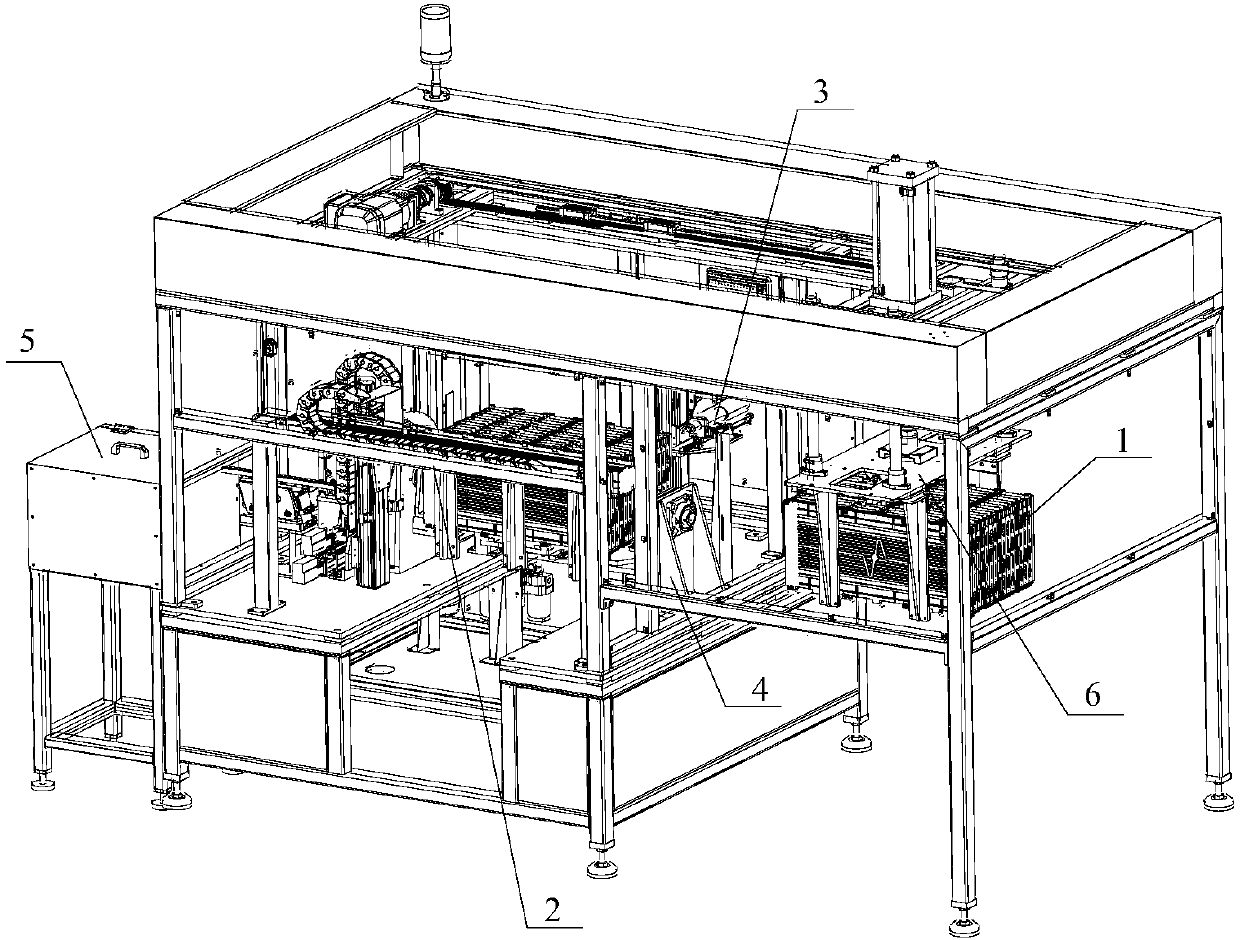

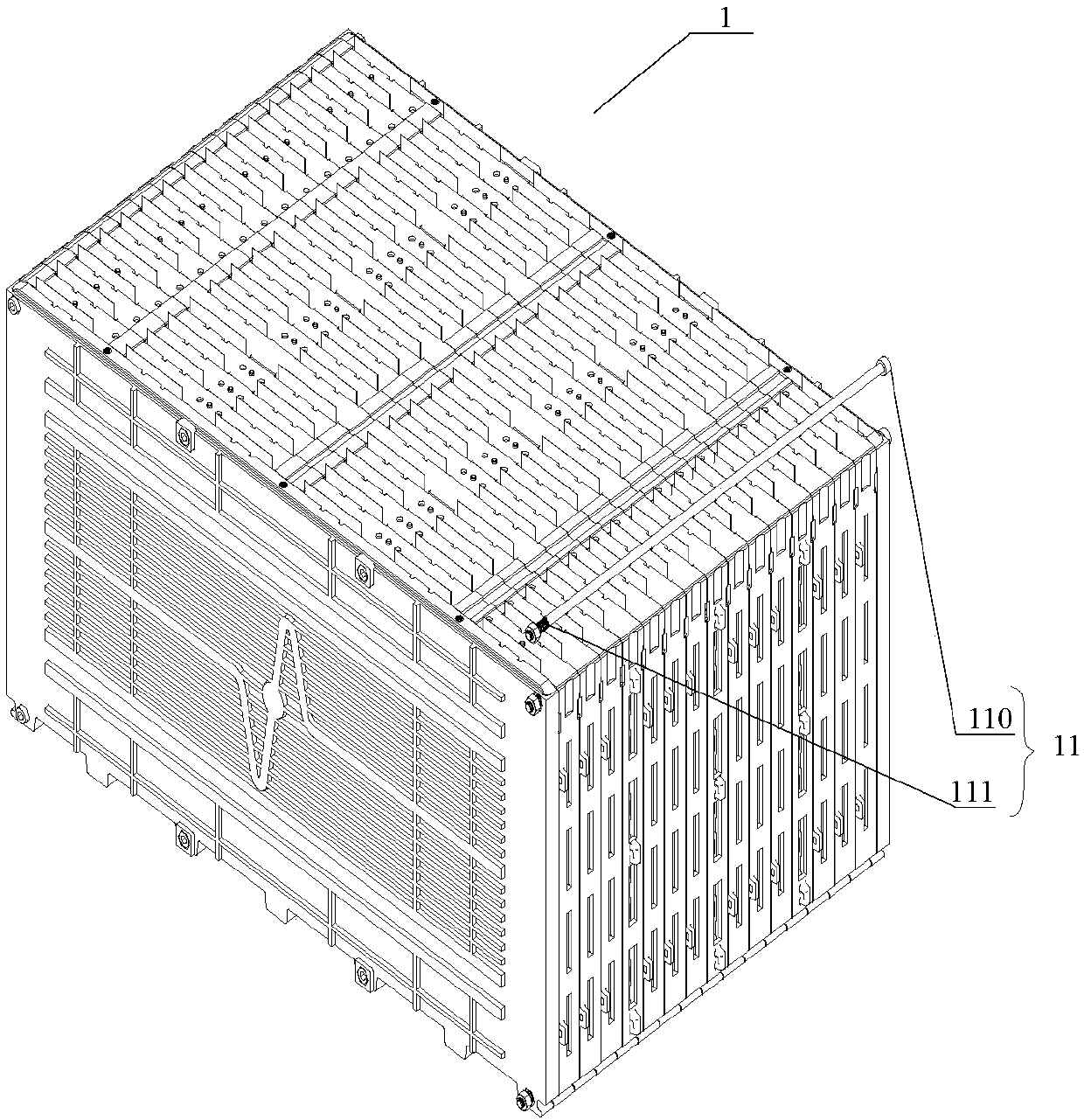

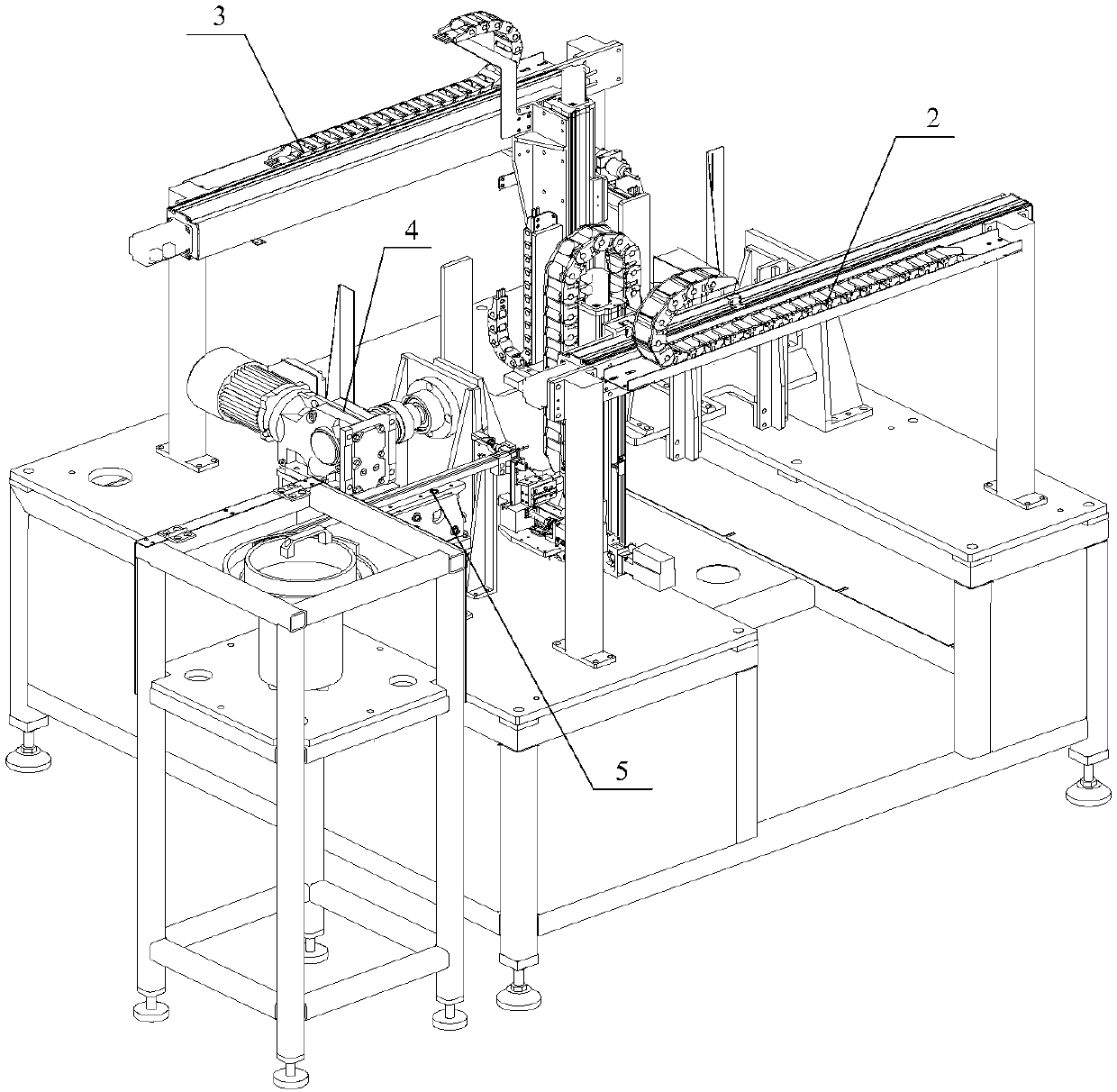

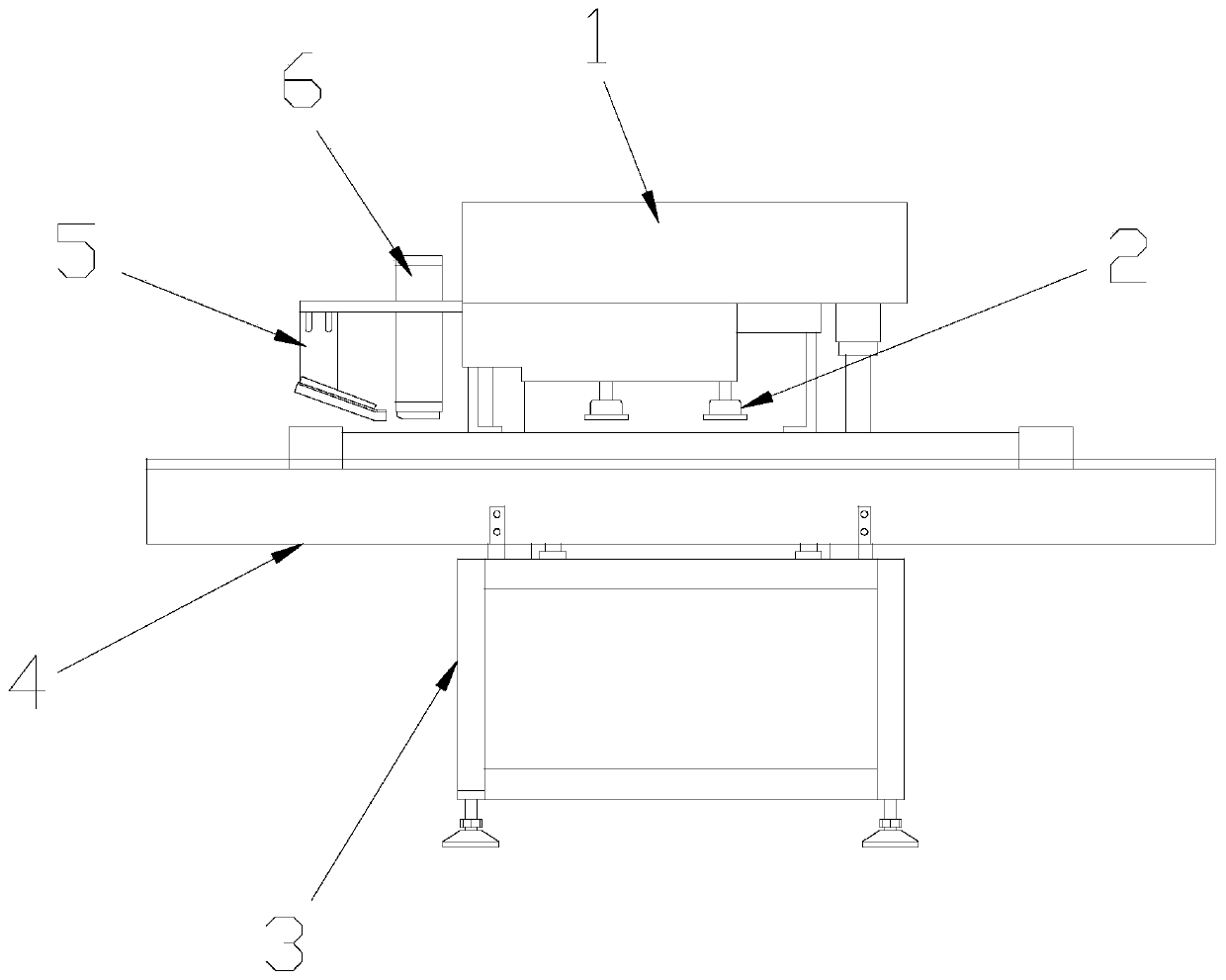

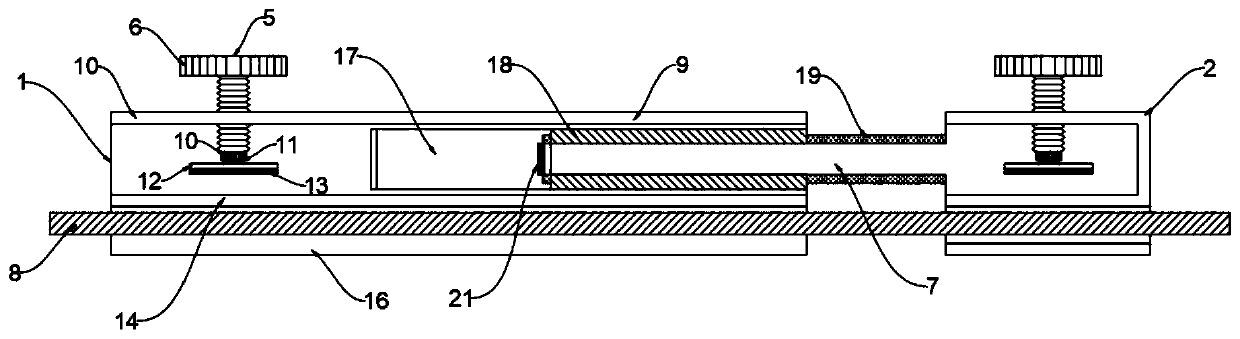

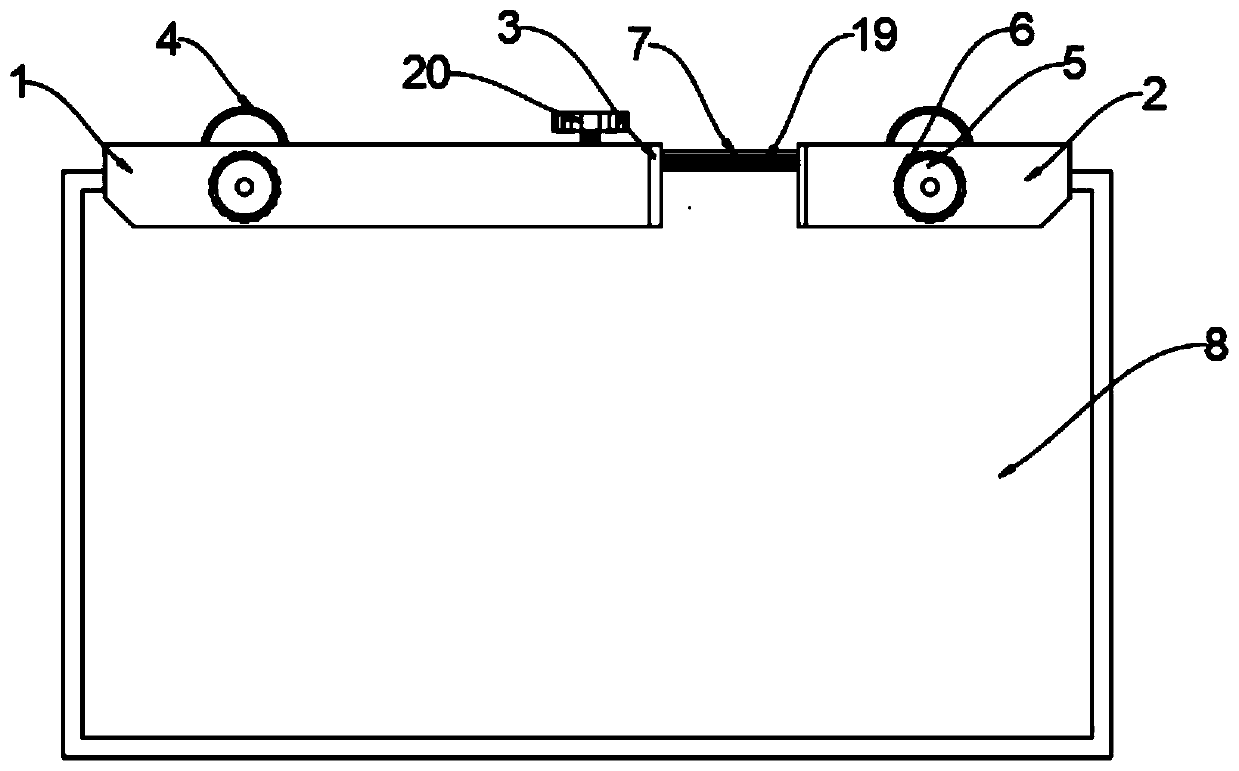

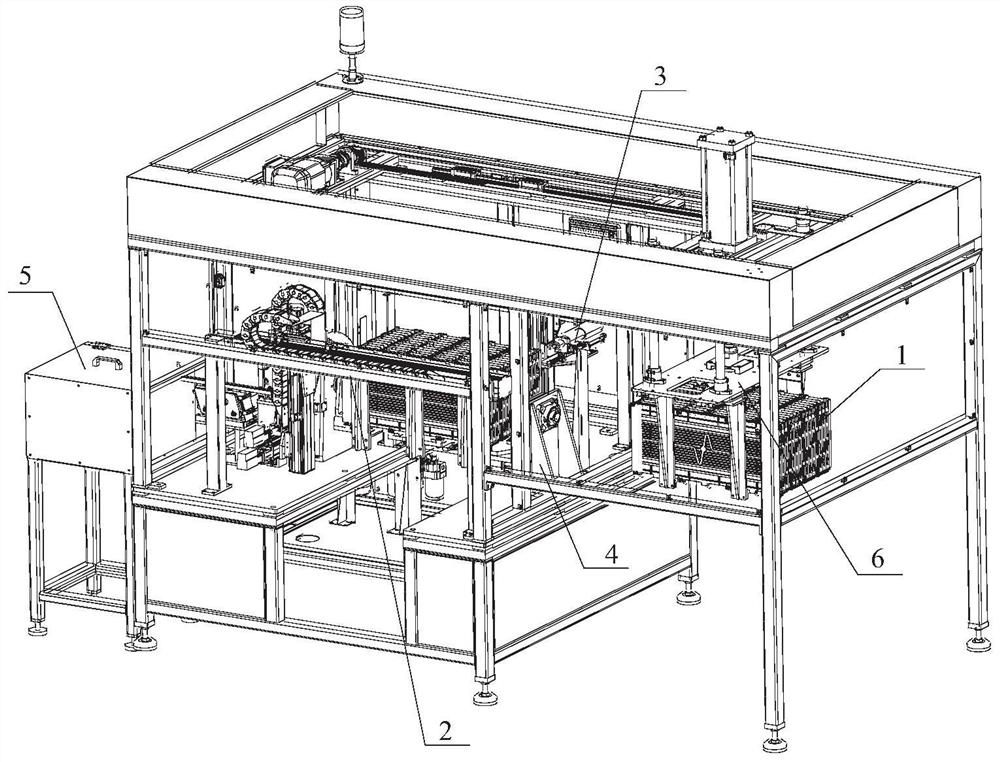

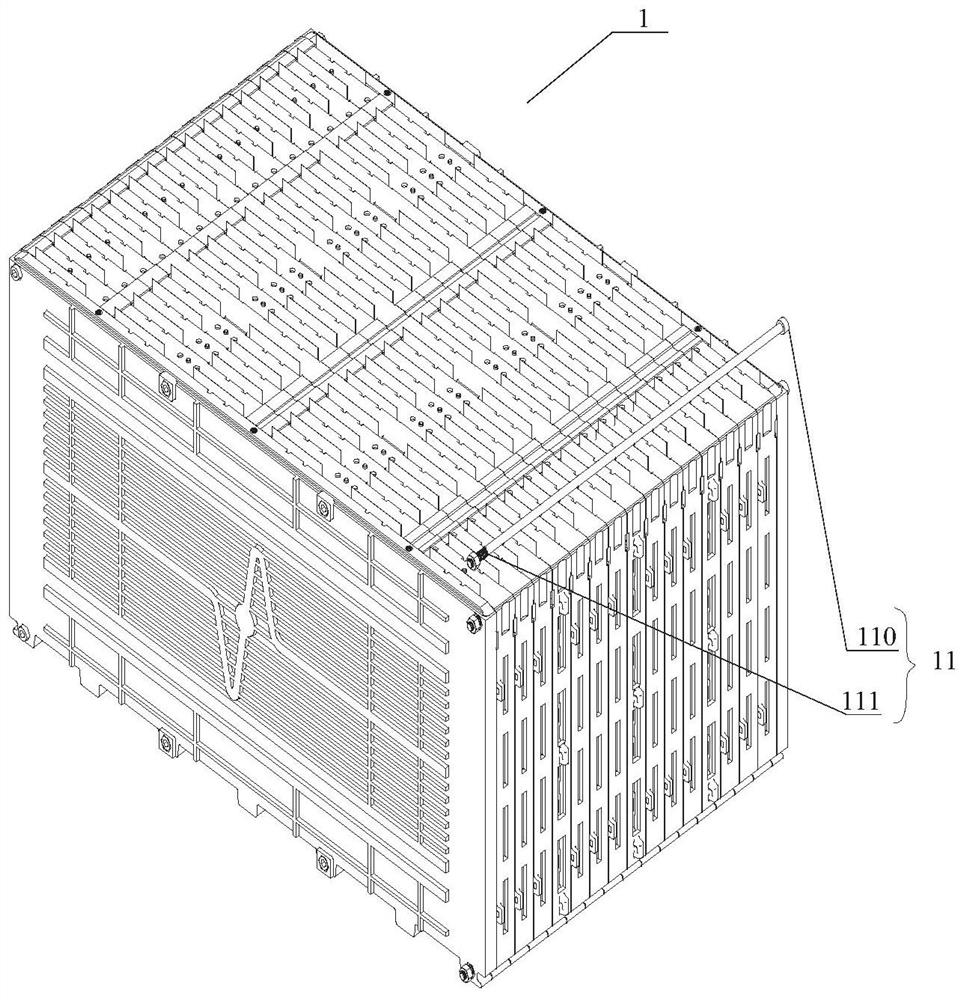

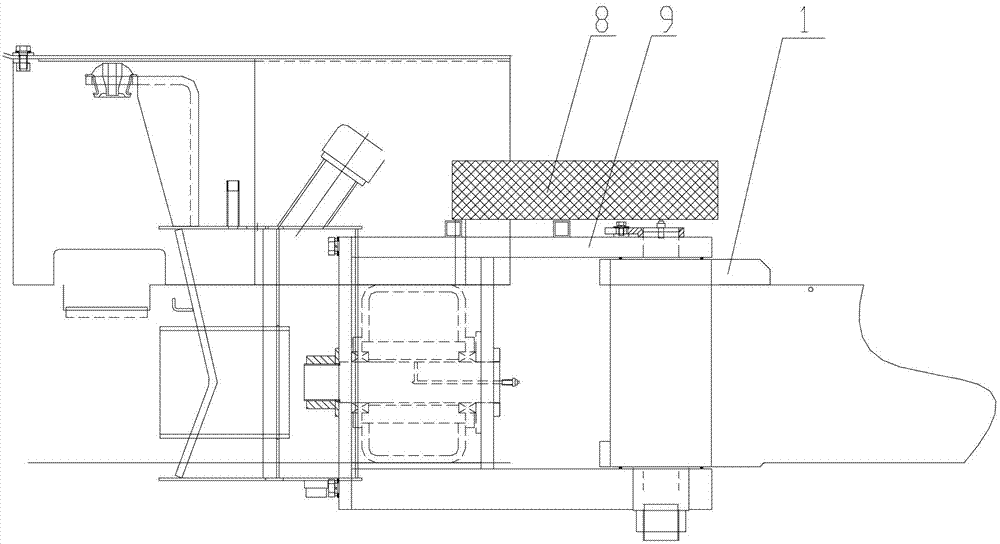

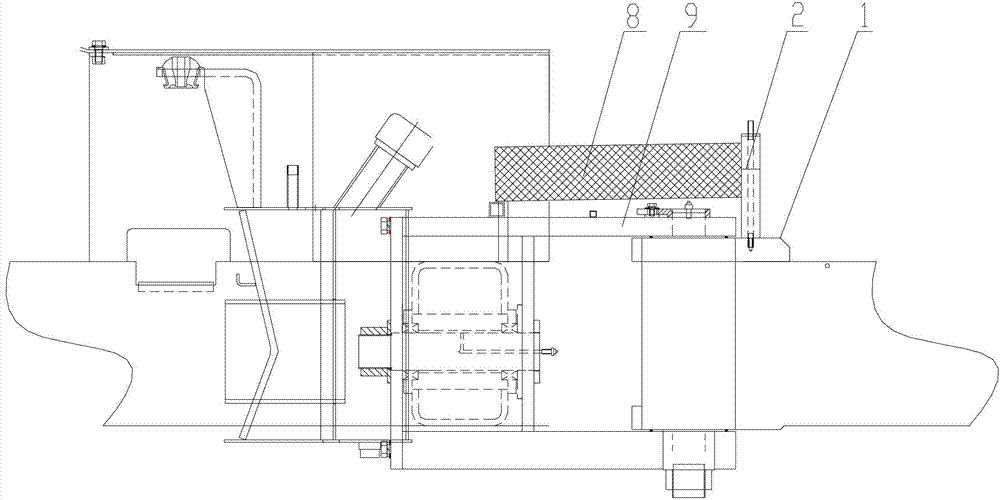

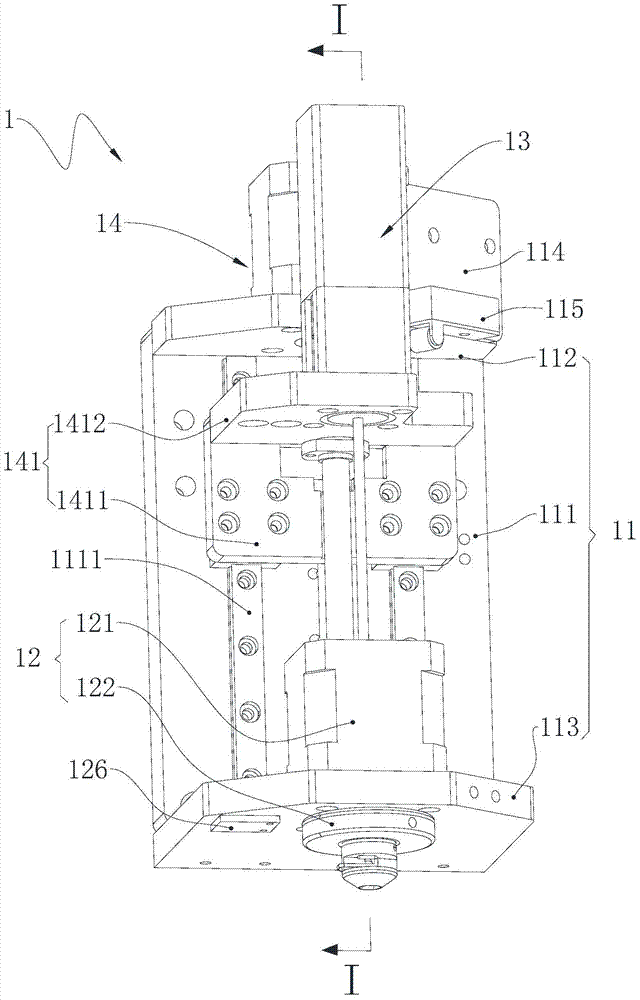

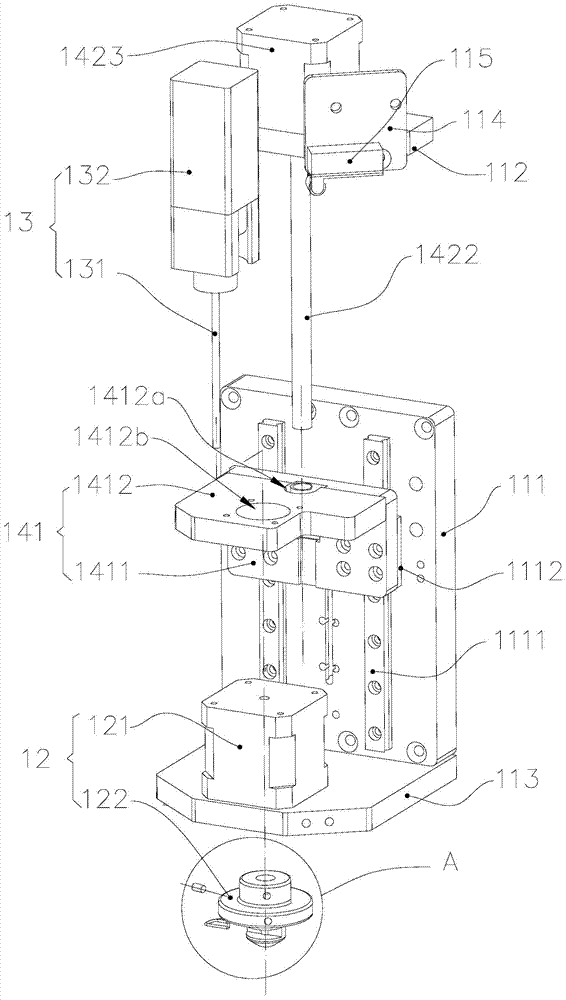

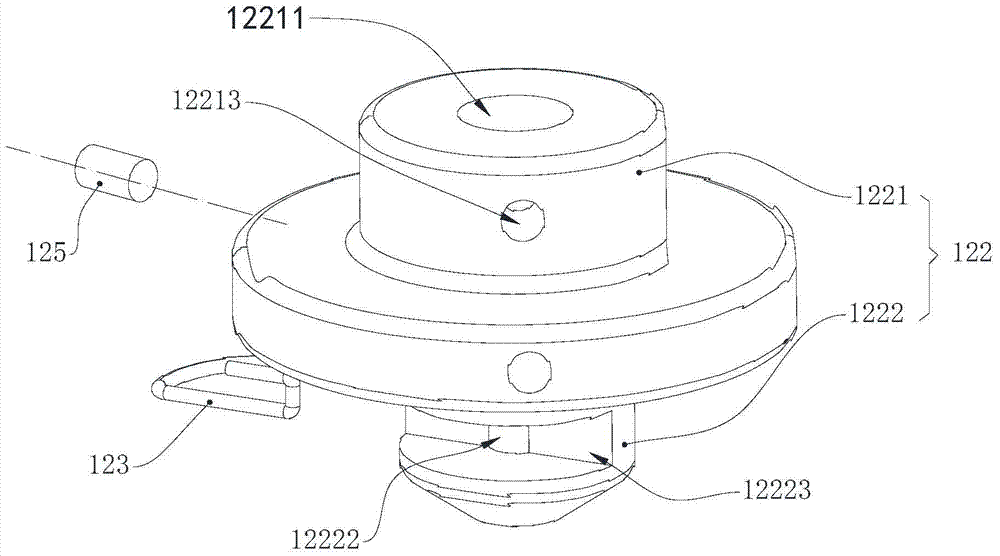

Full-automatic battery module locking device

ActiveCN108054329ARealize automatic tighteningAvoid inconsistent thicknessCell component detailsLocking mechanismEngineering

The invention discloses a full-automatic battery module locking device, which comprises a battery module, a nut positioning mechanism and a torque-adjustable screw locking mechanism, wherein the battery module is provided with a plurality of screws; each screw penetrates through the battery module and comprises a top end part and a thread part; the nut positioning mechanism is arranged at one sideclose to the thread parts and is used for positioning to-be-installed nuts, so that the to-be-installed nuts are overlapped with the axes of the screws; each to-be-installed nut corresponds to one screw; and the torque-adjustable screw locking mechanism is arranged at one side close to the top end parts, and is used for determining locking torque and driving the screws to rotate around the axes of the screws under the action of the locking torque, so that the to-be-installed nuts are arranged at preset positions of the corresponding thread parts. According to the full-automatic battery modulelocking device, automatic tightening of the screws and the nuts is achieved through the nut positioning mechanism and the torque-adjustable screw locking mechanism, tightening missing is avoided, theinconsistency of the locking torque is avoided and the thickness of the locked battery module is consistent, thereby reducing the labor cost and improving the quality and the production efficiency ofthe battery module.

