Repetitive motion planning method for redundant manipulator

A technology of repetitive motion and robotic arm, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of not considering the acceleration limit, physical damage of the mechanical arm, and failure to meet the requirements of the mechanical arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

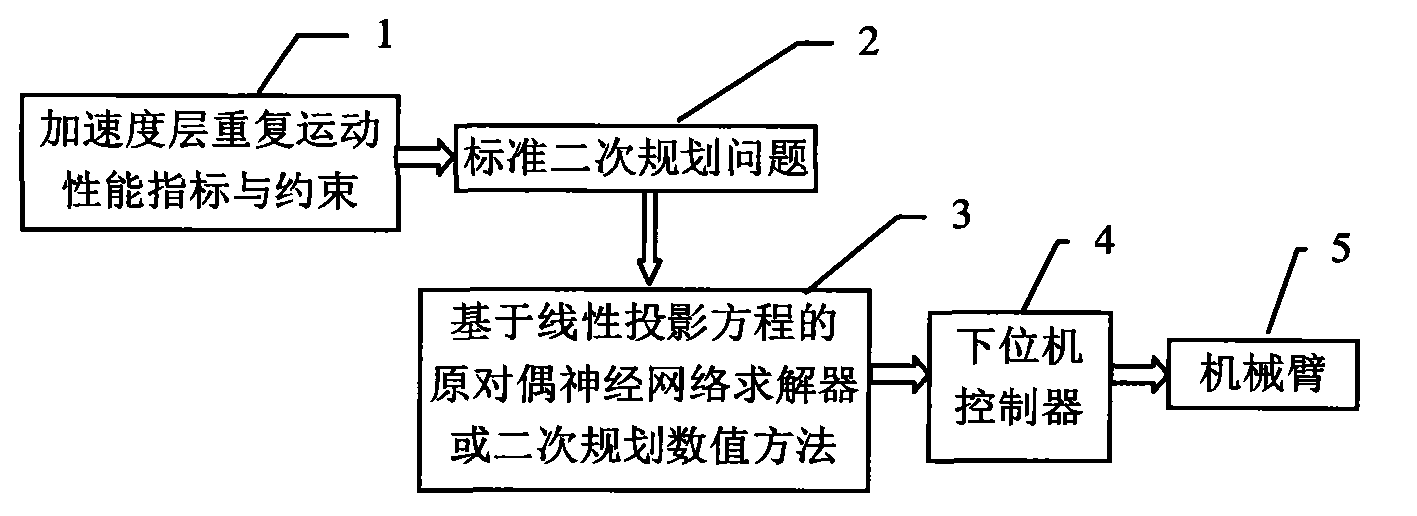

[0020] figure 1 The redundant manipulator repetitive motion planning method shown is mainly composed of acceleration layer repetitive motion performance indicators and constraints 1, standard quadratic programming 2, primal dual neural network solver based on linear projection equations or quadratic programming numerical method 3, lower level The machine controller 4 and the robot arm 5 are composed.

