Deep-sea stress corrosion and seepage hydrogen experimental simulation device

A stress corrosion and experimental simulation technology, applied in the field of measuring instruments, to achieve the effect of reasonable design, reliable and credible data, and true and accurate stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Carry out potentiodynamic polarization curve and AC impedance spectrum test

[0024] 1. Material to be tested: 10CrSiNiCu low-alloy high-strength steel, the size of the sample is designed with reference to GB / T228-2002 rectangular cross-section proportional sample P3 type. Use water abrasive paper to grind the sample to No. 2000, use acetone, deionized water to clean, and dry it with hot air;

[0025] 2. Test solution: 3.5% NaCl solution with pH=2.00 as corrosion medium, and add boric acid (50g / L) as buffer solution;

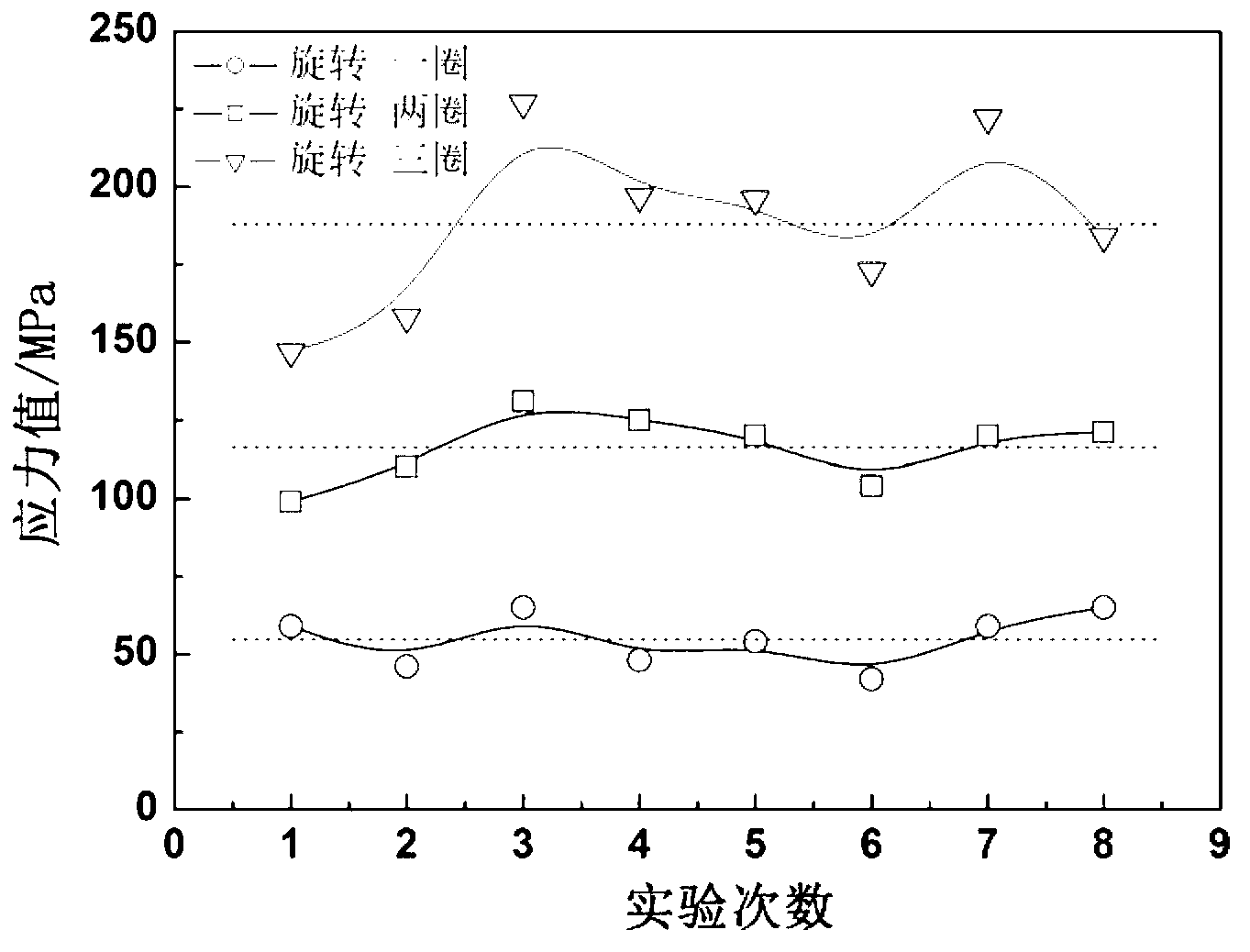

[0026] 3. Stress calibration: The size of the stress is measured by the YC-III stress measuring instrument, and the stress calibration results are as follows image 3 shown. The three calibration lines shown in the figure are the corresponding stress values when the hexagonal bolt is rotated by one-sixth, two-sixths, and three-sixths. It can be seen from multiple tests that the stress values corresponding to the three stressing operation...