Owner:SHENZHEN CLOU ELECTRONICS

Capping machine for food glass pot

InactiveCN111591938AAvoid screwingAvoid Positional ClampingCapsThreaded caps applicationRubber ringRotational axis

The invention discloses a capping machine for a food glass pot. The capping machine for the food glass pot structurally comprises a capping drive device, special-shaped cap clamping mechanisms, a support frame, a conveying frame, a cap loading device and a cap counter. Each special-shaped cap clamping mechanism is formed by a lifting rotation shaft, a rotation cap, an electromagnet, a clamping mechanism and a cap sorting bevel ring; the capping drive device is used for adjusting the horizontal positions of caps through the special-shaped cap clamping mechanisms, so that the occurrence of the phenomenon that the caps cannot be screwed down when being capped rotatably is avoided; the iron caps are attracted through the electromagnets, and the clamping mechanisms are driven to be matched withsoft rubber rings so as to clamp the caps with irregular shapes, so that the diversity in clamping the caps is improved, and the caps cannot slip when being screwed down due to large resistance of the soft rubber rings; glass pots are clamped through an automatic pot bottom clamping mechanism, so that the cost can be reduced; and the structure is characterized by working without main power, so that the glass pots can be prevented from being broken and scratched in appearance during clamping due to the flexible resistance of anti-slip clamping heads.

Owner:晏庆光

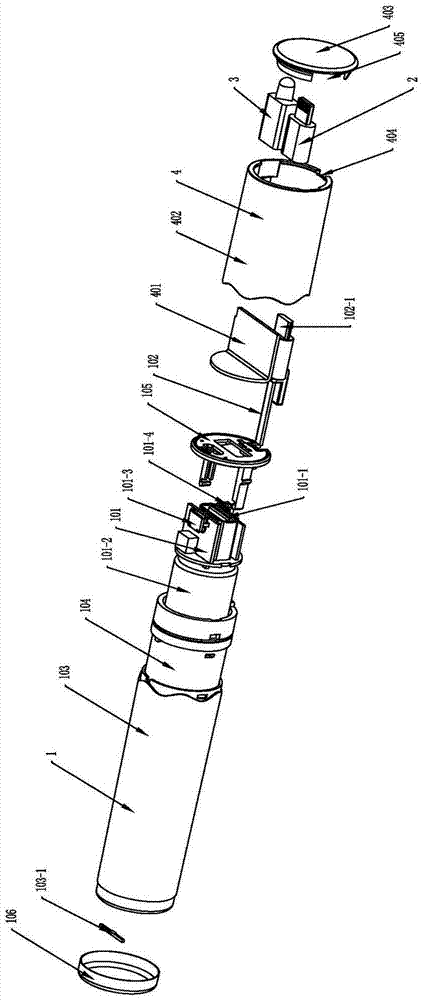

Portable multifunctional mobile power source

InactiveCN103618349AAvoid extra pluggingExtended service lifeBatteries circuit arrangementsElectric powerEngineeringUSB

The invention relates to a portable multifunctional mobile power source comprising a power source body and an accessory box arranged in a cover body. The power source body comprises a PCB and a data line. One end of the data line is fixedly connected with a first output interface of the PCB; the other end of the data line is a Micro USB connector. Electronic products can be charged directly through the data line of the mobile power source, using is convenient, the data line is prevented from being repeatedly plugged in and pulled out of the output interface of the mobile power source, and the service life of the mobile power source is prolonged. The accessory box is used for storing an adaptor and a Micro USB LED lamp, the mobile power source is compact in structure, and the adaptor and the Micro USB LED lamp are convenient to carry and cannot be lost easily.

