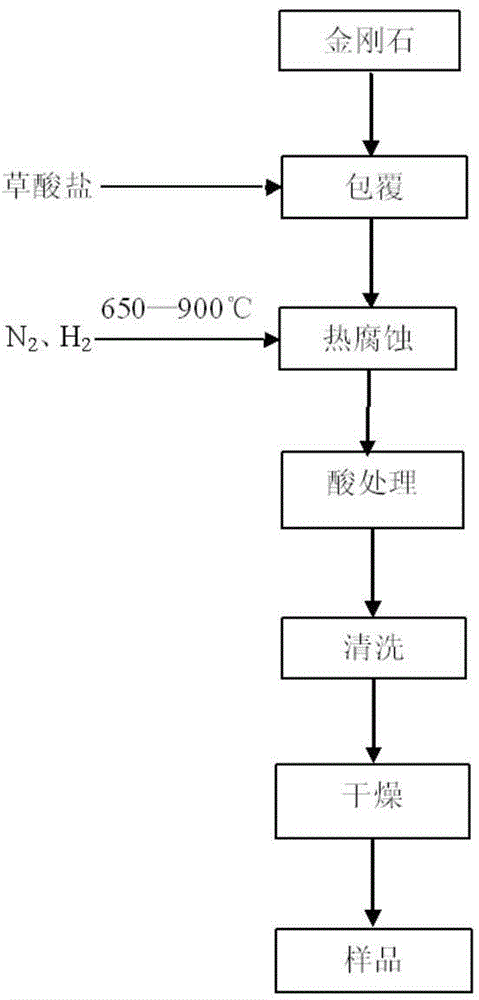

Method for increasing surface roughness of man-made diamond single crystal

A surface roughness and artificial diamond technology, applied in the field of abrasives and grinding, can solve the problems of self-sharpening of diamond tools, inability to apply diamond tools, and grinding wheels without edges, etc., to improve grinding efficiency and processing quality, Improves the effect of easy shedding and prolongs the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

