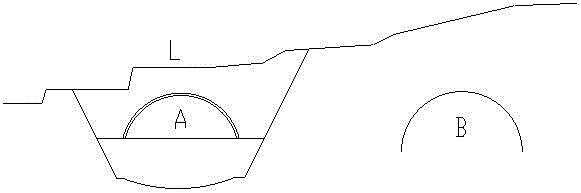

Half-cover and half-dark construction method of separated tunnel passing through high and steep v-shaped gully bias section

A construction method and separate technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of small buried depth and large tunnel buried depth, and achieve small excavation volume, small investment of mechanical personnel, and smooth construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

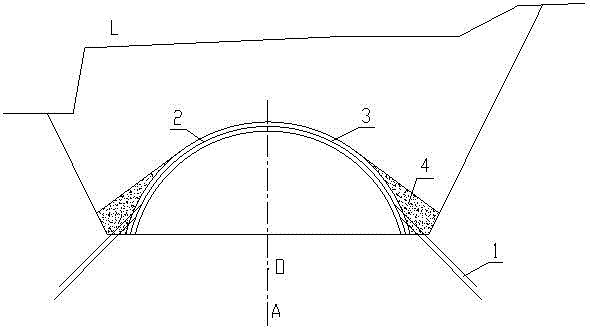

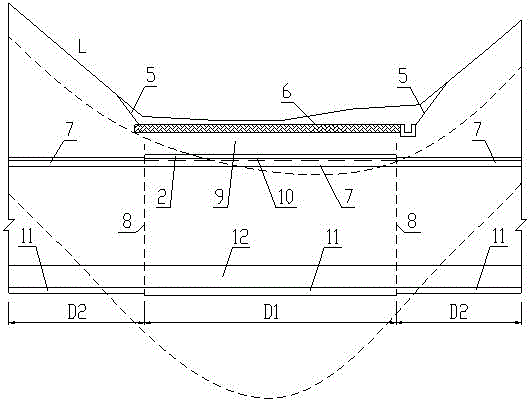

[0048] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0049] Take a two-way four-lane separated tunnel under a certain highway as an example: the tunnel crossing the gully section has a starting and ending mileage of K120+721~K120+739 and a length of 18m, all of which are V-level. rock. The distance from the vault to the surface of the gully section of the left tunnel is 3.6m, and the distance from the vault to the surface of the gully section of the right tunnel is 6.5m. The geological conditions of the strata in this area are as follows: 0~1.4m below the surface is brownish-yellow slope-accumulated gravel soil with relatively wet humidity. The particle size is 6cm, the crushed stone content is 70%, and the filling is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com