Automatic adhesive tape tearing equipment

A tape and equipment technology, applied in the field of automatic tape tearing equipment, can solve the problems of unfavorable winding process, unfavorable continuous processing, unfavorable accurate positioning and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

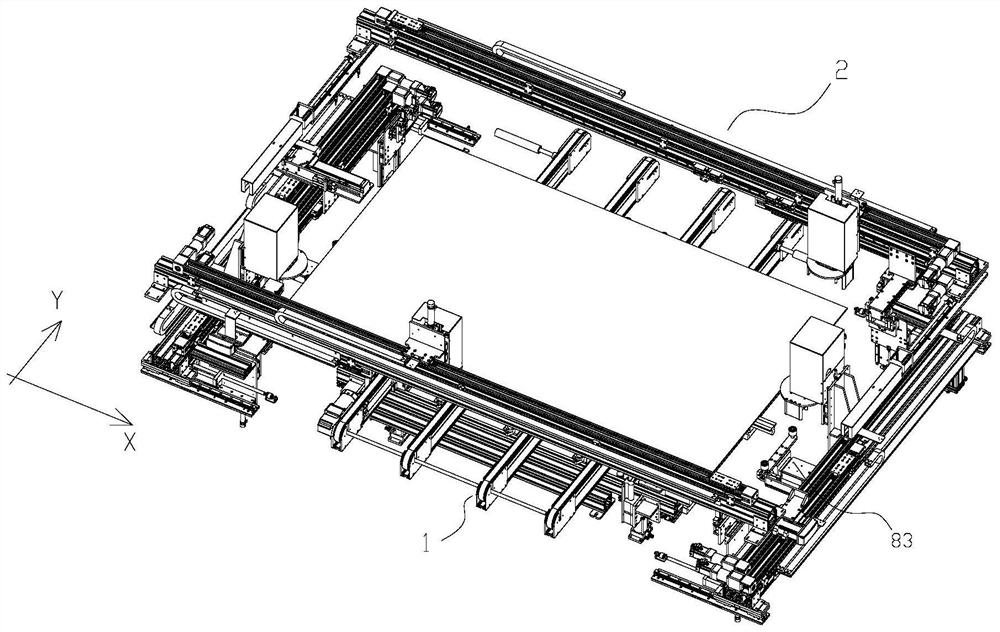

[0036] An automatic tape tearing device is mainly used in the processing of photovoltaic products, especially in conjunction with the automatic production line of photovoltaic products.

[0037] The equipment is structurally carried by the frame 7, and the outside of the frame 7 is a sheet metal outer plate 71. The frame 7 is formed by butting profiles, and can further serve as a bearing basis for a specific structure. Structures such as an industrial control box 72 are also arranged on one side of the frame 7 .

