High temperature and high pressure dynamic electrochemical test and pH in situ monitoring experimental device

A high temperature and high pressure, monitoring device technology, applied in measuring devices, scientific instruments, instruments, etc., can solve the problem of inability to measure electrochemical signals, and achieve the effect of improving the accuracy of rotational speed and concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

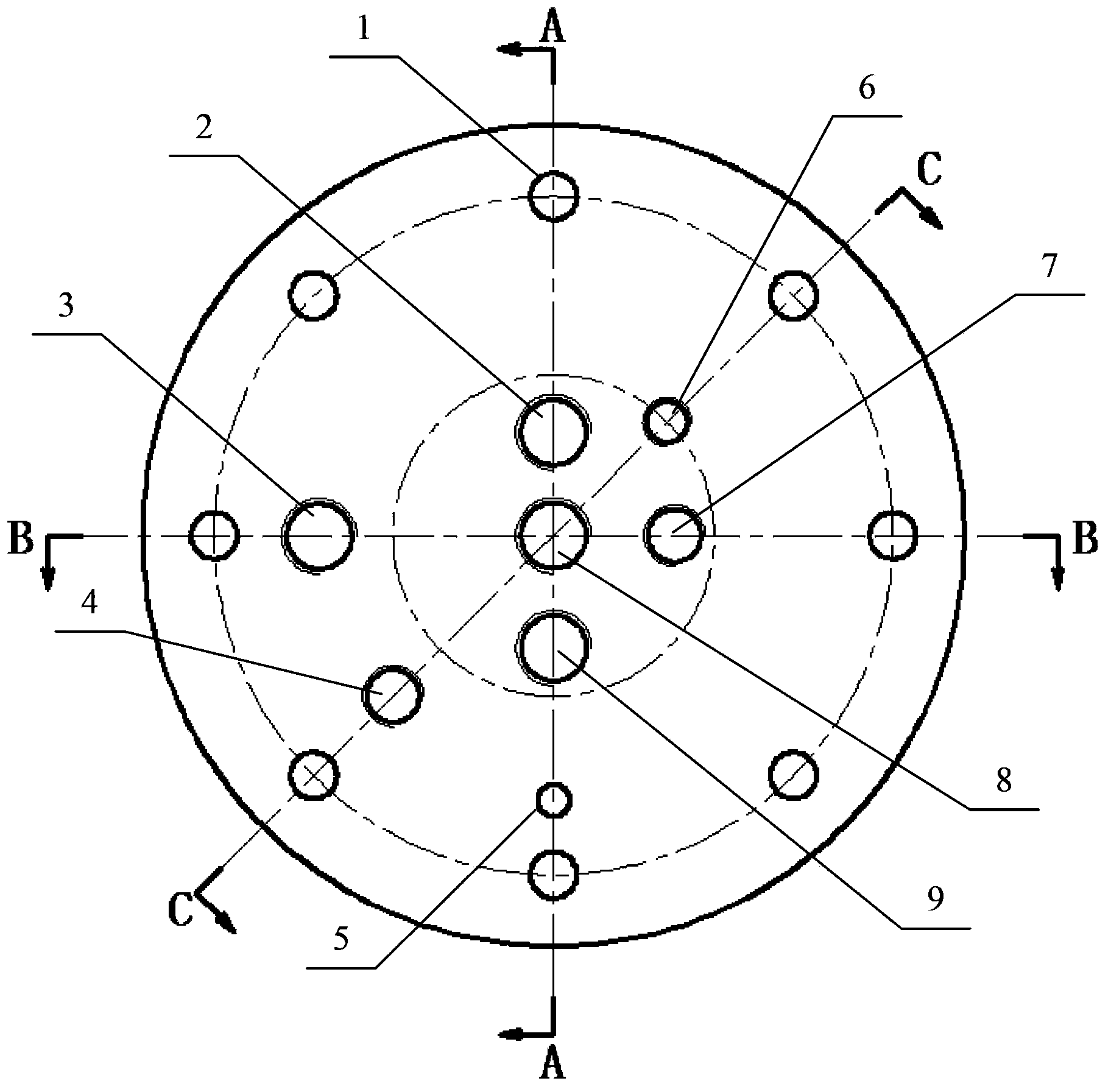

