Lubricating oil discharge and filling structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

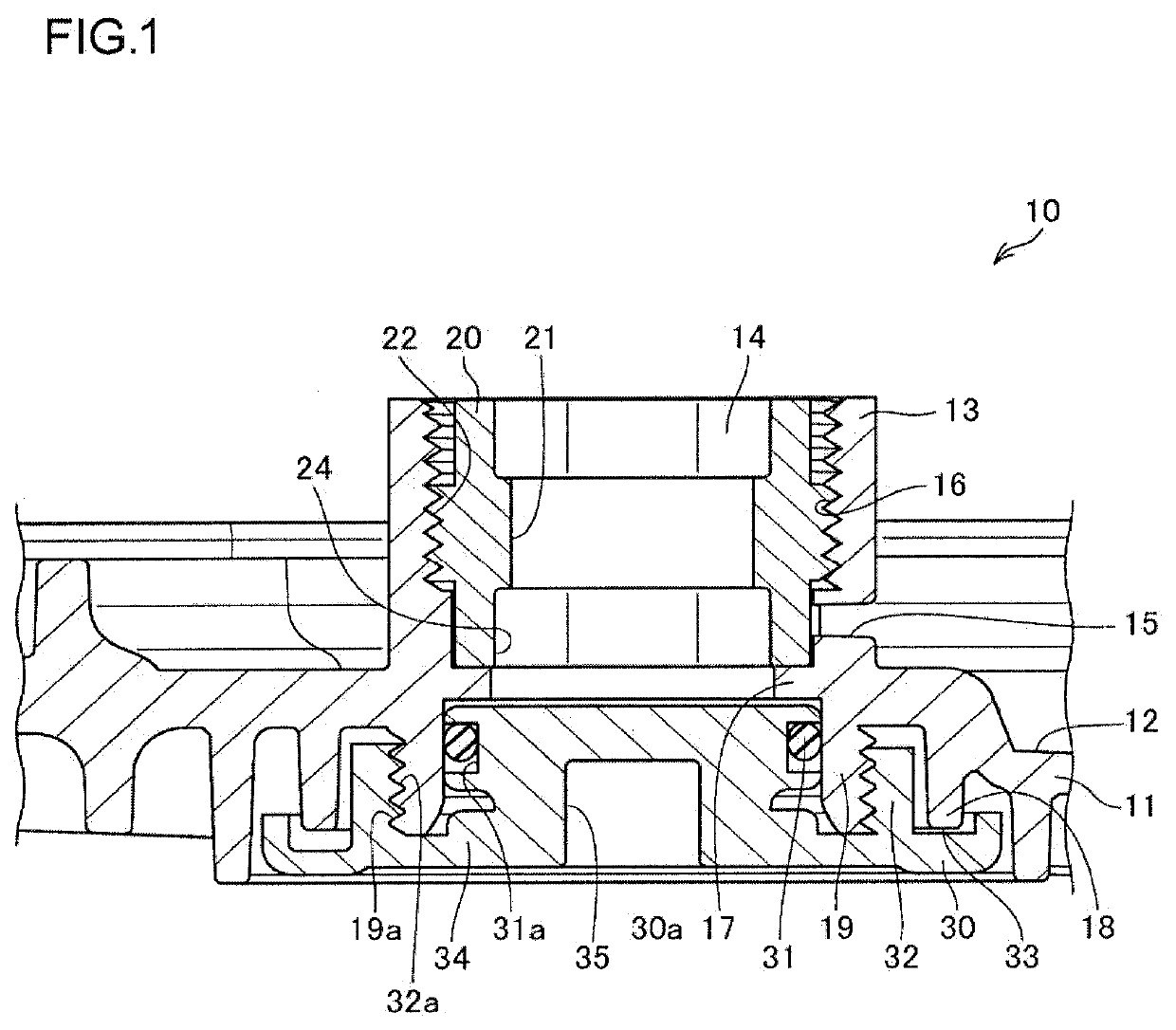

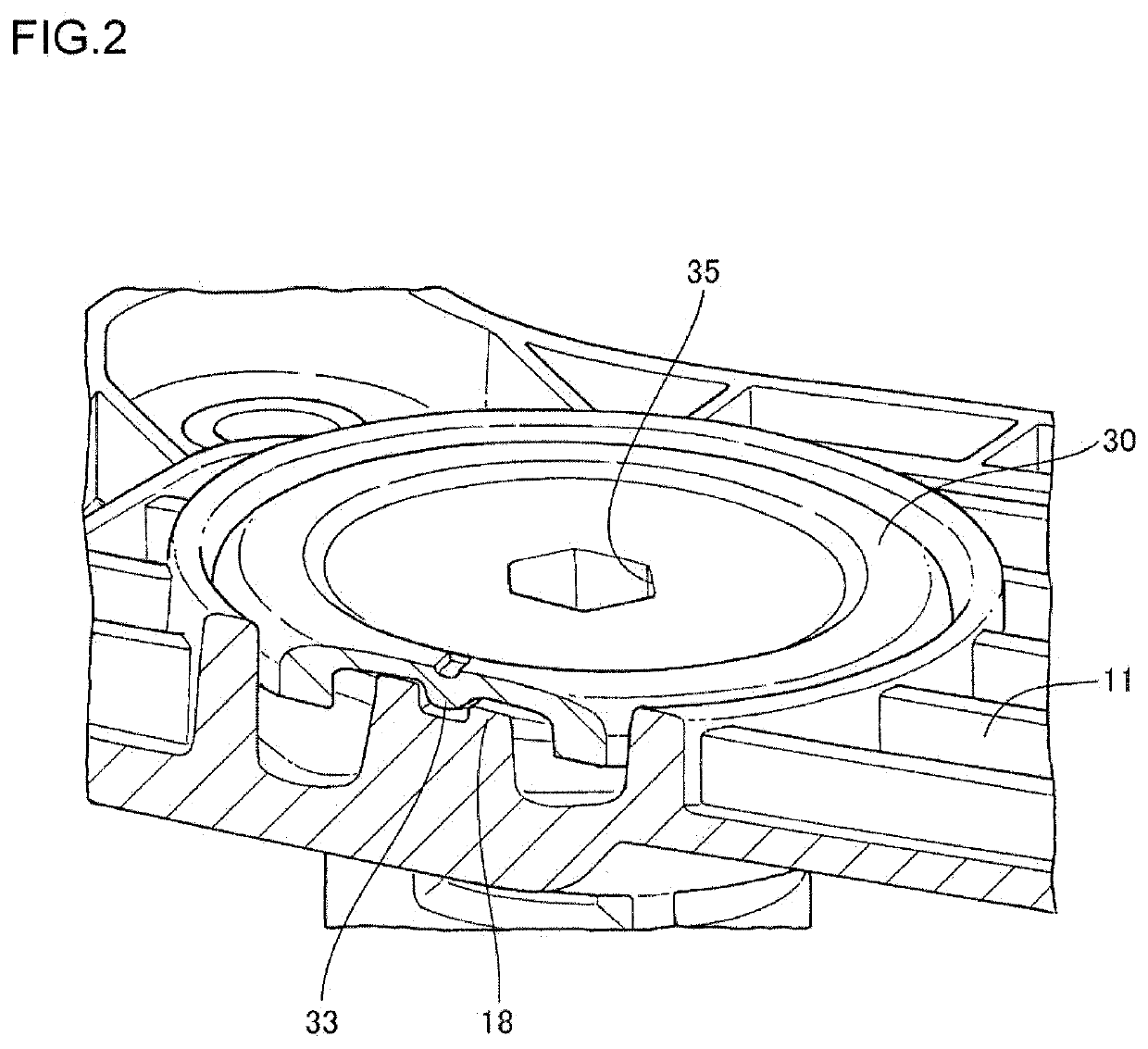

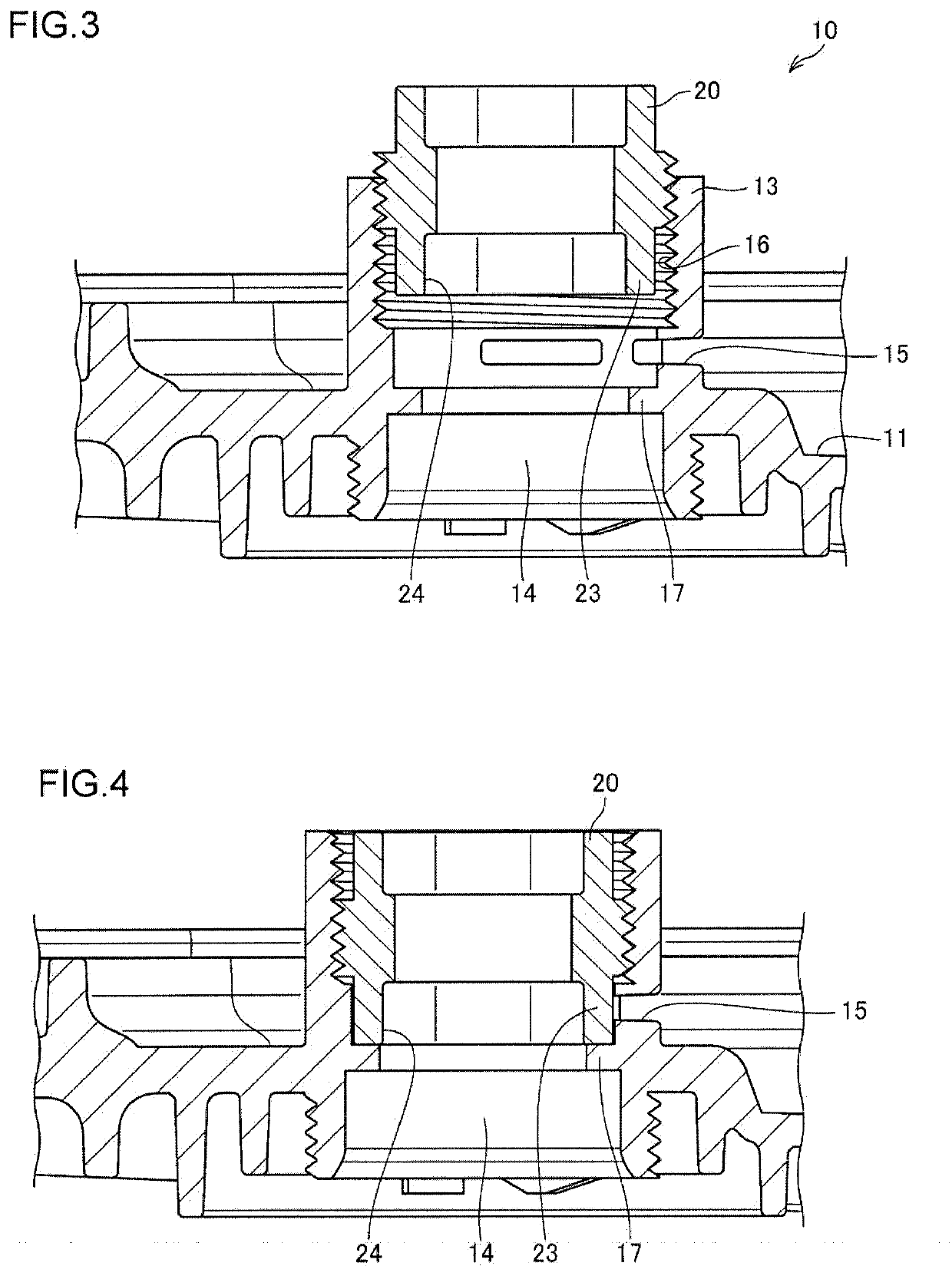

[0029]FIG. 1 is a sectional view for explaining a configuration of a lubricating oil discharge and filling structure according to a first embodiment of the present invention. FIG. 2 is a partial sectional view for explaining the configuration of the lubricating oil discharge and filling structure according to the first embodiment of the present invention. FIG. 3 is a sectional view for explaining a configuration at a time of oil discharge of the lubricating oil discharge and filling structure according to the first embodiment of the present invention. FIG. 4 is a sectional view for explaining a configuration at a time of filling of the lubricating oil discharge and filling structure according to the first embodiment of the present invention. FIG. 5 is a sectional view for explaining a configuration of a falling-off prevention device of the lubricating oil discharge and filing structure according to the first embodiment of the present invention. FIG. 6 is a sectional view for explain...

second embodiment

[0051]In the lubricating oil discharge and filling structure 10 according to the first embodiment described above, explanation is made about the case where the lubricating oil amount adjustment plug 20 is screwed into the screw groove 16 which is formed on the inner circumferential surface of the lubricating oil amount adjustment passage 14, and the lubricating oil amount adjustment plug 20 is mounted movably along the lubricating oil amount adjustment passage 14. In a lubricating oil discharge and filling structure 10′ of a second embodiment that will be described next, explanation is made about an example of a lubricating oil amount adjustment plug 53 having a mode different from the first embodiment. Note that same or similar members as or to those in the case of the aforementioned first embodiment will be assigned with the same reference signs and explanation thereof will be omitted.

[0052]FIG. 7 is a perspective view showing the lubricating oil discharge and filling structure ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com