Model test device and model test for injecting flocculant during dredger fill construction

A flocculant, blowing and filling technology, which is applied in the testing of basic structures, basic structural engineering, construction, etc., can solve the problems of high test and research costs, fast mud flow rate, and vacuum loss, etc., and achieves strong controllability and operation. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

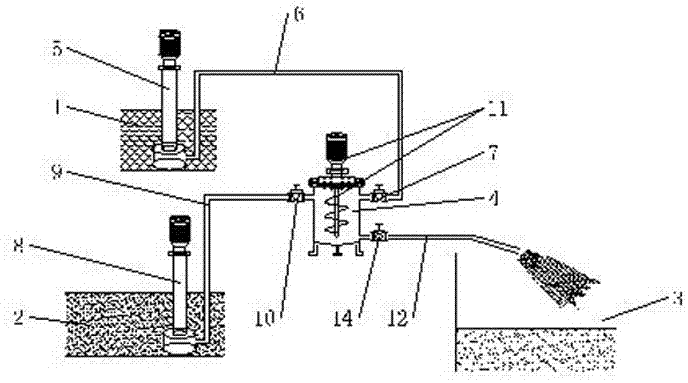

[0010] refer to figure 1 As shown, the model test device for injecting flocculants in the dredging soil construction process provided by the present invention includes a medicament configuration bin 1, a dredged soil sample loading bin 2, a soil sample collection bin 3 and a strong mixing bin 4, and a strong stirring bin 4 Air-tight, the medicament configuration bin 1 is provided with a flocculant delivery pump 5, the flocculant delivery pump 5 communicates with the upper part of the strong stirring bin 4 through the first delivery pipeline 6, and the first delivery pipeline 6 is provided with a first A flow control valve 7, a mud delivery pump 8 is arranged in the filling soil sample loading bin 2, and the mud delivery pump 8 communicates with the upper part of the strong stirring bin 4 through the second delivery pipeline 9, and the second delivery pipeline 9 is provided with a flow control valve 7. There is a second flow control valve 10, an electric stirrer 11 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com