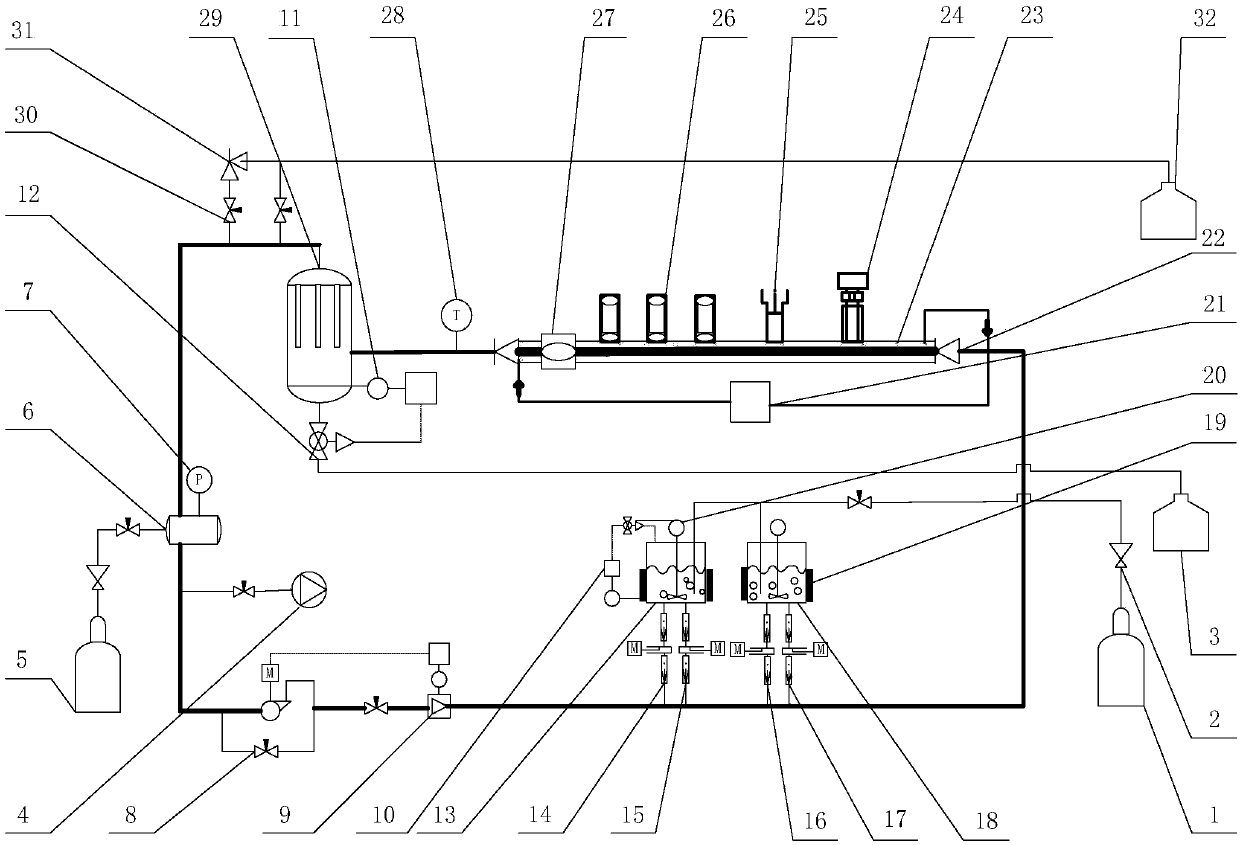

High-speed moisture corrosion loop experimental device for simulating corrosion environment in natural gas pipeline

A technology for natural gas pipelines and moisture corrosion, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. Water phase erosion and other problems, to achieve the effect of good sensitivity, long service life and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] The invention provides a high-speed moisture corrosion loop experiment device for simulating the internal corrosion environment of a natural gas pipeline.

[0023] Such as figure 1 As shown, in the device, the high-pressure gas cylinder A1 is connected to the water tank 13 and the medicine tank 18 through pipelines, and the pressure reducing valve 2 is set on the management of the high-pressure gas cylinder A1, the water tank 13 is connected to the controller 10, and the lower part of the water tank 13 is connected to the plunger metering water pump A14 and plunger metering water pump B15, agitator 20 is arranged in water tank 13 and medicine box 18, plunger metering medicine pump A16 and plunger metering medicine pump B17 are connected to the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com