Sensor for measuring corrosion of inner wall of metal tank body and monitoring method

A technology for inner wall corrosion and metal cans, which is applied in the field of corrosion measurement of the inner wall of metal packaging solid tanks, can solve the problems of quantitative evaluation and inability to realize the corrosion resistance of metal cans, and achieve the effects of rapid data collection, simple test methods, and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

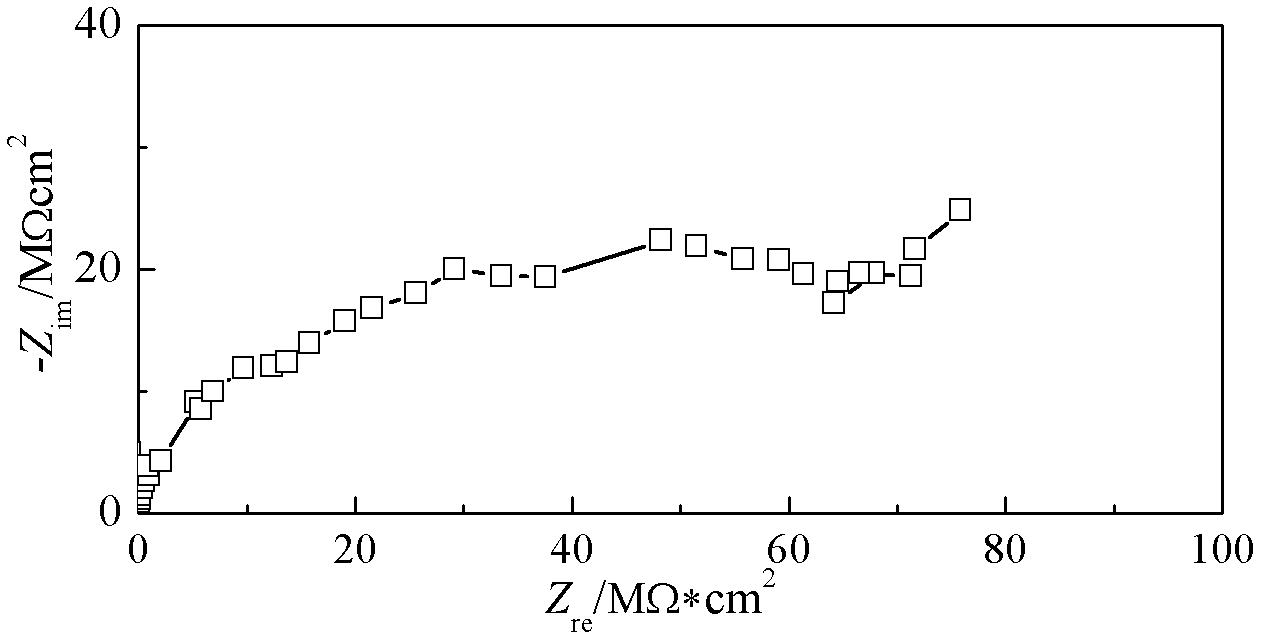

[0051] Using the VersaStat 4 electrochemical workstation and the developed sensor, the electrochemical impedance spectroscopy test was carried out on the metal beverage cans (containing functional beverages) with a storage period of 3 months and an organic phenolic coating on the inner wall. The results are shown in the attached image 3 shown. The measured impedance complex plane is in the shape of a semicircle, and it can be deduced from the value of the radius of the semicircle that the measured inner wall surface has a relatively high coating resistance (80MΩ*cm 2 ), indicating that it has good corrosion resistance. In order to further confirm the accuracy of the experimental data, the metal can was cut open to observe its inner wall coating, and it was found that the surface of the coating was complete and smooth without any damage.

Embodiment 2

[0053] Using the VersaStat 4 electrochemical workstation and the developed sensor, the electrochemical impedance spectroscopy test was carried out on the metal beverage cans (containing functional drinks) with a storage period of 15 months and an organic phenolic coating on the inner wall. The results are shown in the attached Figure 4 shown. The measured impedance complex plane is characterized by double capacitive reactance arcs, but the radius of the capacitive reactance arc is significantly reduced (1-10MΩ*cm 2 ). It shows that part of the built-in solution has penetrated into the metal substrate through the organic coating, and the corrosion protection performance of the organic coating is gradually failing. In order to further confirm the accuracy of the experimental data, the metal can was cut open to observe its inner wall coating, and it was found that there was a small area of damage on the surface of the coating, and the metal substrate in a local area had been ...

Embodiment 3

[0055] Using the VersaStat 4 electrochemical workstation and the developed sensor, the electrochemical impedance spectroscopy test was carried out on the metal beverage cans (containing functional beverages) with a storage period of 30 months and an organic phenolic coating on the inner wall. The results are shown in the attached Figure 5 shown. The measured impedance complex plane shows the characteristics of obvious double capacitive reactance arc, and the radius of the capacitive reactance arc is significantly reduced compared with Example 1 and Example 2 (0.1 ~ 0.5MΩ*cm 2 ). It shows that the internal solution has penetrated the organic coating to reach the surface of the metal substrate and corroded, and the corrosion resistance protection performance of the organic coating has failed. In order to further confirm the accuracy of the experimental data, the metal tank was cut open to observe its inner wall coating, and it was found that there were large areas of black cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com