Device and method for preparing in-situ electron microscopy sample by adopting converged femtosecond laser

A femtosecond laser and electron microscope sample technology, used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems that restrict the reliability of in-situ electron microscopes, cannot be widely promoted and applied, and have a low success rate of sample preparation. , to achieve the effect of eliminating the heat-affected zone and the material collapse of the incision and facilitating real-time observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1 Processing of SEM single crystal Ni stretched V-notch sample in situ.

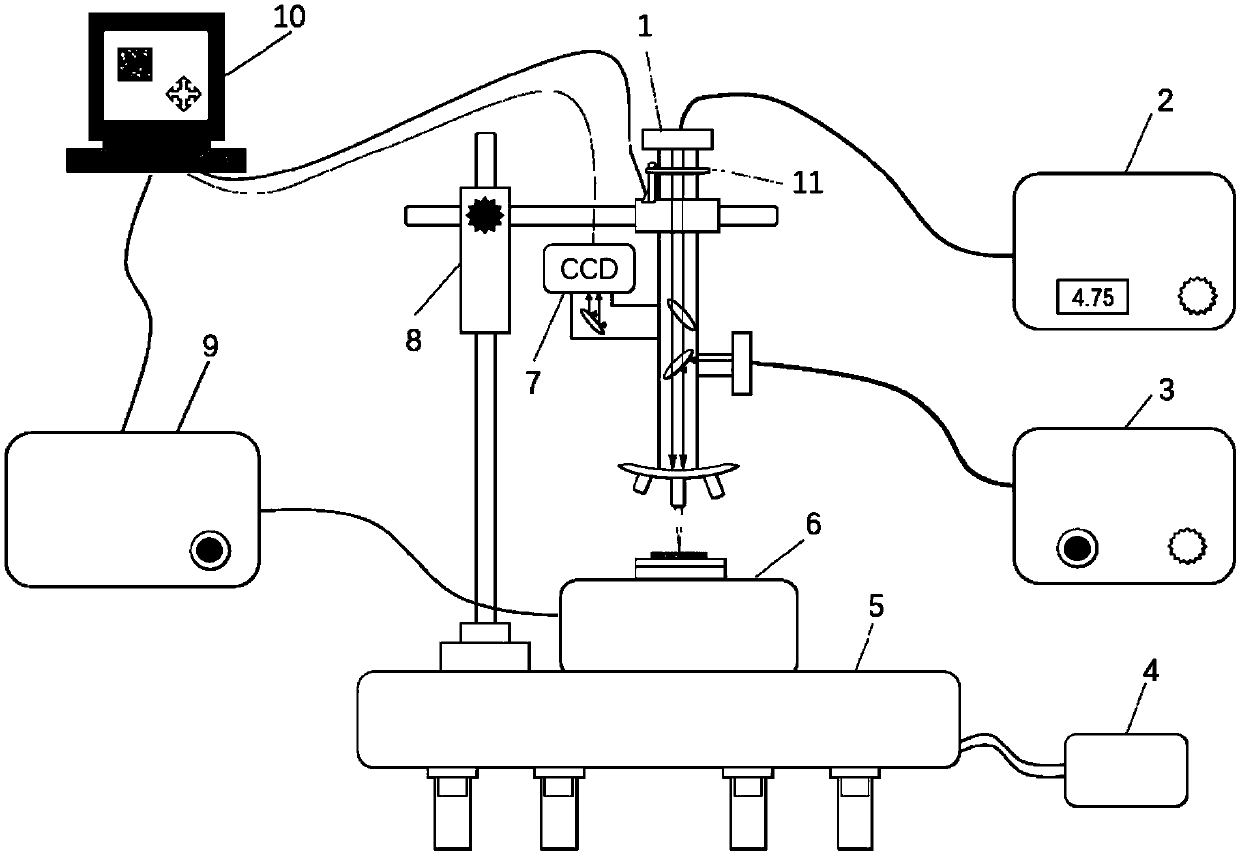

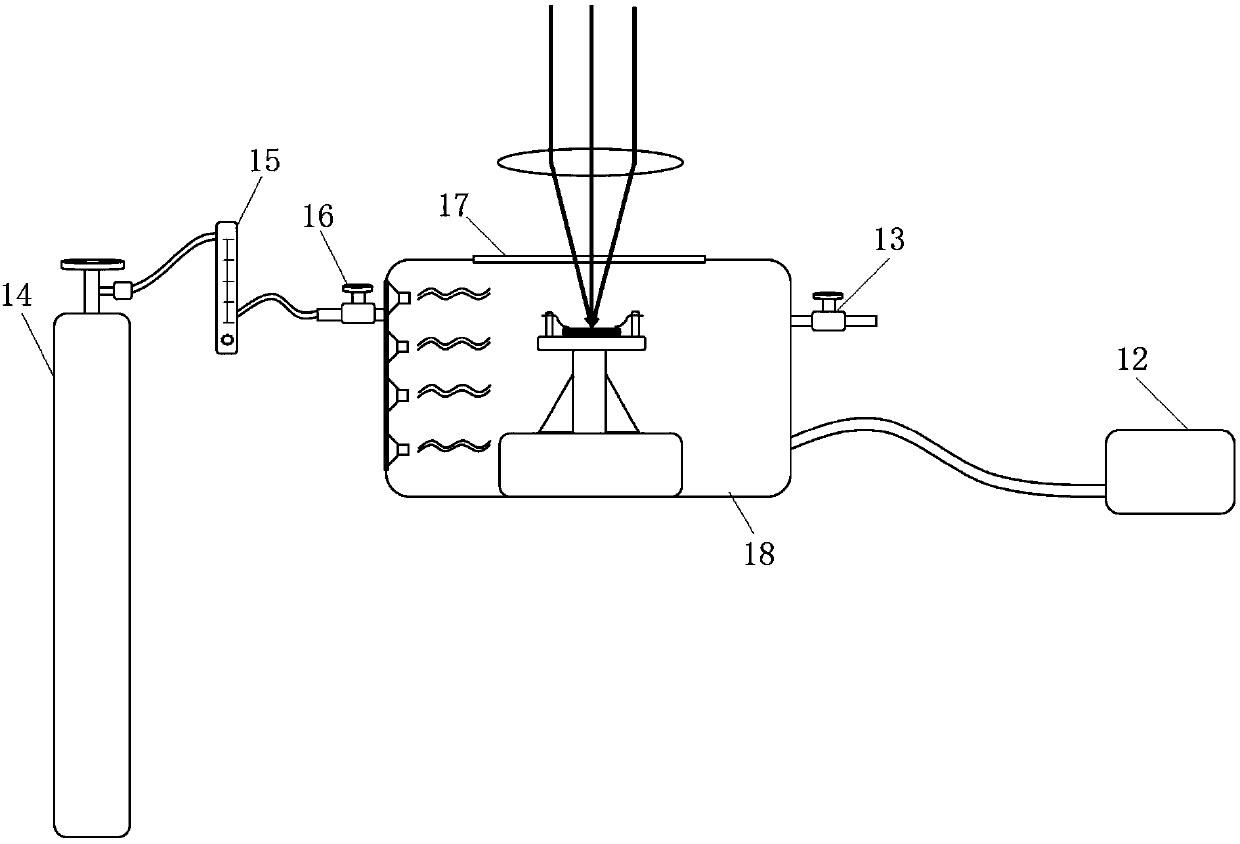

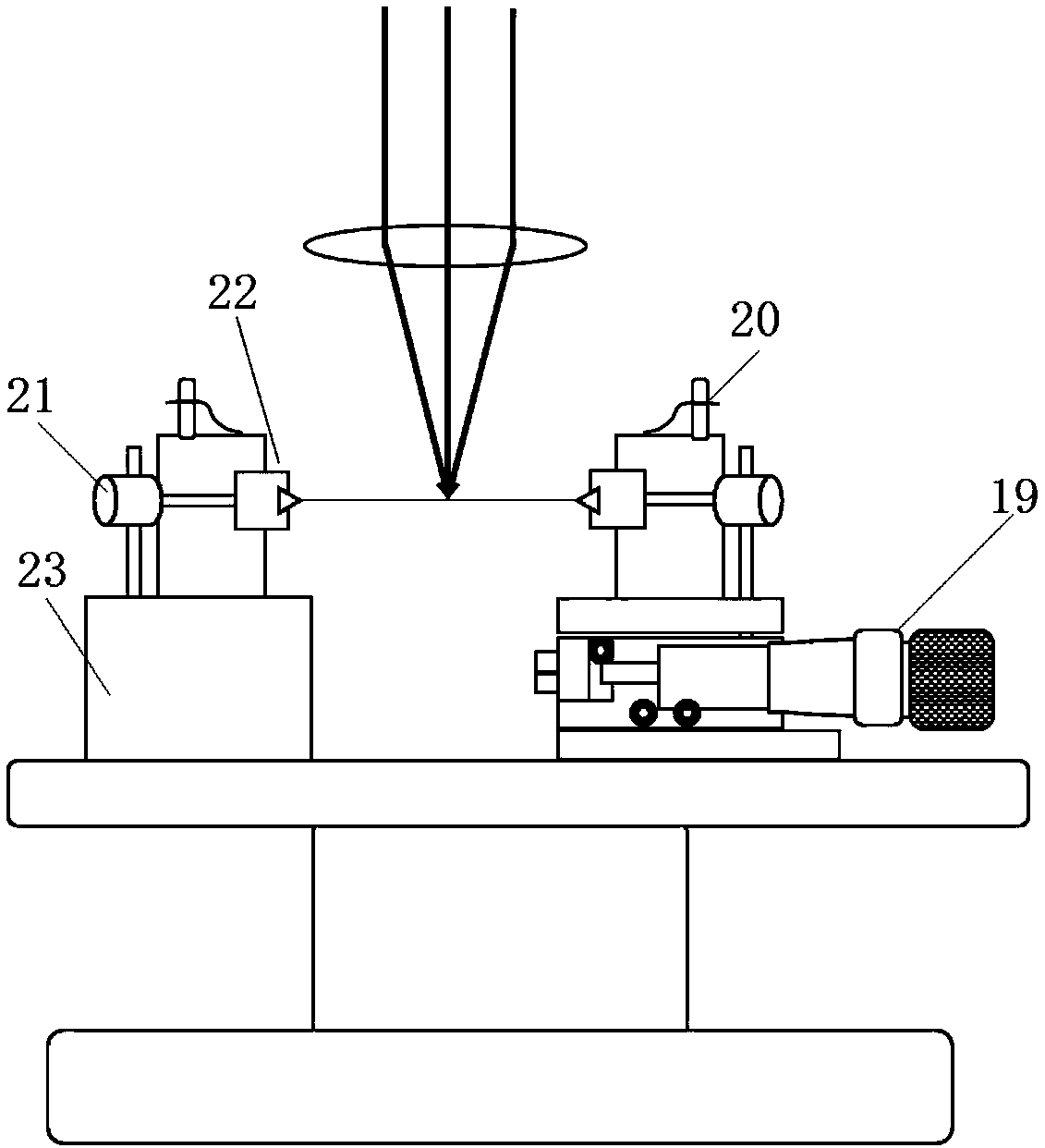

[0089] Such as figure 1 As shown, the equipment used for processing is as described above.

[0090] Processing method: Clamp the single crystal Ni sheet on the sample stage, select an infrared femtosecond laser with a wavelength of 1040nm, and set the power of the laser. By performing the detailed steps of the above-mentioned material processing method, the required strip-shaped scanning in-situ stretching sample with a V-shaped notch can be obtained.

[0091] The results of the examples show that the device of the present invention can quickly and conveniently use the femtosecond laser to finely process various materials, such as metal nickel sheet, transparent quartz glass, etc., with a sample size of less than 10cm×10cm. At the same time, by adjusting the single pulse energy of the femtosecond laser, the spot size, the moving speed of the mechanical platform, etc., an in-situ electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com