Construction method for filling of back of fabricated secondary lining of concealed excavated tunnel

A construction method and prefabricated technology, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems such as the infancy of the prefabricated secondary lining of the buried tunnel, and achieve the control of surface settlement, high safety, and enhanced waterproof ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The construction method for filling behind the assembly type secondary lining of the main line of the underground excavation section of the subway provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Components that are the same as those in the prior art are given the same reference numerals, and their descriptions are omitted.

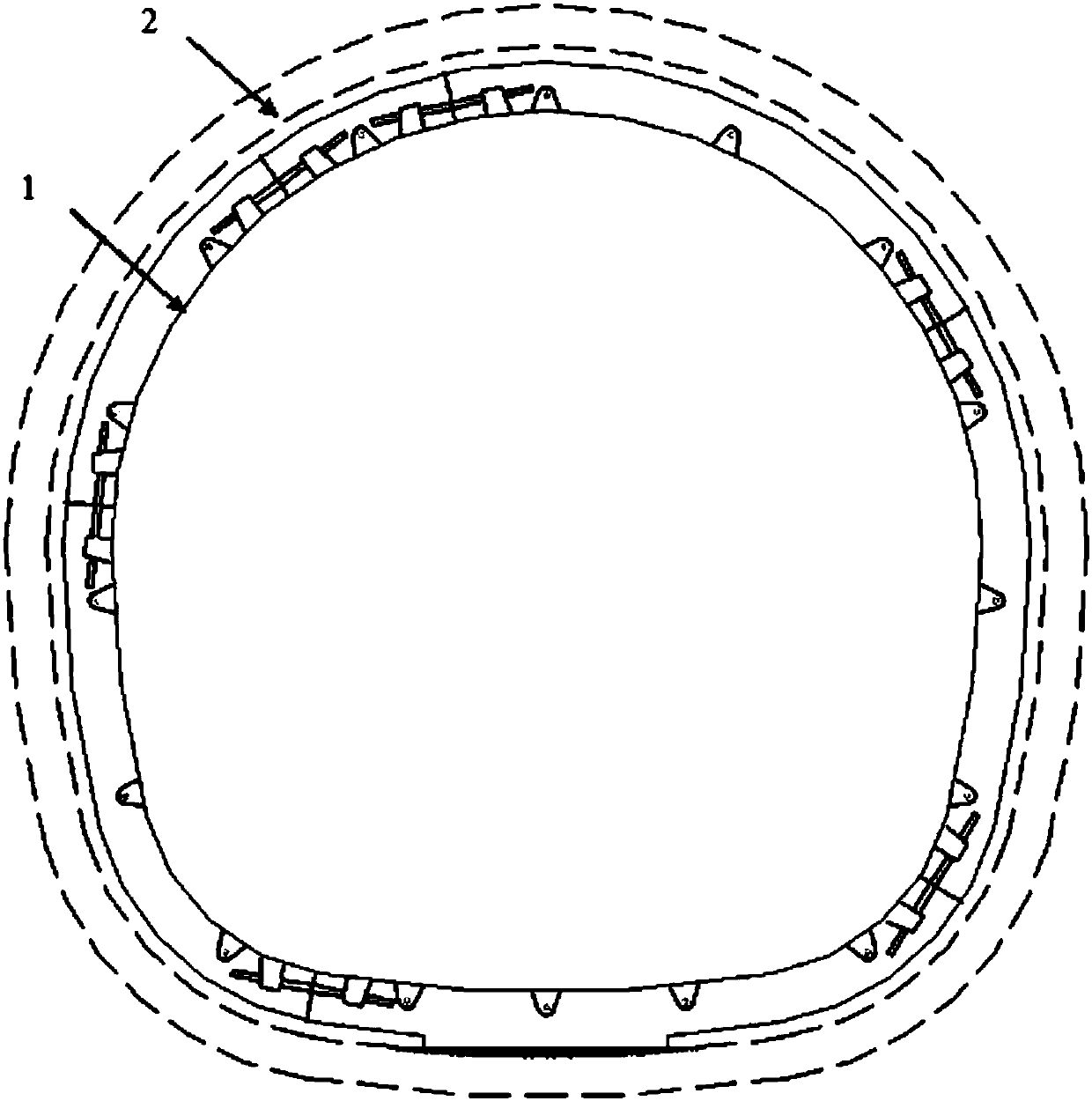

[0025] Now take a certain underground excavation section project of a subway as an example to illustrate: figure 1 As shown, the second lining structure in this section has a horseshoe-shaped cross-section, which is assembled from the first to sixth prefabricated segments. There is a gap between the prefabricated segments and the primary support structure of the main line, which needs to be back filled.