Owner:谭晓容

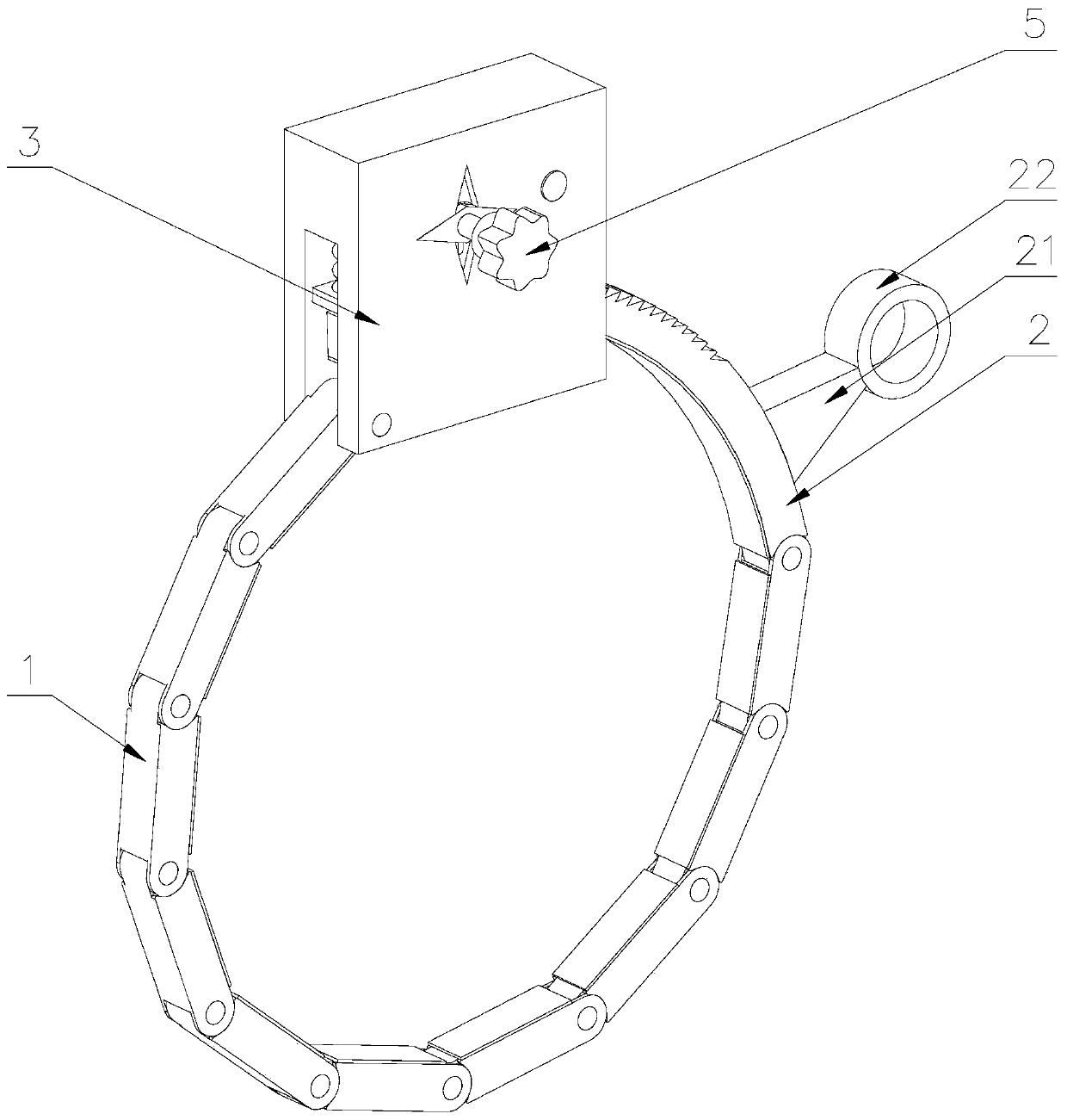

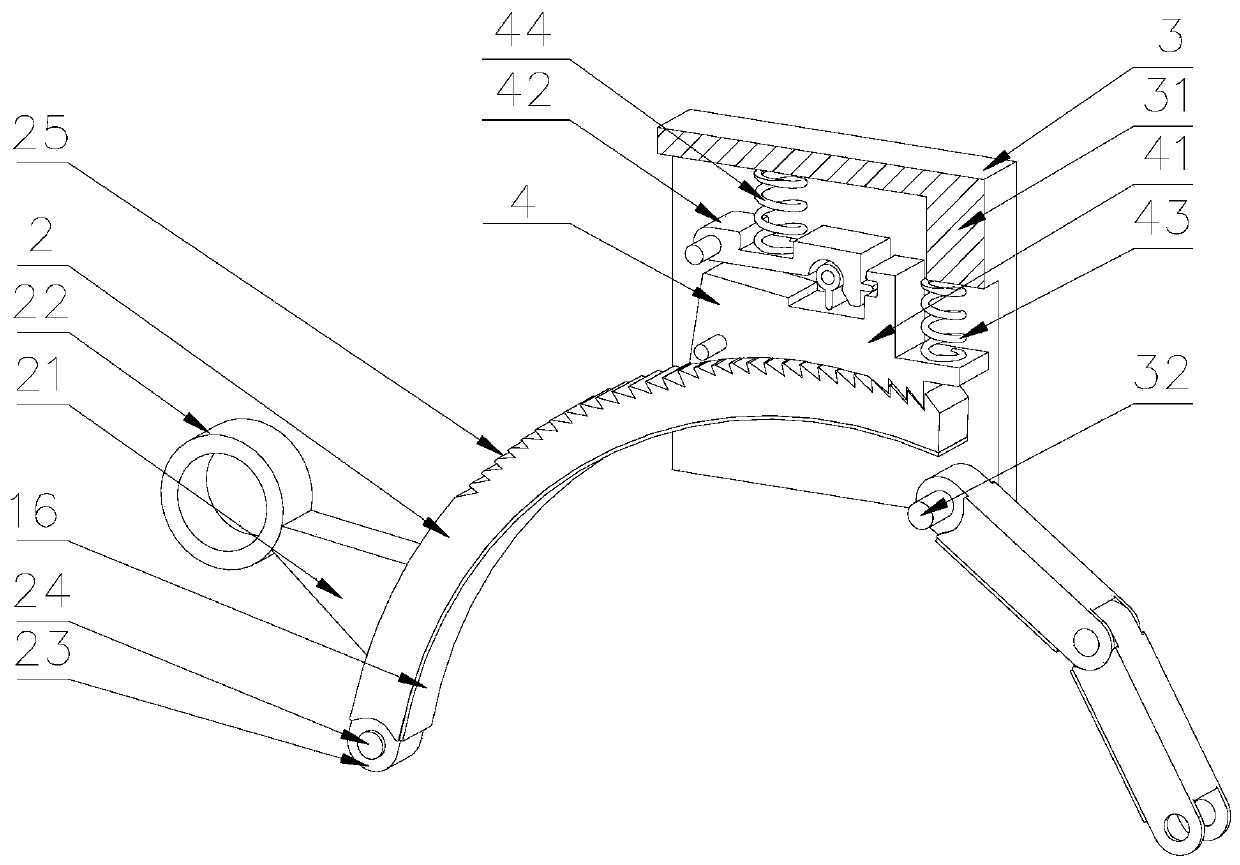

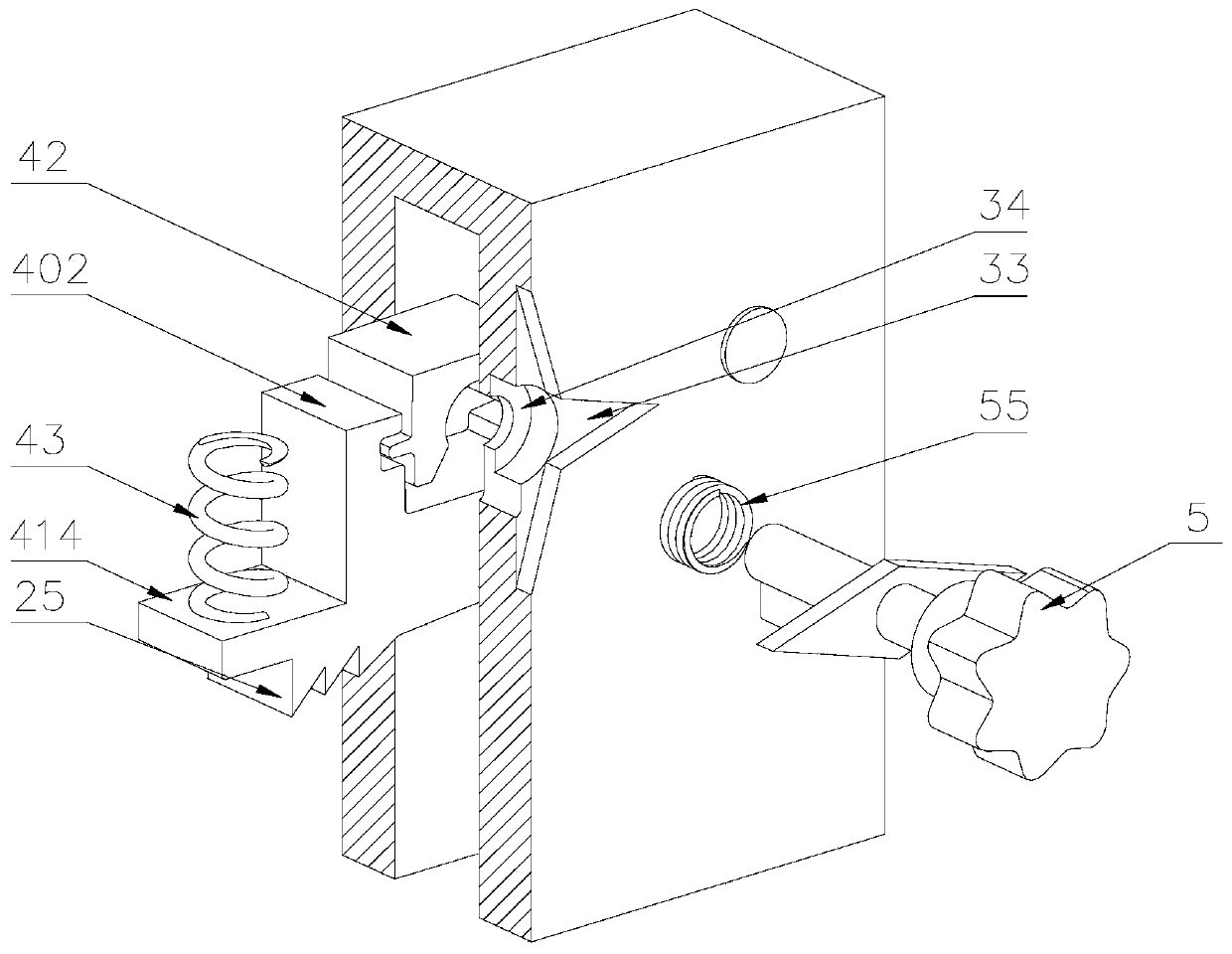

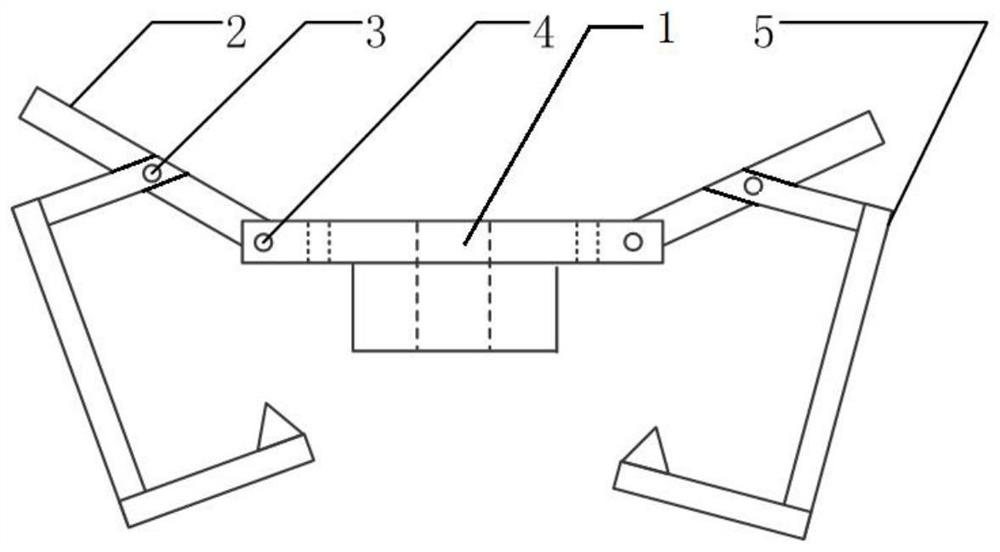

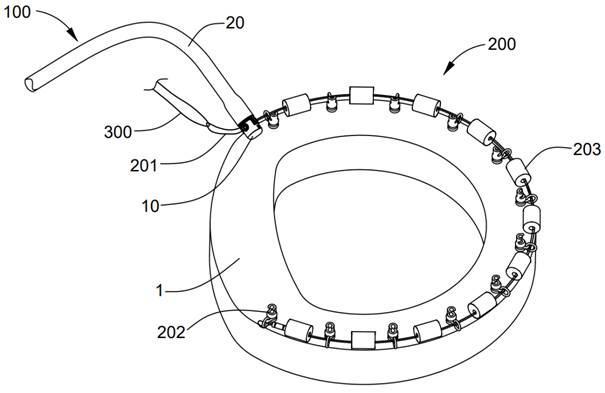

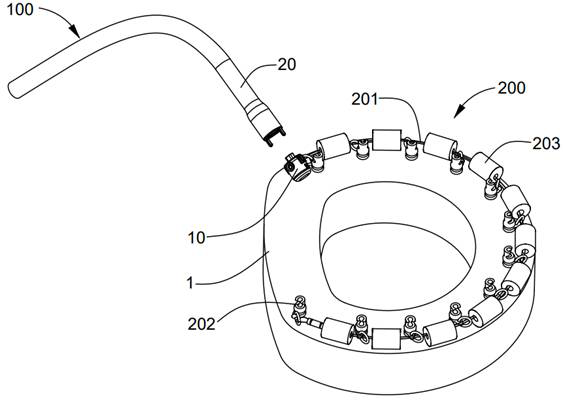

Device capable of preventing strand scattering during wire cutting

The invention discloses a device capable of preventing a strand scattering during wire cutting. First connection arms are provided with a plurality of groups, and multiple sets of the first connectingarms are sequentially connected through first pin shafts and a connecting hole to form a flexible connecting arm; the first connecting arm at the head end is movably connected with a first shield through third pin shafts, a second connecting arm is arranged on one side of the first connecting arm at the tail end, and a plurality of ratchets are arranged on one side of the upper portion of the second connecting arm; a locking mechanism is arranged in the first shield, and the locking mechanism is matched with the ratchet on the second connecting arm; an unlocking device is arranged on one sideof the locking mechanism; a wire clamping device can be used independently or in combination. According to the device capable of preventing the strand scattering during the wire cutting, the multiplefirst connecting arms are arranged, the multiple first connecting arms are connected in sequence through the first pin shafts to form the flexible connecting arm, and when wires are pressed, a circular gap is formed between the first connecting arms and the second connecting arm, the contact area between the connecting arms and the wires is increased, and the phenomenon that the wire is scatteredis avoided.

Owner:QINGHAI POWER TRANSMISSION & TRANSFORMATION ENG +2

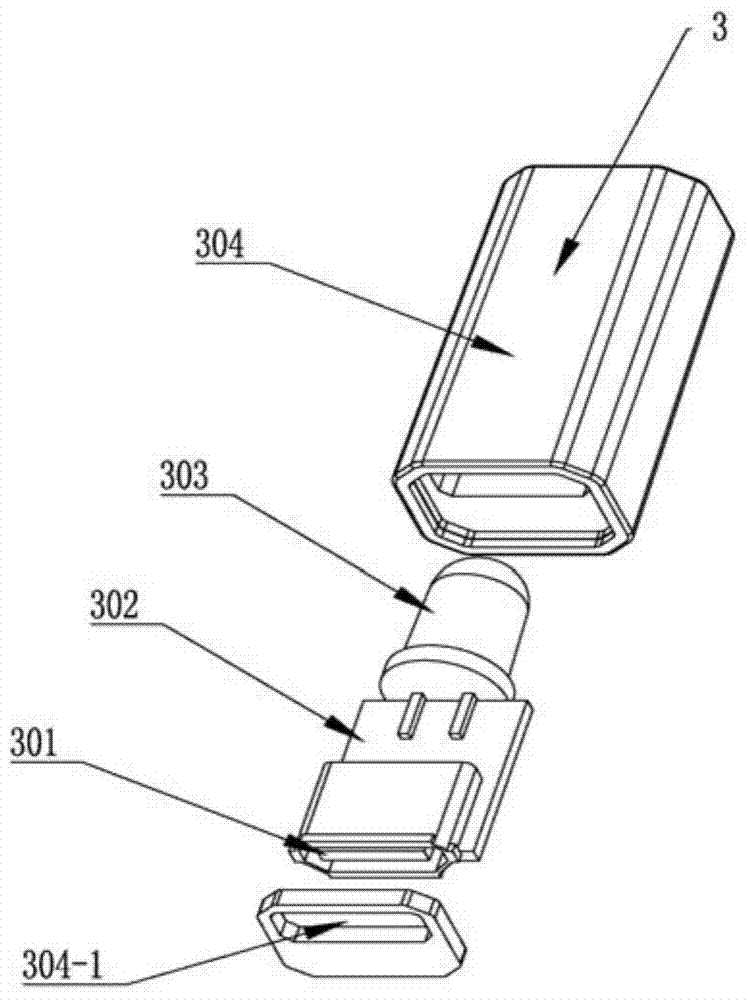

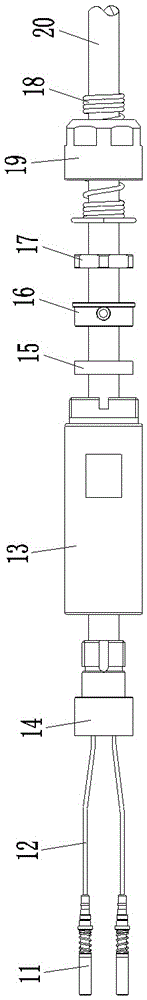

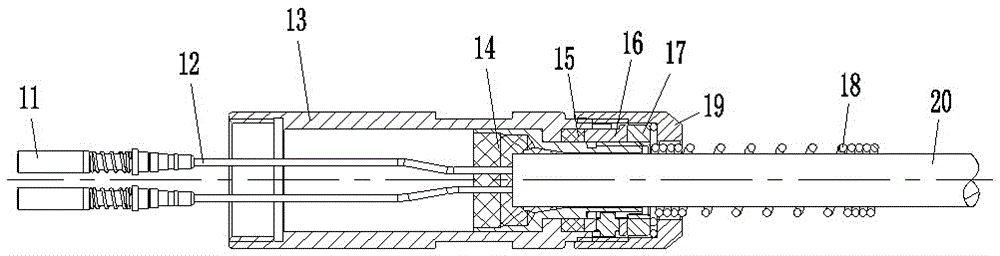

Sealing accessory for optical fiber connector and optical fiber connector using the sealing accessory

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

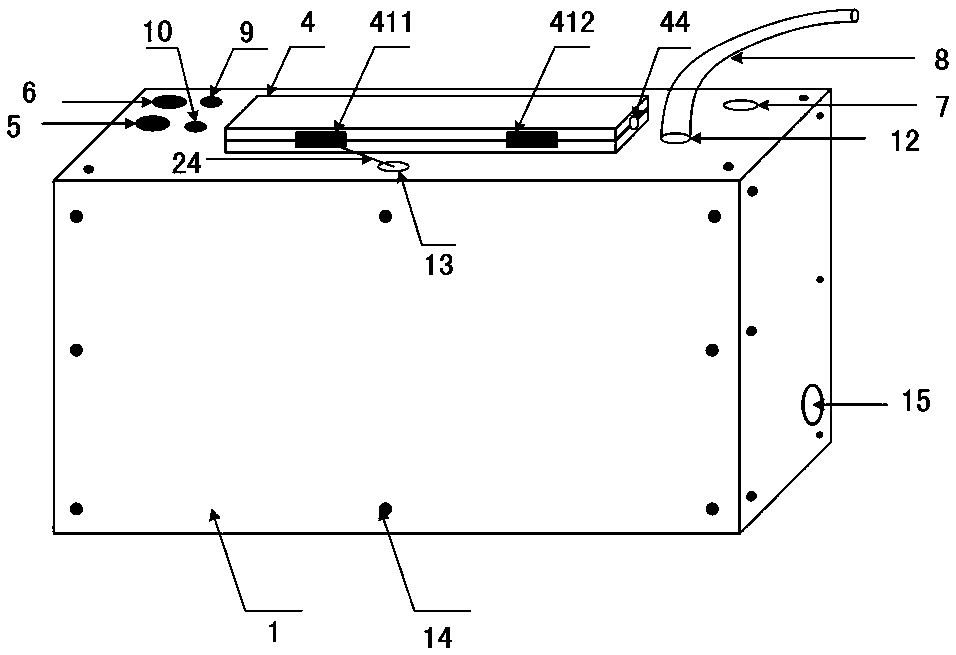

Capillary glass tube heating and air suction device

ActiveCN108508531ASimple structureSimple and fast operationBundled fibre light guideVacuum pumpingControl system

The invention discloses a capillary glass tube heating and air suction device comprising an air suction assembly, a heating fixture, a switch assembly and an air pipe. A control system and a vacuum air pump are arranged in the air suction assembly. The air suction assembly is provided with a vacuum air pump air inlet hole and a vacuum air pump air outlet hole, the vacuum air pump air inlet hole isused for connecting the air pipe with a capillary glass tube, and the heating fixture is used for clamping the capillary glass tube. The capillary glass tube heating and air suction device has the advantages of being simple in structure, simple and convenient to operate and good in use effect.

Owner:NAT UNIV OF DEFENSE TECH

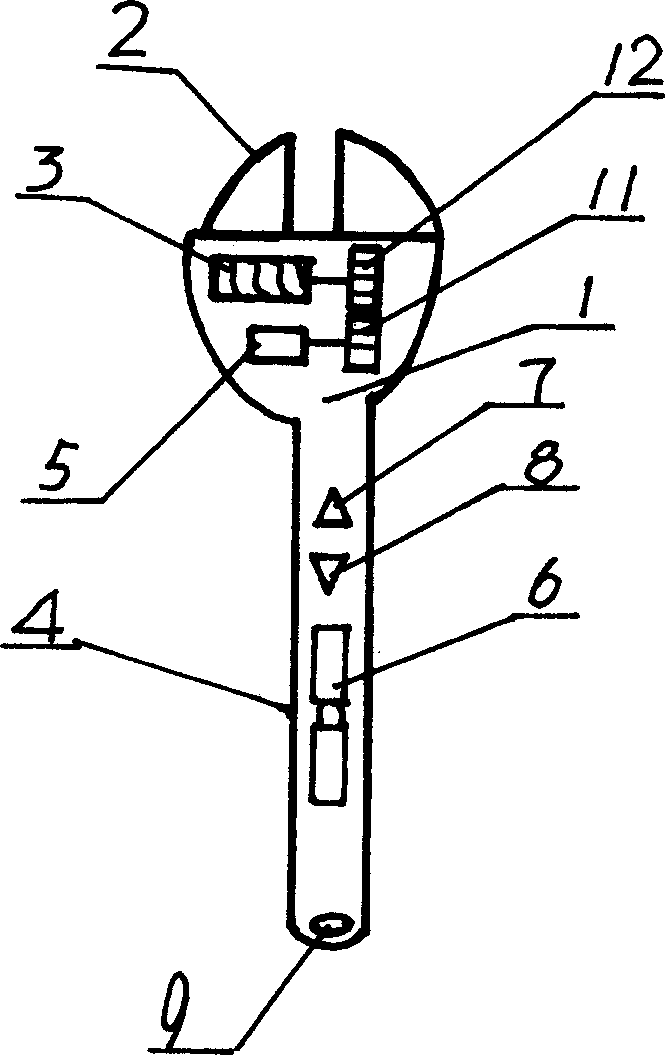

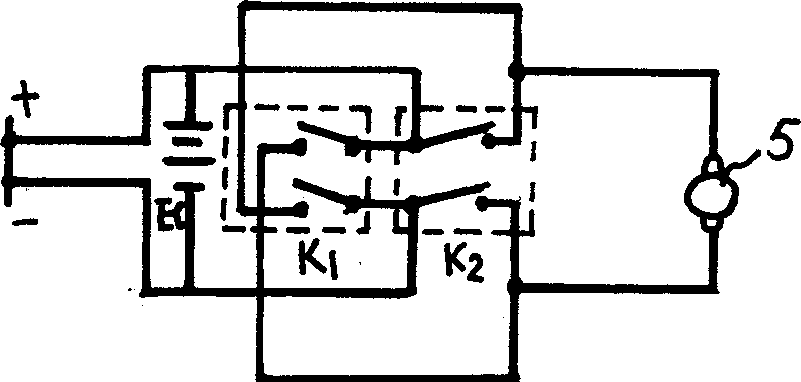

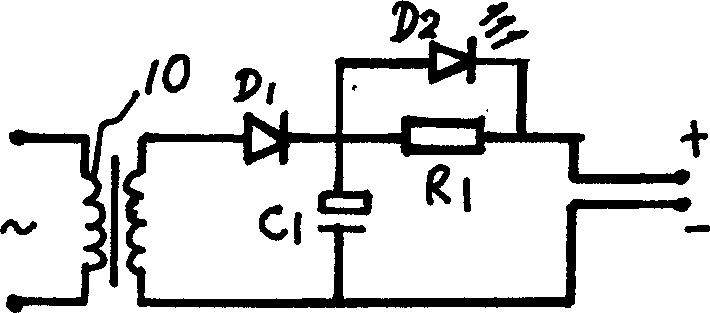

Electric spanner

InactiveCN1748946AAvoid screwingSimple structureBatteries circuit arrangementsElectric powerEngineeringWrench

The electric spanner has reducing motor set below the adjusting nut, the first gear connected to the rotation shaft of the reducing motor, the second gear connected to the adjusting nut and meshed to the first one, and rechargeable battery inside the handle cavity and connected to the charge circuit and connected to motor via DPDT switch. As the improvement of available spanner, the present invention may be used to replace available spanner and has its jaw adjusted via depressing the forward button or backward button slightly. It has simple structure and is practical, especially in oily condition and narrow space.

