Particle detection device

A detection device and particle technology, which is applied in the direction of measuring device, particle size analysis, particle suspension analysis, etc., can solve the problems of increased error and large proportion of impedance change, and achieve the effect of suppressing resistance change, suppressing impedance, and accurate particle amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

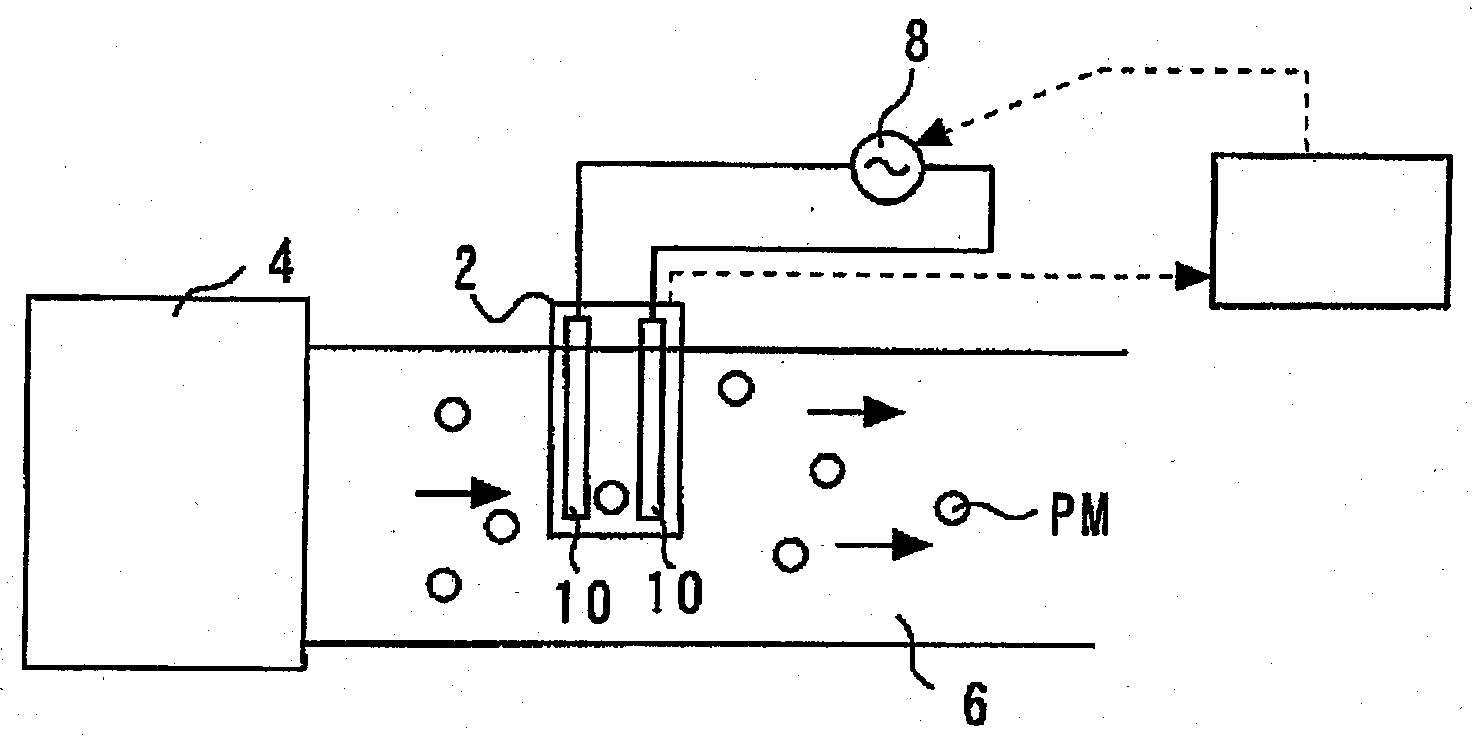

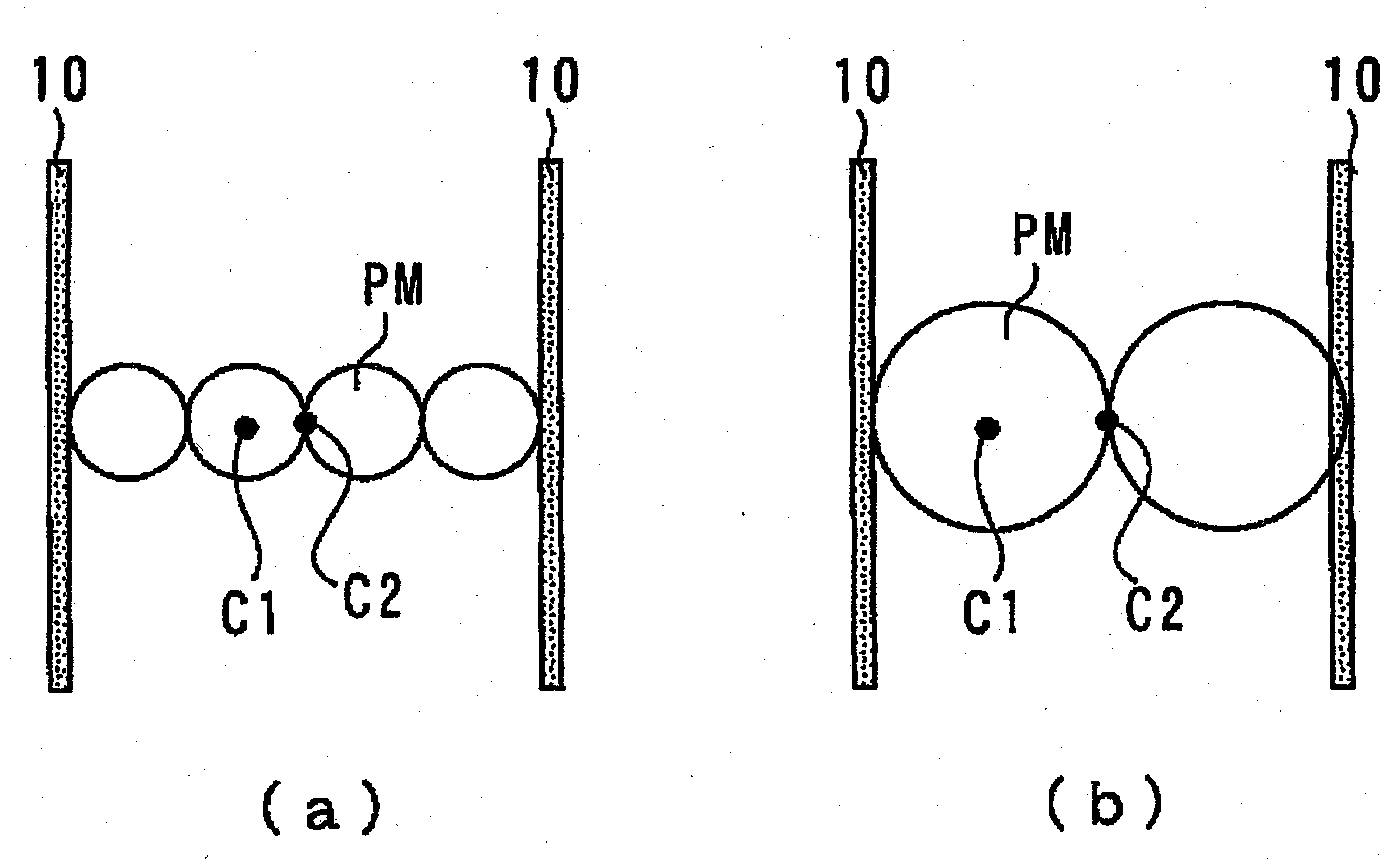

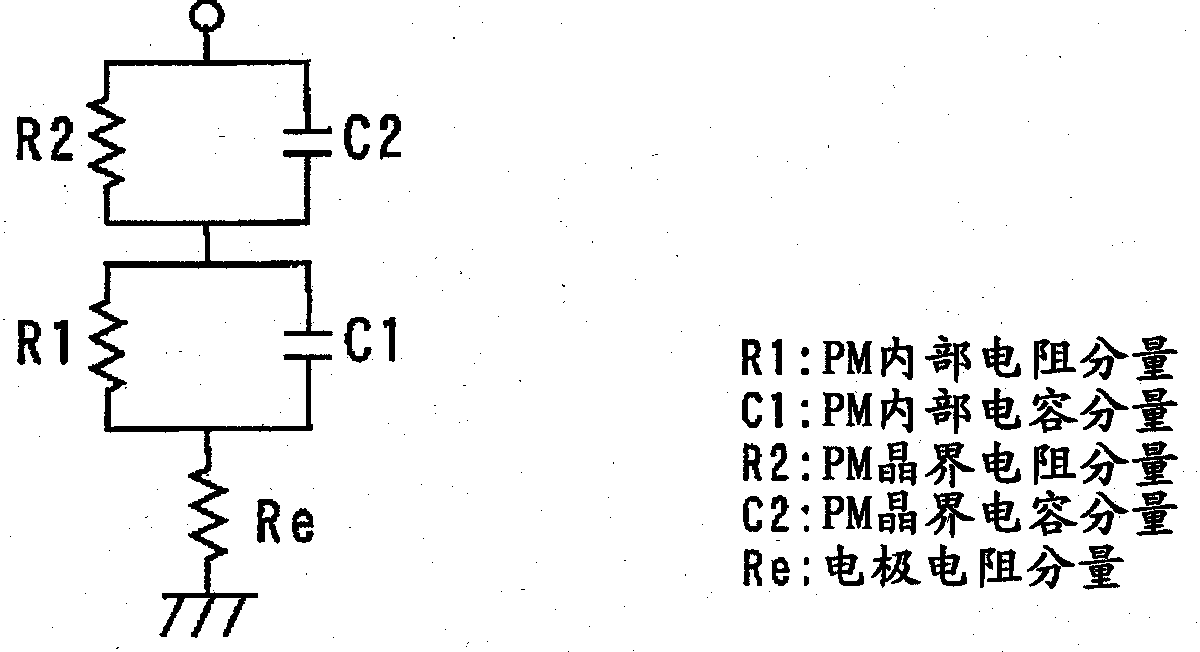

[0046] figure 1 It is a schematic diagram for explaining the installation state of the PM sensor according to Embodiment 1 of the present invention. Such as figure 1 As shown, the PM sensor 2 is provided, for example, in an exhaust path 6 of an internal combustion engine 4 mounted on a vehicle or the like. An AC