Surface grinding device for circular cutting board machining

A cutting board and circular technology, which is applied in the field of surface grinding devices for processing circular cutting boards, achieves the effects of improving grinding speed, quick placement and removal, and easy grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

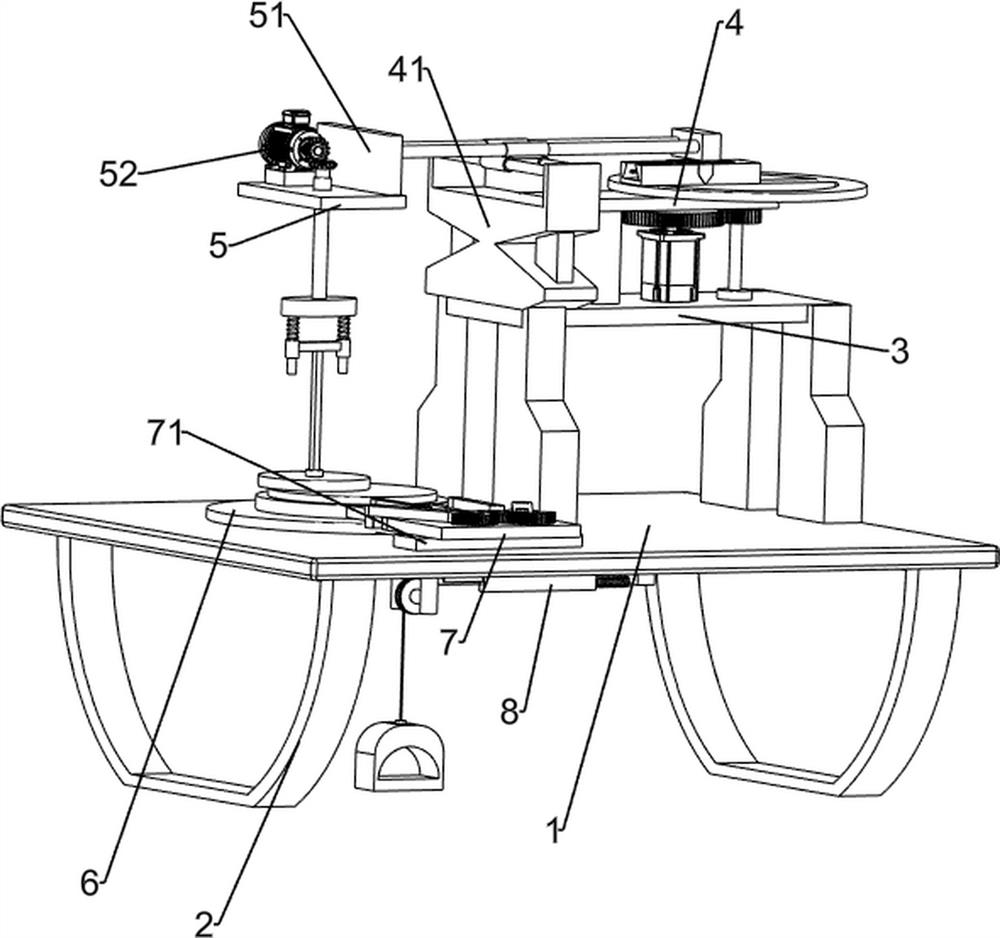

[0025] A surface grinding device for circular chopping board processing, such as Figure 1-3 As shown, it includes a bottom plate 1, a tripod 2, a support frame 3, a rotating mechanism 4, a grinding mechanism 5 and a backing plate 6. Two tripods 2 are symmetrically connected to the bottom of the bottom plate 1, and a support is connected to the top right side of the bottom plate 1. Frame 3, a rotating mechanism 4 is installed on the support frame 3, a grinding mechanism 5 is connected to the rotating mechanism 4, and a backing plate 6 is connected to the left side of the bottom plate 1 top.