Embodiment 2

[0031] Example 2: Double electrolytic cell hydrogen permeation experiment

[0032] 1. Material to be tested: 10CrSiNiCu low-alloy high-strength steel, the sample design is based on GB / T228-2002 rectangular cross-section proportional sample P3 type. Use water-grinding sandpaper to grind both sides of the sample to No. 2000, and polish one side. The polished surface is electroplated with nickel, and the hydrogen is removed in a drying box at 200°C for three hours;

[0033] 2. The experimental solution and stress calibration steps in the corrosion chamber are the same as in Example 1, and 0.2mol / L NaOH solution is used in the oxidation chamber;

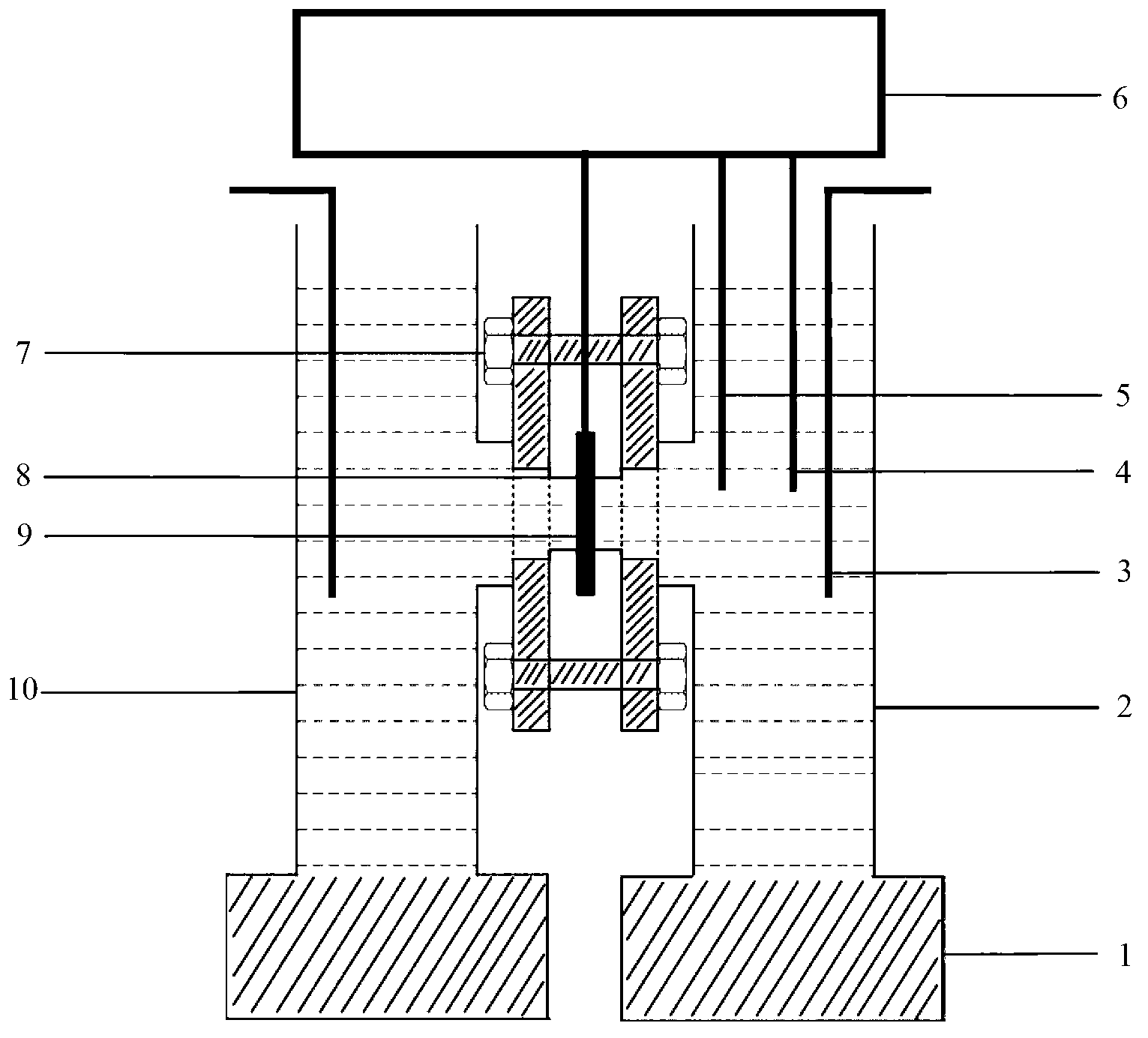

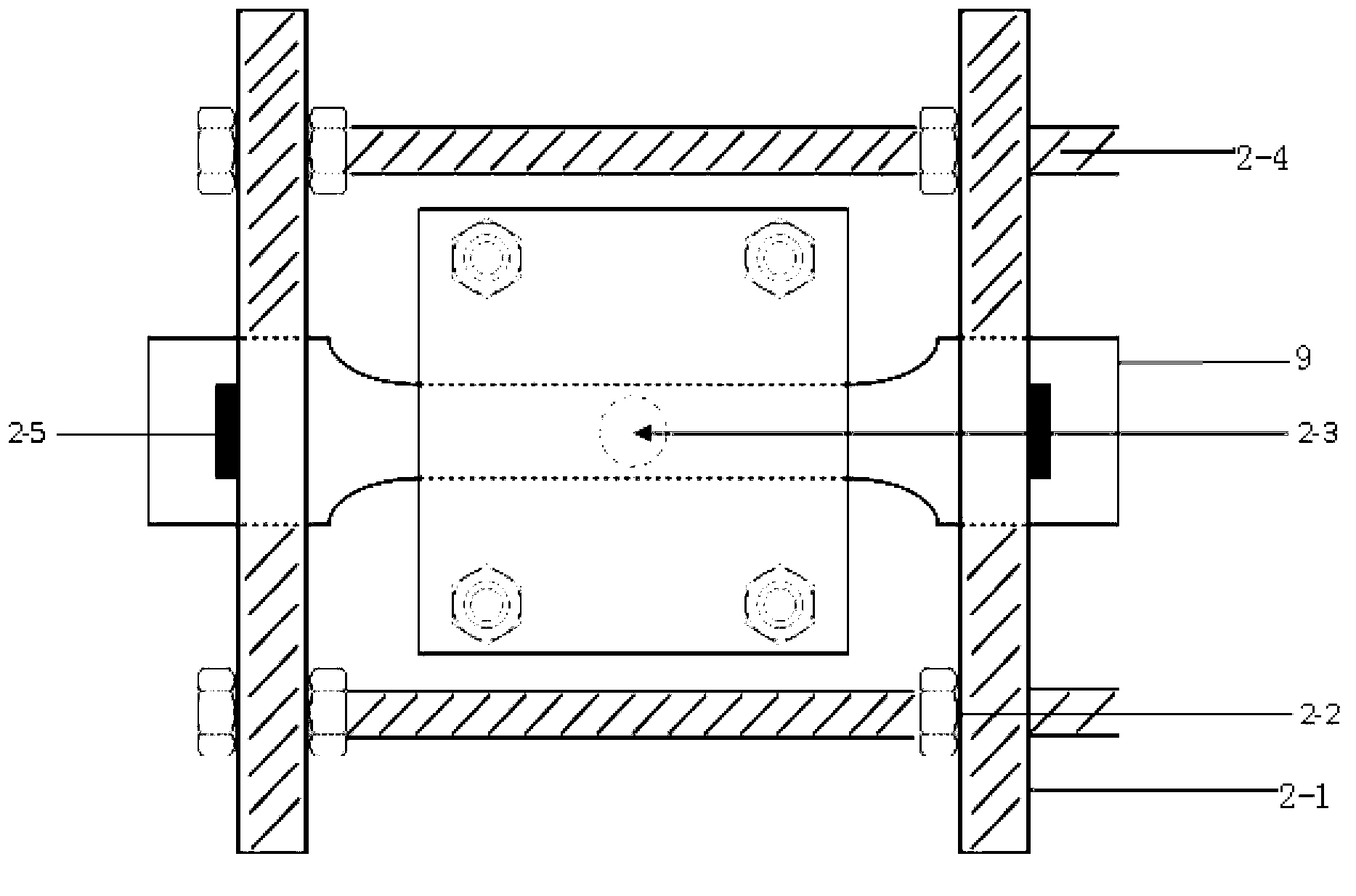

[0034] 4. Experimental steps: use the samples prepared in step 1 figure 1The device is fixed, the electroplating surface of the sample faces the oxidation chamber, and the hydrogen-charging surface faces the corrosion chamber. use figure 2 The device is stressed and the NaOH solution from step 2 is injected into the oxidation chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com