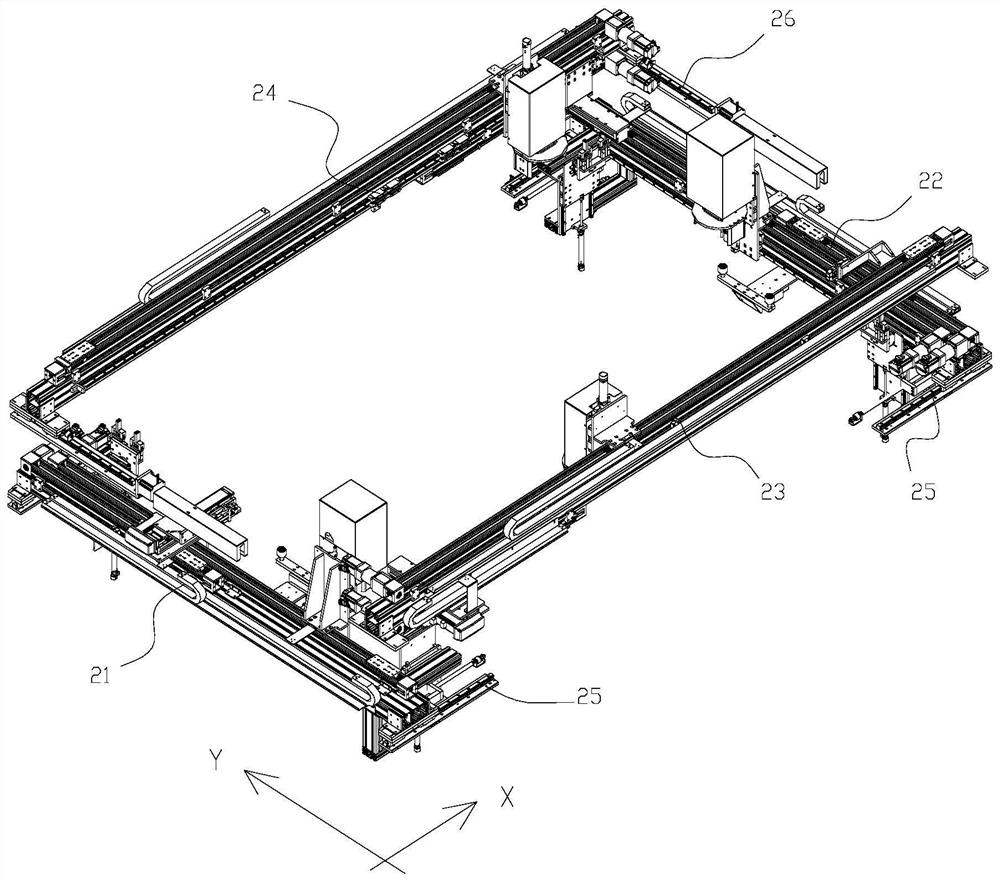

[0038] Based on the loading of the frame 7, the main structure of the equipment includes: a conveying mechanism 1, a transfer mechanism 2, a tape tearing mechanism 3, a receiving mechanism 4, a blanking mechanism 5, a glass lifting mechanism 6, etc. in:

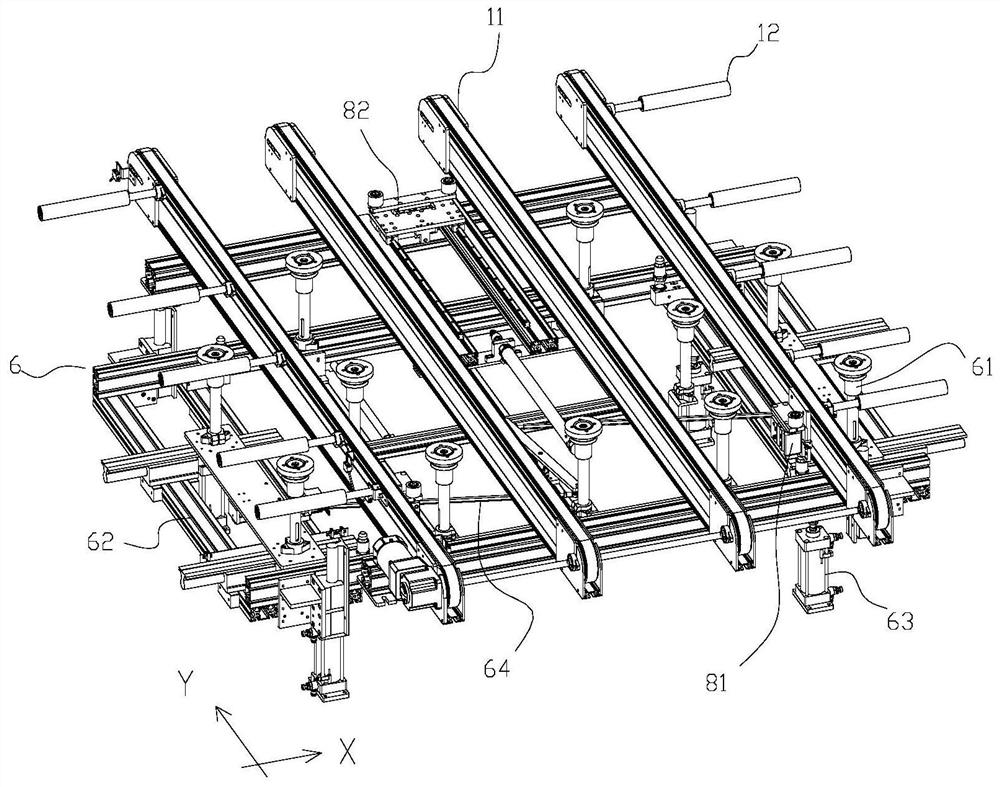

[0039] The conveying mechanism 1 adapts to the assembly line operation in a linear feeding mode; the conveying mechanism 1 includes a plurality of parallel and evenly spaced conveyor belt assemblies 11 arranged si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com