Screwing tool for automatically tagging inner hexagonal bolt

A hexagonal bolt, automatic marking technology, applied to screwdrivers, manufacturing tools, wrench, etc., can solve the problems of wasting production time, bolt missing torque accidents, etc., and achieve the effect of improving work efficiency, not easy to slip, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

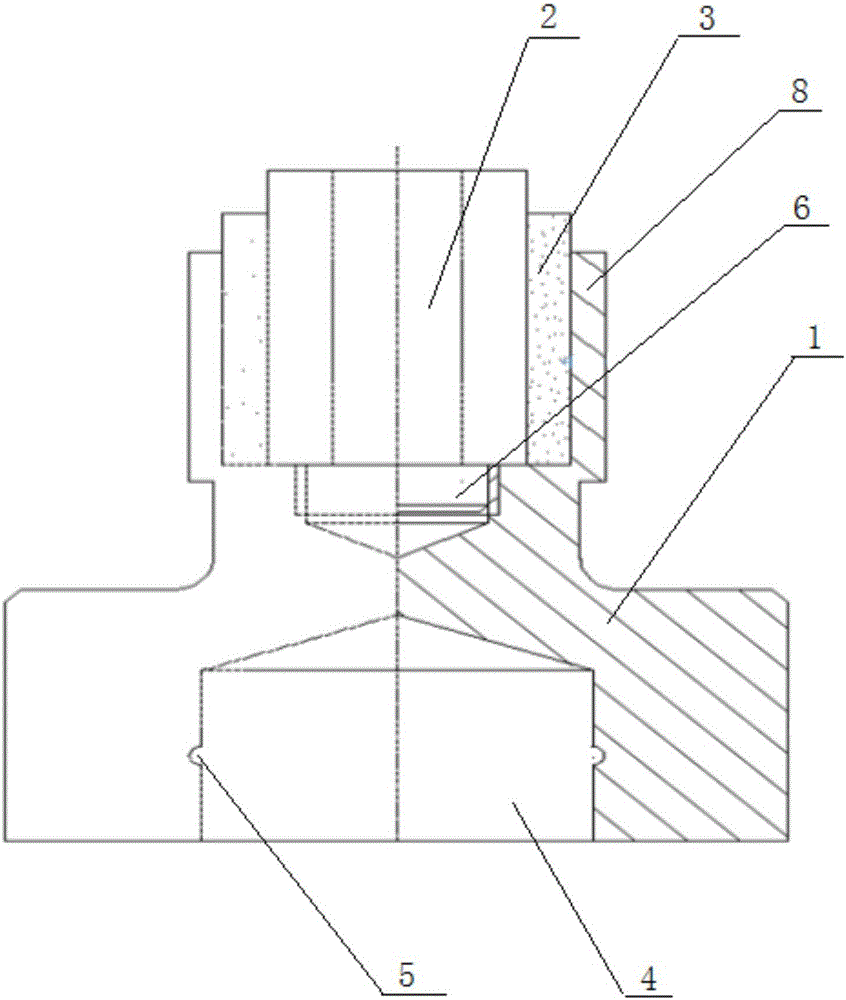

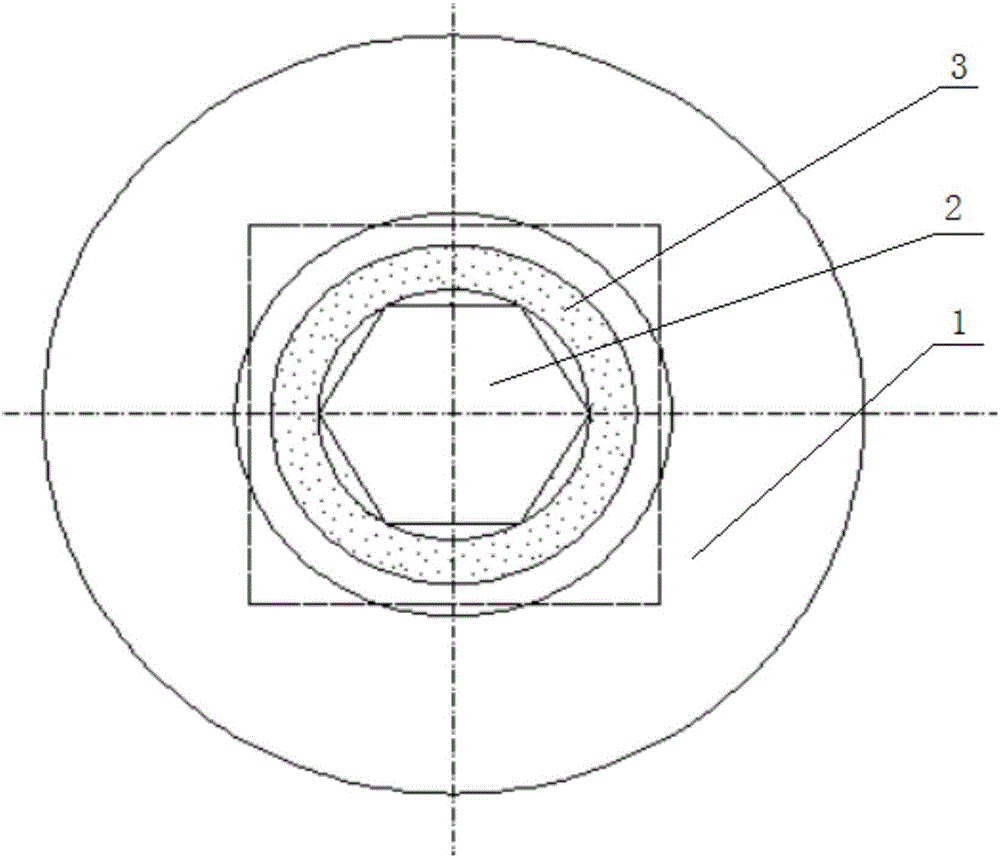

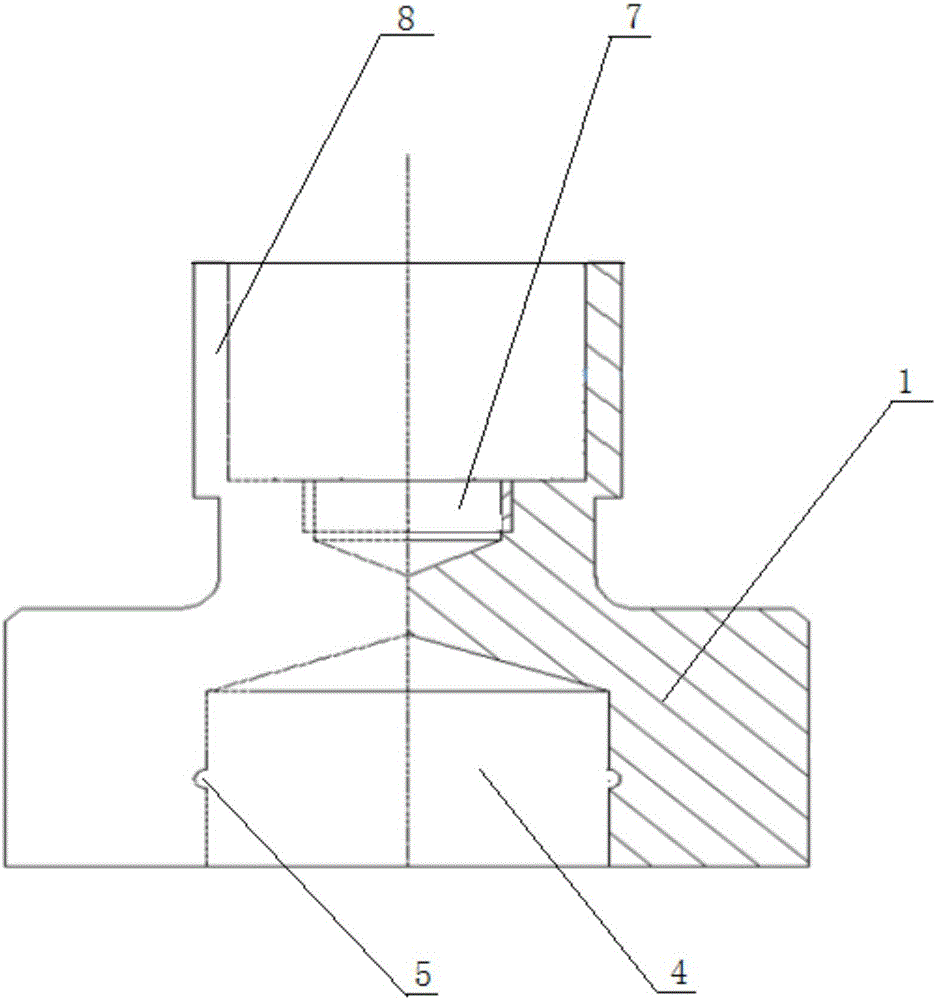

[0018] The specific embodiment of the present invention is like this: with reference to Figure 1-3 As shown, a tool for tightening hexagonal socket head cap bolts with automatic marking, including a base body 1, the base body 1 is a stepped shaft with a small front and a large rear, and an integrally formed structure, which is simple to manufacture, convenient for mass production, and low in cost; the base body 1 The rear end of the base body 1 is provided with a first connection part that is compatible with a wrench, and the front end of the base body 1 is provided with a second connection part that is compatible with a hexagon socket bolt. The axes of the first connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com