A double-sided electrophoresis rack

An electrophoretic and double-sided technology, applied in the direction of electrophoretic plating, electrolytic coating, coating, etc., can solve the problems of inconsistent glass layer thickness, poor parameters, and poor reliability, so as to improve product yield and reliability, and avoid thickness inconsistency , Good consistency of electrophoresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and embodiments:

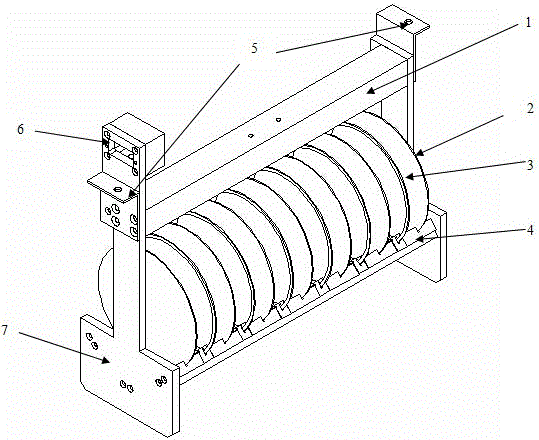

[0013] Reference figure 1 A double-sided electrophoresis rack includes a beam 1, a negative plate 2, a positive ring 3, a supporting plate 4, a positioning plate 5, a slot 6 and a side plate 7, wherein the two ends of the beam 1 are horizontally fixed on the upper part of the two side plates 7 On the inside, two positioning plates 5 are respectively fixed on the upper outer sides of the two side plates 7, the slot 6 for connecting with the electrophoresis equipment power supply is fixed at the upper end of one of the side plates 7, and the two ends of the pallet 4 are fixed horizontally on both sides Inside the lower part of the plate 7, several negative plates 2 and positive rings 3 are alternately fixed on the support plate 4 in turn.

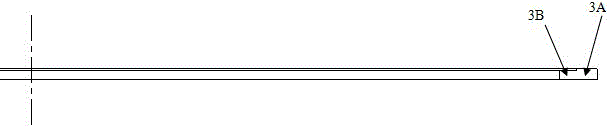

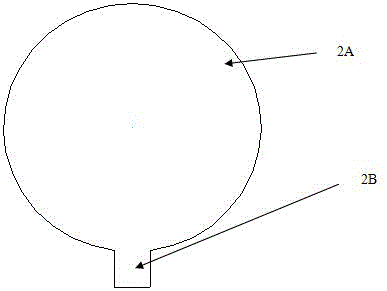

[0014] Reference figure 2 with image 3 , The negative plate 2 fixed on the supporting plate 4 includes a negative plate body 2A and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com