Method for recording and observing corrosion behavior of magnesium alloy microstructure in situ

A microstructure and magnesium alloy technology, applied in the preparation of test samples, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve the problems of complex operation and single means, achieve simple and reliable analysis, and avoid mirror contamination , The effect of simple sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In situ observation and recording of microstructure corrosion behavior of EW75 magnesium alloy after solution treatment in NaCl solution:

[0031] (1) Sample preparation: Take a metallographic sample on the EW75 magnesium alloy material, after rough grinding and fine grinding with 240#, 800#, 2000#, 5000# sandpaper, polish; the polished observation surface is at 4% ( Volume %) After corroding the microstructure in the nitric acid alcohol solution, dry it with a hair dryer and set it aside.

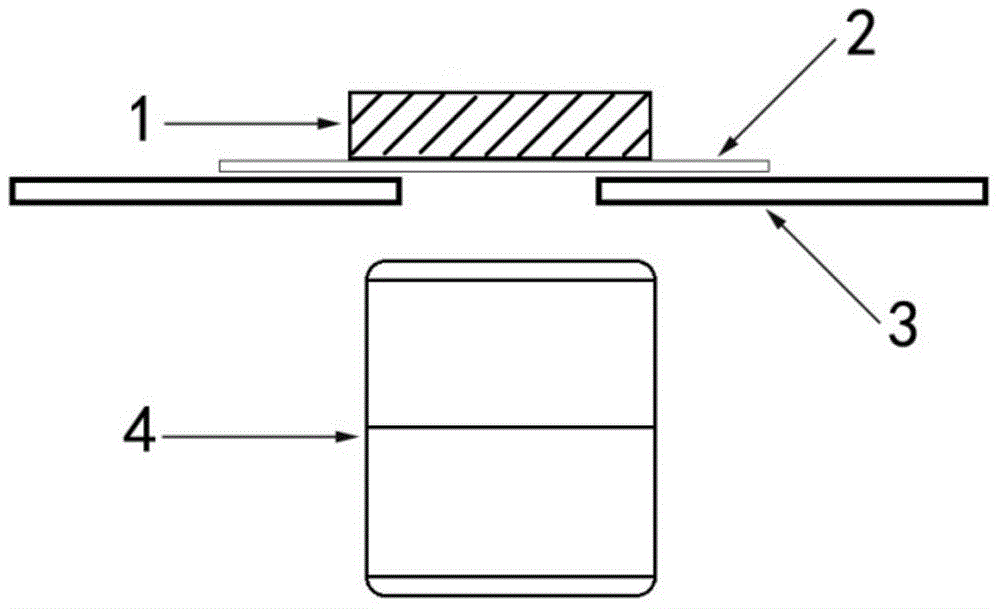

[0032] (2) On the metallographic microscope stage, place a piece of cover glass with good light transmission, the size of the cover glass completely covers the microscope observation hole; place the sample processed in step (1) on the cover glass, adjust The lens has a clear metallographic structure; the thickness of the cover glass is 0.17±0.02mm, otherwise the light transmission is not good, which will affect the observation effect.

[0033] (3) Use a cotton swab to take 1×10 -4...

Embodiment 2

[0038] In situ observation and recording of extruded WE93 magnesium alloy in NaHSO 3 Corrosion behavior of microstructure in solution, the observation condition is: corrosion solution 1×10 -4 mol / L NaHSO 3 , the number of wipes on the observation surface is 8 times, the time interval x=1s, and other steps are the same as in Example 1.

