Axle weight and brake and vehicle speed combined test bench

A composite detection and detection platform technology, applied in vehicle testing, speed/acceleration/shock measurement, speed/acceleration/shock measurement equipment testing/calibration, etc., can solve problems that are not suitable for military vehicle detection work, and achieve weight Effects of lightening, platform height reduction, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

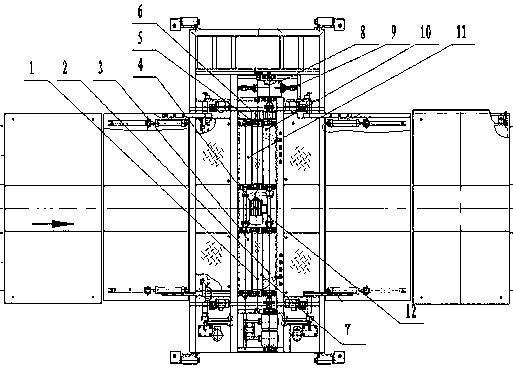

[0023] The invention is a miniaturized and integrated detection device and a detection platform that is easy to deploy and withdraw, and is stacked in a detection shelter, and the shelter is carried by a carrier vehicle. The detection platform is servoed by the drive mechanism, which automatically enters and exits the shelter and unfolds stacking; the detection shelter is lifted and lowered by the self-lifting mechanism to realize the loading and unloading of the shelter. During the inspection, the shelter is separated from the carrier vehicle and lowered to the ground. The inspection platform is stretched out from the inspection shelter and unfolded to form a detection line. At this time, the shelter is used as the inspection control room and rest room. After the detection is completed, it will be withdrawn in the reverse order of expansion.

[0024] The composite detection platform of the present invention is composed of a detection platform base frame, a left and right dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com