[0026] The rotating mechanism 4 includes a special-shaped plate 41, a servo motor 42, a first rotating shaft 43, a full gear set 44, a turntable 45, a first connecting block 46, a screw rod 47, a slider 48, a second connecting block 49, and a first sliding rod 410 , guide rail 411 and the second slide bar 412, the left side of the support frame 3 top is connected with a special-shaped pla...

Embodiment 2

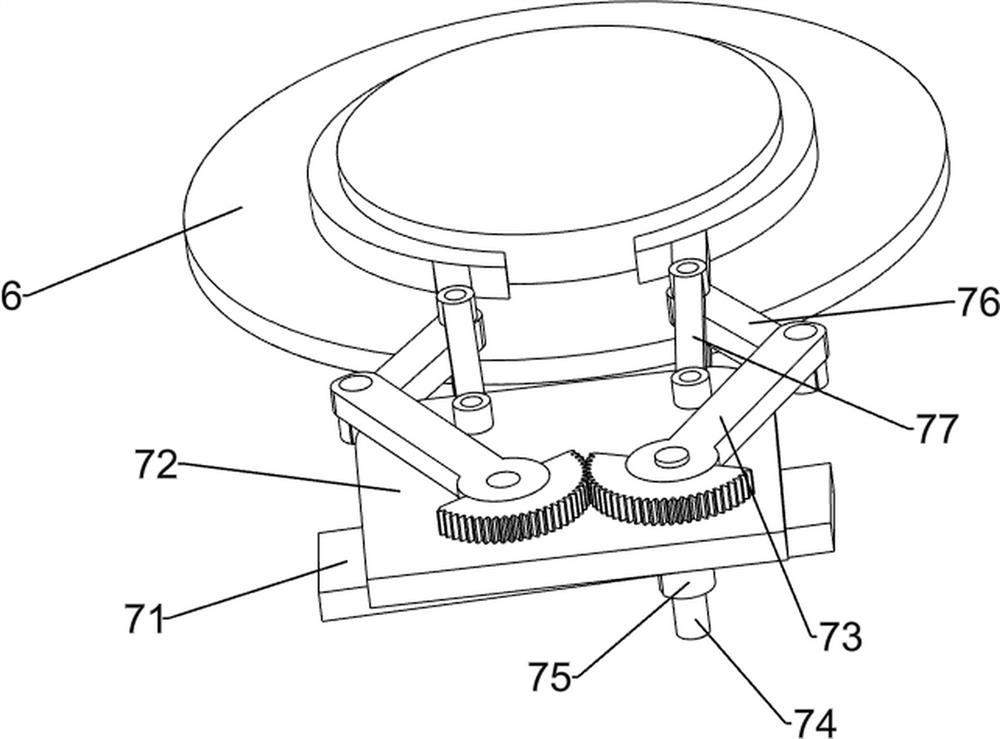

[0030] On the basis of Example 1, such as figure 1 and Figure 4As shown, a clamping mechanism 7 is also included, and the clamping mechanism 7 includes a support block 71, a connecting plate 72, a sector gear rod 73, a third rotating shaft 74, a scroll spring 75, a clamping rod 76 and a connecting rod 77, and the bottom plate 1 The top left front side is connected with a support block 71, the top of the support block 71 is connected with a connecting plate 72, and the right part of the connecting plate 72 is connected with a third rotating shaft 74 in a rotational manner, and the bottom end of the third rotating shaft 74 runs through the supporting block 71 and the bottom plate 1, and the third rotating shaft A scroll spring 75 is connected between 74 and the base plate 1, a sector gear lever 73 is connected to the third rotating shaft 74 top, and a sector gear lever 73 is also rotatably connected to the left part of the connecting plate 72, and the two sector gear levers 73 ...

