Flat knitting machine

A flat knitting knitting and knitting technology, applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of difficult operation of the flat knitting machine, stuck sinker mechanism, unable to work normally, etc. Installation difficulty and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

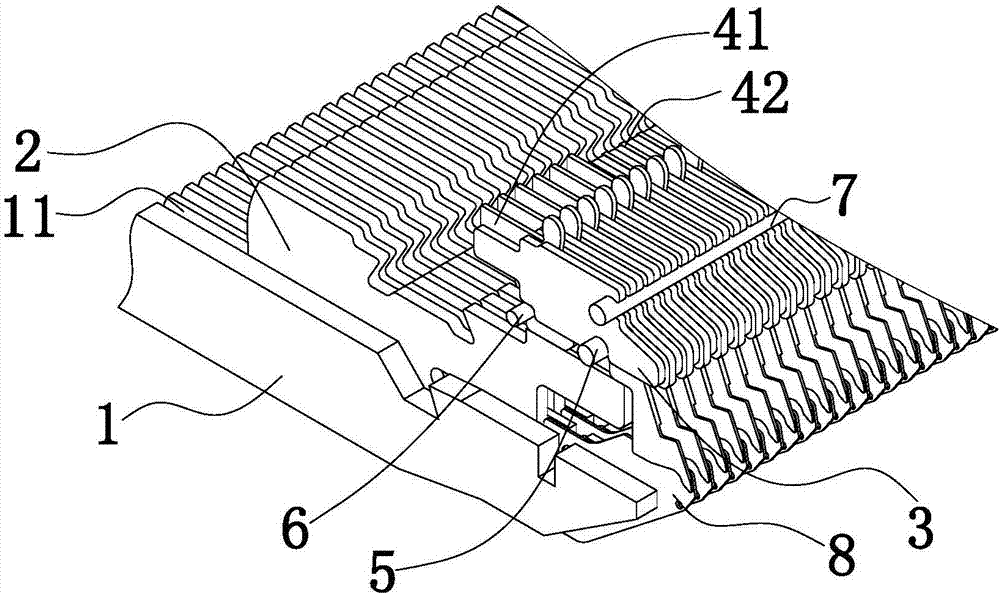

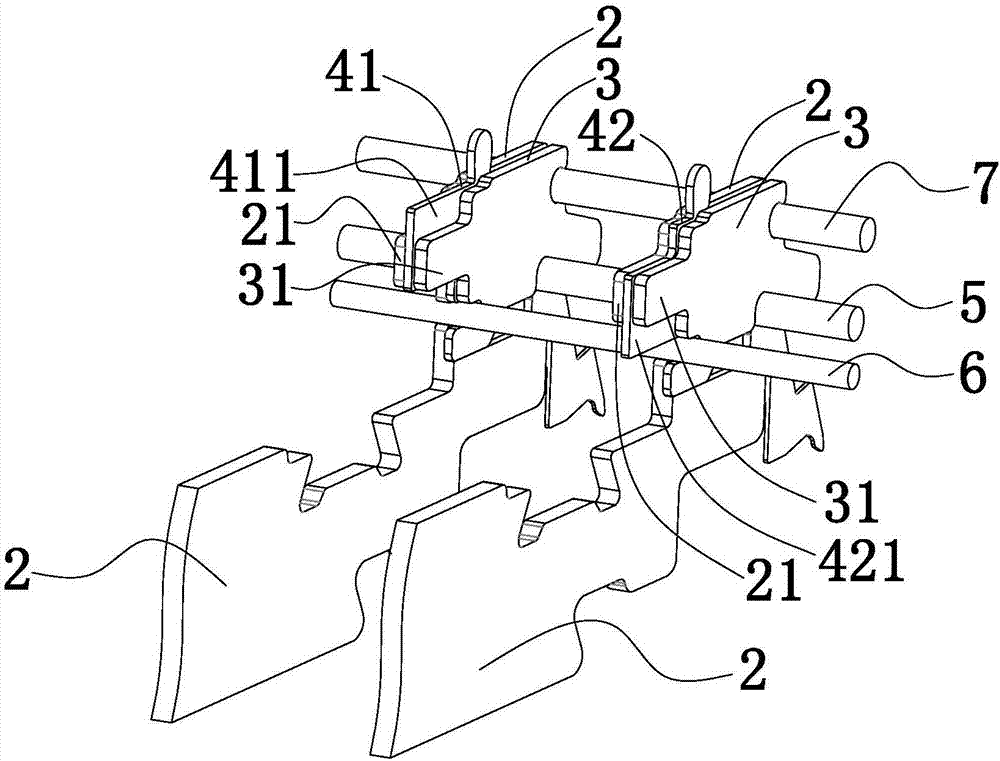

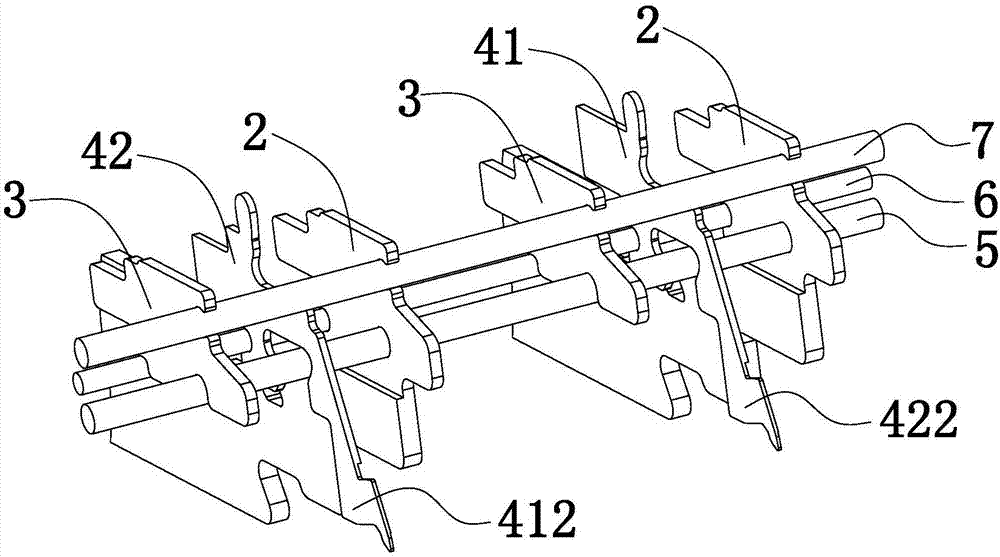

[0047] like Figure 1 to Figure 11 As shown, a flat knitting machine includes a driving mechanism (not shown in the figure), a traction mechanism (not shown in the figure) and a needle bed 1. The needle bed 1 is provided with a plurality of knitting units, and each knitting unit includes an insertion The sheet 2, the spacer 3 and the sinker located between them, the needle bed 1 is provided with slots 11 matching the number of the inserts 2 for installing the inserts 2. The bottom of the front end of the insertion piece 2 is provided with a tooth mouth piece 8, the tooth mouth piece 8 is fixed on the front end of the needle bed 1, and knitting needles 9 are arranged between adjacent insertion pieces 2, and the driving mechanism drives the knitting needle 9 to reciprocate to realize weaving. Inserting sheet 2 rear end is provided with inserting sheet guard plate 21, and the extension direction of inserting sheet guard plate 21 is parallel to the top surface of needle bed 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com