Wood rod binding device

A binding device and wood technology, used in construction, construction material processing, scaffolding accessories, etc., can solve the problems of affecting power supply, collapse of spanning, large required quantity, etc., to avoid waste of steel resources, avoid waste of resources, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

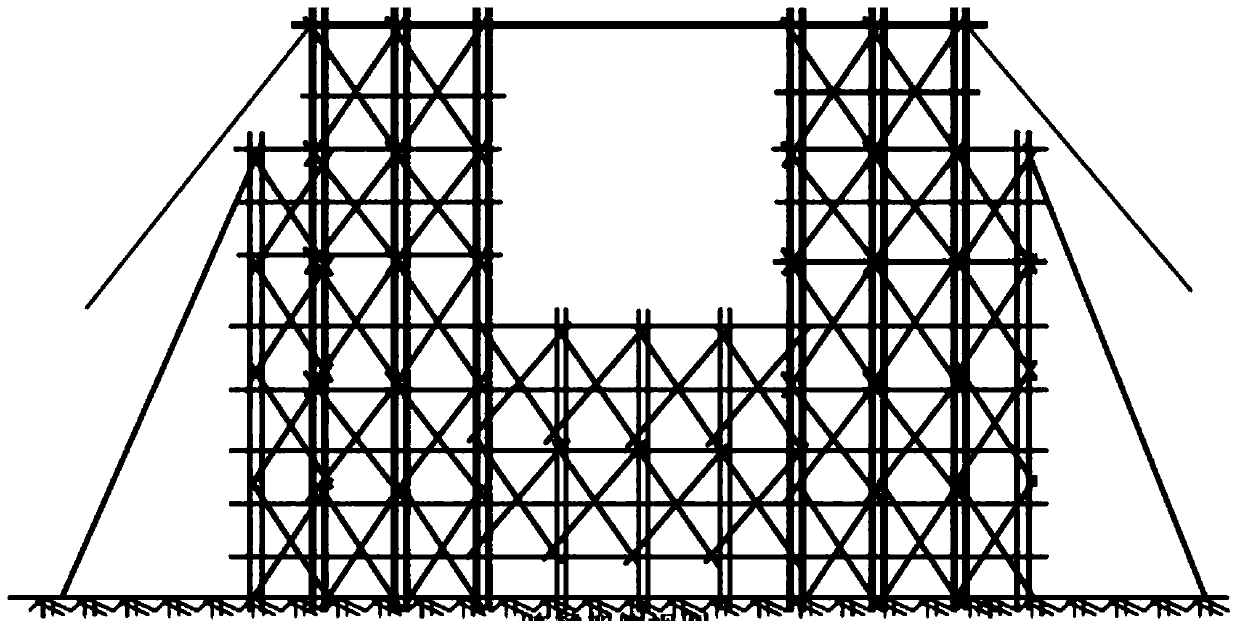

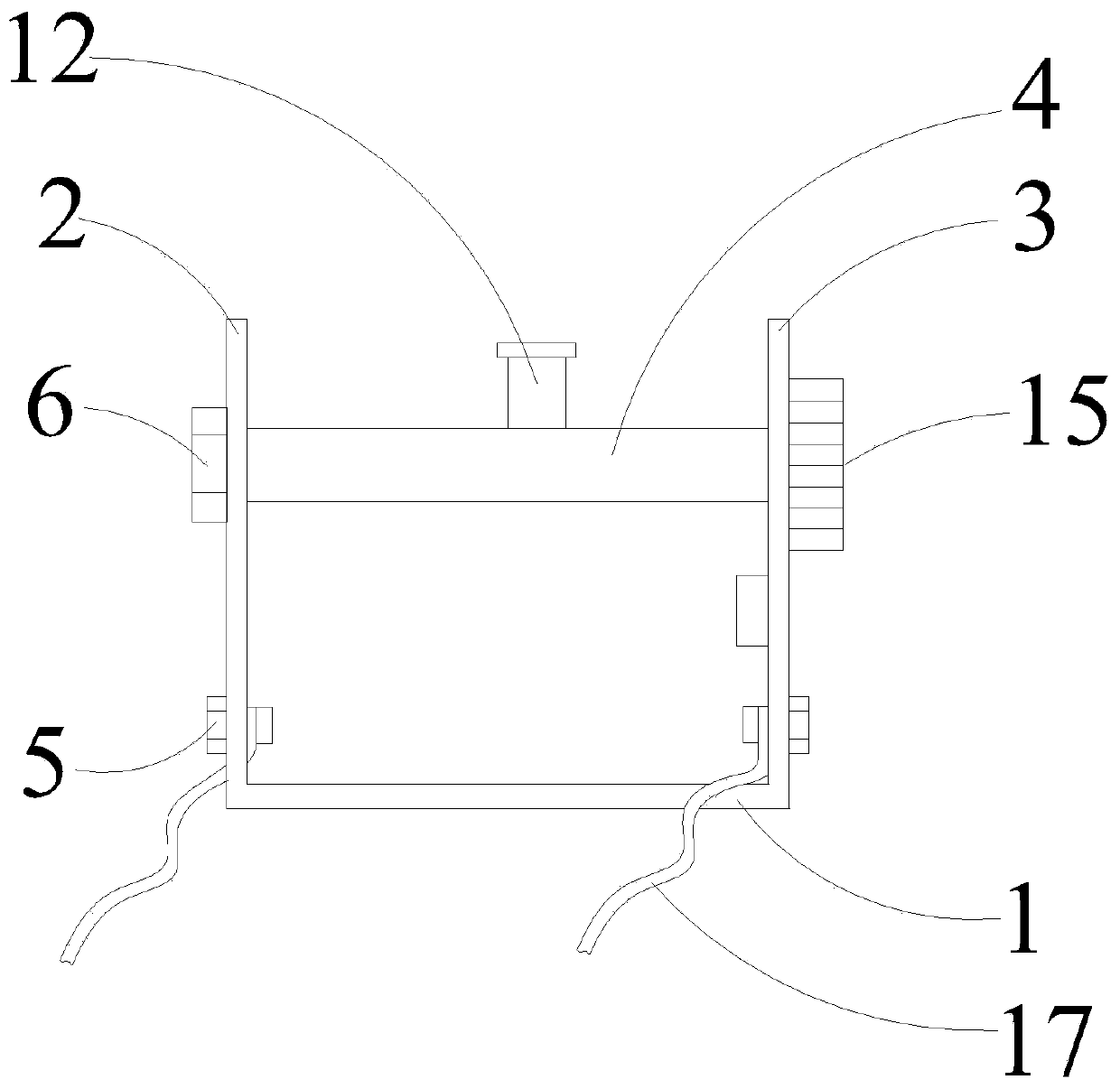

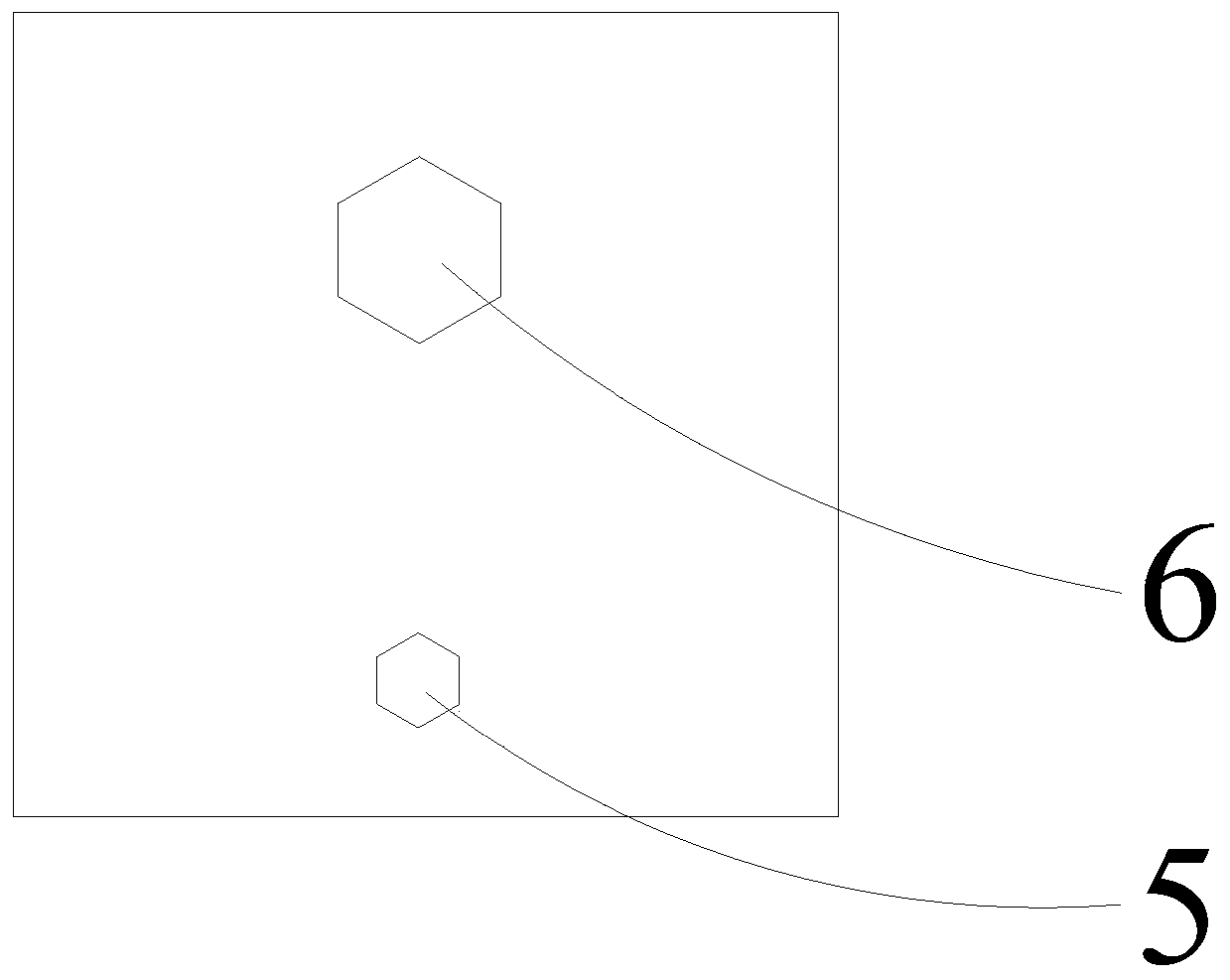

[0044] This embodiment relates to a wooden pole binding device, which is specifically used for wiring of power transmission lines, wherein an exemplary structure is as Figure 2 to Figure 5 shown. It can be seen from the figure that the wooden pole binding device includes a U-shaped metal frame, a steel wire rope and a wire rope fixing piece. The U-shaped