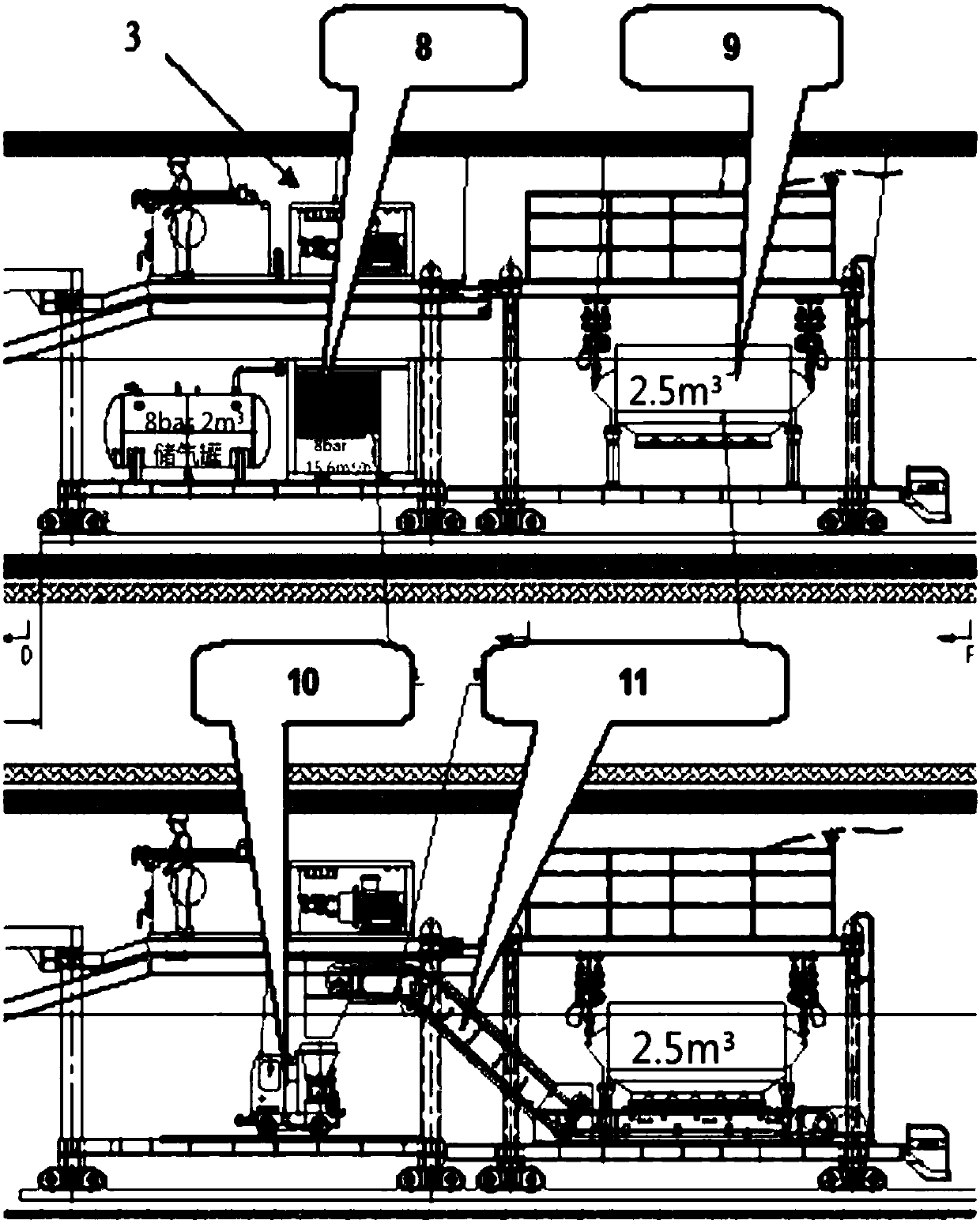

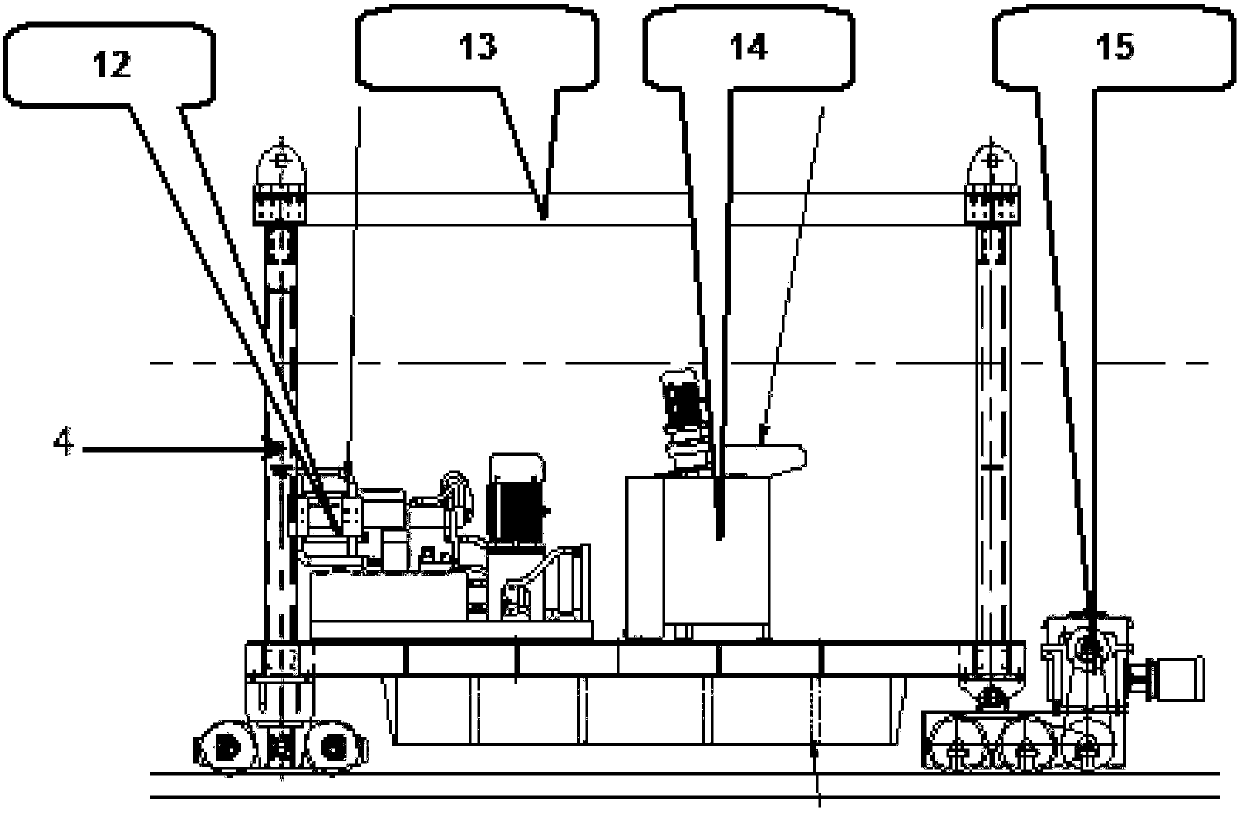

[0026] Such as Figure 1-5 As shown, the method for filling the back of the main line of the underground excavation section of the subway provided by this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com