power source 8 for applying AC and DC voltages is connected to the PM sensor 2 (particle detection device). The PM sensor 2 has a pair of electrodes 10 arranged separately. At least a part of the electrode 10 is provided in the exhaust path 6 in a state capable of contacting the exhaust gas. In addition, although illustration is omitted, the PM sensor 2 is connected to an impedance detector that detects impedance between the electrodes 10 , a frequency detector that detects an AC frequency, and the like.

[0047] The system has a control device 12 . The control device 12 is connected to various detectors of the PM sensor 2 and the AC power supply 8 . The control ...

Embodiment approach 2

[0090] The system of Embodiment 2 is the same as the system of Embodiment 1 except that the timing for calculating the number of PM particles is specified. Figure 8 It is a diagram for explaining the PM accumulation amount and aging of the PM sensor 2 . exist Figure 8 In , the horizontal axis represents time, and the vertical axis represents PM accumulation amount.

[0091] Such as Figure 8 As shown in FIG. 2 , the PM accumulation amount on the PM sensor 2 increases with time, but once it reaches a saturated state, it stops increasing and becomes constant. In addition, since the resistance of the PM sensor 2 changes according to the amount of PM accumulation, when it is in a saturated state and the amount of PM accumulation is constant, the resistance does not change but becomes constant.

[0092] In the second embodiment, when the actual resistance Rm of the PM sensor 2 becomes a resistance indicating a saturated state, an AC voltage obtained by continuously changing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com