A method of manufacturing a local mixed pressure printed circuit board

A technology of printed circuit board and manufacturing method, which is applied in the direction of multi-layer circuit manufacturing, etc., can solve problems such as affecting alignment, low thickness of dielectric layer, and reducing reliability, so as to improve alignment accuracy, improve product quality, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below:

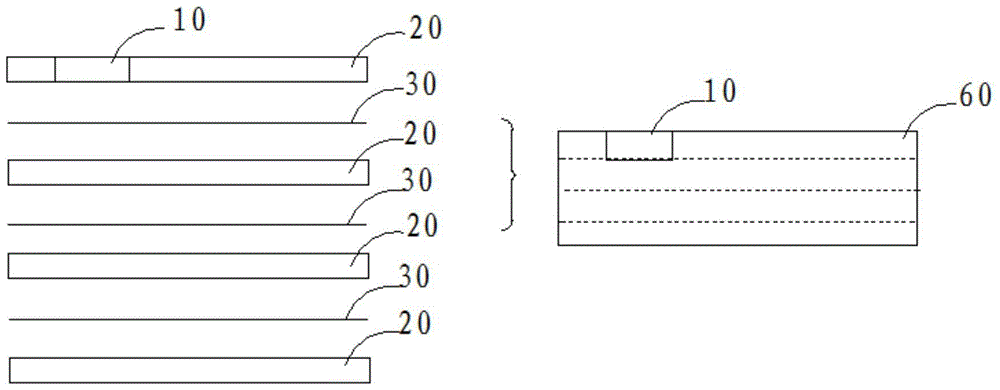

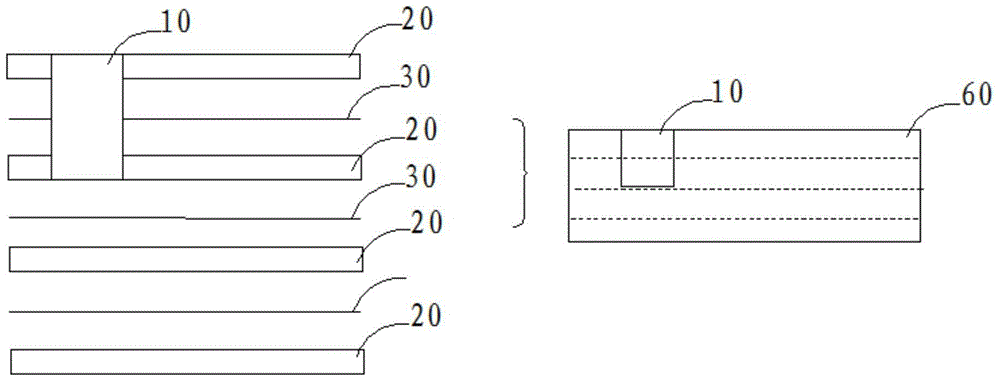

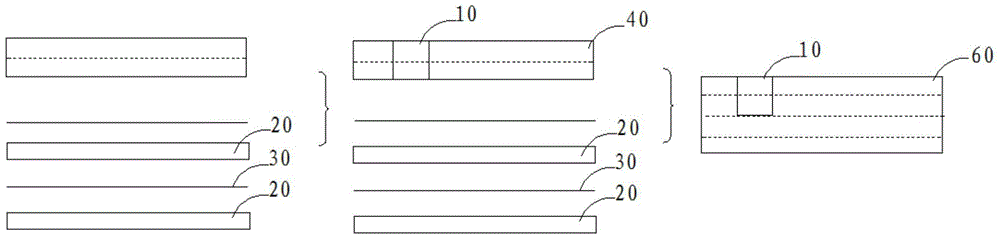

[0028] Such as Figure 5 As shown, it is a flow chart of the method for manufacturing a local mixed-pressure printed circuit board described in Embodiment 1 of the present invention. A method for manufacturing a local mixed-pressure printed circuit board includes the following steps:

[0029] S101, provide a plurality of core boards and prepregs, and place the core boards that need to be embedded with high-frequency materials in overlapping positions according to the positions where high-frequency materials need to be embedded, wherein each of the core boards that need to be embedded with high-frequency materials and the high-frequency materials that need to be embedded The prepregs are placed between each of the core panels of material.

[0030] In this step, determine the position where high-frequency material needs to be embedded in the PCB board and the number of core board layers that need to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com