metal frame includes a first end face 1 , a second end face 2 and a third end face 3 . Preferably, the U-shaped metal frame is integrally formed. Specifically in this embodiment, it is folded from a flat iron with a length of 20cm and a thickness of 4m. The steel wire rope is wound around the first end surface 1, leaving a free end for binding the wooden pole 18 to be bound. Preferably, the diameter of the steel wire rope 17 is 2.5mm. The wooden rod binding device of this embodiment uses φ2.5 steel wire rope, and its breaking force is 500kg, which ensures the binding force during binding. The potential safety hazards of ...

Embodiment 2

[0062] This embodiment relates to a wooden pole binding device, the structure of which is basically the same as that of the wooden pole binding device in the first embodiment, the difference is that: the ratchet part also includes a driving part, and the driving part includes a driving motor 10 and a driving wheel 11, the teeth of the drive wheel 11 are matched with the oblique teeth 13 of the ratchet 7, one end of the drive motor 10 is fixedly connected to the third end face 3, and the other end is movably connected to the drive wheel 11 (Such as Figure 7 shown). Therefore, the wooden rod binding device of this embodiment is slightly different from the first embodiment when used. After the wire rope is wound and fixed, it is only necessary to make the drive motor 10 work. The specific operation method can be selected from the existing technology. control method in . The drive motor 10 drives the drive wheel 11 to rotate through the connecting shaft, and then the drive whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com