Electrochemical test device for metallic corrosion of 90-degree elbow in flowing corrosive medium

A technology of flow corrosion and metal corrosion, applied in measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 (P type)

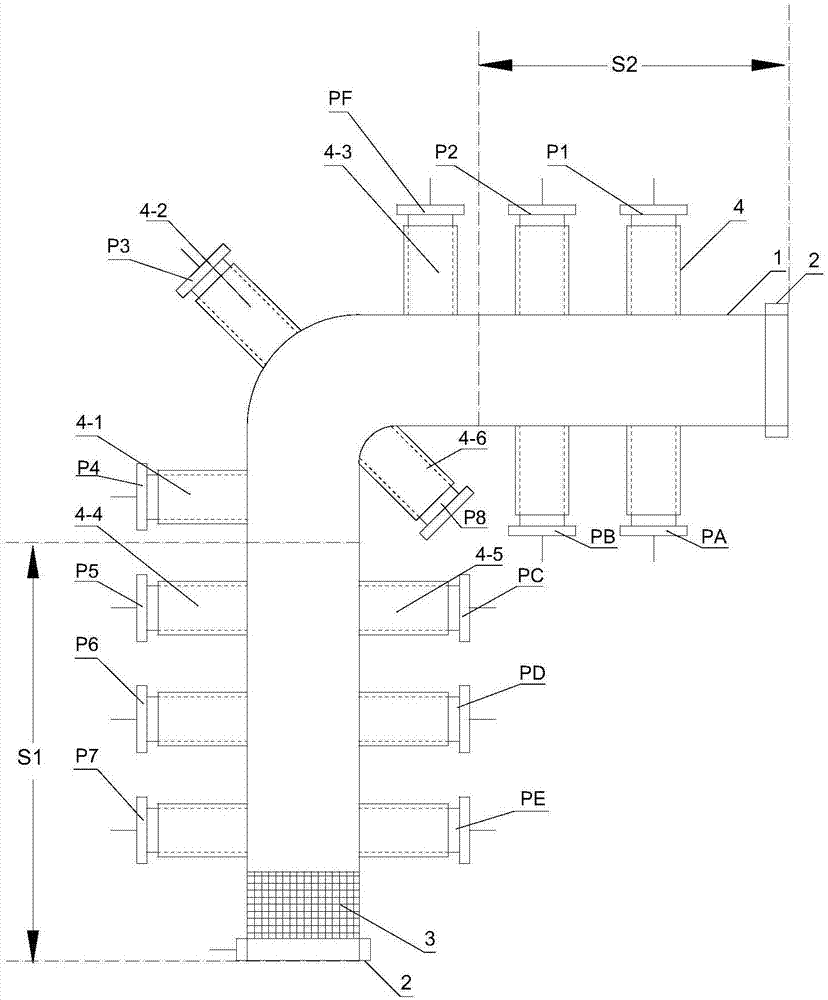

[0045] Such as figure 1 As shown, it includes: a glass pipe with the same structure and size as the 90° elbow pipe to be tested (the inner diameter of the glass pipe is 50mm), the glass pipe is composed of a 90-degree curved pipe section, a first straight pipe section S1 and a second straight pipe section S2 is composed (the glass pipe between S1 and S2 is a 90-degree curved pipe section), the glass pipe is arranged horizontally, and the 90-degree curved pipe section, the first straight pipe section and the second straight pipe section are located on the same horizontal plane. The first straight pipe section is perpendicular to the second straight pipe section and the first straight pipe section and the second straight pipe section communicate with the ports at both ends of the 90-degree curved pipe section respectively, and a glass pipe is installed on the ports on both sides of the glass pipe Teflon screw fittings for connection to circulation sy...

