The method of pushing back the original mix ratio of hardened concrete at early age

A concrete and early-age technology, which is applied in the pushback field of the original mix ratio of concrete, can solve problems such as poor test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

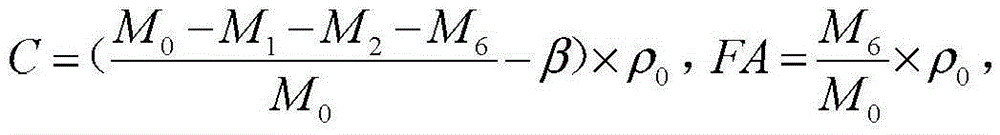

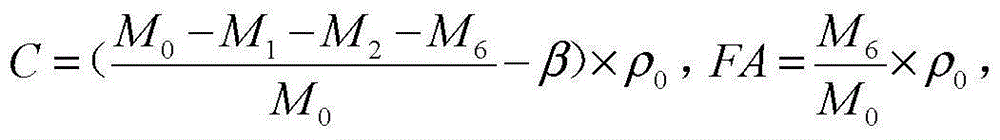

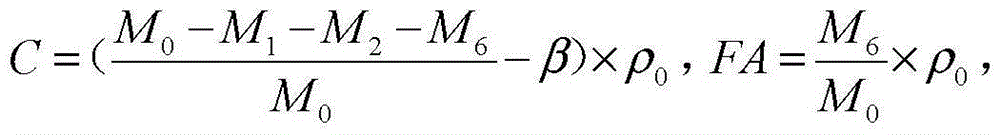

[0019] Specific implementation mode one: the push-back method of the original mix ratio of early age hardened concrete in this implementation mode is carried out according to the following steps:

[0020] Step 1: Take a concrete test block to be tested, and measure the mass m of the concrete test block in the air under the water-absorbed and dry state 1 , and then soak the concrete test block in water for 24h, and measure the mass m 2 , and then dry the concrete test block at 100-105°C to constant weight, and measure the mass m 3 , to calculate the bulk density of concrete in the dry state where ρ 水 is the density of water;

[0021] Step 2: Take another concrete test block to be tested and break it into 30-50mm fragments and dry it to constant weight to obtain concrete fragments, and weigh the mass as M 0 The concrete fragments are packed into acid-resistant plastic containers and poured into a mass of M 0 Dilute hydrochloric acid solution A with 2 to 3 times the volume ...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the dilute hydrochloric acid solution A in step 2 is prepared by mixing 11.6 mol / L concentrated hydrochloric acid and water at a mass ratio of 1:3-6. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the acid-resistant plastic container described in Step 2 and Step 3 is a polyethylene plastic container. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com