Owner:徐群强

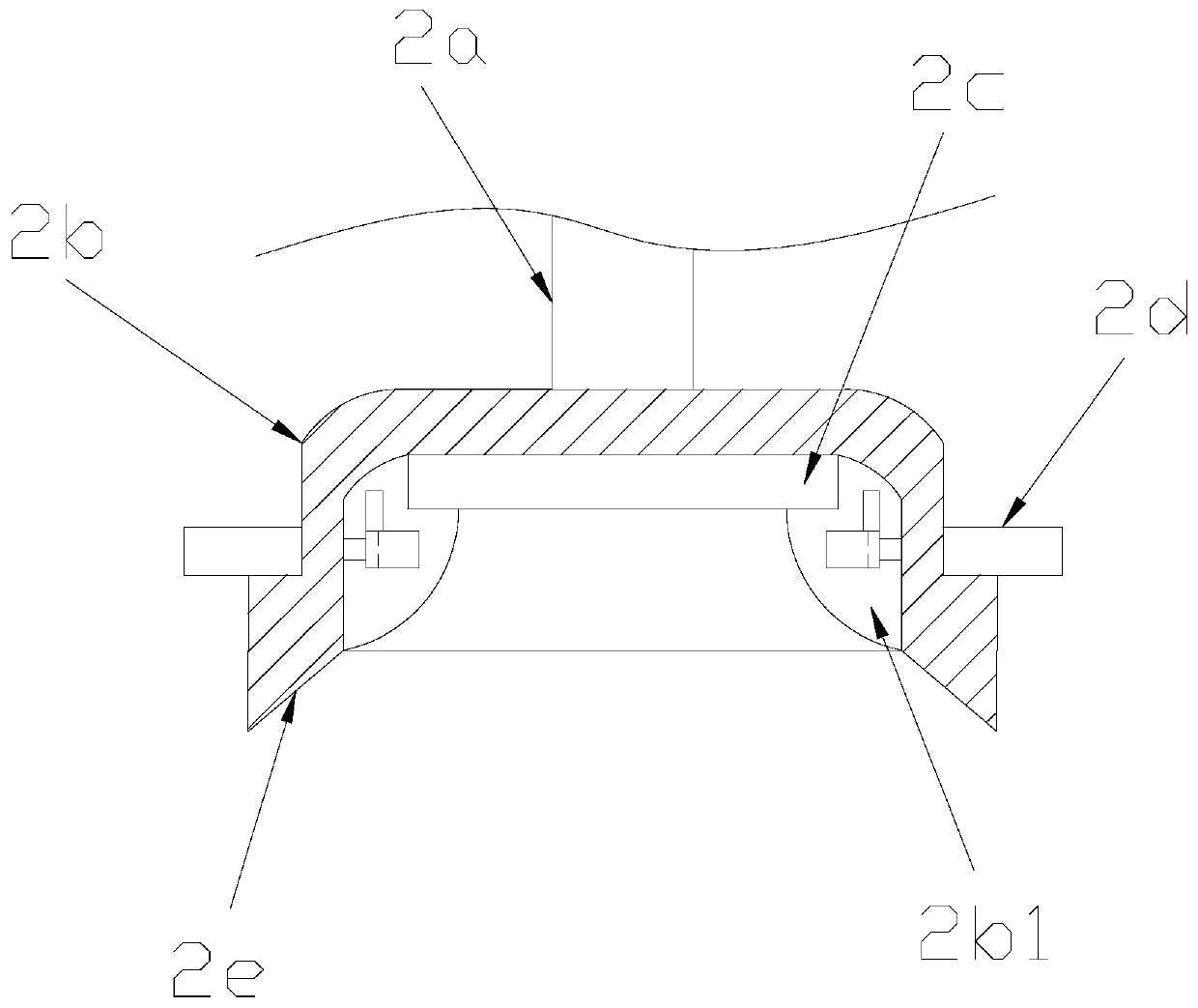

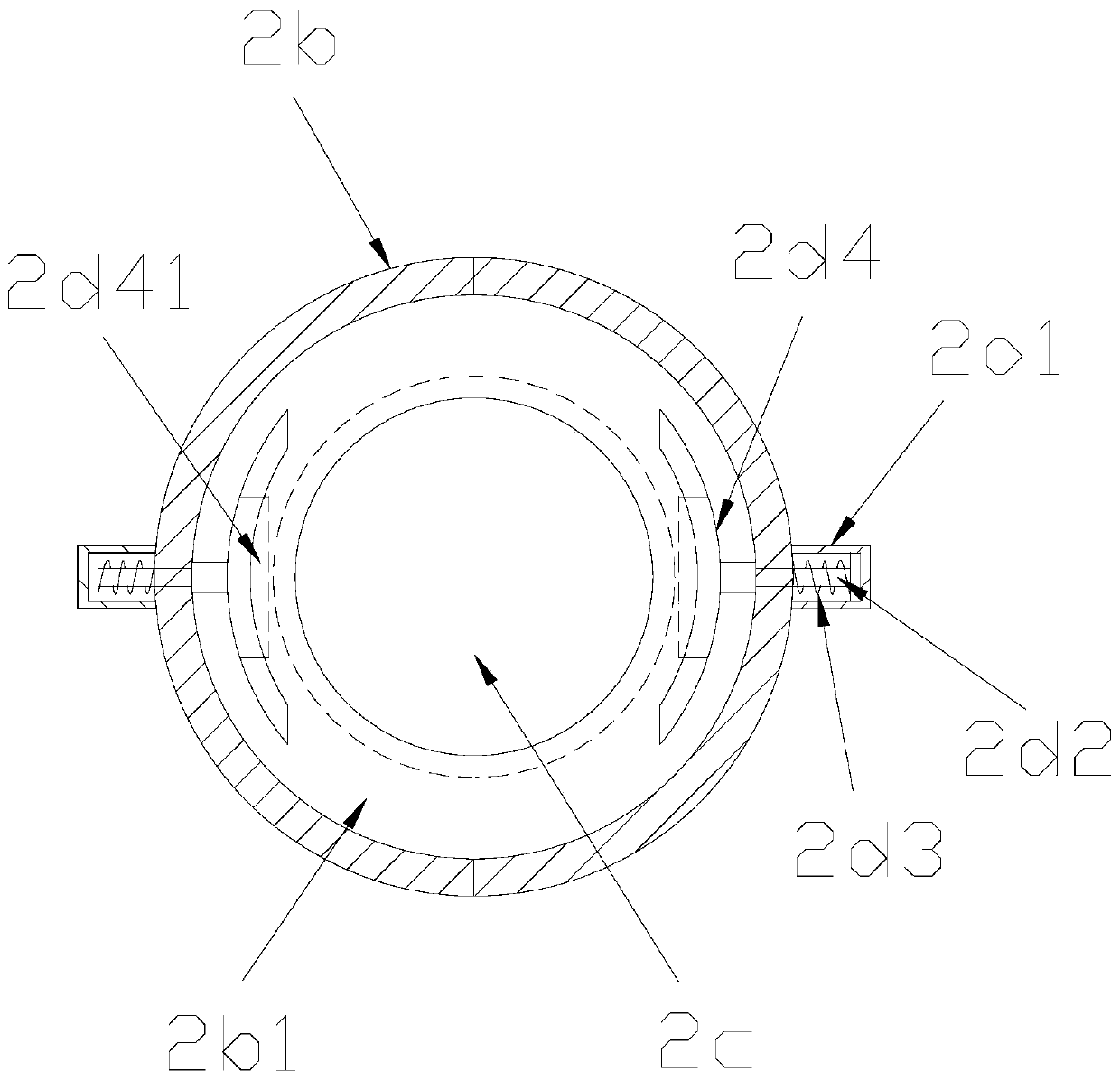

Damping mechanism and mixer truck

PendingCN113771230AGood impact resistanceImprove stability and safetyNon-rotating vibration suppressionCement mixing apparatusTruckVehicle frame

The invention provides a damping mechanism and a mixer truck. The damping mechanism comprises a deflection part, a supporting seat, a fixing seat, a bottom plate, a first damping piece, a second damping piece and a fastening piece. When the damping mechanism with the structure is used, the fixing seat can be directly used as a shell of a speed reducer; or the fixing seat serves as a component of the damping mechanism and is connected with the shell of the speed reducer; and the supporting seat is connected with a mixer truck frame, the gravity and vibration impact force of a mixing barrel are transmitted to the first damping piece through the fixing seat, the first damping piece absorbs horizontal and axial force caused by the gravity of the mixing barrel and the vibration impact force, and stable operation of the mixer truck is guaranteed. The fixing seat is fixedly connected with the deflection part, the speed reducer is arranged on the deflection part, when the stirring barrel vibrates, vibration impact force is transmitted to the speed reducer and the deflection part, the deflection part deflects at any angle in a mounting groove of the supporting seat so as to absorb the vibration impact force of the stirring barrel, the damping mechanism is good in shock resistance, and the stability and safety of operation of the mixer truck are further improved.

Owner:SUOTE TRANSMISSION EQUIP

High frequency heating apparatus

InactiveUS6894260B2Easy to cleanClean applianceDomestic stoves or rangesLighting and heating apparatusHookingFlange

The present invention provides a high frequency heating apparatus having a structure, which can be mounted / dismounted an air-exhausting grill without any tools. In this apparatus, an air-exhausting grill is arranged by that a fixing claw portion having a bent Z-shape, a fixing hooking portion having a concave notch, and a magneto joint plate are arranged, whereas a main body located opposite to the air-exhausting grill is arranged by that a slit hole, a hooking flange, and a magneto fixing plate are arranged. As a result, since the magneto joint plate is absorbed with the magneto fixing plate to be fixed with each other, the mounting / dismounting work capability of the air-exhausting grill can be improved without using the tool in a simple manner, and furthermore, a clean cooking appliance can be secured, while the cooking appliance can be readily cleaned.

Owner:PANASONIC CORP

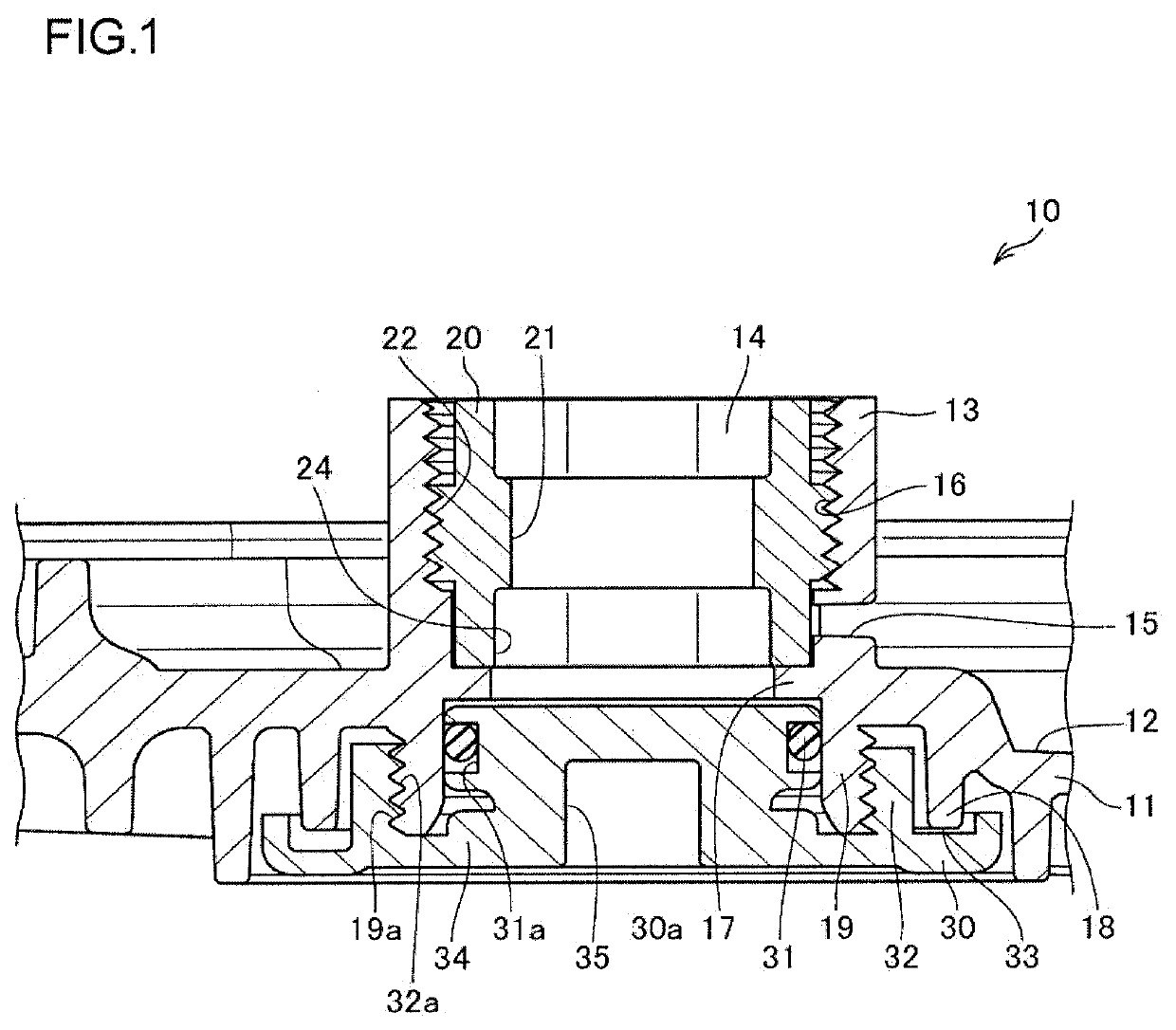

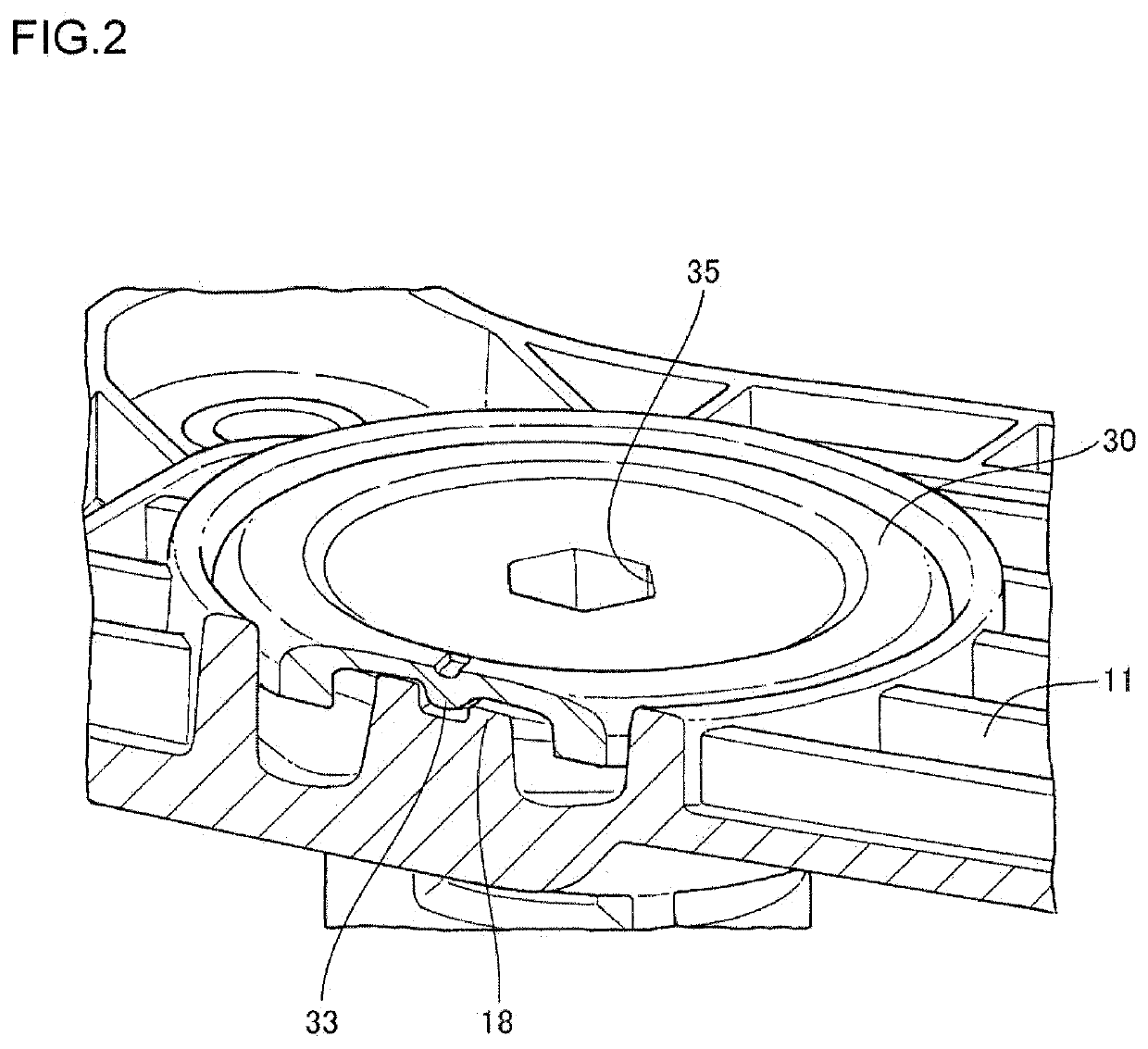

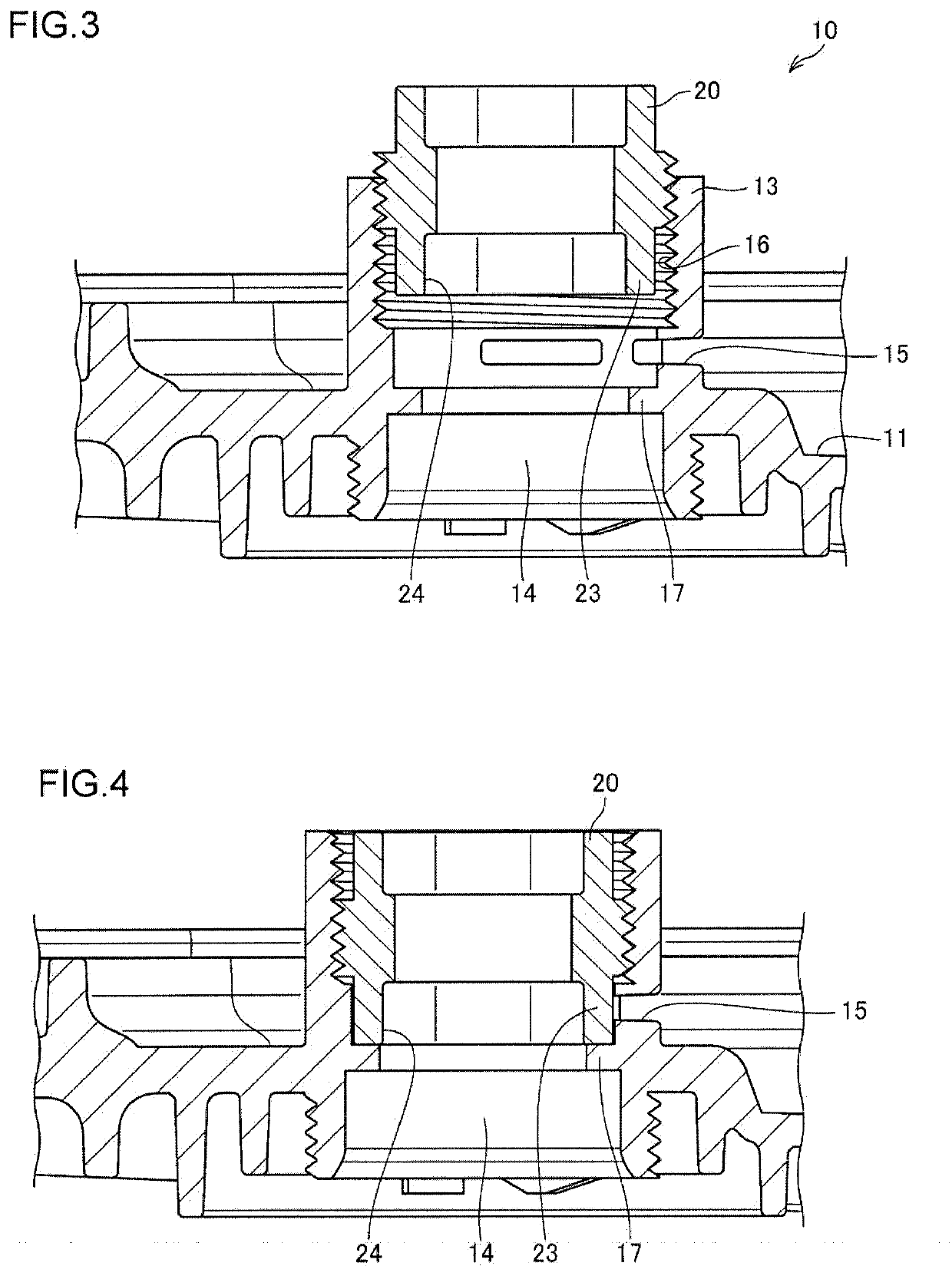

Lubricating oil discharge and filling structure

InactiveUS20200116051A1Secures precisionReliable dischargeOilsumpsMachines/enginesThermodynamicsPetroleum engineering

A lubricating oil discharge and filling structure of an oil pan including a cylindrical lubricating oil amount adjustment wall vertically provided from a bottom surface of the oil pan, and having a lubricating oil amount adjustment passage communicating with an outside of the oil pan, formed on an inner periphery. The lubricating oil amount adjustment wall has a lubricating oil discharge hole formed in a lower part, to the lubricating oil amount adjustment passage, a cylindrical lubricating oil amount adjustment plug in which a communication hole that communicates with the lubricating oil amount adjustment passage is formed is assembled movably along the lubricating oil amount adjustment passage. The lubricating oil amount adjustment plug includes a screw portion that screws into a screw groove formed in the lubricating oil amount adjustment passage, and a sealing wall that seals discharge of the lubricating oil from the lubricating oil discharge hole.

