Weld joint grinding equipment

A technology of equipment and grinding mechanism, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of low efficiency in the grinding process, poor working environment, and different grinding quality from person to person, so as to achieve the mechanism action process. Complicated, improves grinding efficiency, and avoids the effect of long programming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

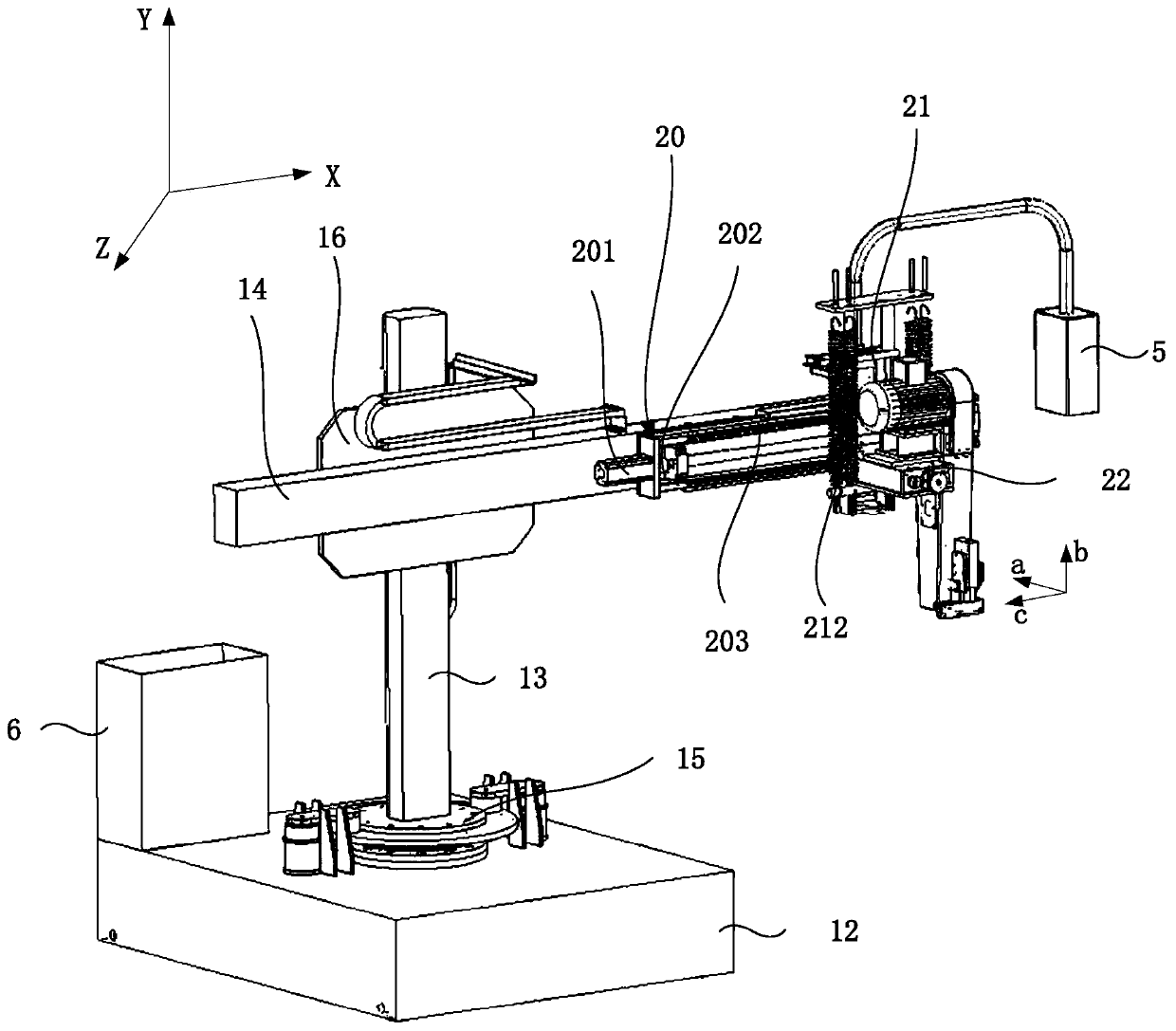

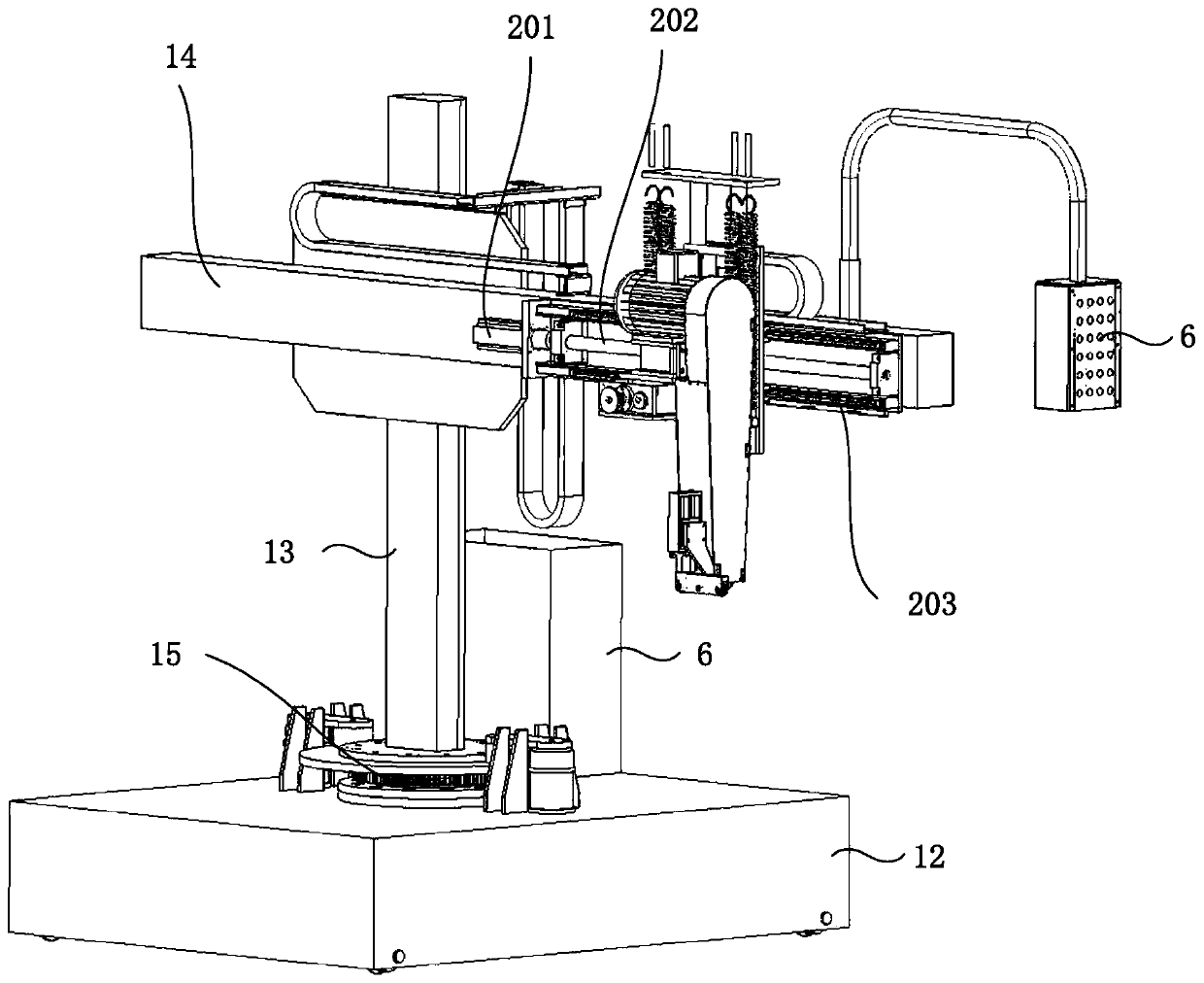

[0087] Combine below Figure 1 to Figure 29 The technical solution provided by the present invention is described in more detail.

[0088] Definitions of terms and terms used in this document.

