Aluminium alloy material for car radiator cooling flat tube

A technology of aluminum alloy materials and heat sinks, applied in the field of aluminum alloy materials, can solve problems such as medium channel corrosion, pitting corrosion, and difficulty in protecting them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

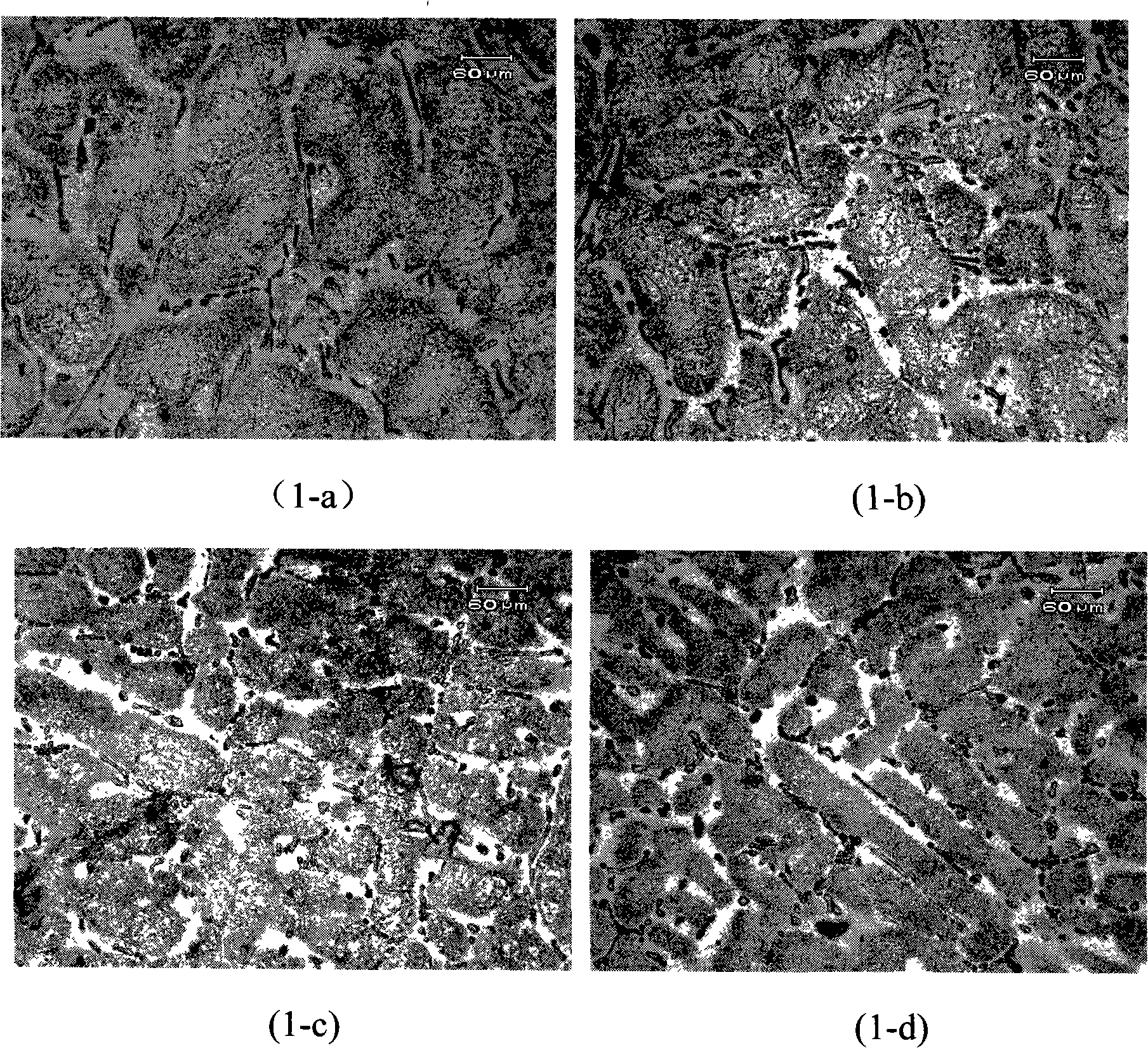

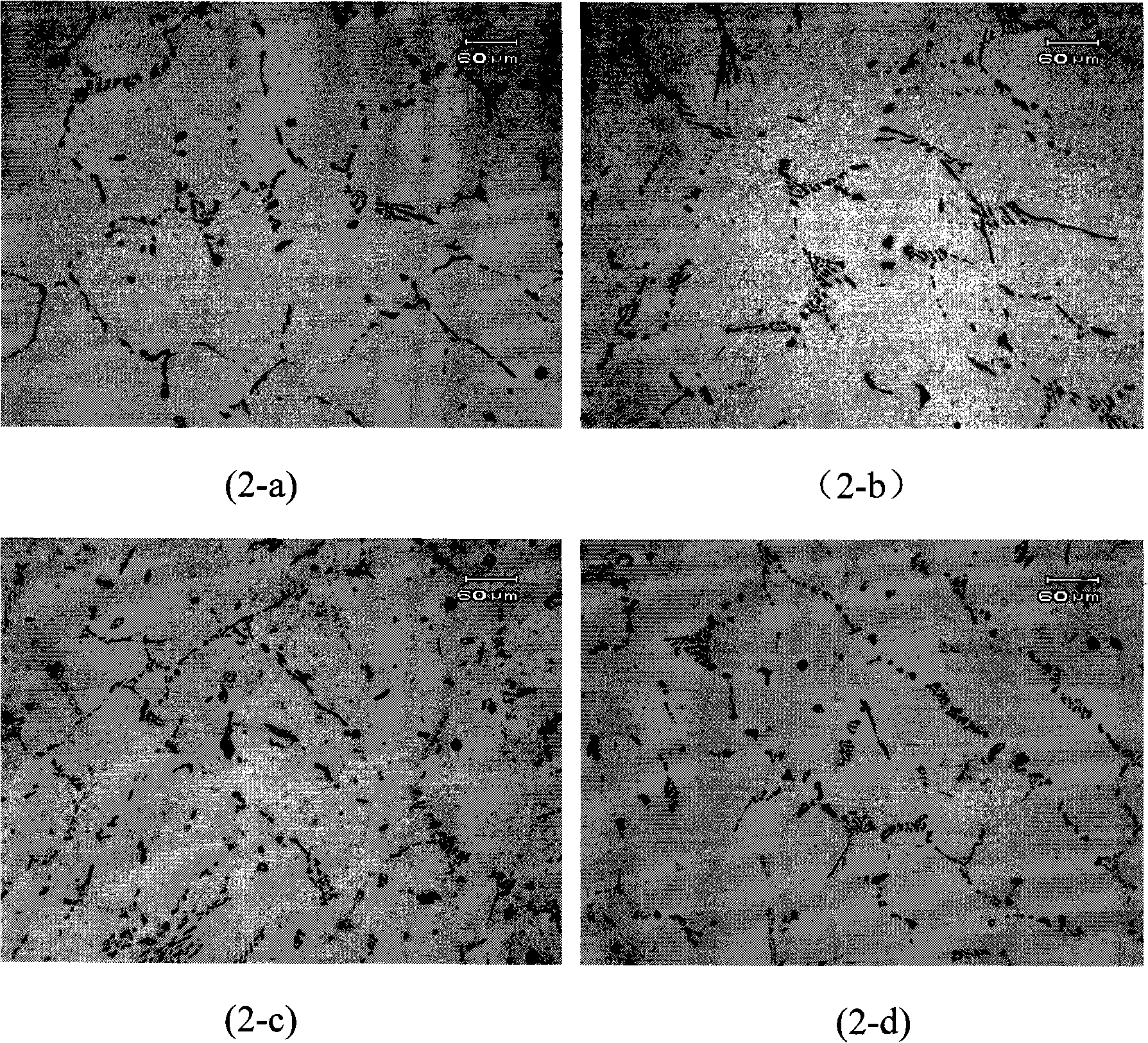

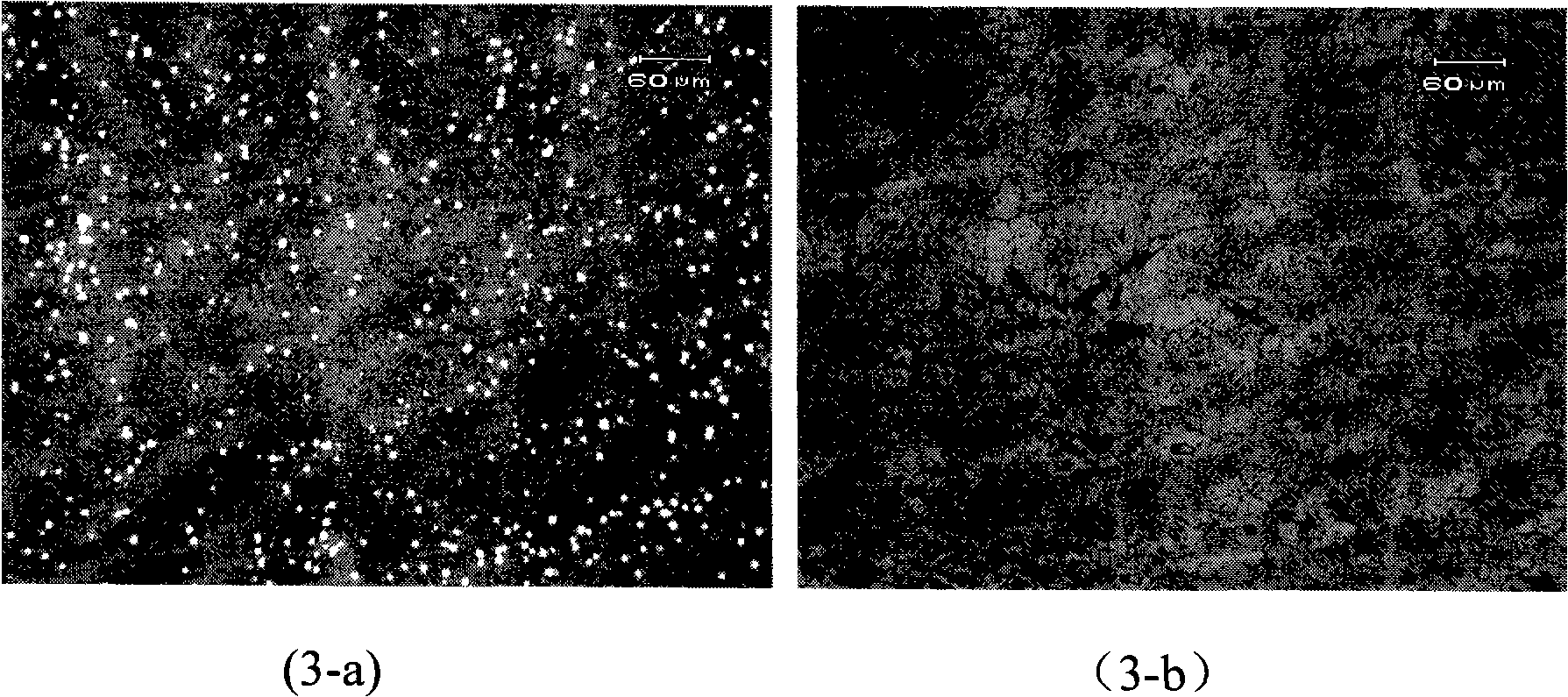

[0026] The present invention is further illustrated in conjunction with the examples during the experiment. The present invention adopts aluminum-manganese alloy ingot as the base material. The base material is smelted according to the composition shown in Table 1-1 according to the percentage by weight, and then added to the melting furnace for melting, and the temperature is raised to 720-740°C for refining, and it is left to stand for 8-20°C. After 12 minutes, the alloy liquid was poured into aluminum ingots after slag removal. Then, mixed rare earth RE mainly composed of Ce is added to the base material aluminum-manganese alloy ingot to smelt aluminum alloys with different rare earth contents. The above two steps can also be carried out simultaneously.

[0027] The weight percentage of rare earth RE in the aluminum alloy obtained by smelting is shown in Table 1-2.

[0028] Table 1-1 Chemical Composition of Base Metal Alloy

[0029]

[0030] Table 1-2 Rare earth conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com