Owner:ROKI CO LTD

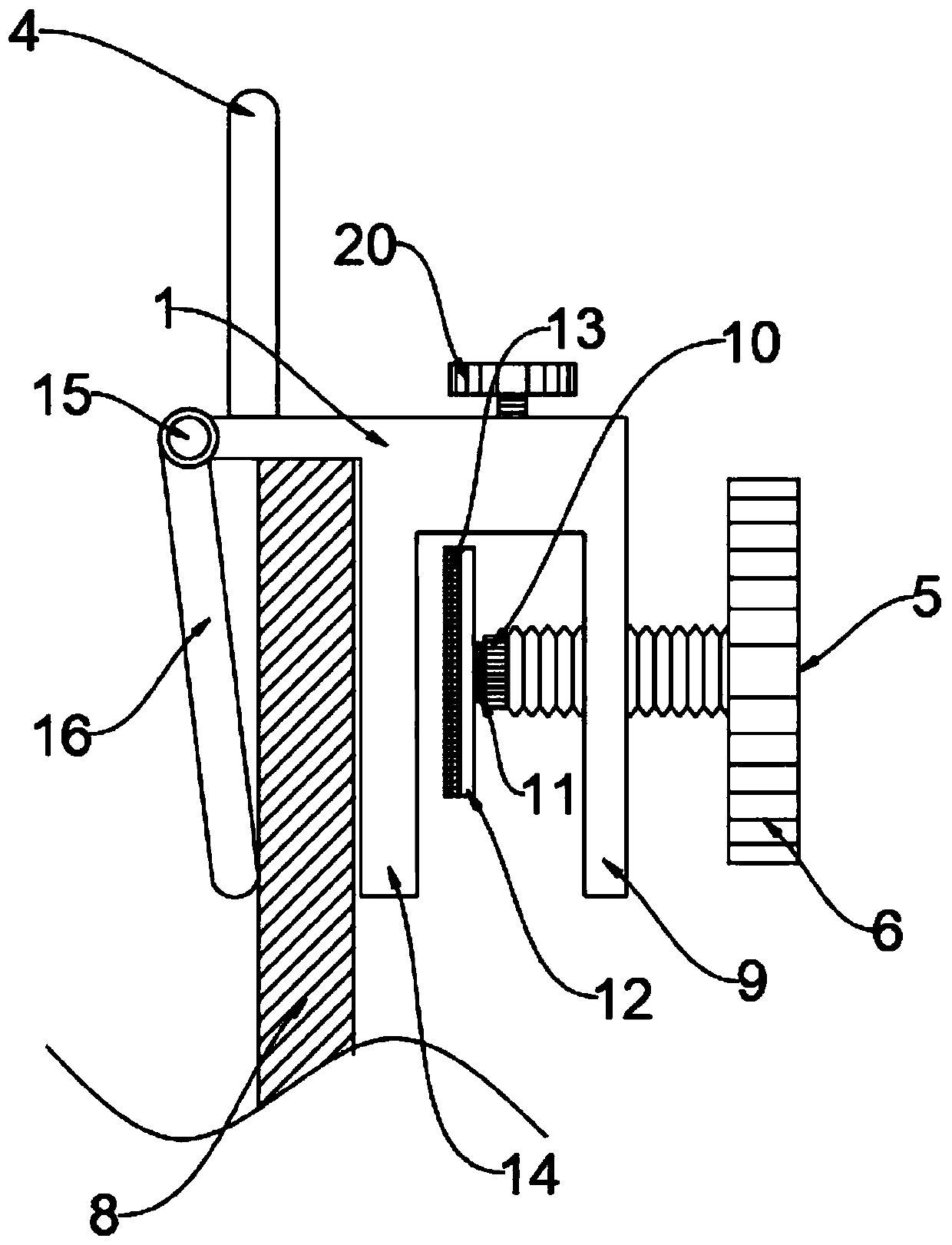

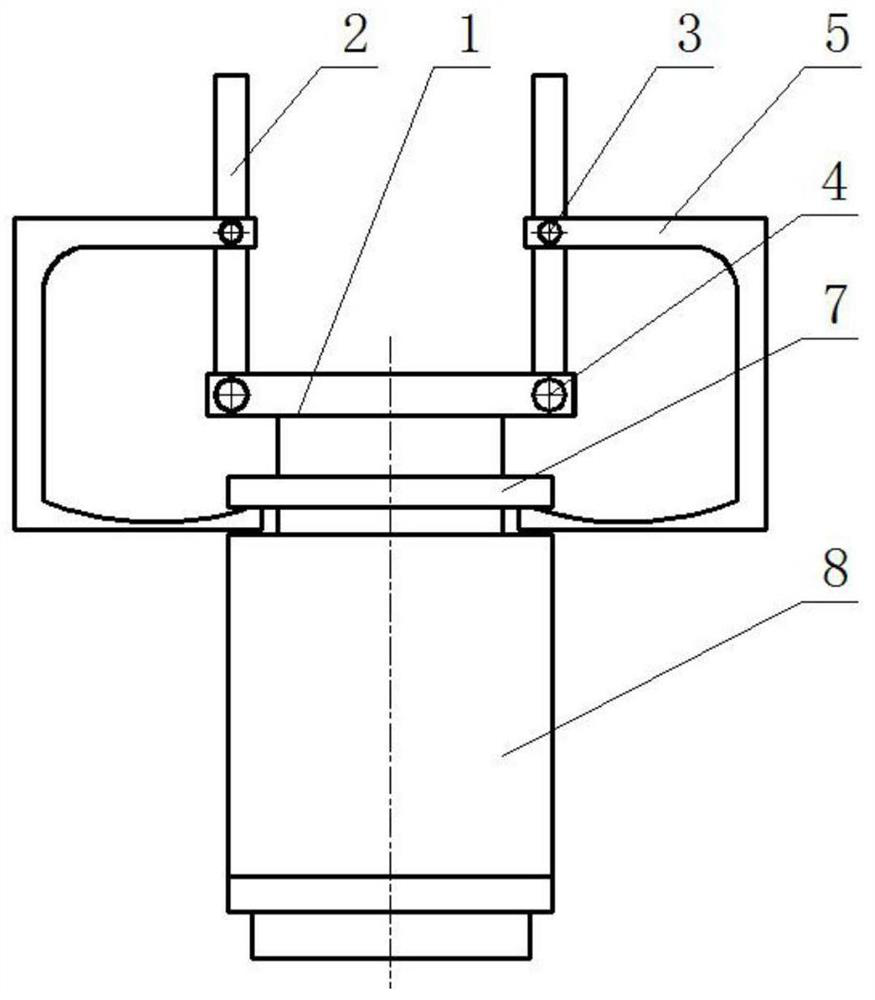

Clamping mechanism for design drawing

InactiveCN110271328AWide range of applicationsImprove practicalityDrawing boardsEngineeringDrawing board

The invention discloses a clamping mechanism for a design drawing and relates to the technical field of clamping mechanisms. Through the clamping mechanism, the problems that in the prior art, clamping force cannot be adjusted, and clamping distance cannot be adjusted flexibly are solved. A main shell comprises a first fixed plate, a second fixed plate, a clamping plate and a sliding groove. The second fixed plate is located on one side of the first fixed plate. The clamping plate is located on one side of the second fixed plate. A sliding rod is arranged in the sliding groove. An auxiliary shell is arranged at the other end of the sliding rod. One sides of the main shell and the auxiliary shell are each provided with a first adjusting bolt. One ends of the first adjusting bolts are provided with bearing outer rings. Bearing inner rings are arranged in the bearing outer rings. Fixed blocks are arranged at the other ends of the bearing inner rings. Rubber blocks are arranged at one ends of the fixed blocks. A drawing board is arranged between the second fixed plate and the clamping plate. The sliding groove is formed in the main shell, and the two sides of one end of the sliding groove are each provided with a limiting block.

Owner:SUZHOU WANDAI INFORMATION TECH CO LTD

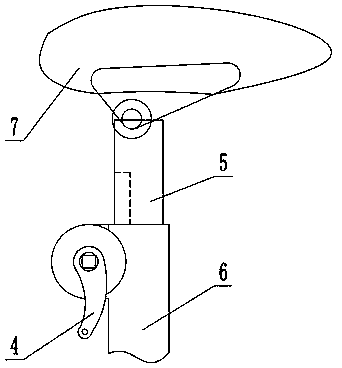

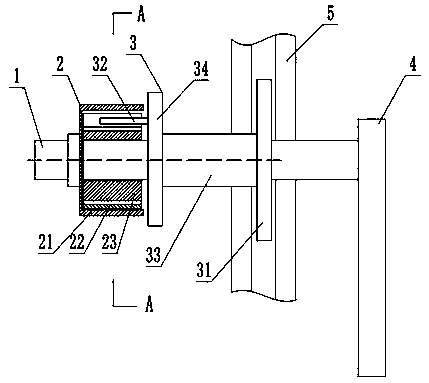

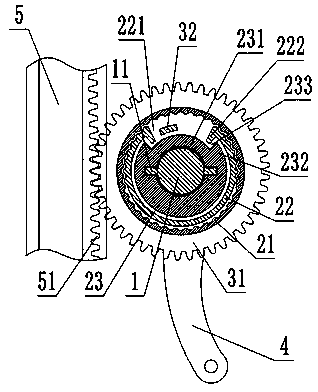

Bicycle seat adjusting device

The invention discloses a bicycle seat adjusting device. The bicycle seat adjusting device comprises a seat tube and a transverse shaft, wherein a cushion is supported by the seat tube. A positioningdevice, a linkage wheel and a handle are arranged on the transverse shaft from left to right in sequence, wherein the linkage wheel is in transmission connection with the positioning device, and the handle is fixedly connected with the right end of the transverse shaft. The positioning device comprises a casing. An elastic stopping ring is arranged on the inner side of the casing. A rotating wheelis arranged on the annular inner side of the elastic stopping ring and is in clearance fit with the elastic stopping ring. The linkage wheel comprises a gear and a stopping bar in linkage with the gear. The stopping bar extends into a first notch to be linked with a stopping block. The rack is arranged on the seat tube and meshed with the gear. The transverse shaft is rotatably connected with thelinkage wheel. The elastic stopping ring plays stopping and positioning roles under the action of friction force when expanding outwards. The process of dismantling and tightening bolts is omitted byadjusting the cushion through the steps.

Owner:李人鹤

A fully automatic battery module locking device

ActiveCN108054329BRealize automatic tighteningAvoid inconsistent thicknessCell component detailsMetal working apparatusControl engineeringMechanical engineering

Owner:SHENZHEN CLOU ELECTRONICS

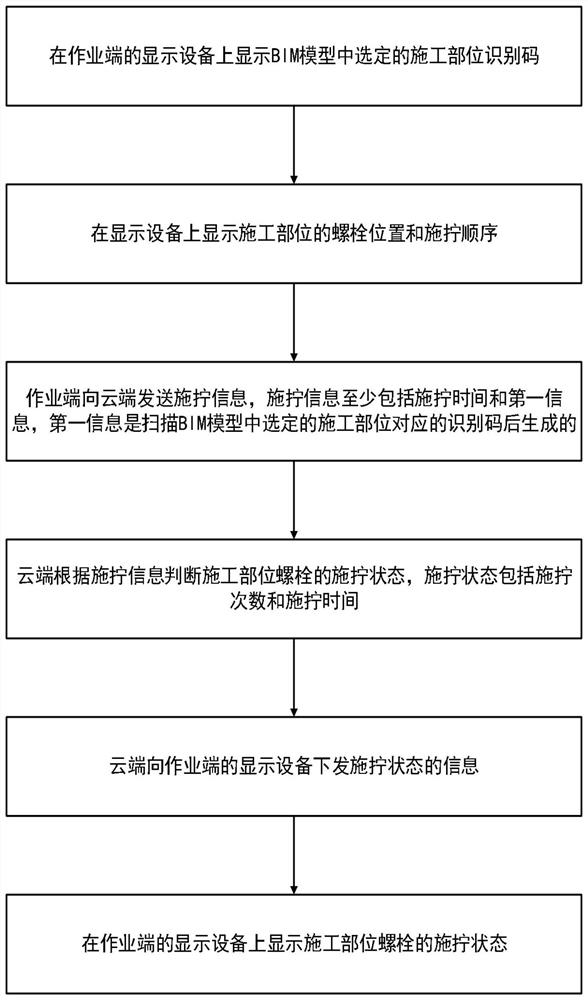

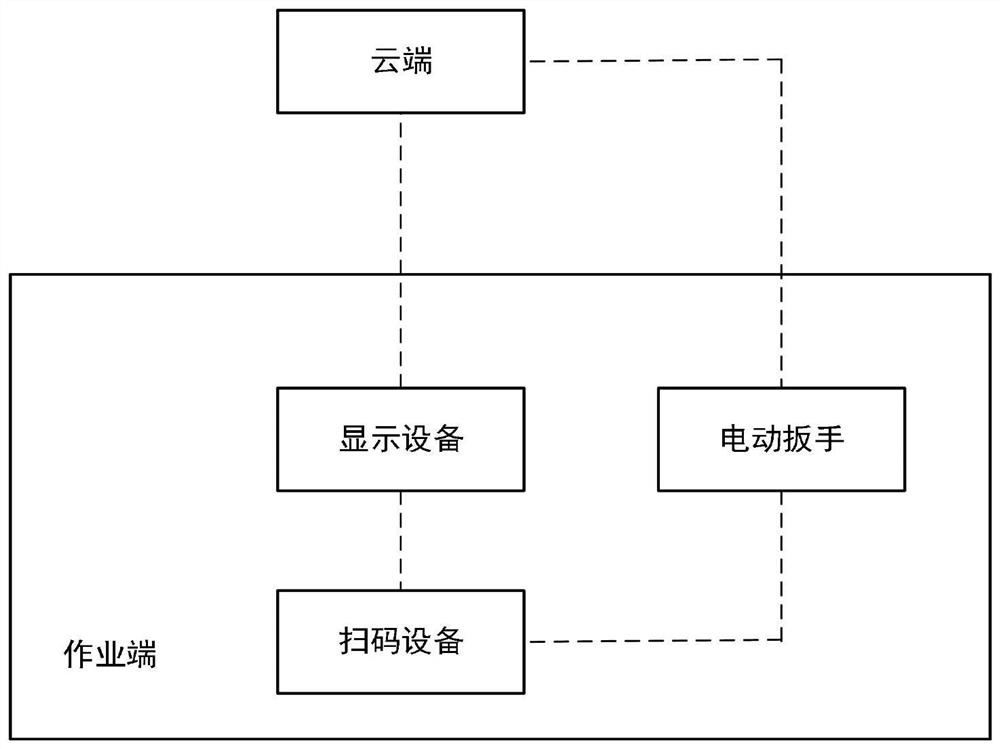

Bolt screwing monitoring method and system based on BIM

PendingCN114037029AAvoid numberingAvoid screwingCo-operative working arrangementsOffice automationDisplay deviceComputer science

The invention relates to a BIM-based bolt screwing monitoring method and system. The BIM-based bolt screwing monitoring method comprises steps that a construction part identification code selected in a BIM model is displayed on display equipment of an operation end; the bolt positions and the screwing sequence of the construction part are displayed on the display equipment; the operation end sends screwing information to the cloud end, the screwing information at least comprises screwing time and first information, and the first information is generated after an identification code corresponding to a selected construction part in a BIM model is scanned; the cloud side judges a screwing state of the bolt at the construction part according to the screwing information, wherein the screwing state comprises screwing times and screwing time; the cloud end issues the information of the screwing state to a display device of the operation end; and the screwing state of the bolt at the construction part is displayed on display equipment of the operation end. According to the method, workers can be guided to carry out construction according to a correct screwing sequence.