[0089] Single-plate butt weld: a weld formed by multi-layer and multi-pass welding between plates of different plate thicknesses. Due to the different stresses of the single plate assembly at different positions, the inclination angle distribution of the butt welds on the same single plate assembly is irregular, and affected by the thickness of the plate, the butt welds are not all on the same horizontal plane.

[0090] Weld seam grinding: The multi-layer weld seam after butt welding between different plate thicknesses is uneven, and the weld seam needs to be ground to reveal the metallic luster to obtain smooth and excessively butt joint plates.

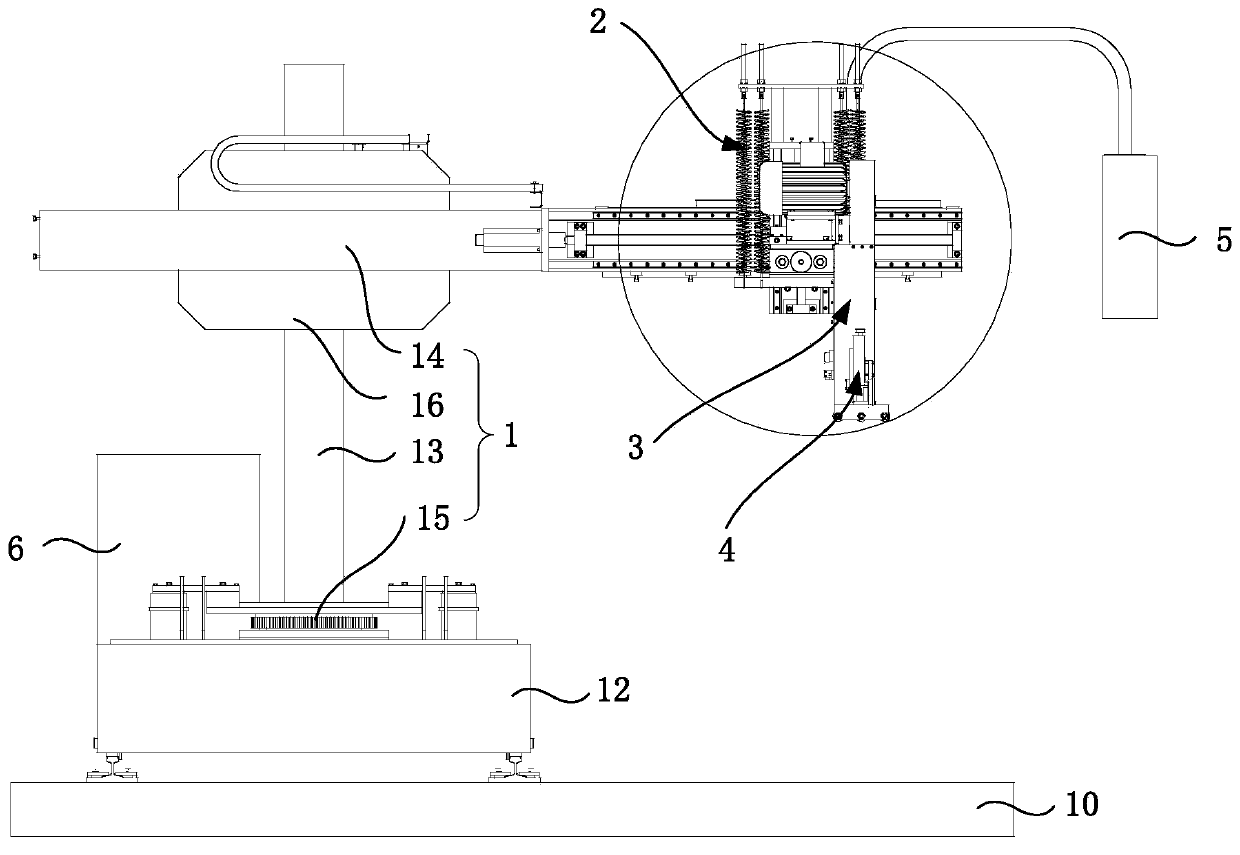

[0091] see Figure 1 to Figure 5 , the embodiment of the present invention provides a weld grinding equipment, which is used for automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com