Method for testing corrosion behavior under thin liquid film in gas environment

A technology of metal corrosion and testing methods, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of stable control, inability to obtain the dynamic behavior of the corrosion process, lack of in-situ monitoring and tracking, etc., to achieve good stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

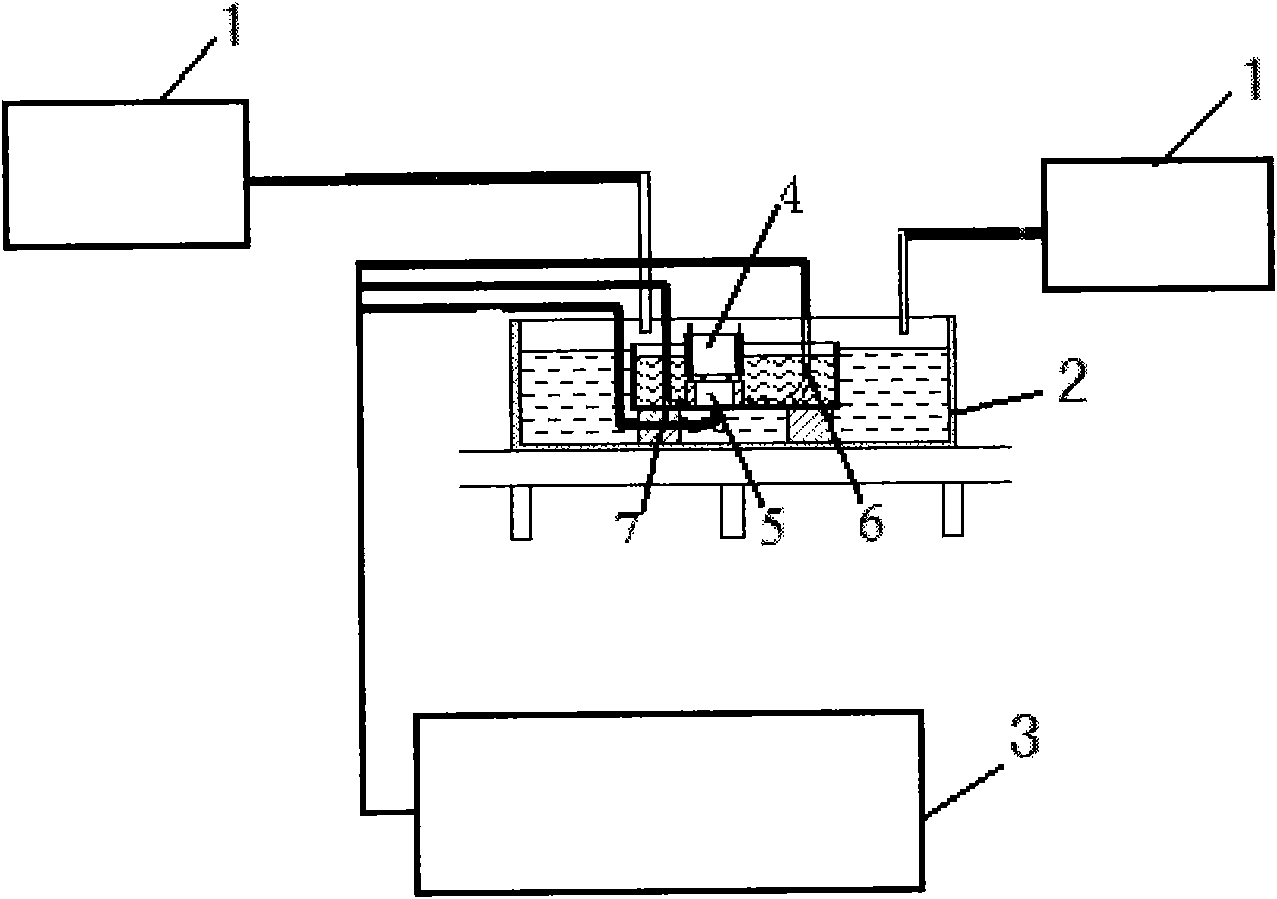

[0020] The test device consists of four parts: corrosion gas generation system 1, corrosion test box 2, thin liquid film control device 4, electrochemical workstation 3; corrosion test box 2 is made of plexiglass, the main purpose is to prevent corrosion gas from overflowing and maintain corrosion The gas concentration is within the range required by the experiment; the three electrodes and the thin liquid film thickness control system are placed in the corrosion test box 2; the thin liquid film control device 4 is composed of a bracket and a waterproof breathable membrane fixed on the end of the bracket section, There are 3 movable pillars on the bracket. During the test, the vertical distance from the top of the 3 pillars on the bracket to the waterproof and breathable membrane must be adjusted to the required length, and then the bracket is placed on the end surface of the tested metal sample 5. directly above, the vertical distance from the top of the pillar to the waterpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com