Embodiment 3

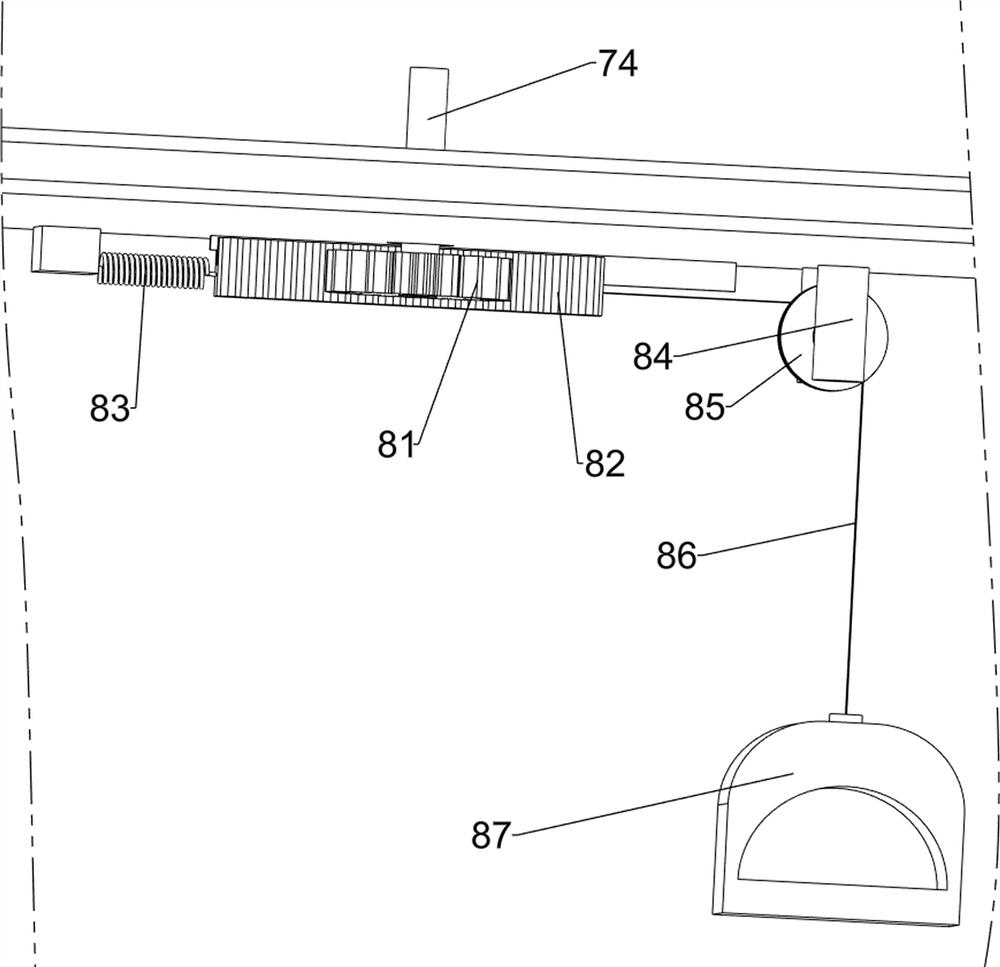

[0033] On the basis of Example 2, such as figure 1 and Figure 5 As shown, pedal mechanism 8 is also included, and pedal mechanism 8 includes spur gear 81, rack 82, back-moving spring 83, fixed mount 84, belt pulley 85, flat belt 86 and pedal frame 87, and the third rotating shaft 74 bottoms A spur gear 81 is connected, a rack 82 is slidably connected to the left front side of the bottom of the base plate 1, the rack 82 meshes with the spur gear 81, a return spring 83 is connected between the rack 82 and the base plate 1, and a fixed Frame 84, fixed frame 84 is positioned at the left side of tooth bar 82, is connected with belt pulley 85 in rotation on fixed frame 84, is connected with flat belt 86 on the left side of tooth bar 82, and flat belt 86 bottom ends around belt pulley 85, and flat belt 86 The bottom end is connected with pedal frame 87.

[0034] When two clamp bars 76 are to be separated, the pedal frame 87 can be stepped on downwards with the feet, and the pedal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com