Embodiment 2

[0061] Example 2 (L type)

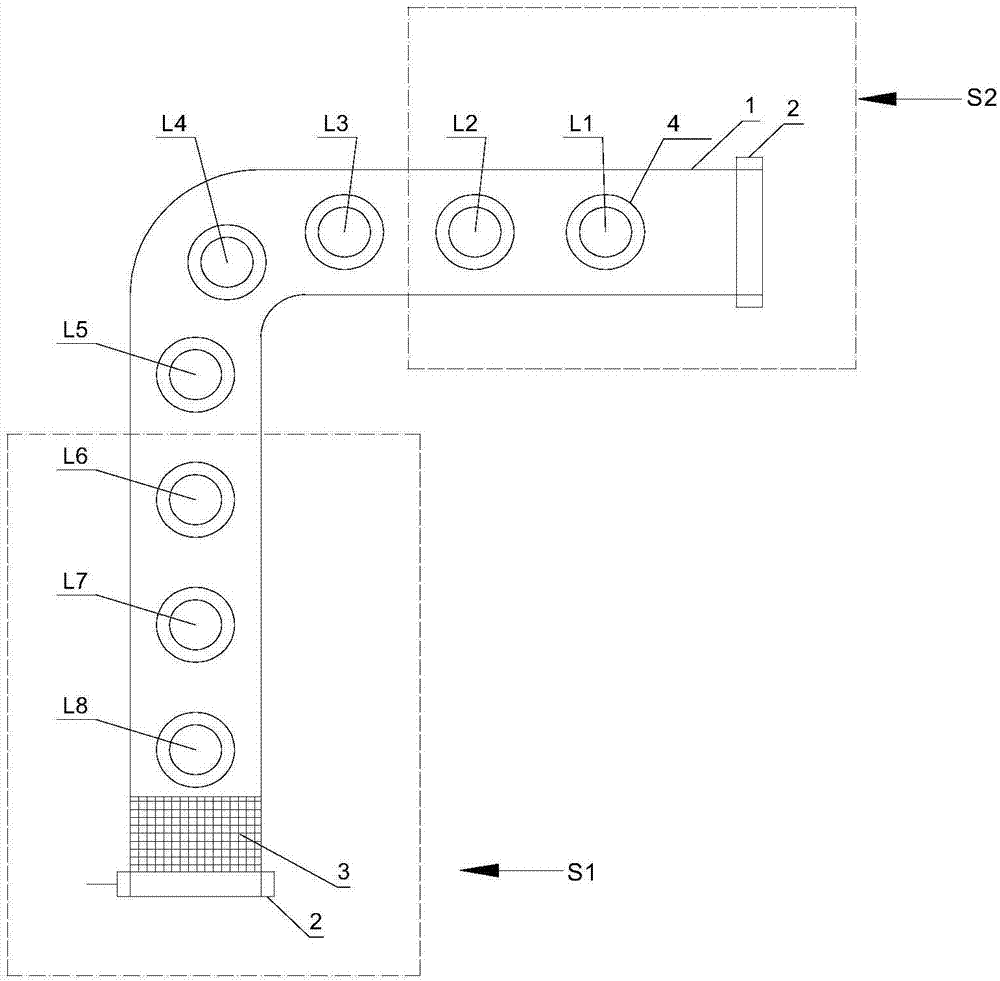

[0062] Such as figure 2 As shown, it includes: a glass pipe with the same structure and size as the 90° elbow pipe to be tested (the inner diameter of the glass pipe is 50mm), and the glass pipe is composed of a 90-degree curved pipe section, a first straight pipe section and a second straight pipe section , the glass pipeline is arranged horizontally, and the 90-degree curved pipeline section, the first straight pipeline section and the second straight pipeline section are located on the same horizontal plane. The first straight pipe section is perpendicular to the second straight pipe section and the first straight pipe section and the second straight pipe section communicate with the ports at both ends of the 90-degree curved pipe section respectively, and a glass pipe is installed on the ports on both sides of the glass pipe Teflon threaded fittings. The 90-degree curved pipe section is radially symmetrical along its curved section. The lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com