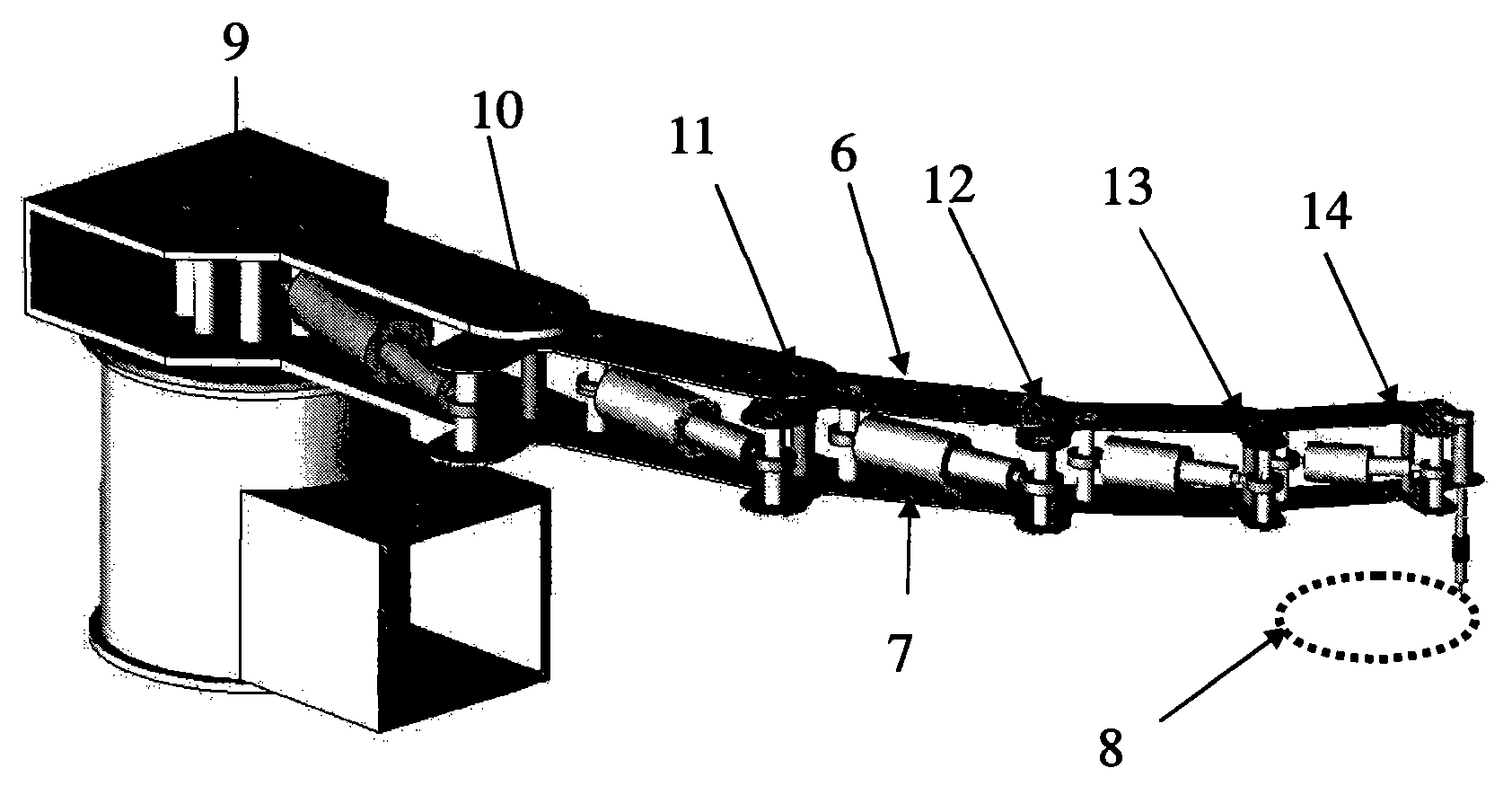

[0021] figure 2 The robot arm shown to implement the present invention is a plane with six degrees of freedom. The mechanical arm is composed of six links, which are composed of joint 9, joint 10, joint 11, joint 12, joint 13 and joint 14.

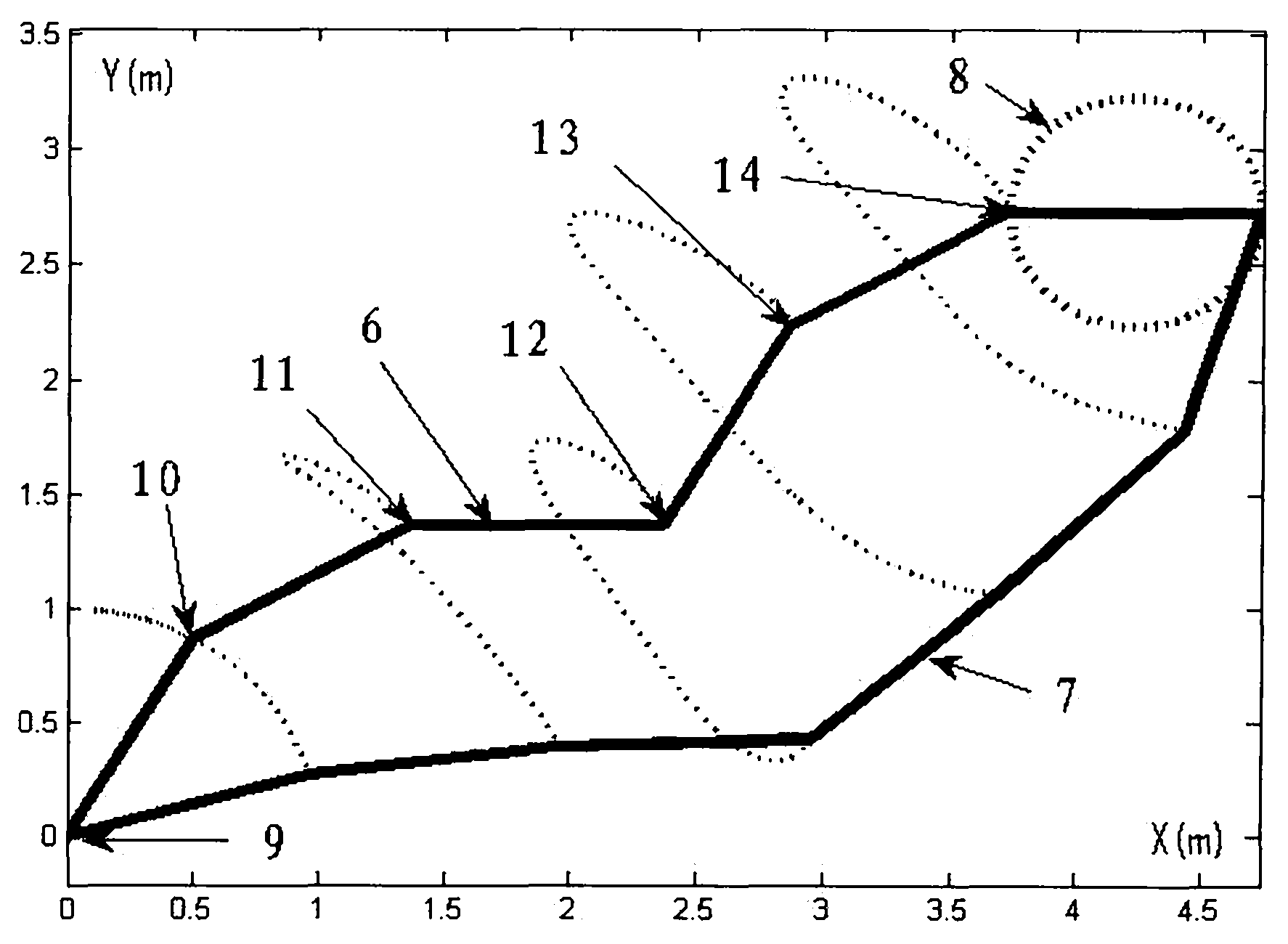

[0022] image 3 The schematic diagram of the non-repetitive motion of the robotic arm shown. Given that the end task 8 is a closed curve, the robotic arm starts to execute from the initial position 6. After completing the task, the robotic arm stops...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com