Owner:中铁桥研科技有限公司 +2

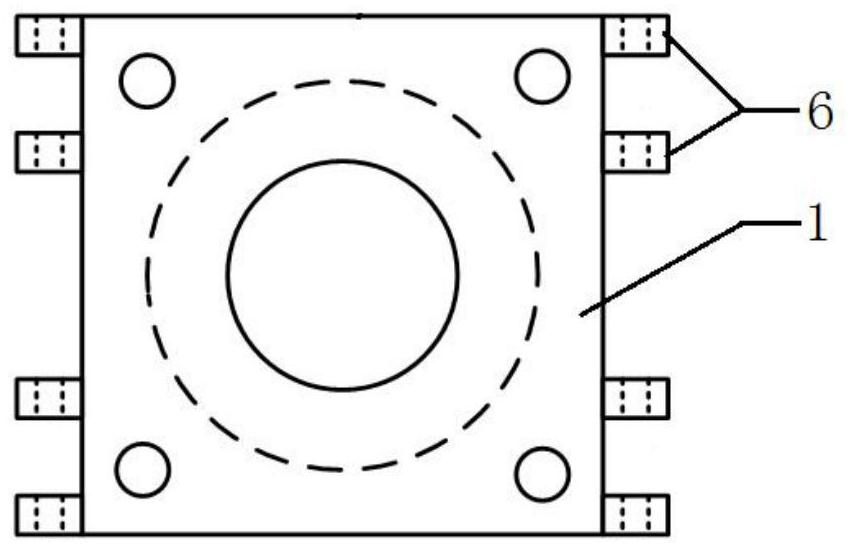

Transformer moisture breather quick change flange

ActiveCN109215957BSolve the complicated replacementImprove replacement efficiencyTransformers/inductances coolingGlass coverTransformer

The invention relates to a quick replacement flange of a transformer moisture absorber, which includes a connecting flange, a pull rod and a pull hook. A vent hole is formed in the center of the connecting flange, and the vent hole is coaxial and equal in diameter to the vent hole of the flange of the moisture absorber. Four pull rods are symmetrically hinged at the four corners of the connecting flange, and a pull hook is hinged on each pull rod. The connecting flange and the dehumidifier flange are connected by a pull hook, and the hook end of the pull hook is hung on the flange hole of the dehydrating absorber flange. Inside. The quick replacement flange of the transformer dehumidifier solves the complicated problem of operation and maintenance personnel replacing the transformer dehumidifier, effectively improves the replacement efficiency of the transformer dehumidifier, and avoids breaking the glass cover of the dehumidifier and disassembling the dehumidifier caused by the replacement of the transformer dehumidifier. Flanges or transformers are screwed down, and even personnel get an electric shock.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Double-steel-wheeled vibratory road roller with hydraulic pipe fastening device

InactiveCN102877396AGuaranteed to workProtection securityRoads maintainenceVehicle frameHydraulic pump

The invention discloses a double-steel-wheeled vibratory road roller with a hydraulic pipe fastening device. The double-steel-wheeled vibratory road roller comprises a rear frame with two threaded holes, wherein a double-ended bolt is fixedly screwed into each threaded hole; the hydraulic pipe fastening device which mainly comprises a first rubber plate and a second rubber plate is arranged on the rear frame; the first rubber plate and the second rubber plate are provided with a threaded hole respectively, are butted together, and are fixedly screwed on the rear frame through the two double-ended bolts; the end parts of the first rubber plate and the second rubber plate are respectively provided with a semi-mounting hole for clamping a hydraulic pipe; the two semi-mounting holes are butted together to form a mounting hole; and the distance between the bottom of the mounting hole and the flat surface of the rear frame is 60 to 80mm. By the double-steel-wheeled vibratory road roller, the problem that hydraulic pipes are frequently abraded is effectively solved, and the safety of the hydraulic pipes and the normal operation of the double-steel-wheeled vibratory road roller are ensured.

Owner:XUZHOU WBEST CIVIL CONSTR EQUIP & SERVICES

Aircraft seat fixing apparatus

InactiveUS20070197098A1Firmly connectedStable and secure mannerElectrically conductive connectionsSeating arrangementsEngineeringMechanical engineering

An aircraft seat fixing apparatus includes at least one insertion region and at least one retaining element, both of which are provided for fixing a shell half to a bracket. The insertion region comprises a recess for enabling the retaining element to be inserted into the insertion region by means of an insertion movement which has a component perpendicular to a main direction of the extent of the retaining element.

Owner:RECARO AIRCRAFT SEATING

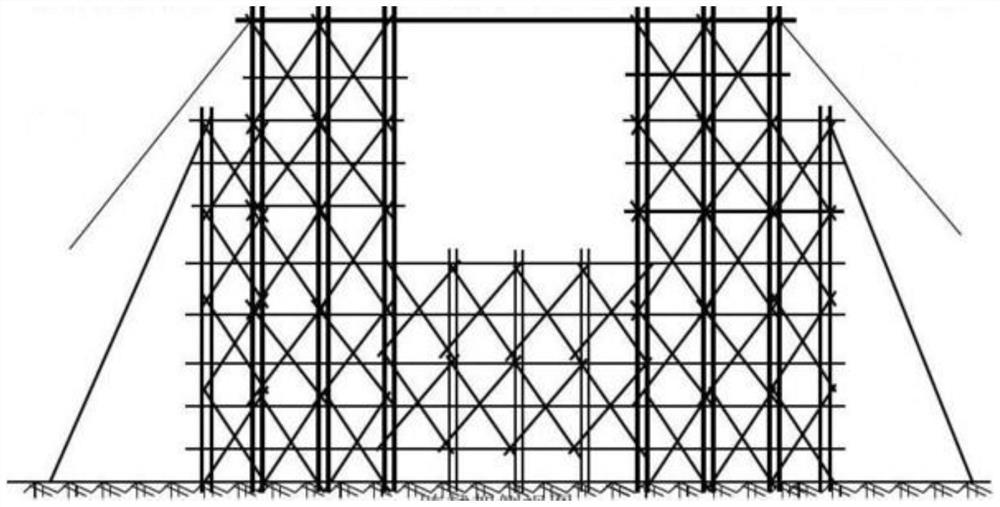

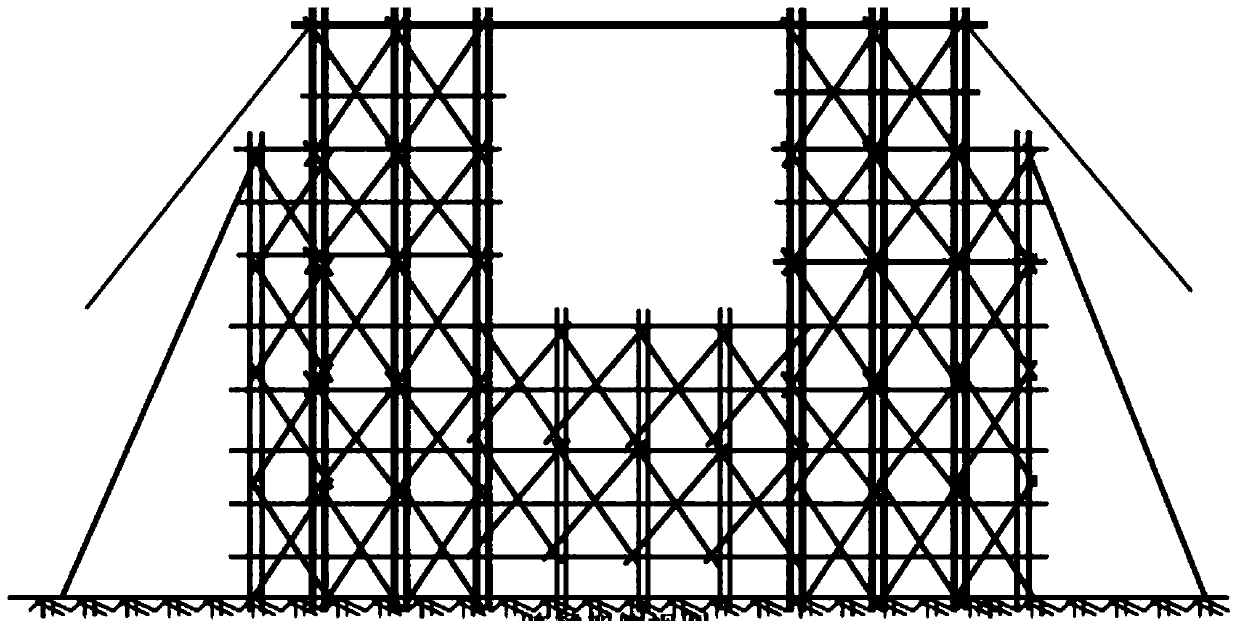

Wooden pole intersection tie-down

ActiveCN110778100BAvoid Dead Knot SituationsAvoid breakingBuilding material handlingScaffold accessoriesSupport pointSafe operation

The invention provides a binding device for wooden poles, which comprises a U-shaped metal frame, a steel wire rope and a steel wire rope fixing piece. The wooden rod binding device of the present invention uses a U-shaped metal frame as a supporting point, uses a steel wire rope as a winding tool, and finally uses a steel wire rope fixing part to lock the steel wire rope, so that various materials are combined into a binding system to complete the binding process. The wooden pole binding The device has completely changed the traditional iron wire binding method, successfully avoiding the dead knot of the iron wire binding in the prior art, and the breakage of the iron wire caused by excessive tightening force, thereby preventing the iron wire from being broken due to the fatigue strength limit of the binding or due to torsional force. The twisting of the ambassador caused the collapse of the spanning frame, which completely eliminated the safety hazard of the spanning frame collapse and ensured personal safety and the safe operation of the spanning object. After the successful development of this achievement, it was immediately put into the field and received unanimous praise from the construction personnel during the field use.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

Wired phone cable twisting eliminating device

InactiveCN103633520AEasy to twistSolve usabilityCoupling device connectionsFlexible/turnable line connectorsPull forceElastic component

The invention discloses a wired phone cable twisting eliminating device. The wired phone cable twisting eliminating device comprises a cable springback device and a cable winding device. The cable springback device comprises a sliding rail, a sliding block arranged on the sliding rail, an elastic component, and a pull rope. One end of the elastic component is fixed on one end of the sliding rail, and the other end of the elastic component is connected with the sliding block. The pull rope is connected onto the sliding block. The cable winding device comprises a first winding reel, a second winding reel, a third winding reel, an axis rod and a housing. The first winding reel, the second winding reel and the third winding reel are fixedly installed on the axis rod successively. The axis rod is installed in the housing and can be rotated around the axis of the axis rod. The pull rope is connected with the first winding reel. A wired phone cable is wounded onto the second winding reel and the third winding reel. By adopting the wired phone cable twisting eliminating device of the invention, the inconvenience caused by the phone cable twisting situation can be effectively avoided so as to bright convenient for the daily life of people.