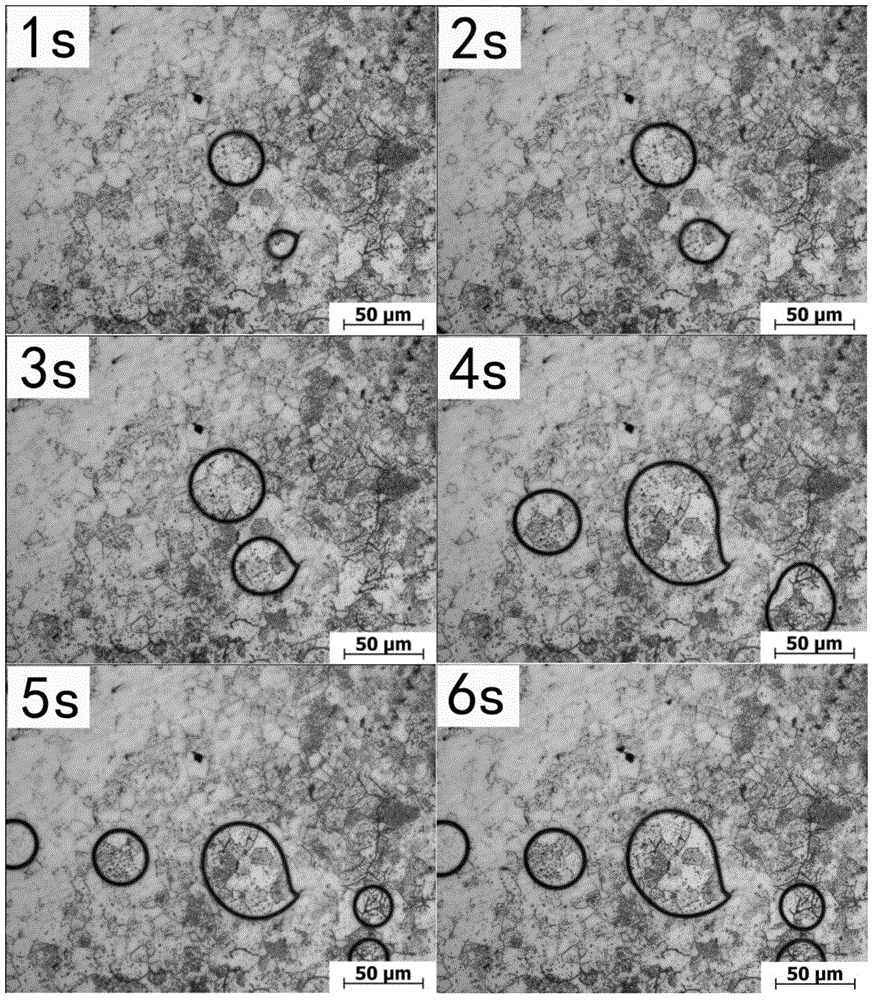

[0039] image 3 It is a 500 times metallographic photograph of continuous observation of in-situ corrosion of WE93 magnesium alloy in extruded state for 1-6 seconds. from image 3 It can be seen that the corrosion is obvious in the area where the size of the second phase is larger. The larger the size of the second phase, the more obvious the effect of the potential difference between the matrix and the second phase, and the galvanic corrosion occurs on the interface between the matrix and the second phase. The larger the trend, the alloy corrosion produces H 2 Bubbles are formed. Due to the direct contact between the cover glass and the obs...

Embodiment 3

[0041] In-situ observation and recording of the microstructural corrosion behavior of aged AZ80 magnesium alloy in NaCl solution, the observation conditions are: corrosion solution 1×10 -5 mol / L NaCl, the number of wipes on the observation surface is 3 times, the time interval x=2s, other steps are the same as in Example 1.

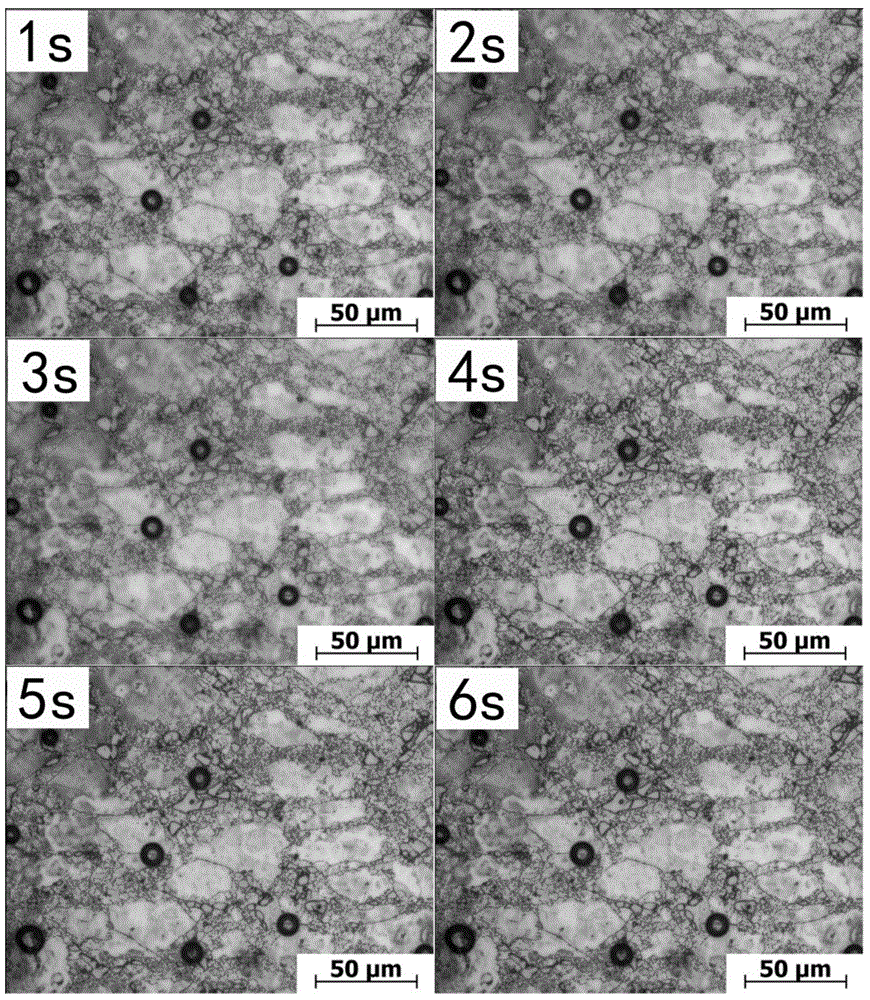

[0042] Figure 4 The 200 times metallographic photographs of the AZ80 magnesium alloy in the aging state were continuously observed for in-situ corrosion for 2 to 12 seconds. from Figure 4 It can be seen that the second phase Mg of the aged AZ80 magnesium alloy 17 Al 12 Relatively thick, and to some extent connected into a network. The alloy undergoes galvanic corrosion due to the potential difference effect between the matrix and the second phase. In the place where the second phase is relatively sparse, the alloy corrodes preferentially, and as the corrosion progresses gradually, the corrosion area gradually expands to the surrounding area. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com