Online mounting equipment for crankshaft spring of pump body

A technology for installing equipment and springs, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of spring deformation, small size, low degree of automation, etc., achieve the effect of convenient replacement and disassembly, and meet the technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

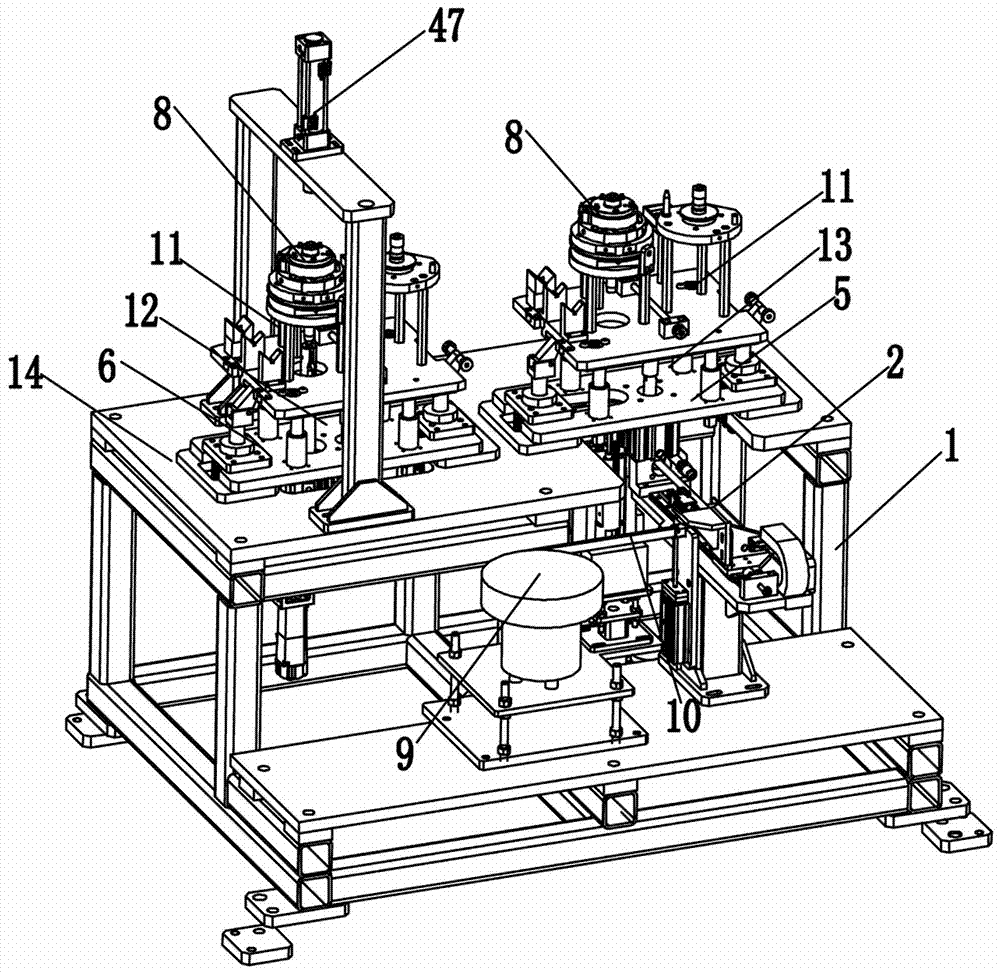

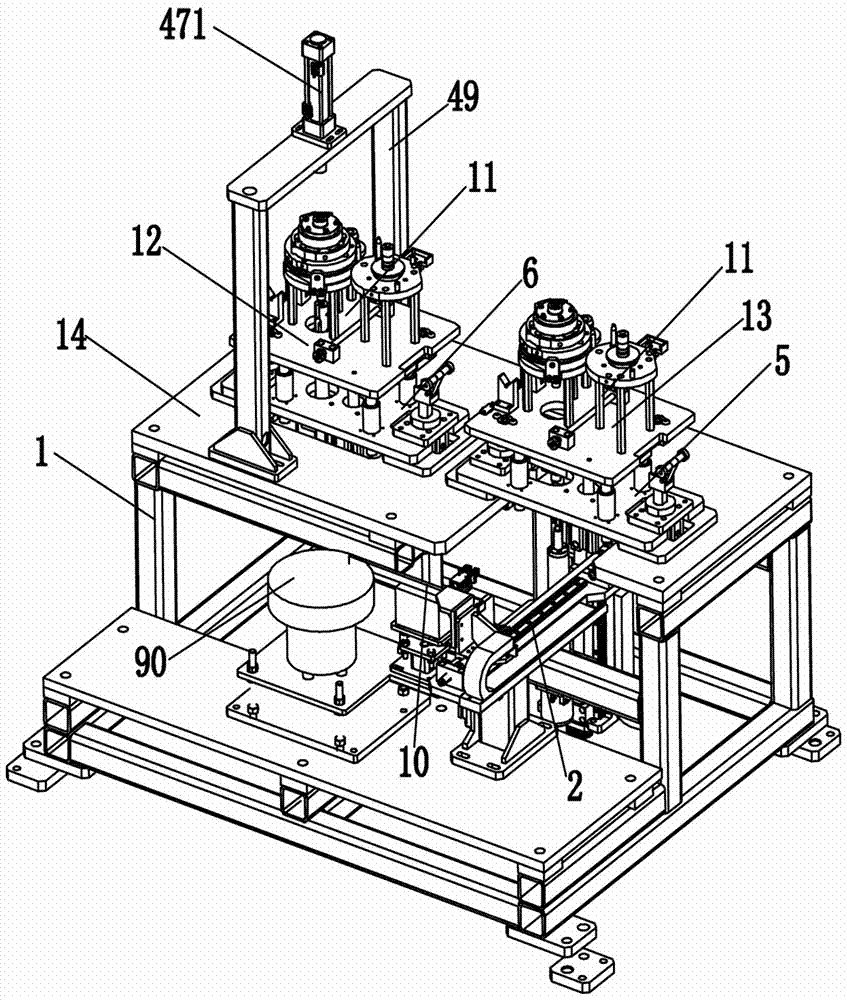

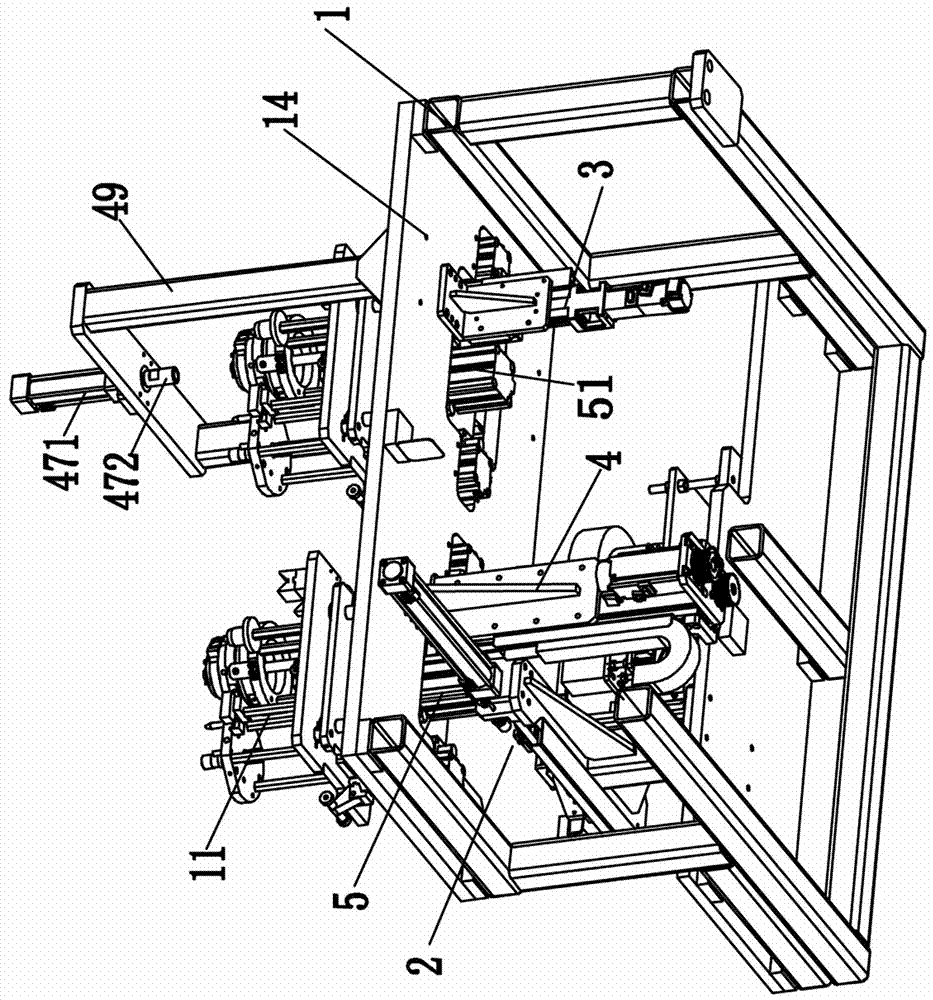

[0071] Embodiment one, such as Figure 1 to Figure 22 As shown, a crankshaft spring online installation equipment for a pump body includes a frame 1, a control device (not shown in the figure), a vibrating feeding mechanism 9, a feeding mechanism 2, a first tooling plate positioning jacking mechanism 5, a spring pre-set The jacking mechanism 3, the second tooling plate positioning jacking mechanism 6, the spring jacking in place and the detection mechanism 4, and the pressing mechanism 47, the frame 1 is provided with a workbench 14.

[0072] The workbench 14 is provided with a spring pre-installation station 13 and a spring installation and detection station 12 .

[0073] The control device is arranged on the frame and is used for controlling the above-mentioned mechanism and supplying power to the above-mentioned mechanism.

[0074] The vibrating feeding mechanism 9 is used for vibrating and screening the conical springs 7 and delivering the conical springs 7 to the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com