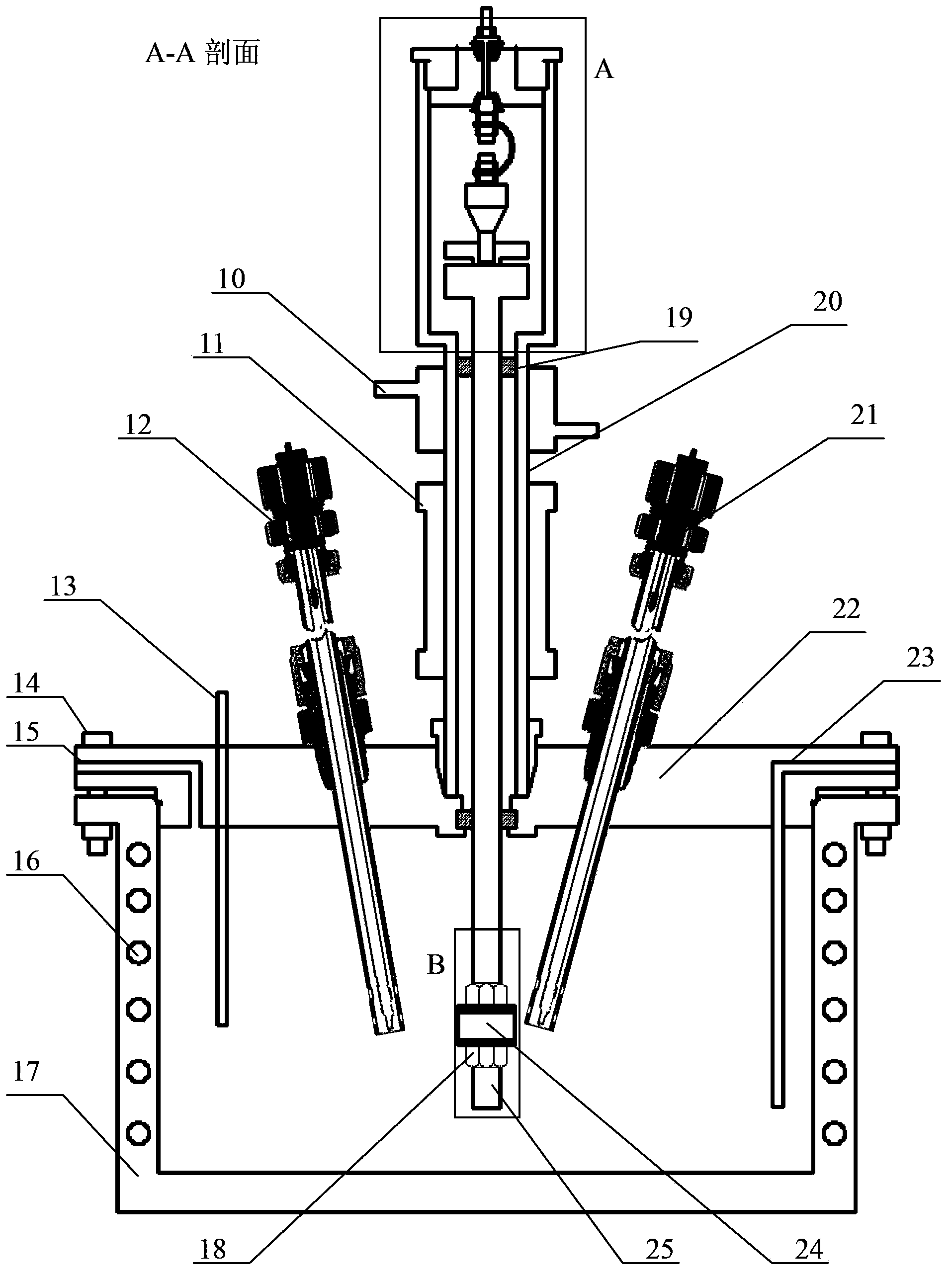

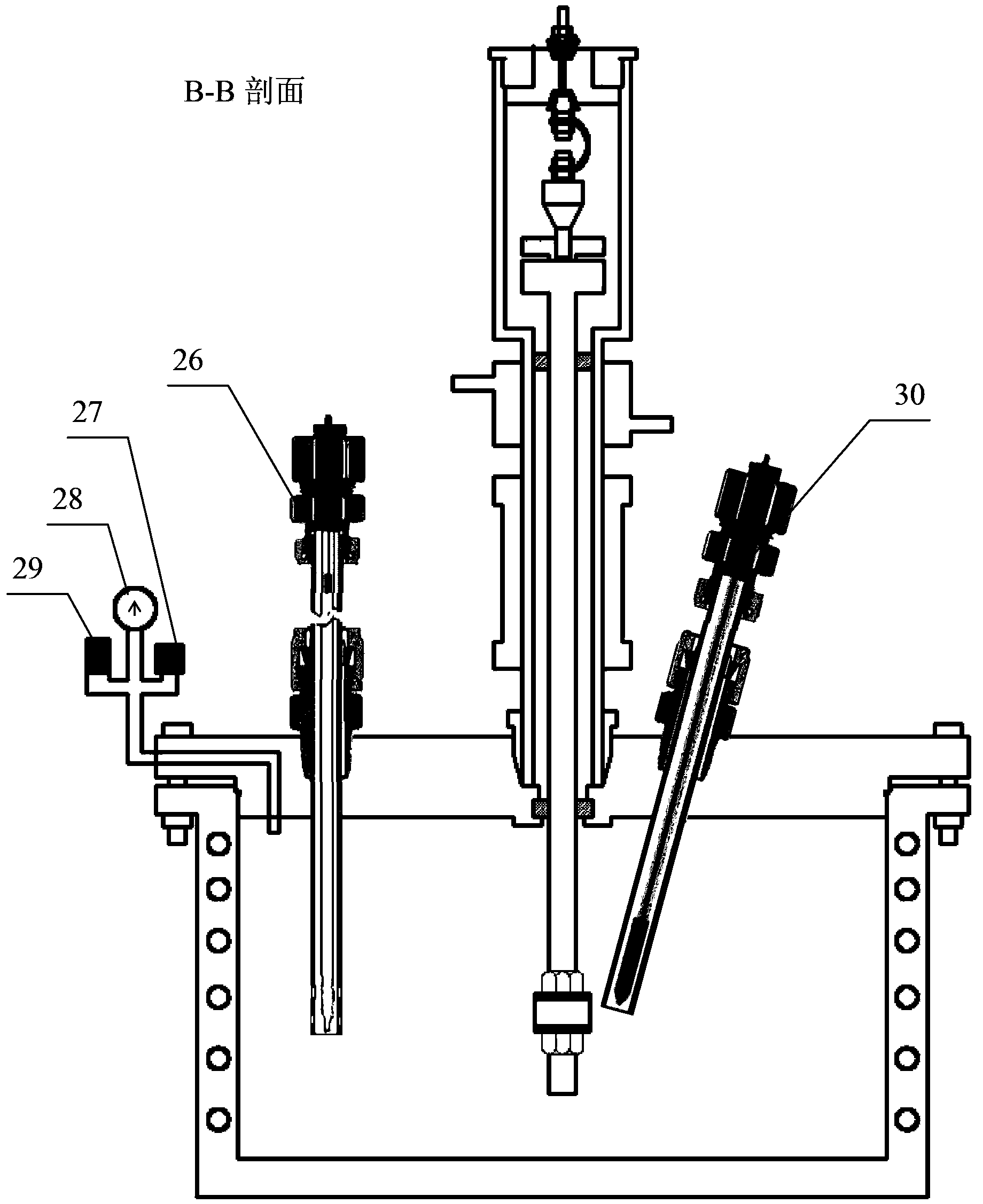

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] like Figures 1 to 6As shown, the present invention is a high-temperature and high-pressure dynamic electrochemical test and pH in-situ monitoring device, which includes a high-temperature and high-pressure reaction kettle, a heating and heat preservation system, a three-electrode system, a first pH composite electrode system, a second pH composite electrode system, Working electrode signal conduction path, rotation system, external control box, external gas supply system, external electrochemical test instrument, external pH instrument and computer;

[0035] The high-temperature and high-pressure reaction kettle is composed of an autoclave cover 22, an autoclave body 17, an air inlet pipe 23, and a gas outlet

[0036] Pipe 15, pressure sensor 27, pressure gauge 28 and safety valve 29 constitute;

[0037] The three-electrode system c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com