Loop test device for imitating gas phase erosion corrosion of natural gas

A technology of erosion corrosion and loop test, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring device, testing wear resistance, etc., can solve the lack of electrochemical and corrosion behavior tests that cannot simulate erosion corrosion conditions, and cannot effectively evaluate Erosion and corrosion resistance of materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

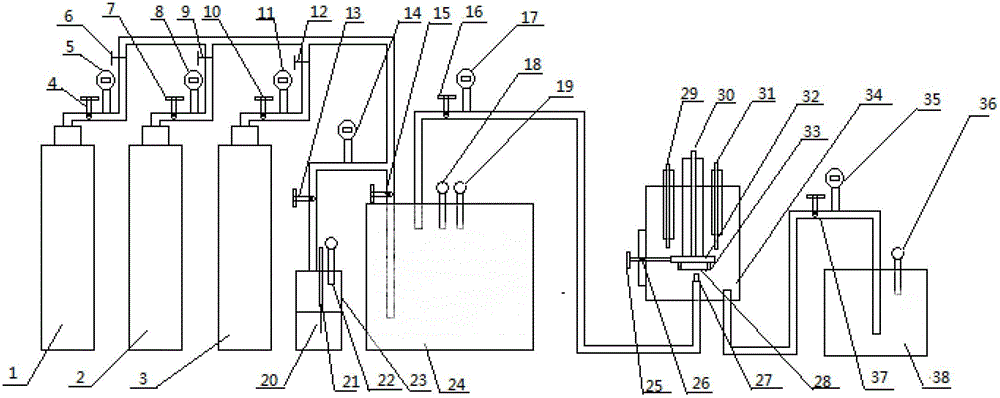

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] like figure 1 As shown, during the test, the sample is put into the autoclave 34, and the rotating sample stage is adjusted so that the sample and the nozzle form a required angle. Ensure that all valves are closed before the test starts, open the gas valves and regulating valves 4, 7, 10, 15 of the high-pressure gas cylinders 1, 2, 3, and adjust the gas flow into the autoclave 24 through 4, 7, 10 h 2 S, CO 2 , N 2 Three gas ratios and flow rates, when the pressure probe test value reaches a certain pressure, close the high-pressure gas cylinders 1 and 2, close the regulating valve 15, open the regulating valve 13, and set the N 2 Feed in the autoclave 23, open the electric heater 21, close the valve of the high-pressure cylinder 2 when the temperature and pressure reach a certain value, open the steam that the regulating valve 15 produces in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com