Foldable engine turnover frame

An engine and folding technology, which is applied in the field of turnover racks, can solve the problems of inconvenient transportation and loading, effective utilization of unfavorable space, etc., and achieve excellent corrosion resistance, effective use of space, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

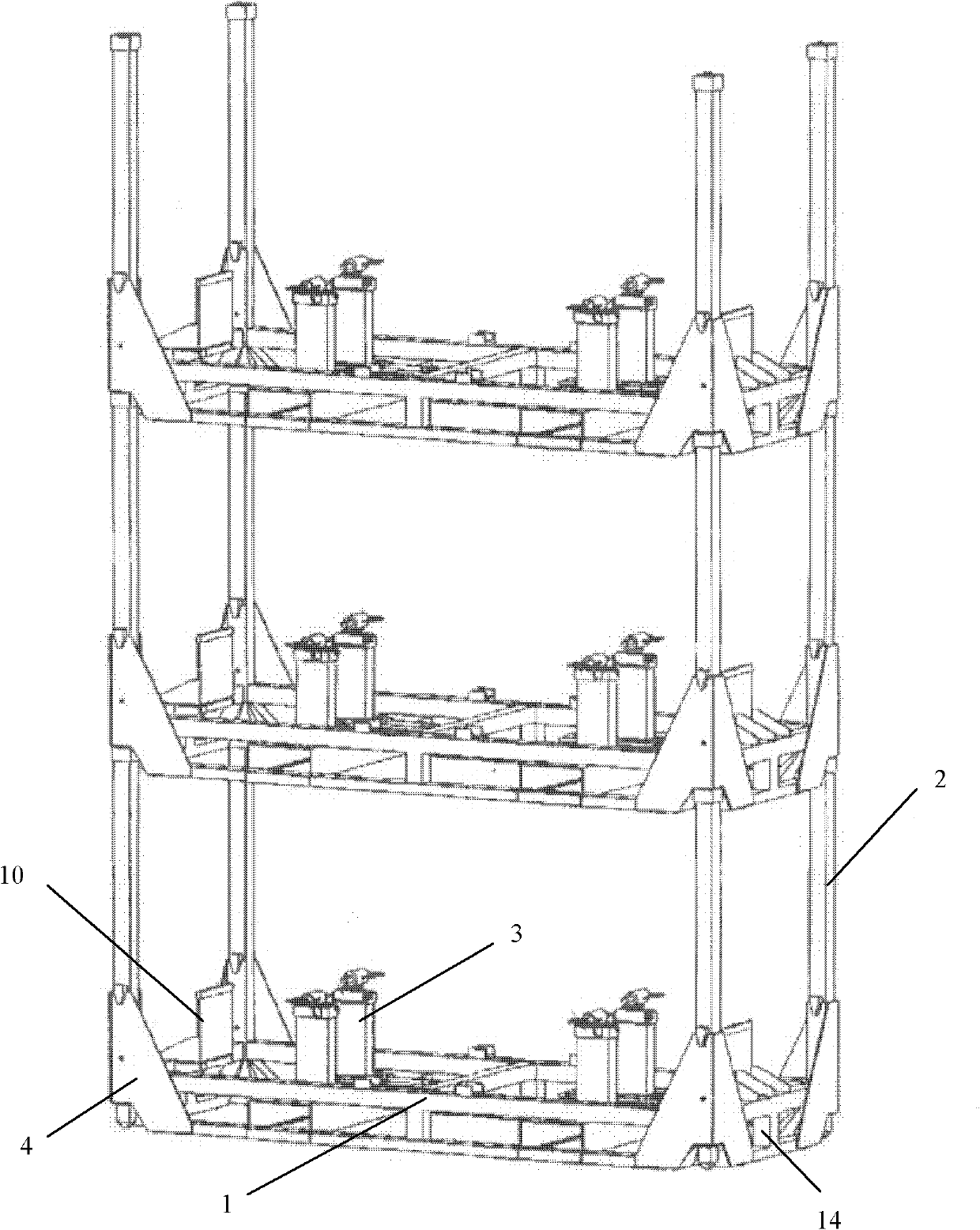

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

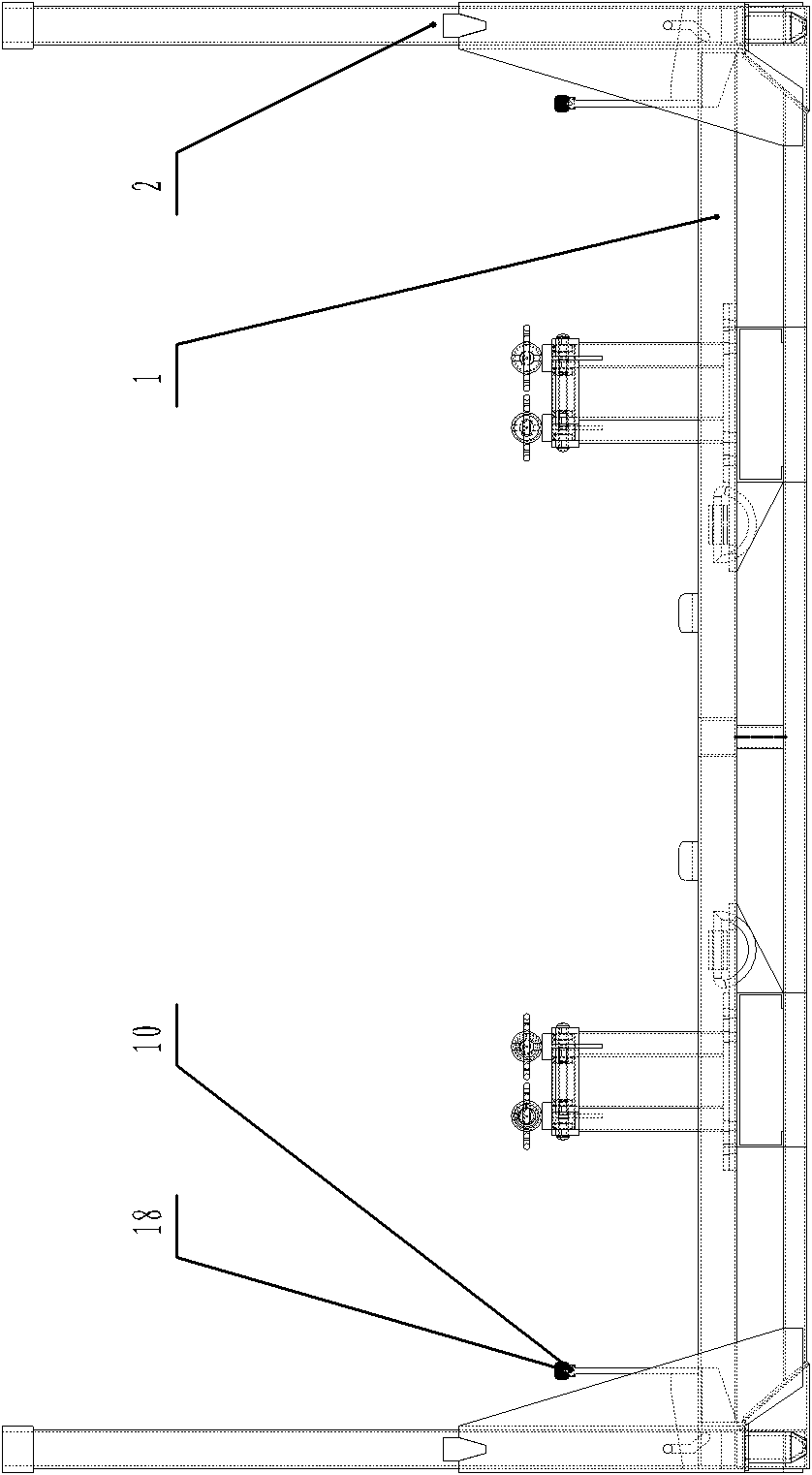

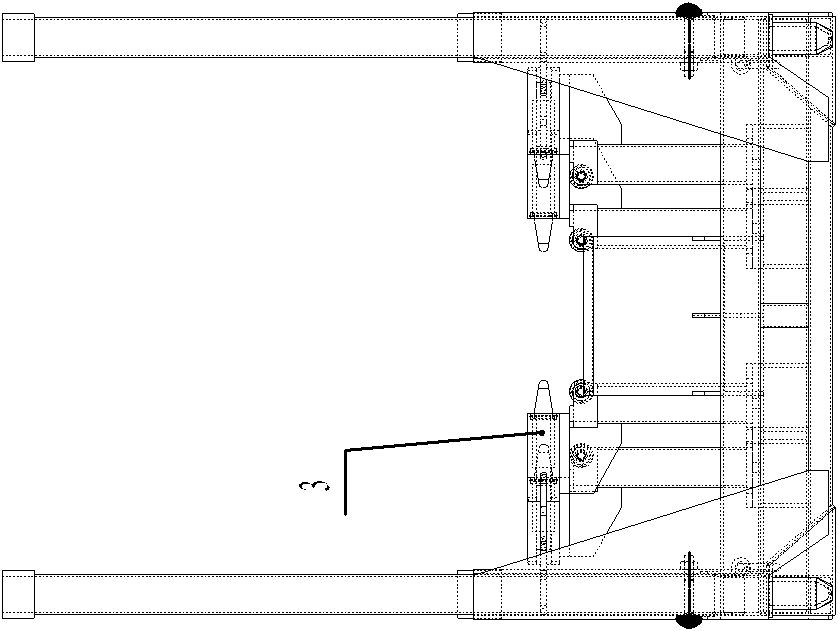

[0032] see Figure 5-7 , Figure 14-16 ,as well as figure 1 and 2 The shown folding engine turnover frame of the present invention includes a rectangular base 1 composed of long-side beams and wide-side beams. Wherein, each corner of the base 1 is supported and fixed on the outer sides of the long side beam and the wide side beam by the corner frame 4 .

[0033] The corner frame 4 includes two side plates at an angle of 90 degrees and respectively located outside a crossbeam, and each side plate surface is in the shape of a right-angled trapezoid. The bottom at the right angle of the corner frame 4 is an upwardly recessed groove body 8 . Insertion legs 17 are arranged in the tank body 8 ; the pillar 2 is arranged at the right-angle junction of the corner frame 4 directly above the insertion legs 17 .

[0034] like figure 1 As shown, the support can be stacked by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com