Capping machine for food glass pot

A technology of glass jars and capping machines, which is applied in the direction of capping containers tightly with caps, application, screw caps, etc. It can solve the problems of difficult production quality assurance, inconvenient maintenance, and serious injury to workers' hands, and achieve the goal of reducing costs. Expenditure, avoid product breakage, avoid the effects of appearance scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

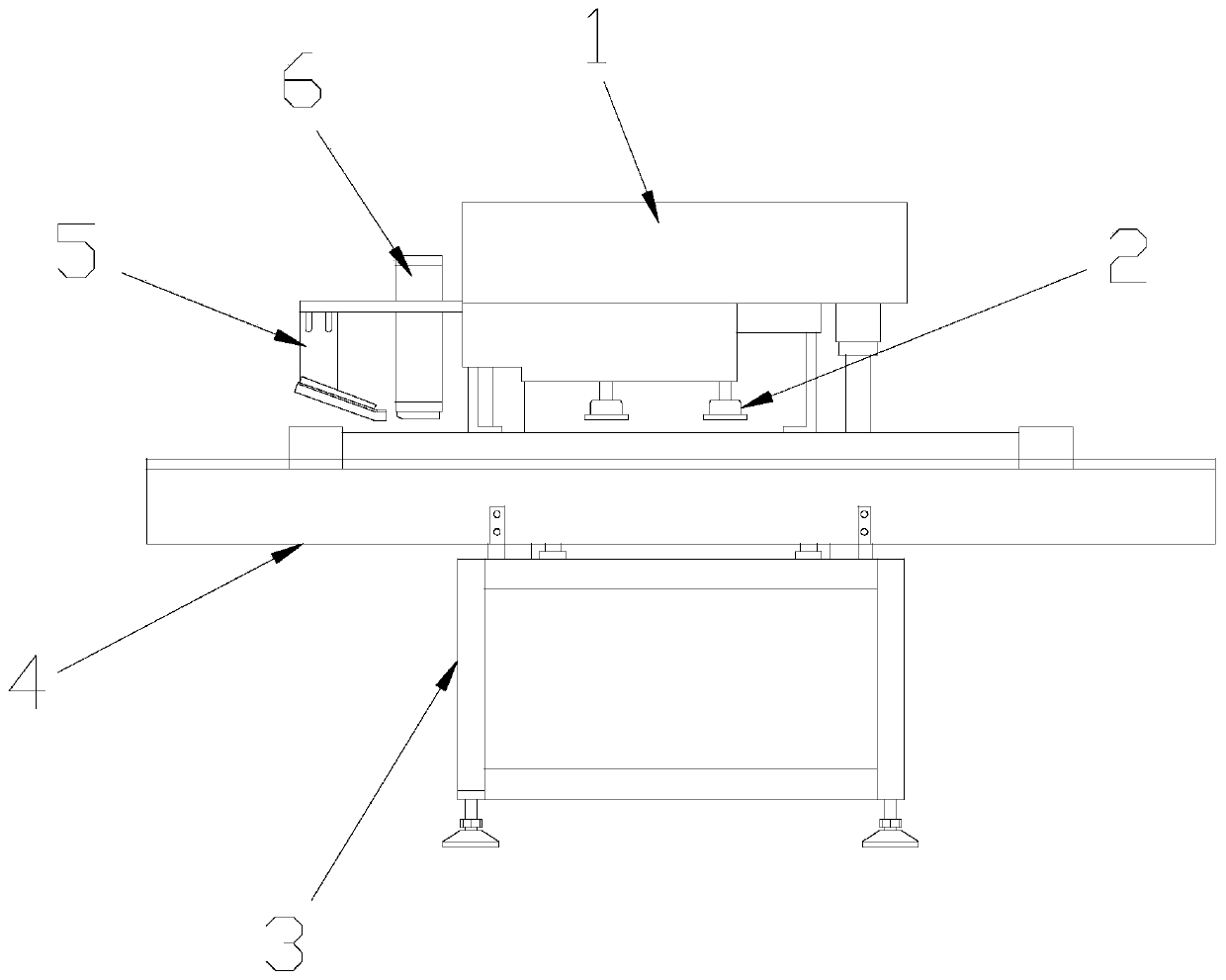

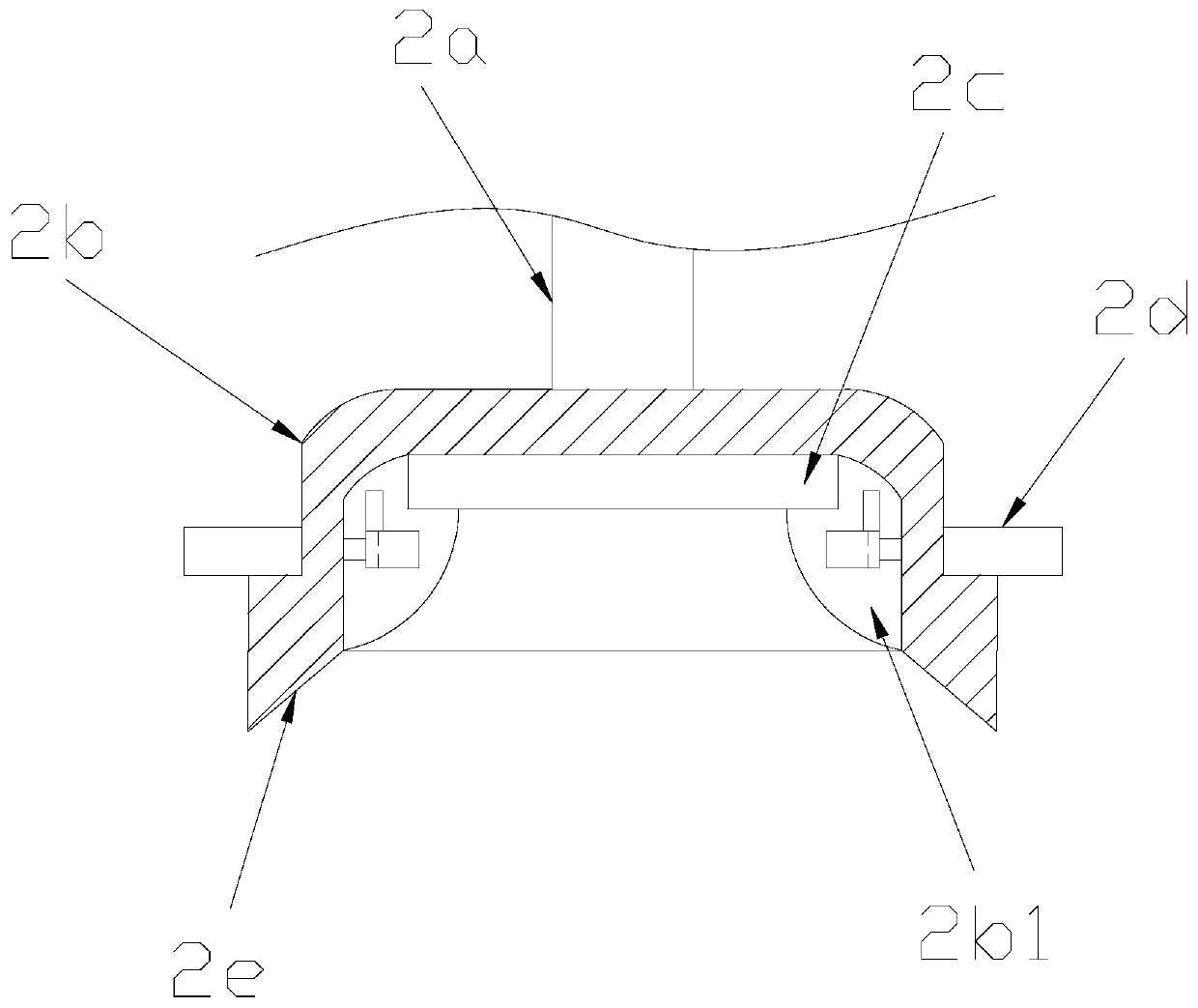

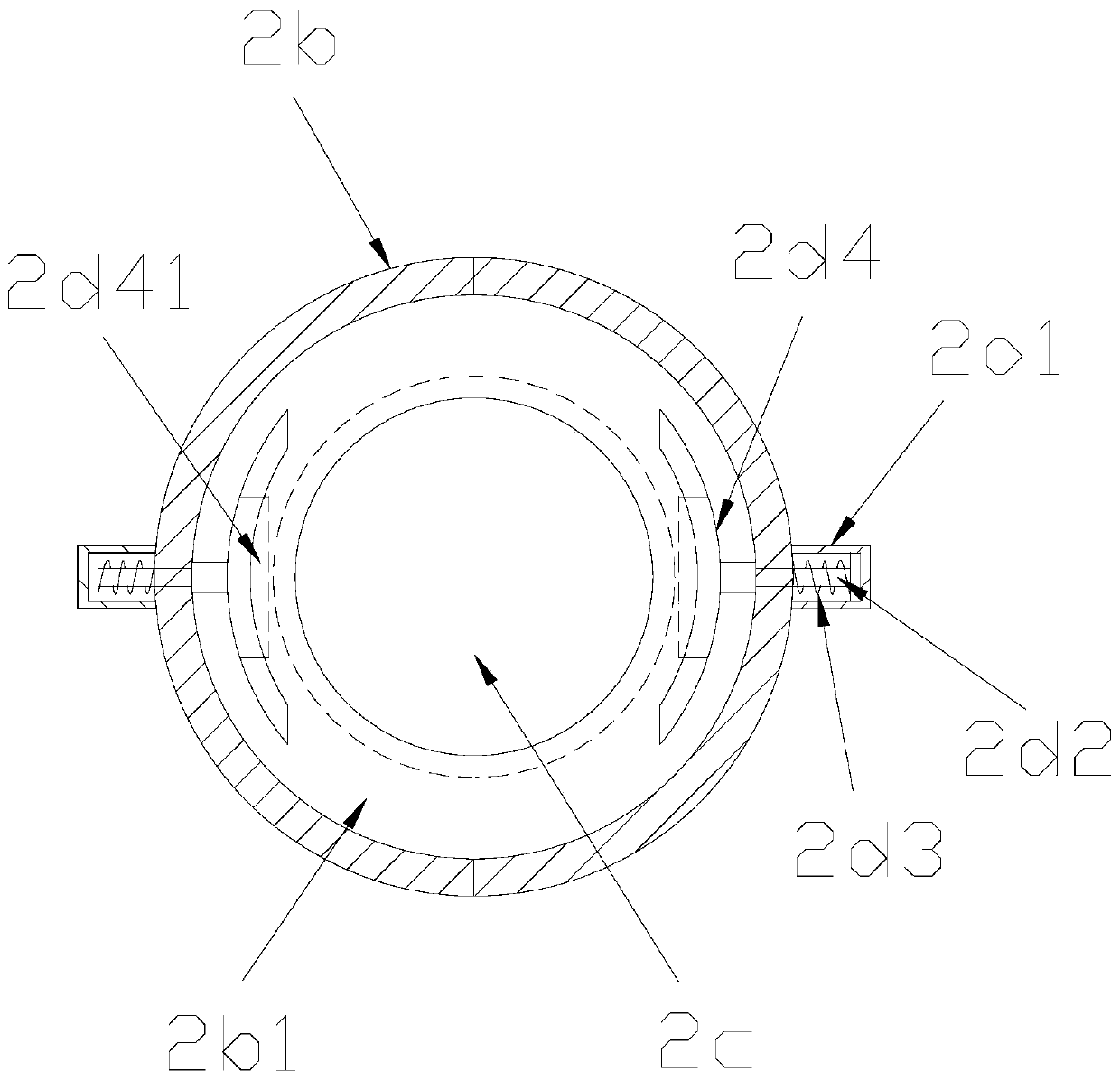

[0028] see Figure 1-Figure 3 , the present invention provides a capping machine for food glass jars, the structure of which includes a capping drive device 1, a special-shaped capping mechanism 2, a support frame 3, a conveying frame 4, a capping device 5, and a cap counter 