Owner:许春雷

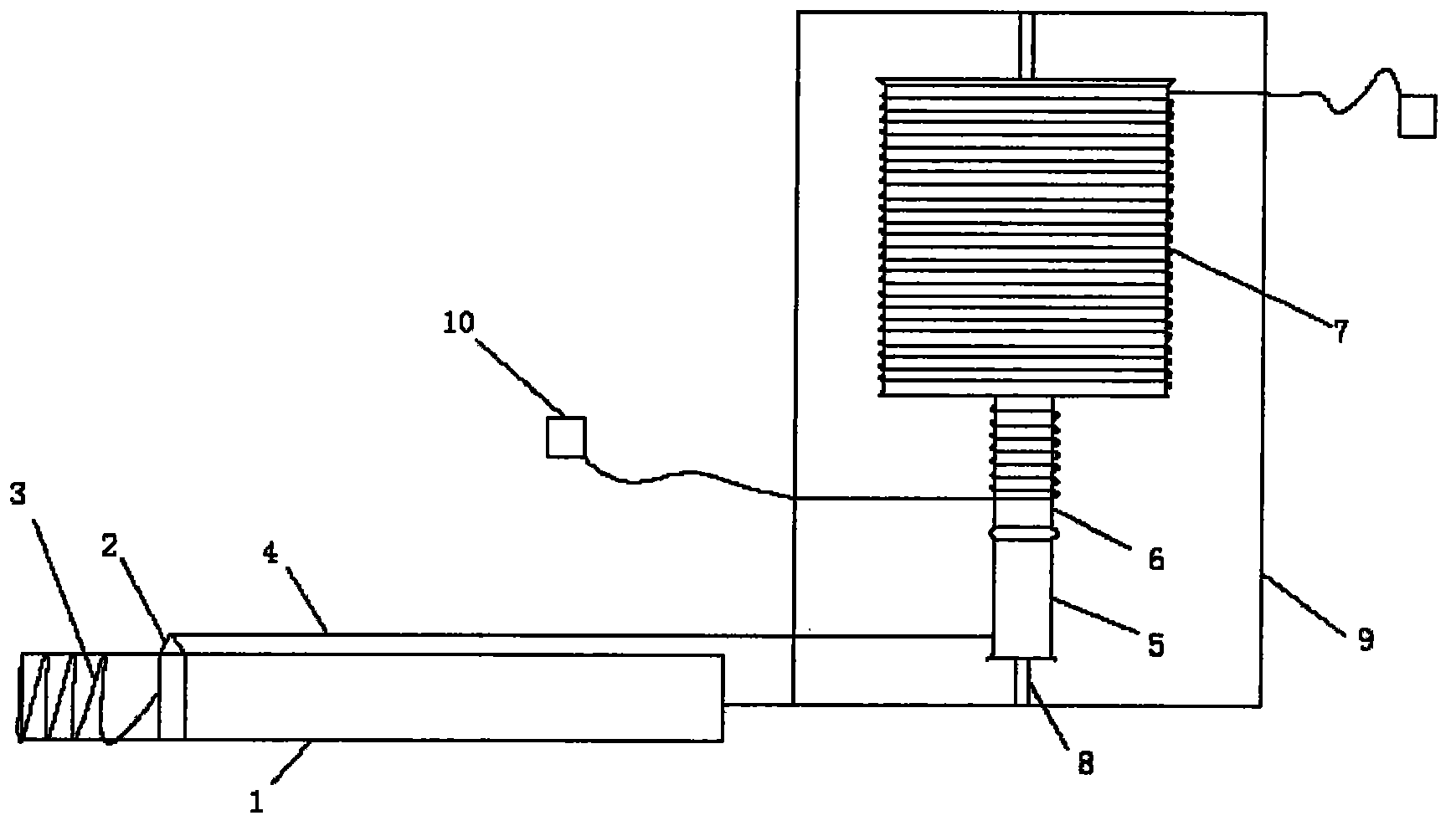

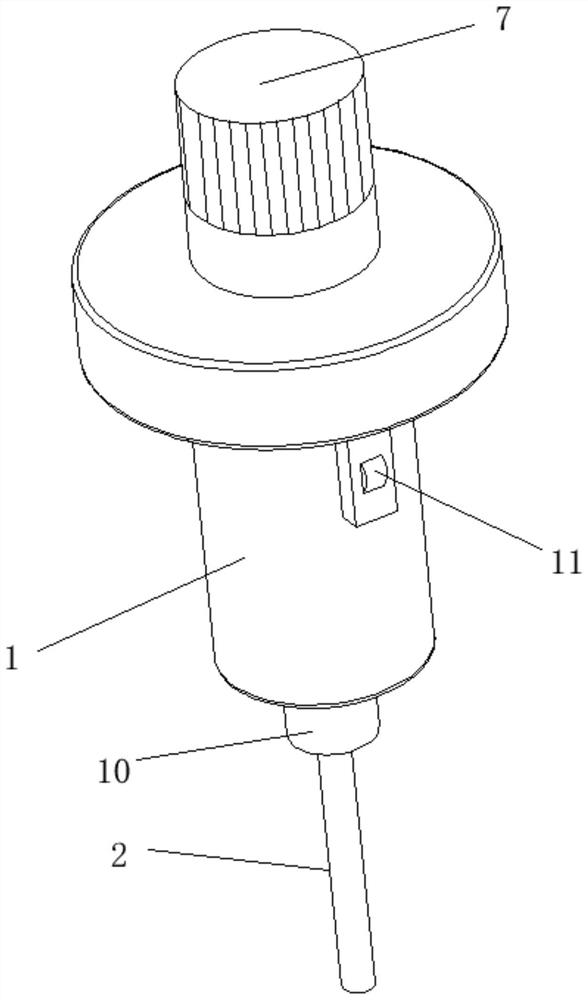

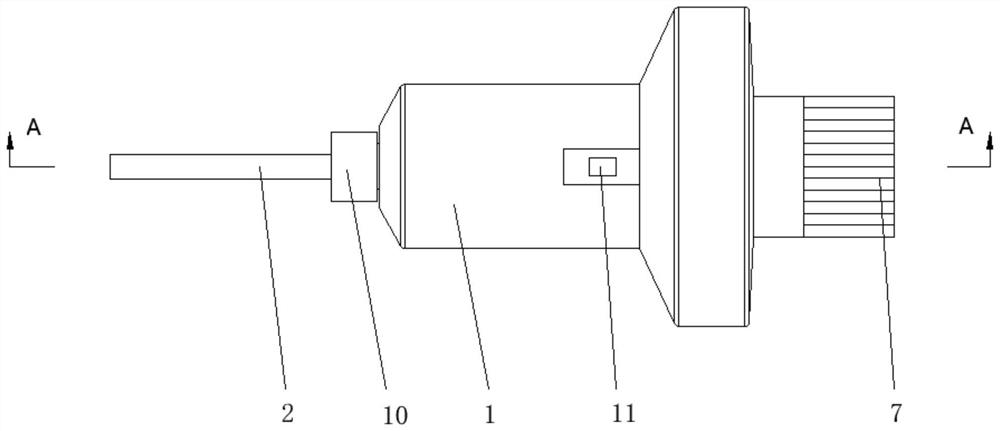

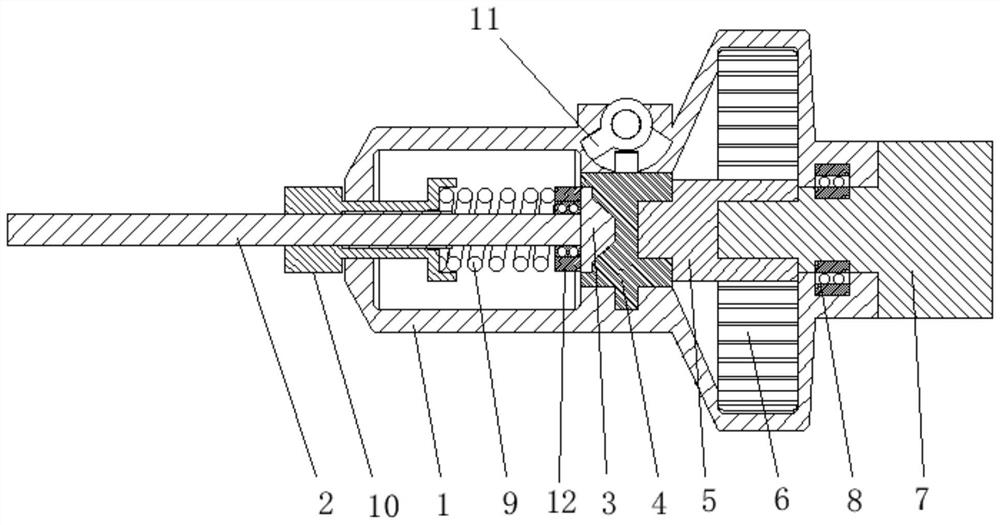

A clockwork energy storage screwdriver

The invention belongs to the field of screwdrivers, and particularly relates to a spring energy storage screwdriver. The problems that in the prior art, time and labor are wasted when a screwdriver isused for tightening a screw, and the screw cannot be continuously screwed are solved. According to the technical scheme, the spring energy storage screwdriver comprises a shell (1), a knife rod (2) and a coil spring (6); a transmission shaft (5) is fixedly connected to the inner end portion of the coil spring (6); one end of the transmission shaft (5) is connected with the knife rod (2); the other end of the transmission shaft (5) is connected with a knob (7); and the outer end portion of the coil spring (6) is fixedly connected with the shell (1). According to the spring energy storage screwdriver, continuous rotating of the knife rod can be realized through the coil spring, a user does not need to restore the positions of hands, alignment is not needed, and manpower and time are saved.The spring energy storage screwdriver is suitable for tightening or loosening various screws.

Owner:SOUTHWEST JIAOTONG UNIV

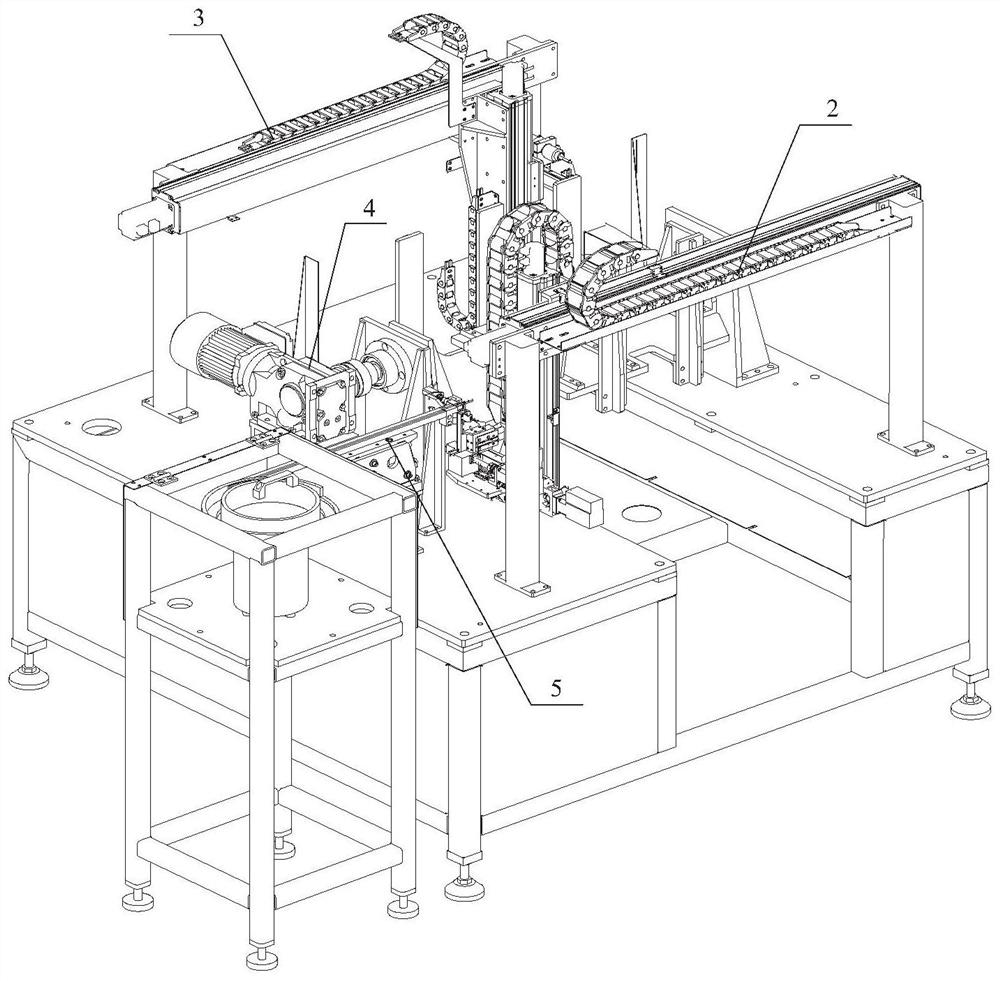

Automatic threading screw machine and screw nut locking device

The invention relates to the technical field of assembling of screws and nuts, and provides a screw and nut locking device. The device comprises a mounting rack, a nut locking mechanism, a screw screwing mechanism and a lifting mechanism, wherein nut locking mechanism, the screw screwing mechanism and the lifting mechanism are arranged on the mounting rack; the nut locking mechanism is used for positioning the screw and the nut as well as enabling overlapping of the axes of the screw and the nut; the screw screwing mechanism is used for screwing the screw to rotate about an axis of the screw; the lifting mechanism is used for driving the screw screwing mechanism to move up and down relative to the mounting rack and enabling the contact of the screw screwing mechanism and the top end part of the screw while the screw screwing mechanism moves up and down. Compared with the prior art, the device has the advantages that the screw and nut can be automatically fixed to a workpiece, thus that the screw is ignored to screw can be avoided, the problem of non-uniform screwing force can be solved, and as a result, the product quality can be ensured. The invention further provides an automatic screw assembling machine. Compared with the prior art, the machine has the advantages that the workload of workers can be reduced, thus the labor cost can be decreased, and the production efficiency can be improved.

Owner:SHENZHEN WAVE MULTIMEDIA

Wood rod binding device

ActiveCN110778100AAvoid Dead Knot SituationsAvoid breakingBuilding material handlingScaffold accessoriesSupport pointWire rope

The invention provides a wood rod binding device. The wood rod binding device comprises a U-shaped metal frame, steel wire ropes and steel wire rope fixing pieces. The wood rod binding device takes the U-shaped metal frame as a supporting point, the steel wire ropes are taken as winding tools, the steel wire rope fixing pieces are finally adopted to lock the steel wire ropes, and the binding process is commonly completed by combining the materials into one binding system. According to the wood rod binding device, a traditional iron wire binding mode is completely changed, the wood rod bindingdevice successfully avoids the situations that iron wires are knotted during binding in the prior art, the iron wires are broken due to too large twisting force, and the iron wires are accordingly broken by reaching the fatigue strength limit during binding or are twisted to be broken due to the excessive torsional force, so that the collapse accidents of a crossing frame occur is avoided, the potential safety hazards of the crossing frame collapse are completely eliminated, and personal safety and the safety operation of cross objects are guaranteed. After the wood rod binding device is successfully developed, the wood rod binding device is immediately put into the field for use, and the consistent high evaluation of constructors is obtained in the field use process.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

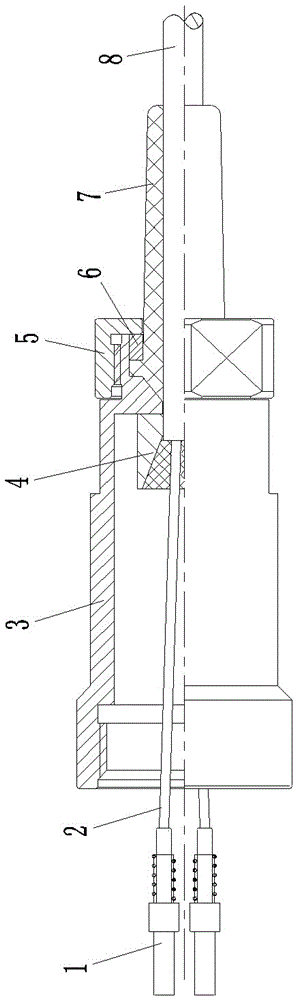

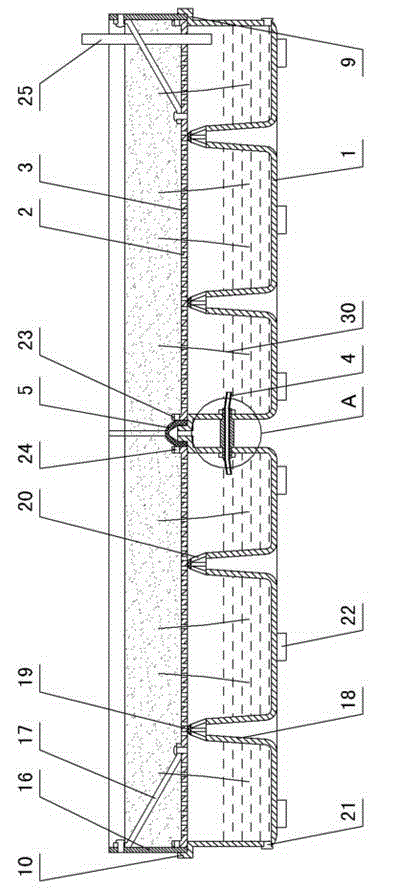

A recyclable head-expanding bolt and its construction method

The invention relates to a recyclable expansion anchor rod and a construction method thereof. The recyclable expansion anchor rod comprises an anchor head, a rod body, a protecting bag and a rod body protecting tube; the anchor head is composed of a screw, a herringbone expanding head, a spiral steel wire, a steel wire protecting tube and an anchoring piece; the herringbone expanding head is screwed in the screw; the spiral steel wire penetrates the herringbone expanding head to extend into the steel wire protecting tube; the steel wire protecting tube sleeves the screw; the anchoring piece is mounted at one end of the rod body; the rod body is composed of a plurality of equidistantly arranged steel strands, steel strand position fixing parts and steel strand tensioning parts, and the steel strands are respectively fixed on the anchoring piece, the steel strand position fixing parts and the steel strand tensioning parts; the protecting bag is arranged outside the anchor head; the rod body protecting tube sleeves the rod body and are in butt joint with the protecting bag. The recyclable expansion anchor rod and the construction method thereof have the advantages that simpleness in structure, convenience in mounting, repeated use and low cost are achieved and the like.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

Screwing tool for automatically tagging inner hexagonal bolt

The invention discloses a screwing tool for automatically tagging an inner hexagonal bolt. The screwing tool comprises a base body, wherein a first connecting part adaptive to a wrench is arranged at the back end of the base body, the front end of the base body is provided with a second connecting part adaptive to the inner hexagonal bolt, and the axes of the first connecting part and the second connecting part are coincided with that of the base body; the second connecting body comprises an outer hexagonal screwing head detachably mounted on the base body; and the screwing tool also comprises a tagging structure which is matched with the outer hexagonal screwing head for working and tags the inner hexagonal bolt. The screwing tool is reasonable in structure, convenient, practical, simple in operation, capable of automatically tagging a tag, meaning that the inner hexagonal bolt has been screwed, on the inner hexagonal bolt, the missing of torque tightening work of the bolt is prevented, the quality of the machine and device is ensured, and the working efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

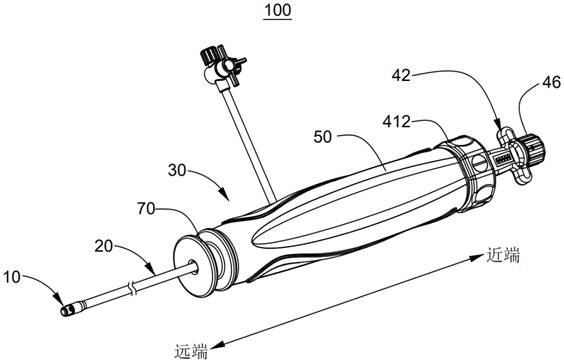

Take-up system

ActiveCN114533348AAvoid premature releaseImprove safety and reliabilityAnnuloplasty ringsEngineeringMechanical engineering

The invention provides a take-up system. The take-up system comprises a take-up device, a conveying device and an operating handle. The take-up device comprises a winding shaft, and the winding shaft is used for winding the flexible long and thin piece. The conveying device comprises a connecting rod and a connecting pipe which are movably sleeved. The operating handle comprises a driving assembly, the driving assembly comprises a first rotating part and a second rotating part which are movably sleeved, the near end of the connecting pipe and the first rotating part are connected for synchronous movement, and the near end of the connecting rod and the second rotating part are connected for synchronous movement; wherein the take-up system has a first state and a second state, in the first state, the first rotating part and the second rotating part relatively stop rotating, in the second state, the first rotating part and the second rotating part can relatively rotate, and the second rotating part moves in the axial direction relative to the first rotating part so that the take-up system can be converted into the second state from the first state. When the take-up system is in the first state, in the process of driving the winding shaft to wind the flexible slender piece, the winding shaft, the connecting pipe and the connecting rod rotate synchronously.

Owner:HANGZHOU VALGEN MEDTECH CO LTD

Series connection mechanism for water storage type flowerpot

InactiveCN104813906AFirmly connectedPrevent fallingSelf-acting watering devicesWater storageEngineering

A series connection mechanism for a water storage type flowerpot is characterized by comprising pot bodies. Separating plates are arranged in the pot bodies, through holes are formed in the separating plates, the upper portions of the separating plates are used for planting plants, the pot bodies are provided with water storage cavities on the lower portion of the separating plates, more than two pot bodies are arranged, and water pipes are arranged between the pot bodies and the water storage cavities of the pot bodies. On one hand, the water passing effect is achieved; that is to say, the water storage cavities of every two adjacent flowerpots are connected; water is added to the first flowerpot and when the water level of the first flowerpot reaches the height of the water pipes and the water continues being added to the first flowerpot, the water can flow to the water storage cavity of the second flowerpot through the water pipes, the rest can be done in the same manner until all the connected flowerpots are full of water, the water is added very conveniently, and the working efficiency is improved; on the other hand, the water pipes are connected to achieve the connecting effect, and the flowerpots are connected more tightly and more reliably.

Owner:张卫军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com