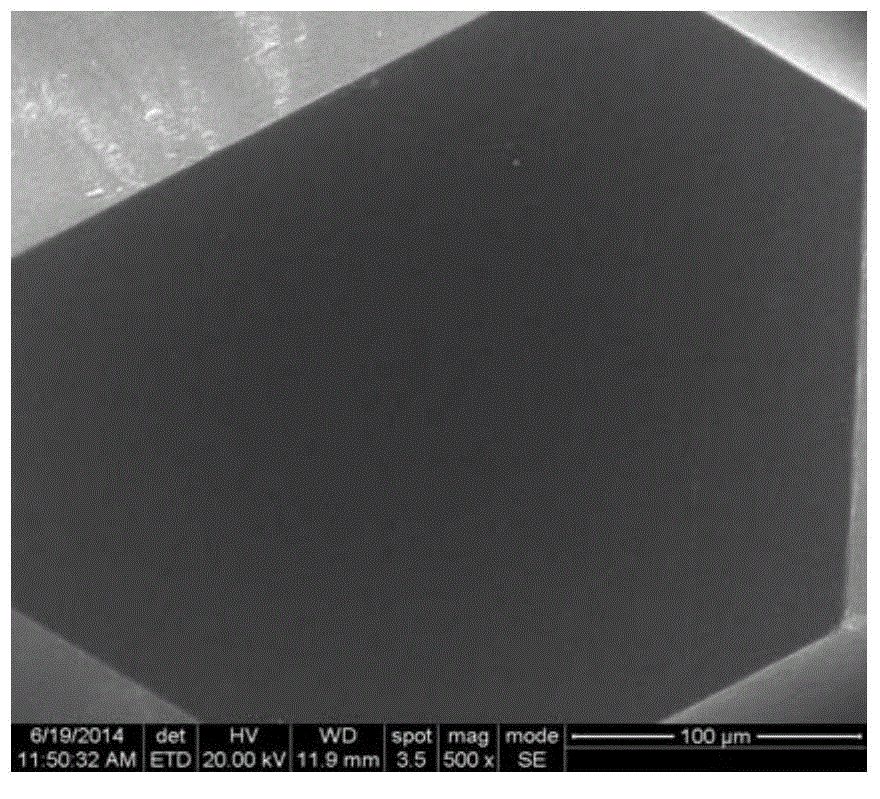

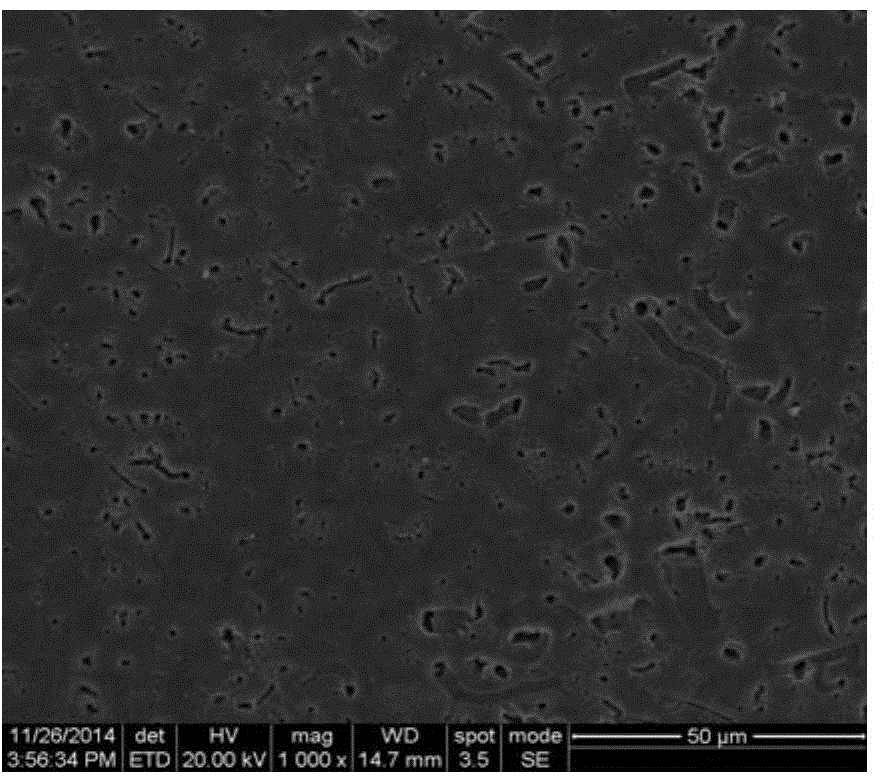

Image

Examples

Embodiment 1

[0043] Cobalt oxalate powder is evenly wrapped on the diamond surface according to the mass ratio of 1:1, so that the two are in full contact.

[0044] The coated diamond is then loaded into a ceramic crucible or boat and placed in a tube furnace. Adjust the sintering process curve, the heating rate is 3°C / min, the final sintering temperature is 800°C, and the holding time is 1h. During the heating process, nitrogen gas is introduced when the temperature rises to 200 °C, hydrogen gas is introduced when the temperature is 500 °C, hydrogen gas is stopped when the temperature drops to 500 °C during the cooling process, nitrogen gas is stopped at 200 °C, and the flow rate of hydrogen gas is adjusted to 1 L / min. The flow rate of nitrogen is 2.7L / min.

[0045] Finally, carry out pickling operation, prepare aqua regia with the ratio of nitric acid: hydrochloric acid = 1:3, and then carry out acid treatment on the corroded diamond, and then wash it with water until it is neutral, and...

Embodiment 2

[0047] Wrap the iron oxalate powder on the surface of the diamond according to the mass ratio of 1:1, so that the two can fully contact.

[0048] The coated diamond is then loaded into a ceramic crucible or boat and placed in a tube furnace. Adjust the sintering process curve, the heating rate is 3°C / min, the final sintering temperature is 800°C, and the holding time is 1h. In the process of heating up, nitrogen is introduced when the temperature rises to 200°C, hydrogen is introduced at 500°C, hydrogen is stopped when the temperature drops to 500°C during the cooling process, nitrogen is stopped at 200°C, and the flow rate of hydrogen is adjusted to 1L / min. The flow rate is 2.7L / min.

[0049] Finally, carry out pickling operation, prepare aqua regia with the ratio of nitric acid: hydrochloric acid = 1:3, then carry out acid treatment on the corroded diamond, and then wash it with water until it is neutral, and dry it.

Embodiment 3

[0051] Wrap the iron oxalate powder on the surface of the diamond according to the mass ratio of 1:1, so that the two can fully contact.

[0052] The coated diamond is then loaded into a ceramic crucible or boat and placed in a tube furnace. Adjust the sintering process curve, the heating rate is 3°C / min, the final sintering temperature is 650°C, and the holding time is 1h. In the process of heating up, nitrogen is introduced when the temperature rises to 200°C, hydrogen is introduced at 500°C, hydrogen is stopped when the temperature drops to 500°C during the cooling process, nitrogen is stopped at 200°C, and the flow rate of hydrogen is adjusted to 1L / min. The flow rate is 2.7L / min.

[0053] Finally, carry out pickling operation, prepare aqua regia with the ratio of nitric acid: hydrochloric acid = 1:3, then carry out acid treatment on the corroded diamond, and then wash it with water until it is neutral, and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com