Rare earth complex, catalyst, preparation method thereof and preparation method of polybutadiene

A rare earth complex and rare earth catalyst technology, applied in the field of polymers, can solve the problems of strong corrosion of the catalytic system and pollution of the environment, and achieve the effects of rich species, small corrosion and high cis content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

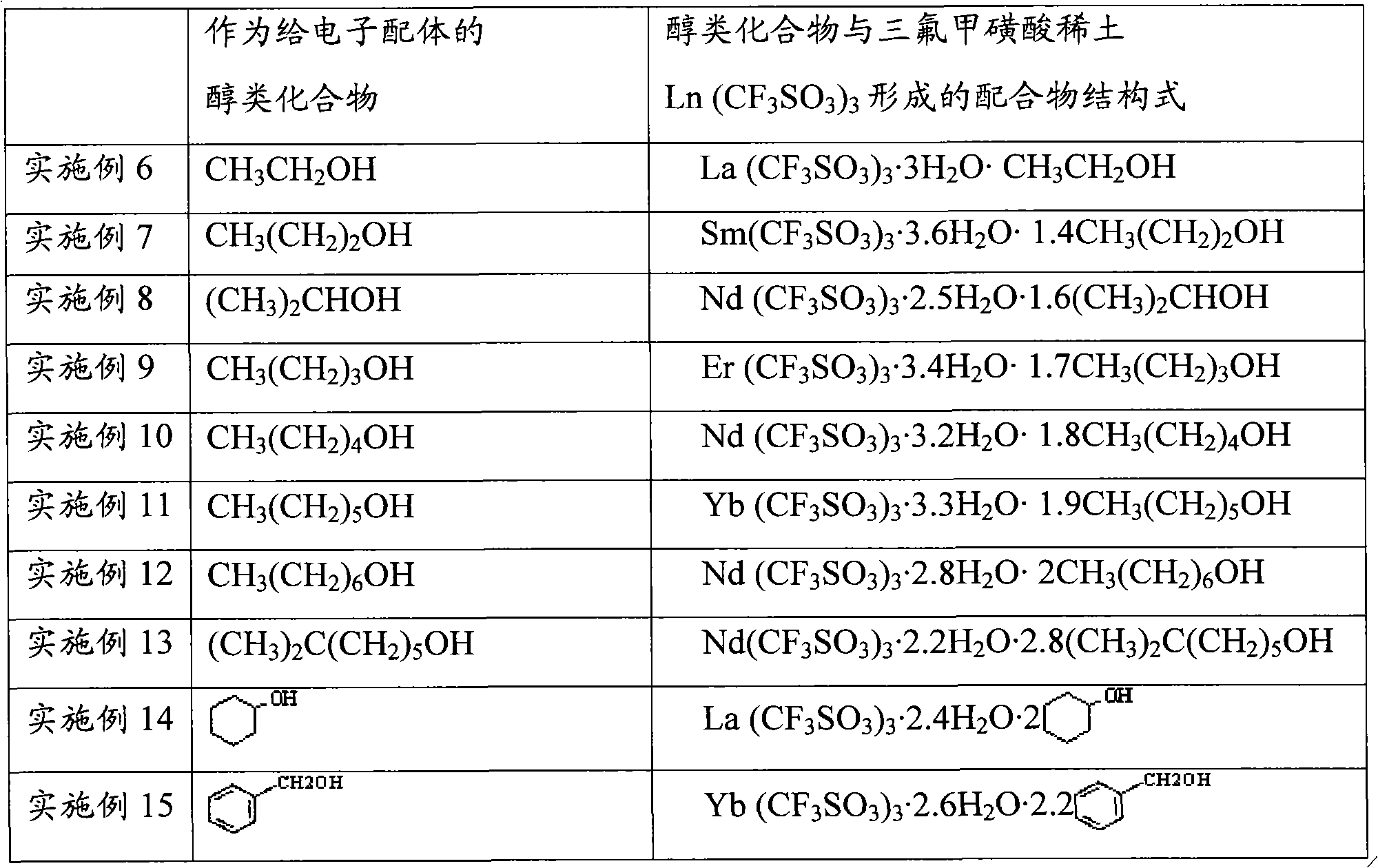

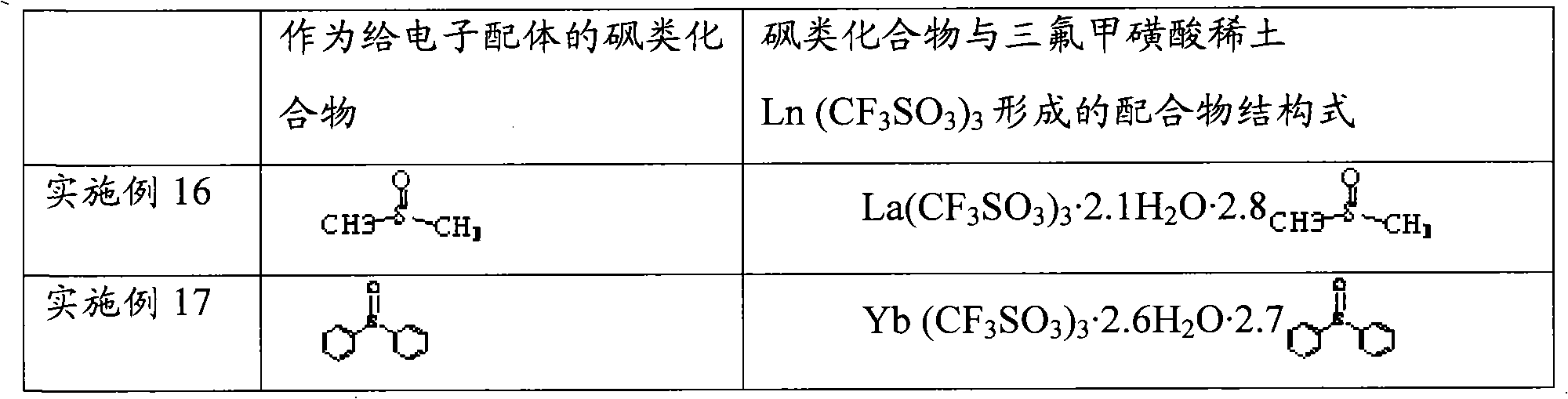

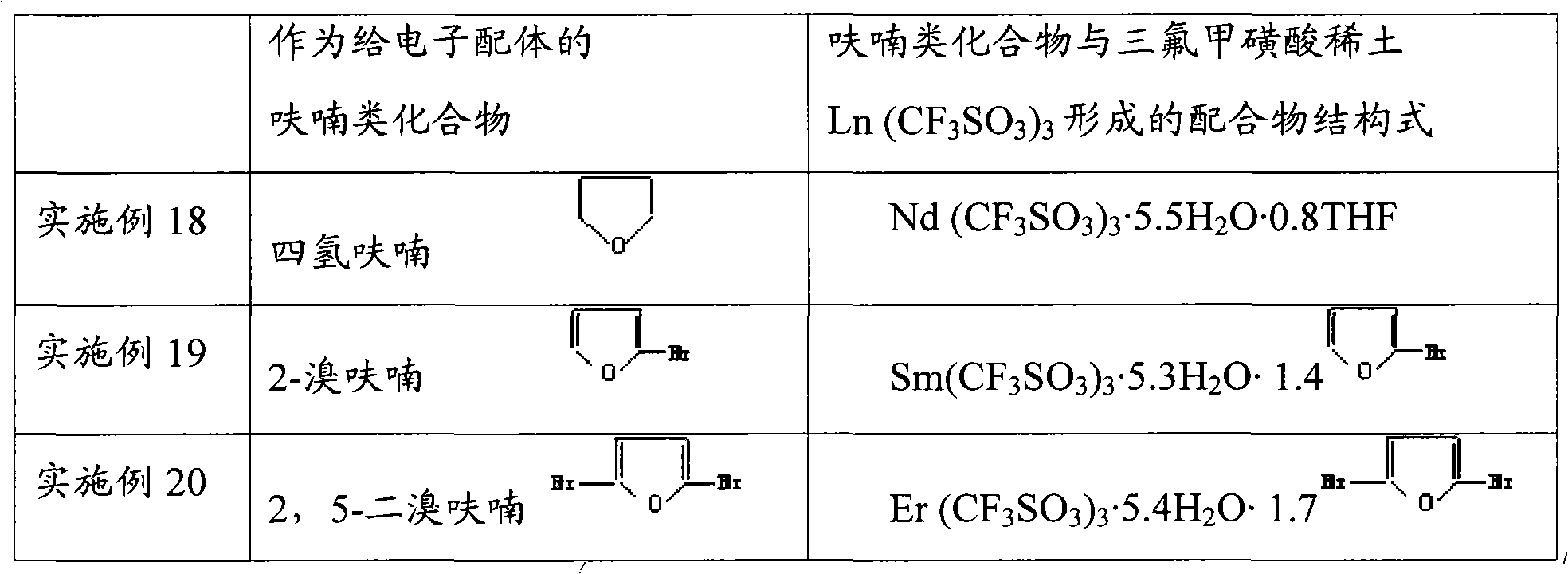

[0027] The invention also provides a preparation method of the sulfonic acid rare earth catalyst, which includes:

[0028] Mixing the rare earth trifluoromethanesulfonate compound, the electron donating ligand and the solvent, heating to obtain the rare earth trifluoromethanesulfonate complex, the molar ratio of the rare earth element to the electron donating ligand is 1:3-10;

[0029] The rare earth trifluoromethanesulfonate complex and the alkyl aluminum are mixed to obtain a sulfonate rare earth catalyst, and the molar ratio of the alkyl aluminum to the rare earth element in the rare earth trifluoromethanesulfonate complex is 10-60:1 .

[0030] The above-mentioned rare earth trifluoromethanesulfonate compound is preferably prepared according to the following method:

