Cable checking circuit structure and common-line-free cable checking method

A technology for calibrating circuits and calibrating methods, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as wasted man-hours, instrument burnout, instrument can not work normally, etc., to achieve the effect of convenient line calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

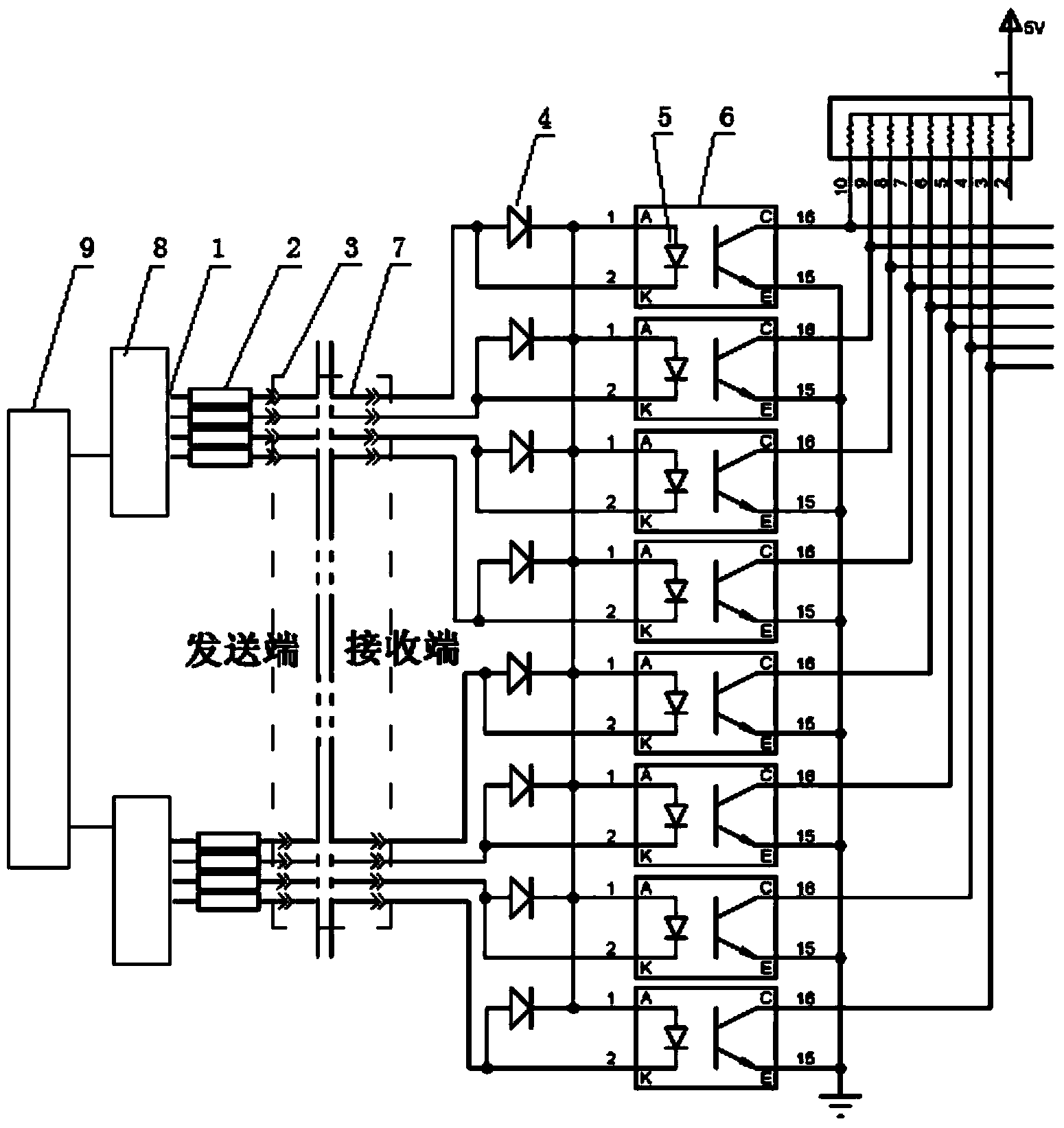

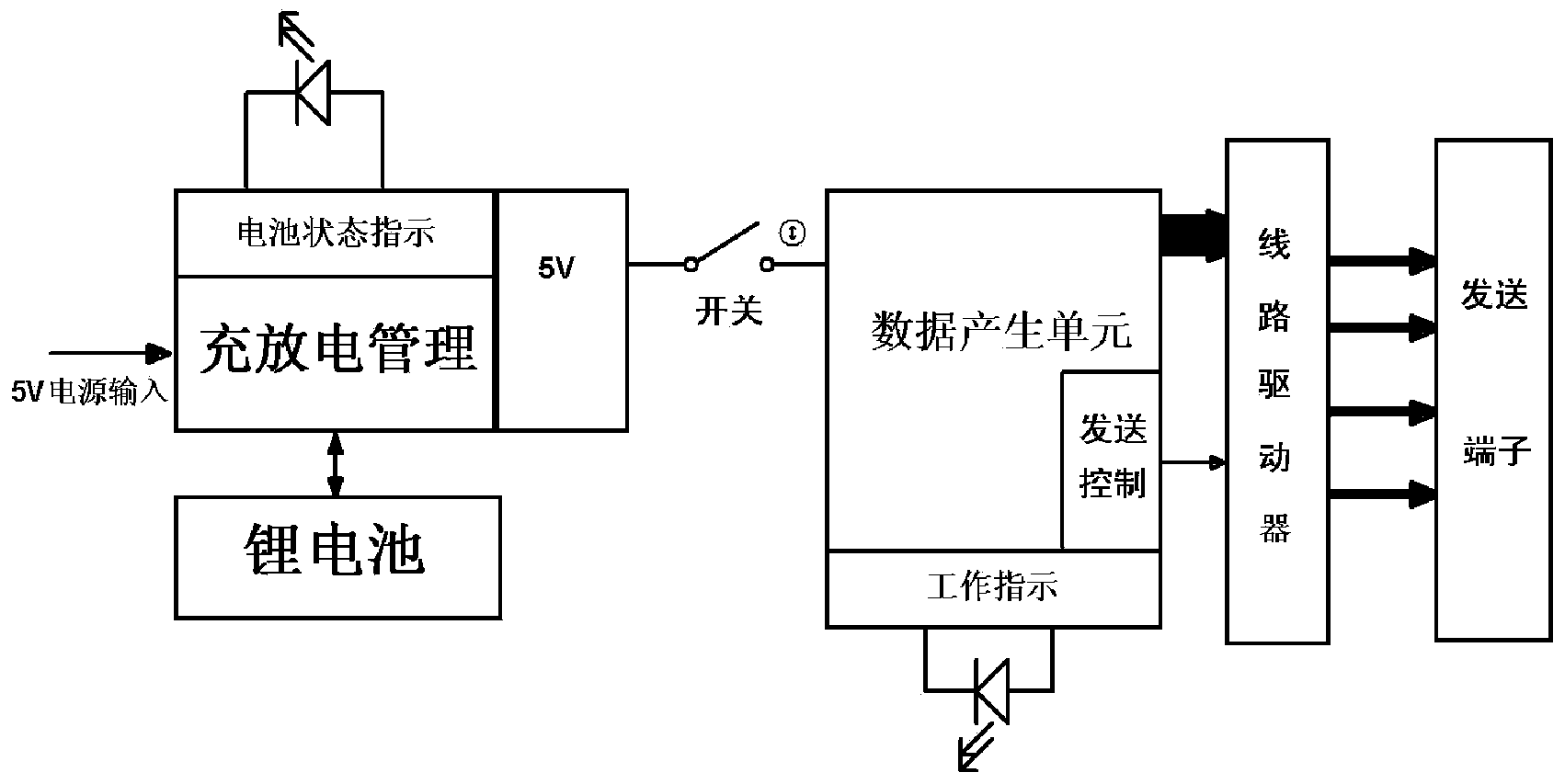

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 As shown in , the structure of the cable verification circuit includes a verification signal sending end device circuit and a verification signal receiving end device circuit connected by the tested cable 3, and the tested cable 3 includes at least 2 tested cables Line 7.

[0033] Taking the signal coupler as an example of an optocoupler, the line across the calibration signal sending end and the calibration signal receiving end only needs the tested cable 7 itself without a common reference end, and each tested cable calibration line includes a current limiting resistor 2 and the signal coupler 6 of the measured cable 7, the isolation diode 4, and the signal coupler 6 of the calibration signal receiving end connected sequentially from the equipment interface of the verification signal sending end; The anode of the light-emitting tube is connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com