6. Two special-shaped clamping mechanisms 2 are installed under the bottom of the capping driving device 1, the described capping driving device 1 and the special-shaped clamping mechanism 2 are mechanically connected, and the left side of the described capping driving device 1 is provided with an upper Covering device 5, the described capping driving device 1 and the upper cover device 5 are movably connected, a cover counter 6 is installed between the described capping driving device 1 and the upper cover device 5, and the described capping driving device 1 is set On the middle position of the top end of the conveying frame 4, the described capping driving device 1 is connected with the conveying frame 4...

Embodiment 2

[0036] see Figure 1-Figure 5 , the present invention provides a capping machine for food glass jars, the conveying frame 4 also includes a positioning groove 4a, a support plate 4b, a position limiting bar 4c, an automatic bottle bottom clamping mechanism 4d, the described Two positioning grooves 4a are provided on the surface of the conveying frame 4, and three bottle bottom automatic clamping mechanisms 4d are equidistantly distributed under the inner bottom of the positioning grooves 4a, and the positioning grooves 4a and the bottom of the bottle are automatically clamped. The clamping mechanism 4d is connected, and the surface of the automatic clamping mechanism 4d at the bottom of the bottle is provided with a support plate 4b, and the automatic clamping mechanism 4d at the bottom of the bottle is movably connected with the support plate 4b. A position-limiting resistance bar 4c is provided, and the support plate 4b is connected with the position-limiting resistance bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com