[0031] The rare earth oxide and trifluoromethanesulfonic acid are mixed, heated to 40-80°C, and reacted for 2-10 hours to obtain a rare earth trifluoromethanesulfonic acid compound. The molar ratio of the rare earth o...

Embodiment 1

[0048] Preparation of Neodymium Trifluoromethanesulfonate

[0049] In the reactor, add neodymium oxide to the trifluoromethanesulfonic acid solution at a molar ratio of 10:1 to neodymium oxide and trifluoromethanesulfonic acid, heat to 70°C under stirring, and react for 8 hours. Unreacted neodymium oxide is removed, the aqueous neodymium trifluoromethanesulfonate is concentrated, and then the concentrated neodymium trifluoromethanesulfonate aqueous solution is placed at room temperature to naturally precipitate crystals, that is, neodymium trifluoromethanesulfonate with crystal water.

Embodiment 2

[0051] Preparation of Lanthanum Triflate

[0052] In the reactor, lanthanum oxide was added to the trifluoromethanesulfonic acid solution at a molar ratio of 10:1 to the lanthanum oxide and trifluoromethanesulfonic acid solution, heated to 70°C under stirring, reacted for 8 hours, filtered, Unreacted lanthanum oxide is removed, the lanthanum triflate aqueous solution is concentrated, and then the concentrated lanthanum triflate aqueous solution is placed at room temperature to naturally precipitate crystals, which is lanthanum triflate with crystal water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com