Efficient Al alloy sacrificial anode suitable for low-temperature seawater environment and preparation process thereof

A sacrificial anode and aluminum alloy technology, which is applied in the field of corrosion and protection, can solve problems such as abnormal use, uneven dissolution, and reduced service life, and achieve the effect of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The aluminum alloy sacrificial anode formula is: Zn 3.2%, In 0.007%, Sn 0.018%, Bi 0.01%, the balance is Al, and Al contains impurity elements Fe 0.092%, Si 0.07%, Cu≤0.001%,

[0017] The preparation process adopts the melting and casting method. Before melting, the aluminum ingot and zinc ingot are preheated to 100°C to remove the moisture in the aluminum ingot and zinc ingot; , so that the aluminum ingots are completely melted, and then add zinc ingots according to the proportion of the formula based on the fact that there is no solid aluminum ingots visually. Continue heating until the temperature of the mixture of liquid aluminum and liquid zinc rises to 720-750°C, stop heating; use a small crucible to scoop up the liquid mixture of liquid aluminum and liquid zinc, and mix the indium ingot, tin ingot and bismuth ingot according to the formula ratio Wrap it with aluminum foil and add it to a small crucible, stir to dissolve it, then pour it into a high-temperature he...

Embodiment 2

[0020] The aluminum alloy sacrificial anode formula is: Zn 4.15%, In 0.01%, Sn 0.016%, Bi 0.08%, and the balance is Al, of which Al contains impurity elements Fe 0.087%, Si 0.05%, Cu≤0.001%, and the preparation process is the same Example 1.

Embodiment 3

[0022] The aluminum alloy sacrificial anode formula is: Zn 5.8%, In 0.005%, Sn 0.02%, Bi 0.2%, the balance is Al, of which Al contains impurity elements Fe 0.077%, Si 0.05%, Cu≤0.001%, the preparation process is the same Example 1.

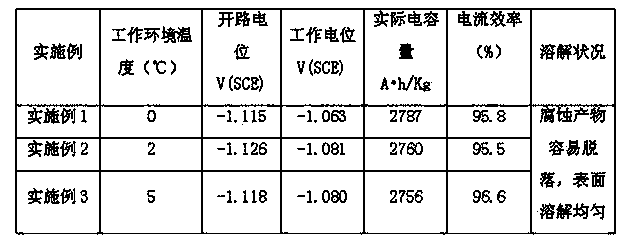

[0023] Table 1 Electrochemical properties of the high-efficiency aluminum alloy sacrificial anode suitable for low-temperature seawater environment in this example.

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com