Device and method for testing chloride corrosion of reinforced concrete member under continuous load

A reinforced concrete and testing device technology, applied in the direction of applying stable tension/compression to test the strength of materials, can solve the problems of difficulty in reaching the normal load level of in-service structural members, limited load level, etc., to achieve a simple structure and basically consistent load , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

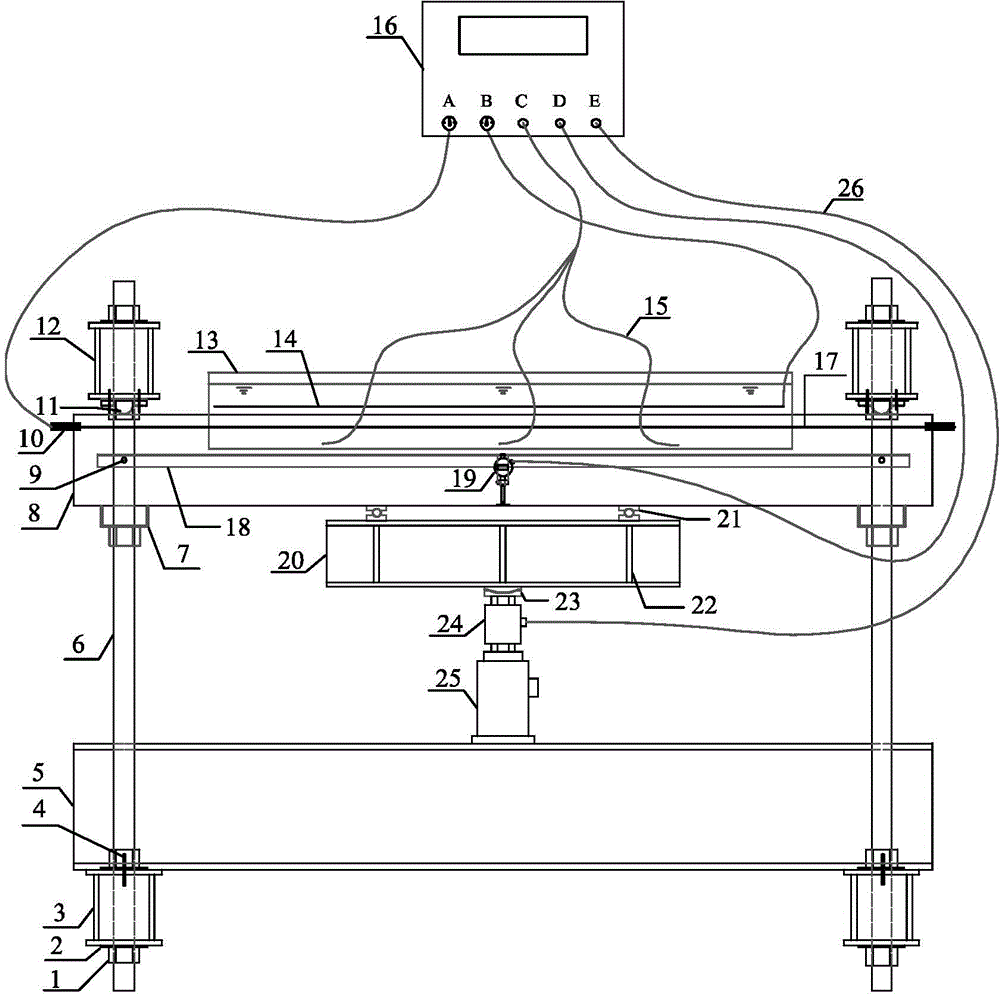

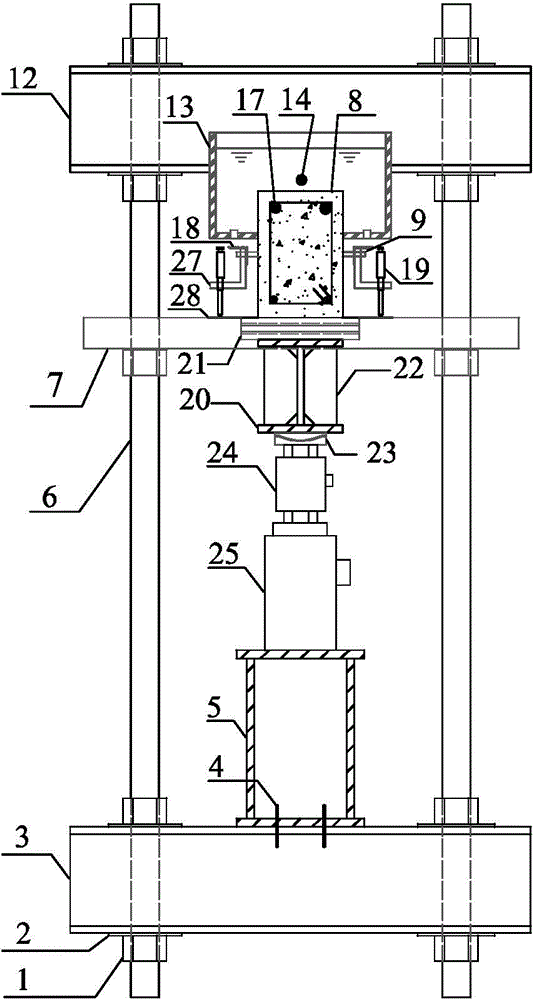

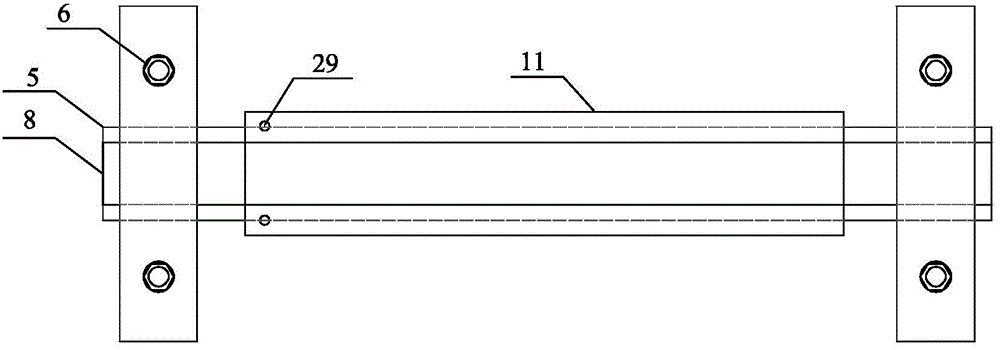

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] like Figure 1-Figure 5 Shown, a kind of test device of chlorine salt corrosion reinforced concrete member under continuous load, comprises loading frame, loading driving device, and described loading frame comprises lower beam 3, upper beam 12, test beam support frame 7, reaction beam 5, The loading frame screw 6, the nut 1 and the side support 11, the upper beam 12, the test beam support frame 7 and the lower beam 3 are sequentially perforated and connected by the loading frame screw 6, and the upper and lower beams are connected by nuts 1 at the openings of the upper and lower beams. The crossbeam is fixed on the loading frame screw 6, and the positioning nut 1 is set at the opening of the lower end of the test beam support 7, and the lining plate 2 is set between all the nuts 1, the crossbeam and the support, and the reaction beam 5 is supported by the cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com